Composite Chimney Muffler

A muffler and chimney technology, which is applied to machines/engines, combustion product treatment, combustion methods, etc., can solve problems such as difficulty in meeting the noise reduction requirements of high-pressure fan chimneys, and achieve the quality indicators of sound environment, optimize aerodynamic structure, reduce Effect of smoke exhaust resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

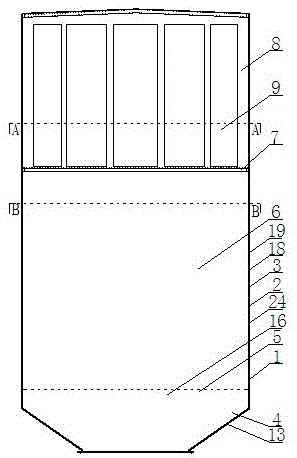

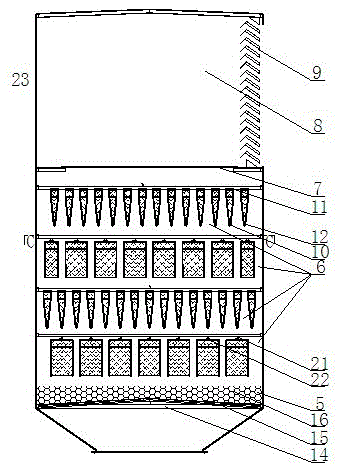

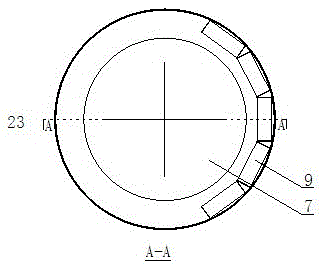

[0020] exist figure 1 , 2 , In the embodiment shown in 3 and 4, a composite chimney muffler includes a load-bearing steel structure, a cylindrical steel structure shell (1), and an impedance composite noise reduction structure. The cylindrical steel structure shell (1) is equipped with an inner sound insulation layer (2) and a sound absorption layer (3), and the air inlet diversion section (4), the oil resistance structure layer (5), The wedge sound-absorbing structure (6), the annular structural plate (7), the expansion anechoic chamber (8), the wind-out noise-absorbing louvers (9); the wedge sound-absorbing structure (6) is a single wedge structure, Composed of a tip (10) and a base (11), the top of the tip (10) is an arc-shaped guide (12), and the wedge sound-absorbing structure (6) is arranged in multiple layers, with multiple wedge sound-absorbing structures on each layer (6) Arranged in parallel and evenly distributed on the vertical plane of the anechoic channel, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com