Device for automatically removing bamboo outer skin and bamboo joints

A slub and automatic technology, applied in mechanical equipment, force/torque/power measuring instruments, measuring devices, etc., can solve problems such as low accuracy, different surface smoothness and flatness, low yield rate, etc., to improve Work efficiency, consistent surface smoothness and flatness, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

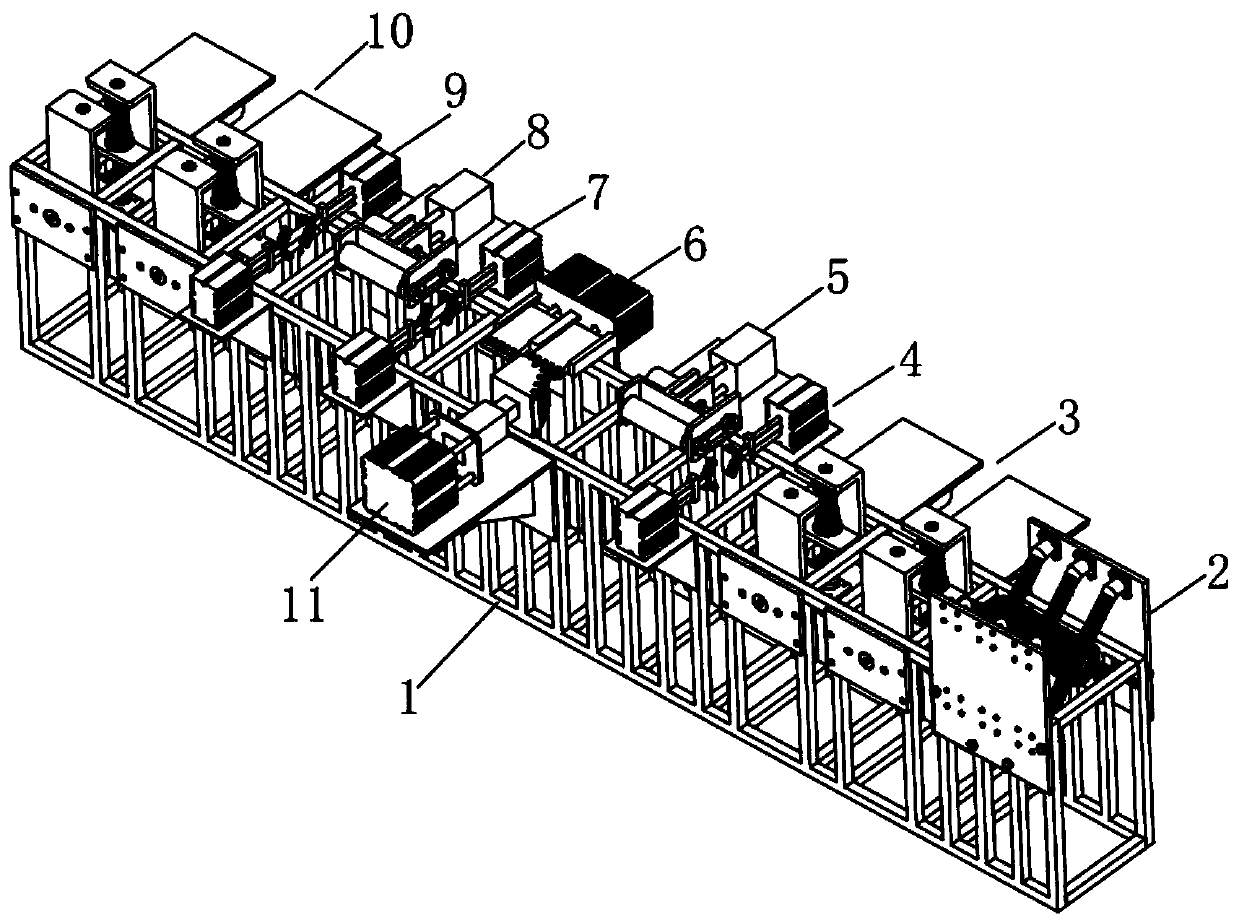

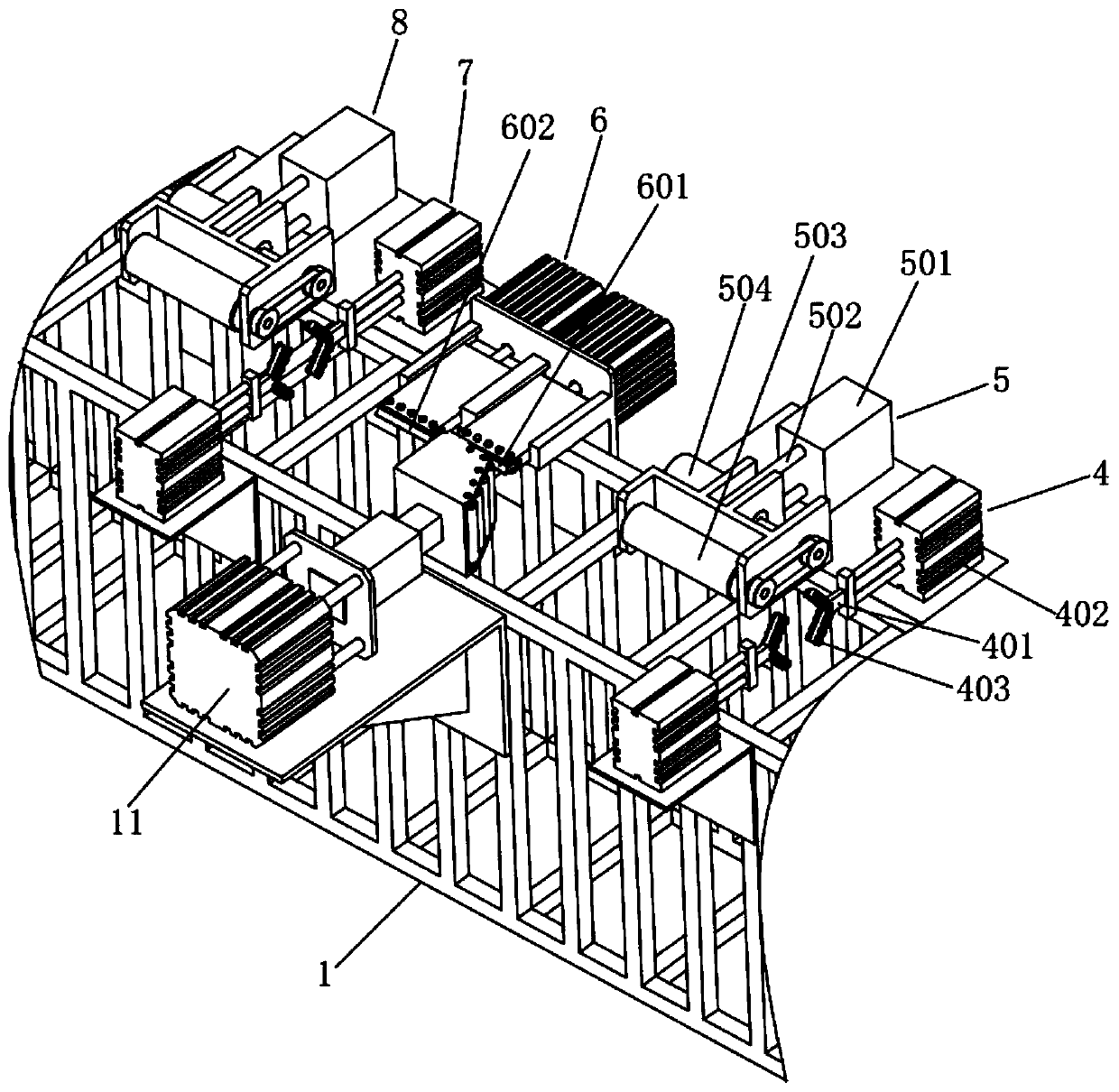

