The Method of Improving the Rolling Quality of Strip Tail

A strip steel quality technology, applied in the field of improving the coil quality of the strip steel tail, can solve problems such as edge overflow, low running speed, and light weight of thin strip steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

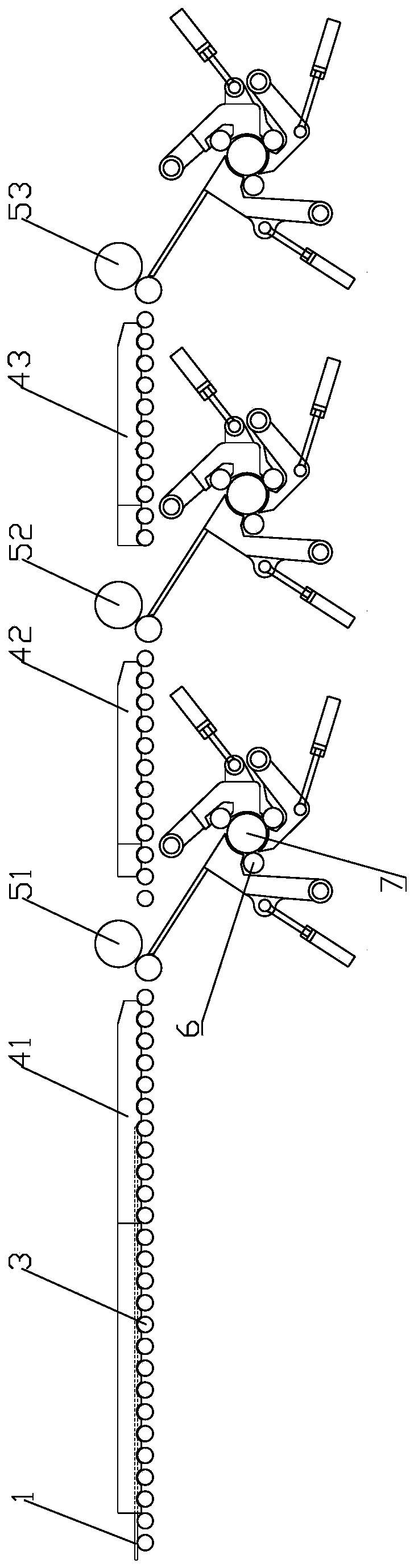

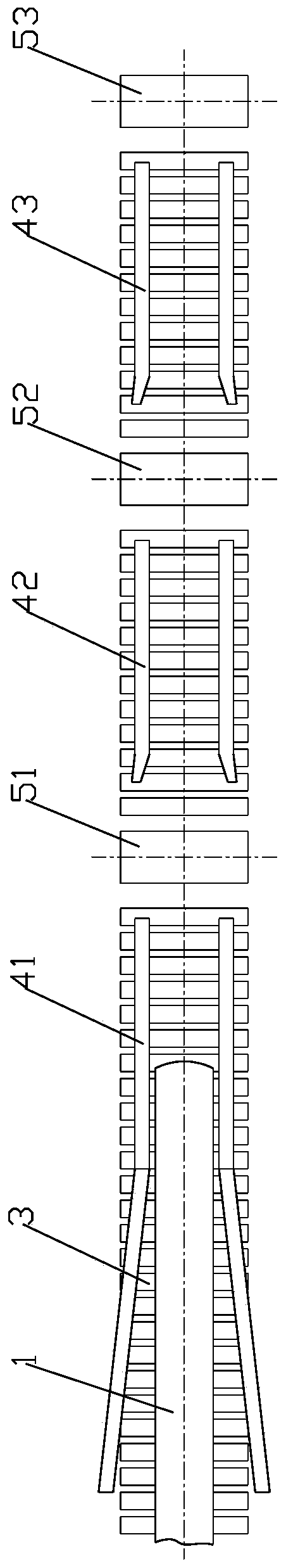

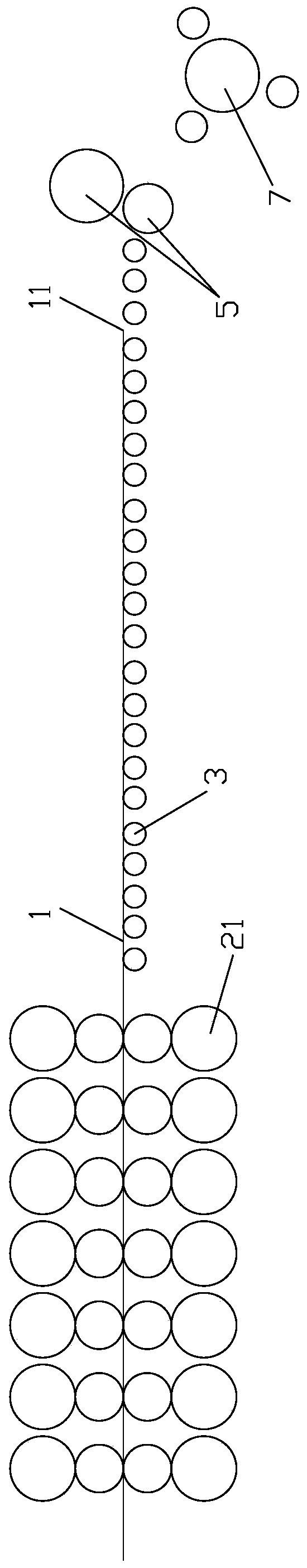

[0032] The method for improving the coil quality of the steel strip end of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

[0033] For the convenience of description, each coiler included in the coiling equipment after the hot rolling unit is called the first coiler, the second coiler and the third coiler in turn along the running direction of the strip. The pair of side guide plates on both sides of the sorting roller table used to position the strip before the first coiler, the second coiler and the third coiler are called the first side guide plate and the second side guide plate in turn along the running direction of the strip steel. Second side guide and third side guide.

[0034] Such as Figure 11 and Figure 8As shown, the method for improving the coiling quality of the strip tail in the present invention includes: when the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com