Equilateral wedge-shaped composite muffler

A muffler and wedge-shaped technology, applied in the field of side wedge-shaped composite mufflers, can solve the problem that the muffler is difficult to meet the requirements of large air volume, high noise and noise reduction, and achieve the effect of ensuring the emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

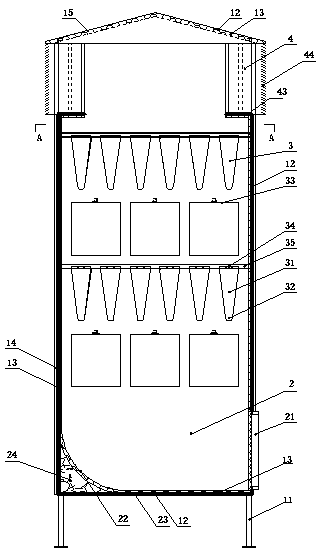

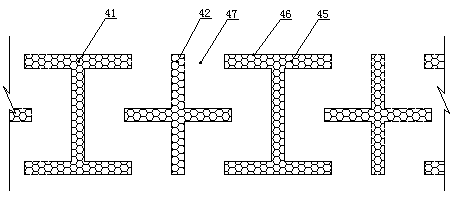

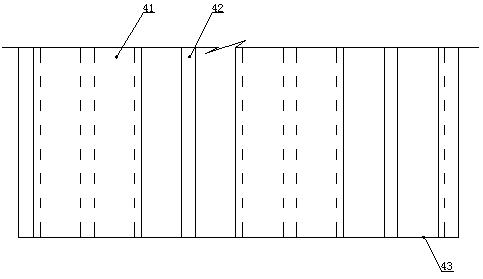

[0018] exist figure 1 , 2 , In the embodiment shown in 3 and 4, an equilateral wedge-shaped composite muffler includes a muffler shell (1), an inlet wind muffler structure (2), an equilateral wedge-shaped sound absorber (3), an outlet wind muffler Acoustic Structure (4). The muffler shell (1) includes a supporting steel structure (11), a shell steel plate (12), an inner sound-absorbing structure (13), an outer reinforcing rib, an outer sound-insulating decorative module (14), and a double pouring ceiling on the top (15 ); the shell of the equilateral wedge-shaped sound absorbing body (3) is a composite pinhole aluminum sound-absorbing panel (31), the top is arc-shaped (32), the bottom is a rectangular steel plate groove frame (33), and the steel plate groove frame (33 ) is connected to the load-bearing steel structure (35) by installing fasteners (34), no sound-absorbing material is provided inside, the distance between the bottoms of the equilateral wedge-shaped sound-abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com