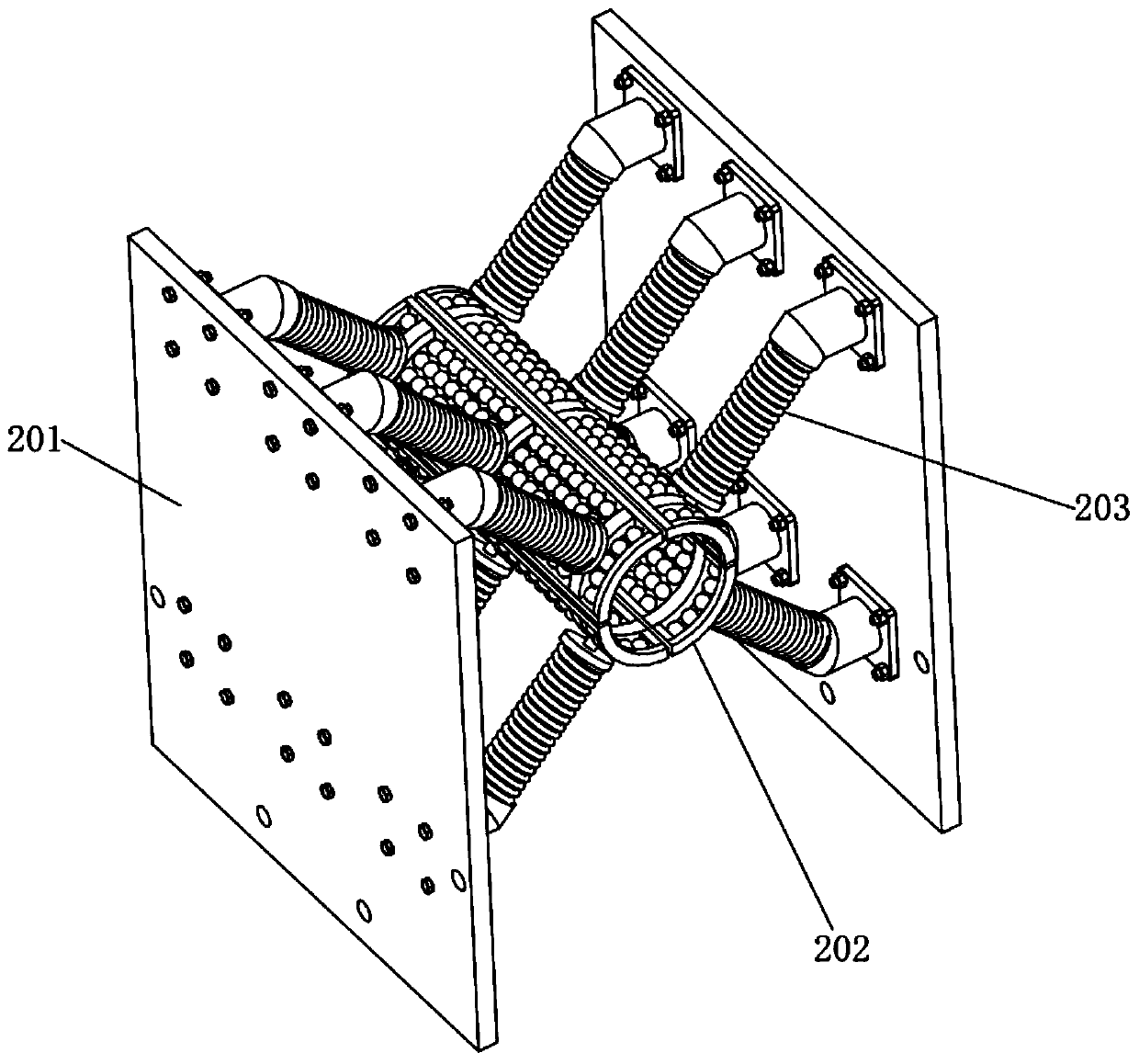

[0034] Embodiment: A device for automatically removing green bamboo knots in this embodiment, such as figure 1 , figure 2 As shown, the frame 1 is included. The frame 1 is provided with a guide mechanism 2, a first conveying mechanism 3, a first supporting mechanism 4, a first bamboo rod driving mechanism 5, a bamboo green bamboo joint removing mechanism 6, and a second The supporting mechanism 7, the second bamboo rod driving mechanism 8, the third supporting mechanism 9, and the second conveying mechanism 10. The first conveying mechanism 3 and the second conveying mechanism 10 are used to transport the bamboo rods from the front side of the frame 1 to the back of the frame 1. On the other hand, the guide mechanism 2 is used to guide the bamboo poles, the first support mechanism 4, the second support mechanism 7, and the third support mechanism 9 are all used to support the bamboo poles. The first bamboo pole drive mechanism 5 and the second bamboo pole drive mechanism 8 are u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com