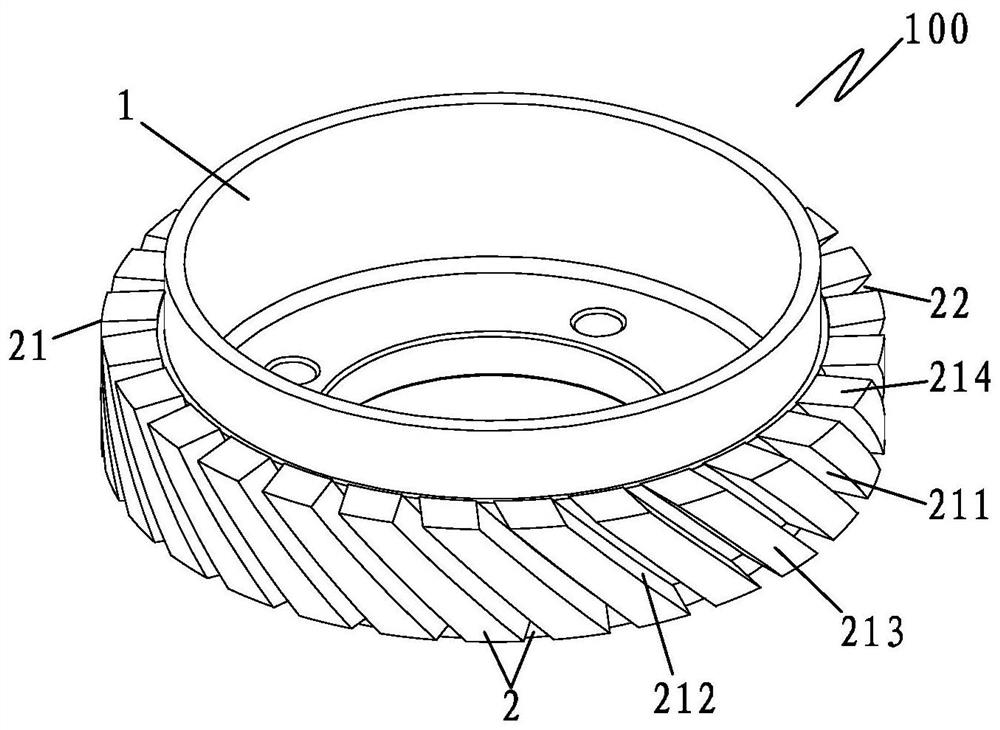

Helical-tooth split-tooth roller

A technology of helical teeth and rollers, which is applied in the field of grinding tools, can solve the problems of poor sharpness, poor use stability, and inconvenient chip removal, etc., and achieve the effect of ensuring sharpness, simple structure, and improving chip removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

