Composite chimney silencer

A technology of muffler and chimney, applied in machine/engine, combustion product treatment, combustion method, etc., can solve the problem of difficulty in meeting the noise reduction requirements of high-pressure fan chimney, achieve the quality indicators of sound environment, reduce smoke exhaust resistance loss, Optimizing the effect of the aerodynamic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

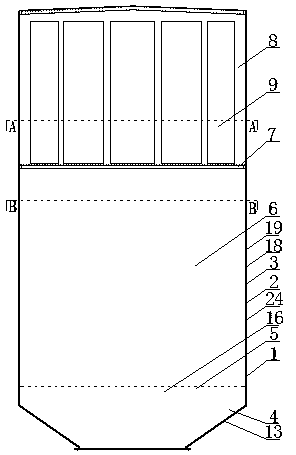

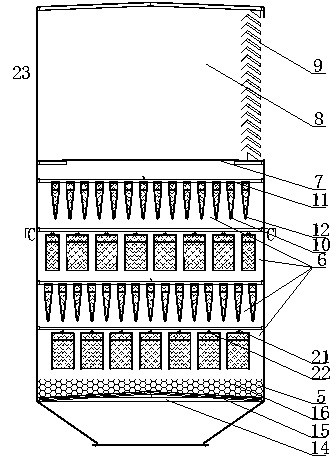

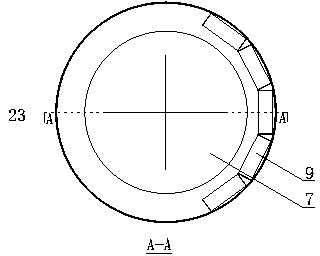

[0020] in figure 1 , 2 In the embodiments shown in, 3 and 4, a composite chimney muffler includes a bearing steel structure, a cylindrical steel structure shell (1), and an impedance composite muffler structure. The cylindrical steel structure shell (1) is provided with an inner sound insulation layer (2) and a sound absorption layer (3), and the air inlet diversion section (4), oil barrier structure layer (5), The wedge sound-absorbing structure (6), the annular structural plate (7), the expansion anechoic chamber (8), the wind noise silencing louver (9); the wedge sound-absorbing structure (6) is a single-point wedge structure, It is composed of a tip (10) and a base (11). The arc-shaped fluid conductor (12) at the top of the tip (10), the wedge sound-absorbing structure (6) is arranged in multiple layers, and each layer has multiple wedge sound-absorbing structures (6) Arranged in parallel, evenly distributed on the vertical plane of the silencing channel, the wedge sound-ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com