Hollow stabilizer bar producing process

A production process and stabilizer bar technology, applied in the field of hollow stabilizer bar production process, can solve the problems of high labor intensity, affecting bushing press-fitting, low production efficiency, etc., to reduce operation intensity, reduce operators, and simplify production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

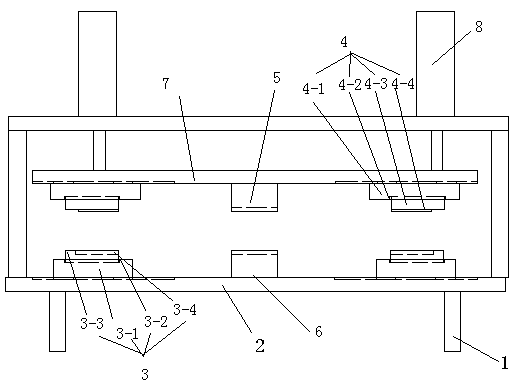

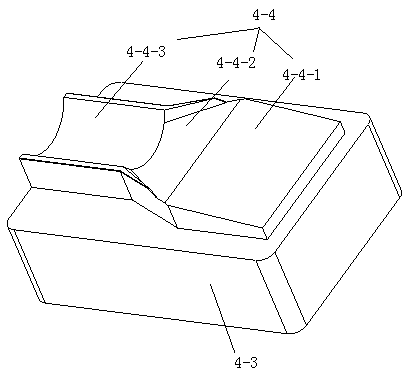

[0038] See attached picture.

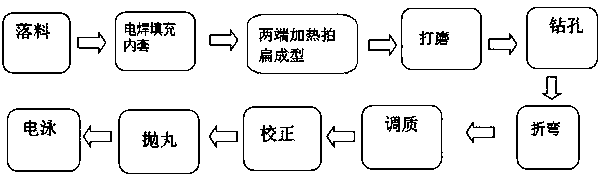

[0039] A hollow stabilizer bar production process is characterized in that it specifically includes the following steps:

[0040] (1), blanking

[0041] The qualified hollow metal pipe raw material is positioned at the positioning end, and then the raw material is hoisted to the machine station using a crane, and cut to the designed length on the circular sawing machine. The sawn material is removed, transported to a special trolley and stacked Neatly ready for use;

[0042] (2) Electric welding filled inner sleeve

[0043] Insert the filling inner sleeve at both ends of the blanking rod, and ensure that the end face of the filling inner sleeve and the end face of the rod body are slightly inward by 2 to 3 mm, and then fix the filling inner sleeve by spot welding on each end face;

[0044] (3) Heating and flattening at both ends

[0045] Put both ends of the rod body with the filling inner sleeve after step (2) into the induction coil at the same time

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com