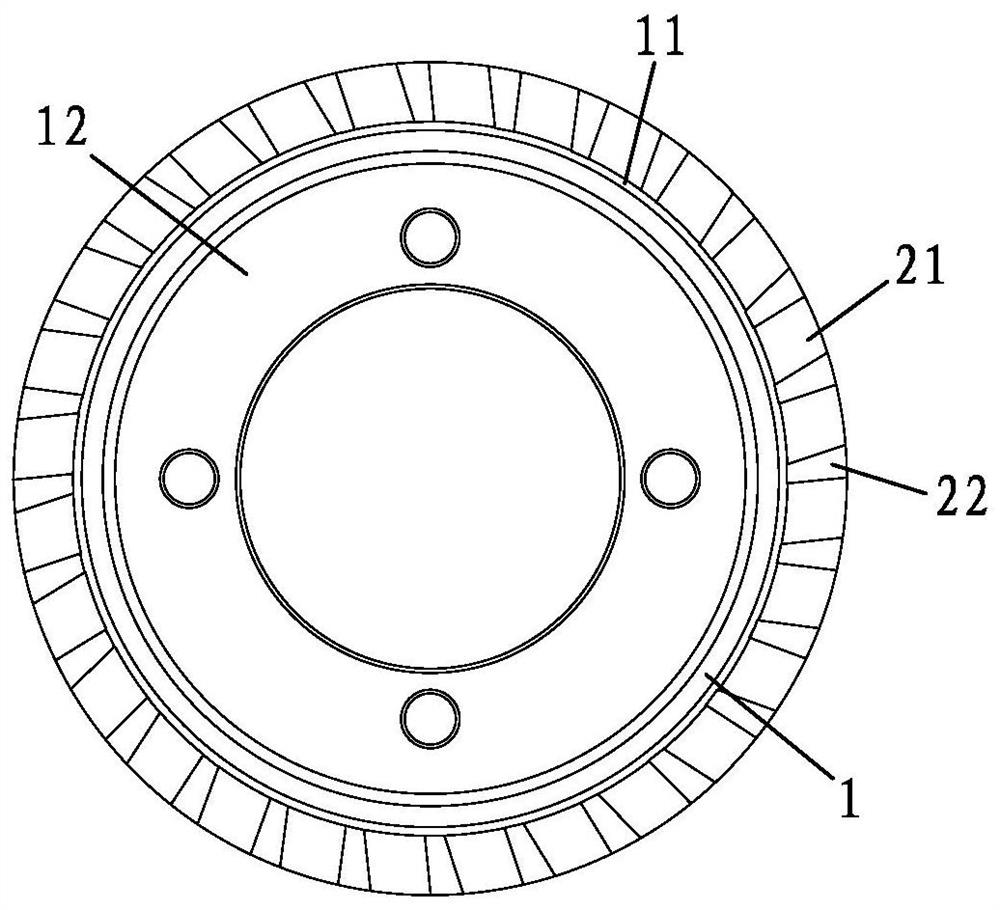

[0030] The embodiment of the present invention solves the technical problems of poor sharpness, poor use stability and inconvenient chip removal in the existing saw-blade rollers by providing a helical-toothed roller, and realizes the ability to take into account the sharpness of the cutter head. The technical effect of speed and smoothness of use.

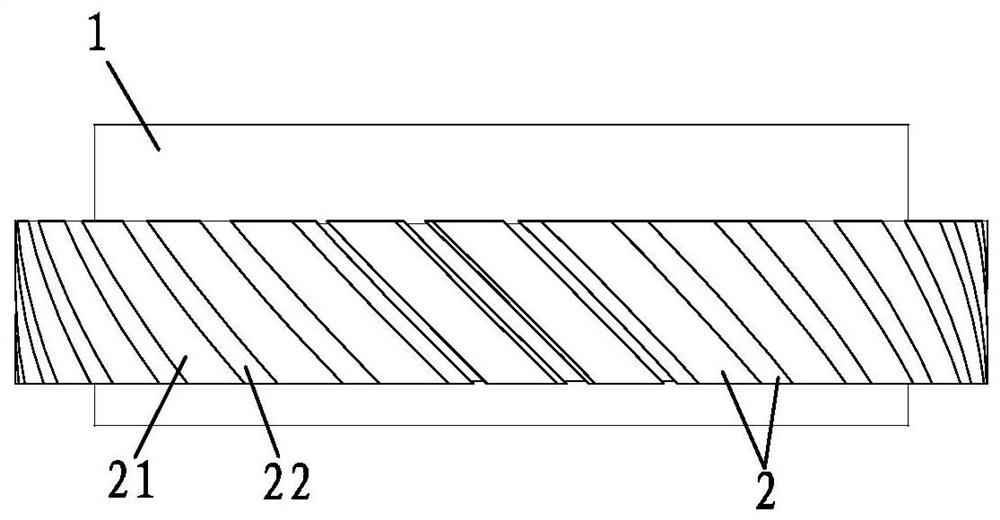

[0031] The technical solution in the embodiment of the present invention is to solve the above-mentioned problems. The general idea is as follows: the cutter head on the drum is designed as a split-toothed helical cutter head, and one side of each helical cutter head has chip removal grooves. Combined with the design, the sharpness of the entire cutter head is improved; at the same time, the helical tooth cutter heads are arranged in a special way, so that the effective area of any section cutter head along the axial direction is consistent, ensuring the stability of use .

[0032] In order to better understand the above techni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com