Three-dimensional printer

A technology of 3D printers and printing nozzles, which is applied in the directions of additive manufacturing, 3D object support structure, and processing data acquisition/processing. The effect of printing accuracy and model quality, clear line routing, and increased heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

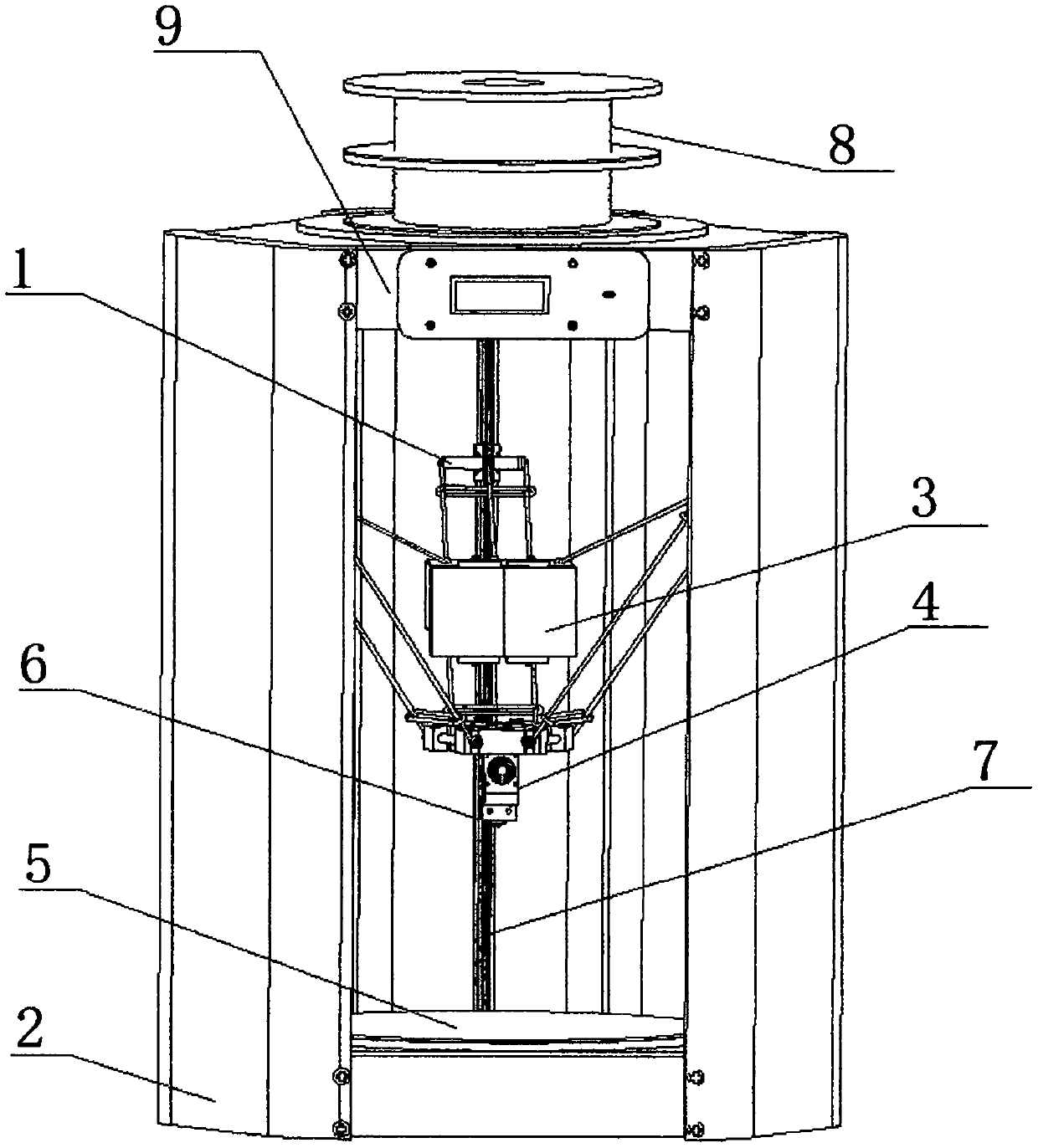

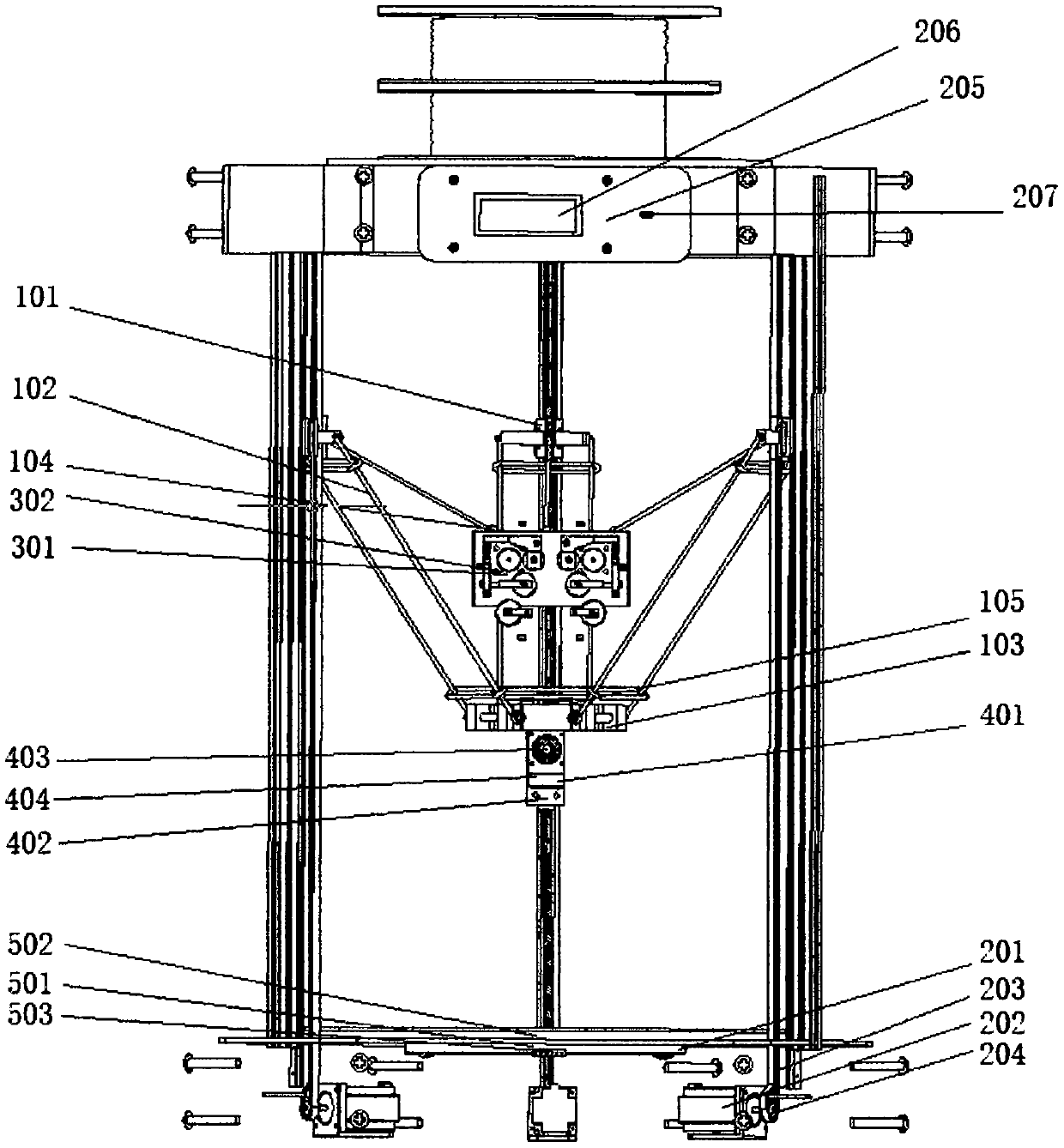

[0031] refer to Figure 1-4 , the present invention provides a technical solution: a three-dimensional printer, including an integral frame 2, a synchronous belt 7 is provided inside the integral frame 2, a parallel drive mechanism 1 is provided on the synchronous belt 7, and a parallel drive mechanism 1 is provided at the lower end Double-jet fixed-range closed wire feeding system 3, the lower end of the double-jet fixed-range closed wire feeding system 3 is provided with an effector 4, the lower end of the effector 4 is connected with a printing nozzle 6, and the inner bottom of the integrated frame 2 is provided with a heating bed 5 , the hot bed 5 is located directly below the print nozzle 6, the upper end of the integral frame 2 is provided with consumables 8, and the interior of the integral frame 2 is provided with an integrated controller 9.

