Air layer knitted fabric and preparation method thereof

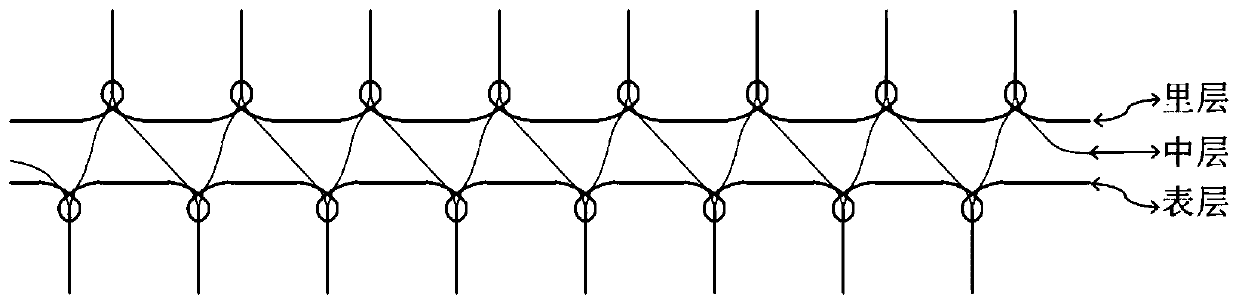

A technology of knitted fabrics and air layers, applied in knitting, weft knitting, decorative textiles, etc., can solve the problems of poor anti-pilling performance, uneven surface and inner layers, etc., and achieve anti-pilling performance Reinforcement, good thermal performance, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

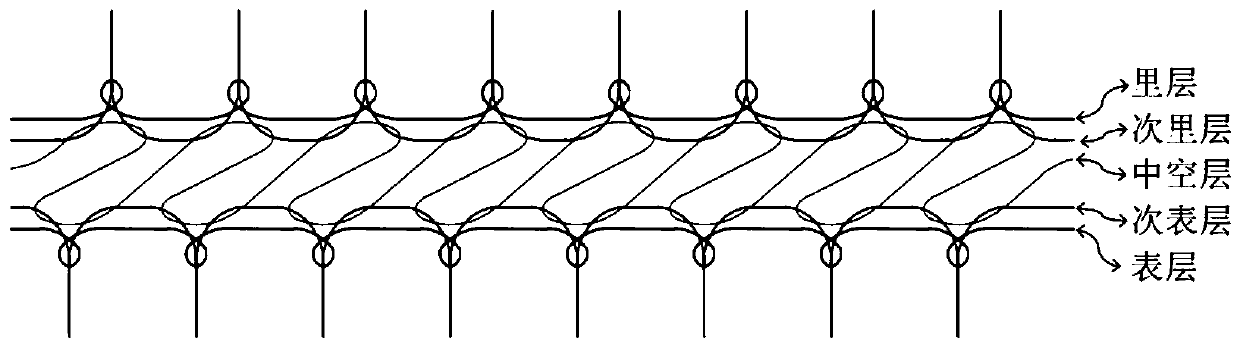

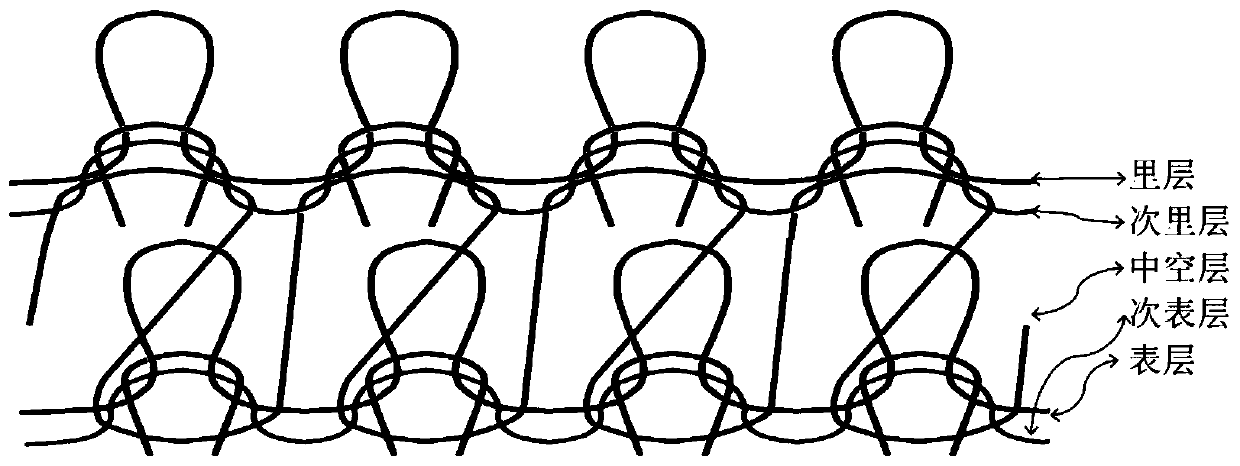

[0026] An air layer knitted fabric, which sequentially includes a surface layer, a subsurface layer, a hollow layer, a secondary inner layer, and an inner layer; The fine denier filaments of the hollow layer are interlocked with each other to separate the filaments of the hollow layer from the surface layer and the inner layer; the subsurface layer and the surface layer are woven through a plating structure, and the yarn count of the surface layer is completely Covering the yarn count of the subsurface layer; and weaving the second inner layer and the inner layer through a plating structure, the yarn count of the inner layer completely covering the yarn count of the second inner layer;

[0027] Wherein, the yarn count of the surface layer and the yarn count of the inner layer are 32SJC combed cotton yarn, T / C yarn, R / C yarn, T / R yarn, polyester filament or nylon filament; The yarn count and the yarn count of the second inner layer are 30D / 24F polyester DTY; the yarn count of t...

Embodiment 2

[0030] A kind of preparation of air layer knitted fabric, comprises following weaving process:

[0031] 24G double-sided rib machine is adopted, with 5 channels and one knitting cycle; the yarn count of the surface layer is 32SJC (combed cotton yarn), the yarn count of the subsurface layer is 30D / 24F (polyester DTY), and the yarn count of the hollow layer is 75D / 36F (polyester DTY), The yarn count of the second inner layer is 30D / 24F (polyester DTY), and the yarn count of the inner layer is 32SJC (combed cotton yarn).

[0032] The first way: needle cylinder, dial knitting needles all come out to form a tuck, and feed 75D / 36F (polyester DTY) at the same time;

[0033] The second way: the knitting needles on the dial first follow the trajectory of the starting triangle of the dial, and return the 75D / 36F (polyester DTY) in the needle hook and the old coil 32SJC (combed cotton yarn) in the inner layer to the needle bar together. Above, along the track of the needle pressing tria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com