Embodiment approach

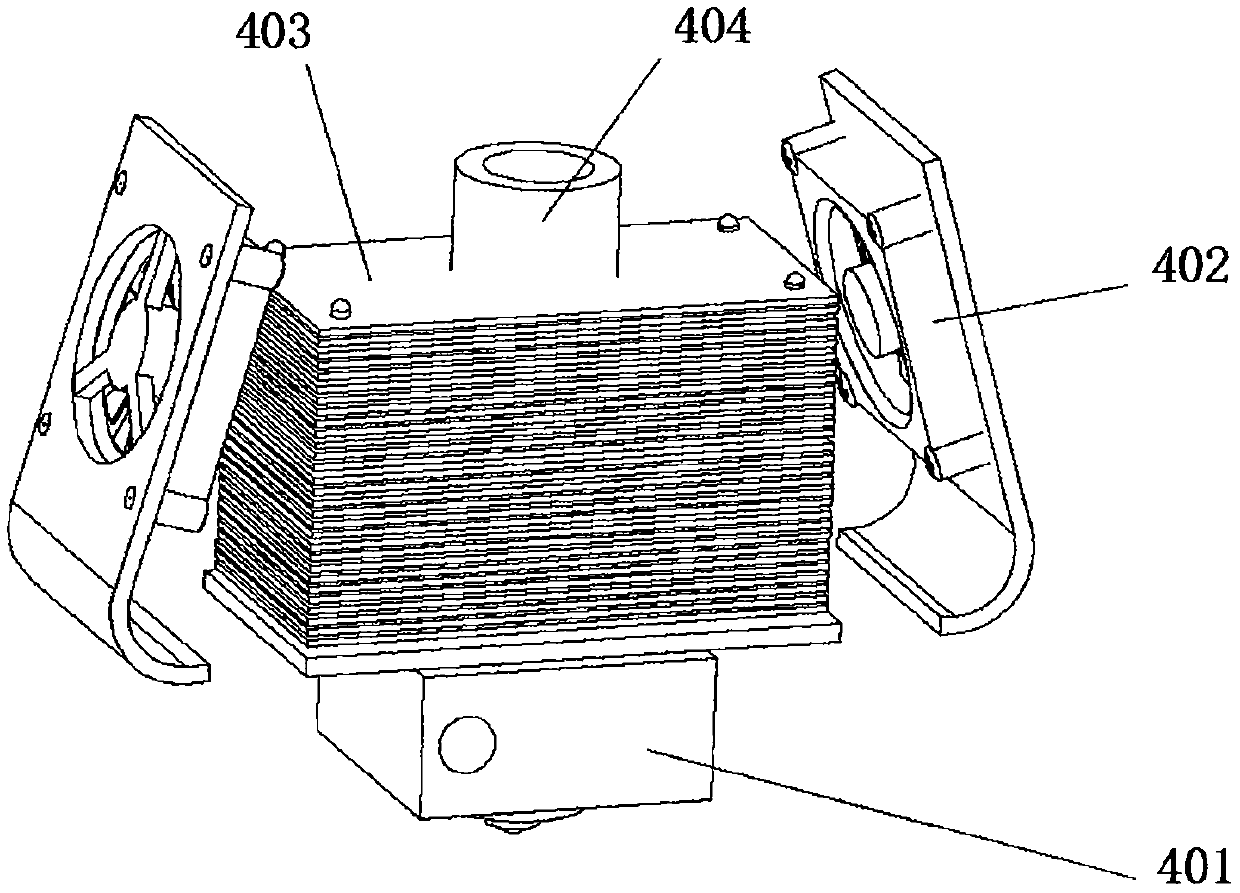

[0032]A preferred embodiment of the present invention: the parallel drive mechanism 1 includes three sets of linear guide rail modules 101, carbon fiber connecting rods 102, moving platforms 103, hinges 104 and throat pipes 105, and one end of the linear guide rail module 101 is connected with a slider, The other end of the linear guide rail module 101 is rotatably connected to the carbon fiber connecting rod 102, and the end of the carbon fiber connecting rod 102 away from the linear guide rail module 101 is connected to the moving platform 103 for control. Fixed on the timing belt 7, the hinge 104 is sleeved on the carbon fiber connecting rod 102, the throat pipe 105 is located at the inner center of the moving platform 103, each carbon fiber rod 102 is connected by a linear slide rail slider, passed through the timing belt 7 Control the X-axis, Y-axis, and Z-axis movement of the moving platform 103 and the printing nozzle 6. In addition, the moving platform 103 ensures the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com