Patents

Literature

51results about How to "Guaranteed to be tight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method of green tea

ActiveCN102960482APromote sustainable developmentImprove tree down ratePre-extraction tea treatmentGreen teasProcess engineering

The invention provides a processing method of green tea, which is used for solving the problem of bitter taste of a large amount of green tea produced in Sichuan province. The processing method of the green tea is characterized by comprising the following steps of: picking fresh leaf, tedding green leaves, deactivating enzymes, rolling, conducting first-step roasting, conducting secondary rolling, conducting deblocking, conducting second-step roasting, spreading and airing, roasting to be dry, spreading and airing, and drying and extracting flavor, wherein twice rolling processes are carried out by hot rubbing. According to the processing method of the green tea, the bitter taste of the large amount of the green tea produced in the Sichuan province can be effectively reduced, the quality of tea leaves can be improved, and the heavy, mellow, fresh and brisk degrees can be increased; and the good foundation is established for expanding the tea markets of Sichuan and promoting the export of the tea in Sichuan.

Owner:YIBIN CHUANHONG TEA IND GRP

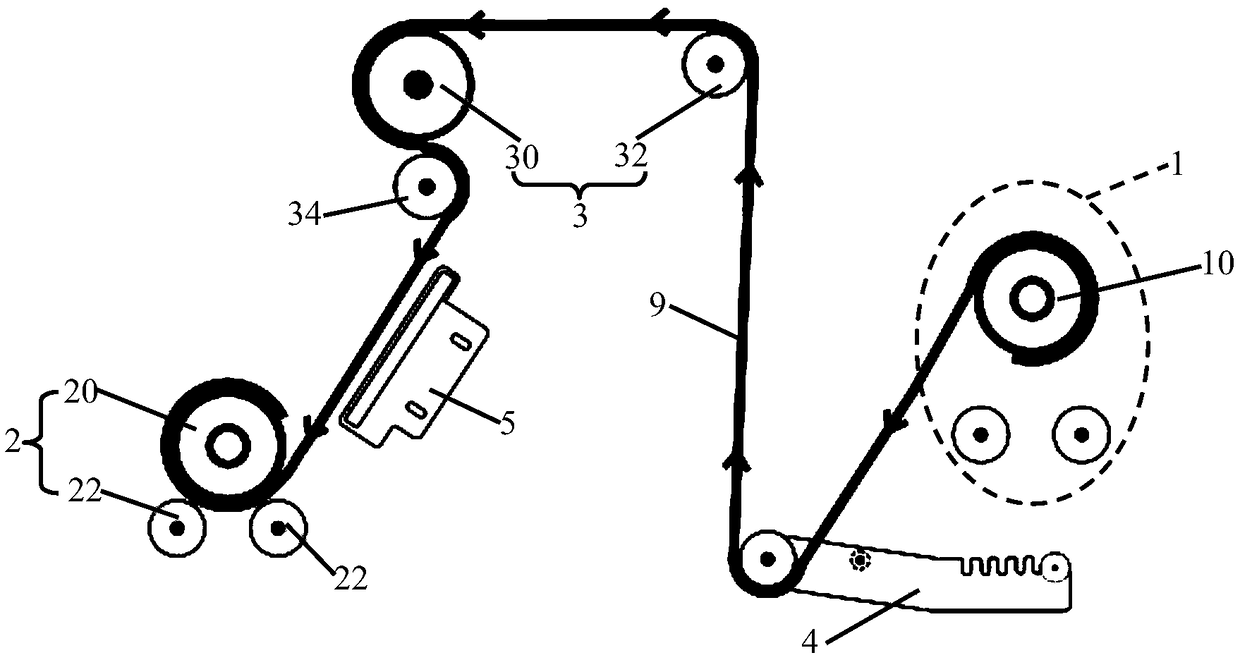

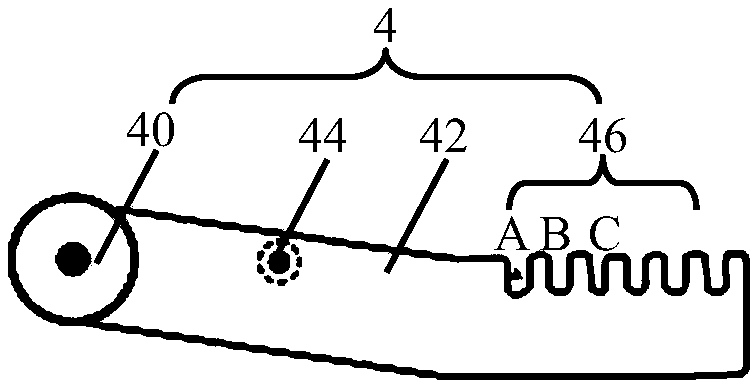

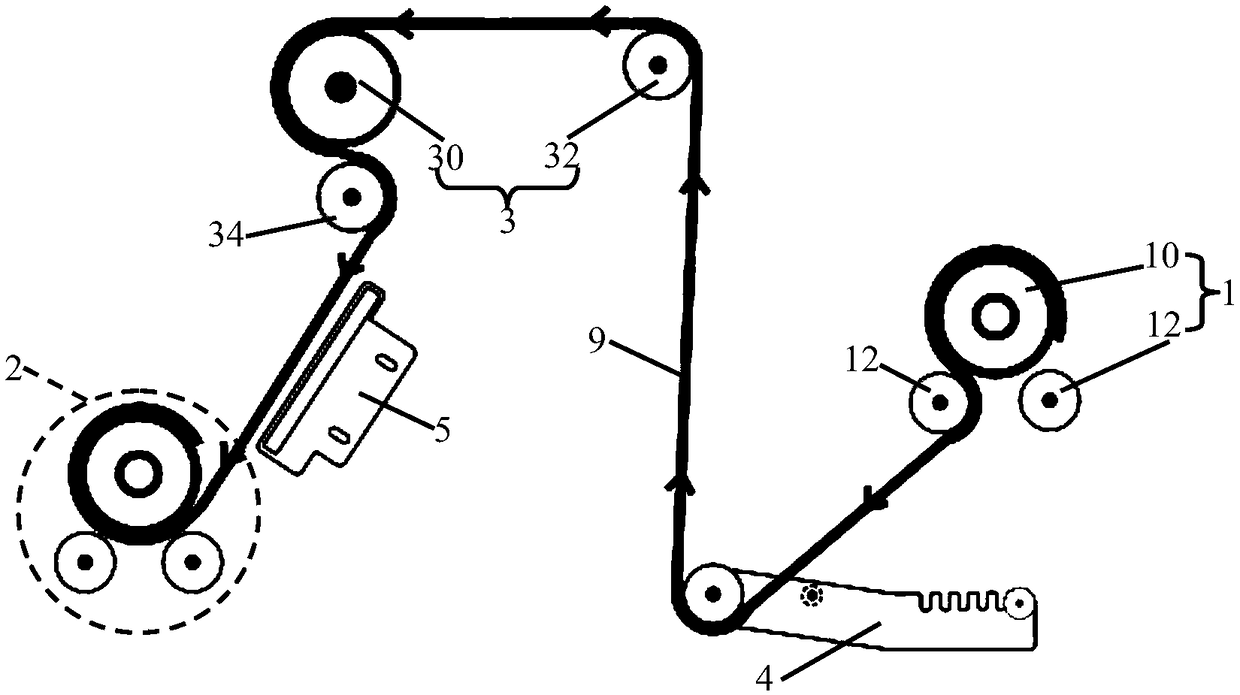

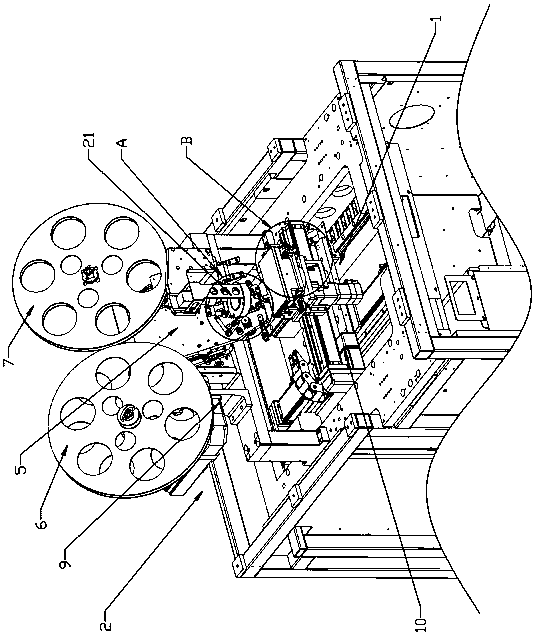

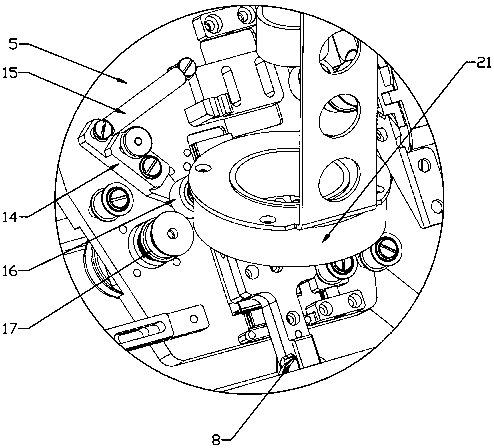

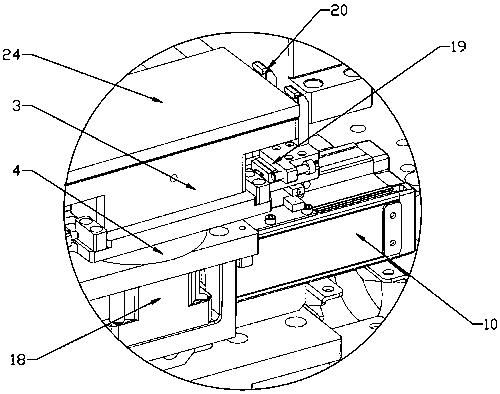

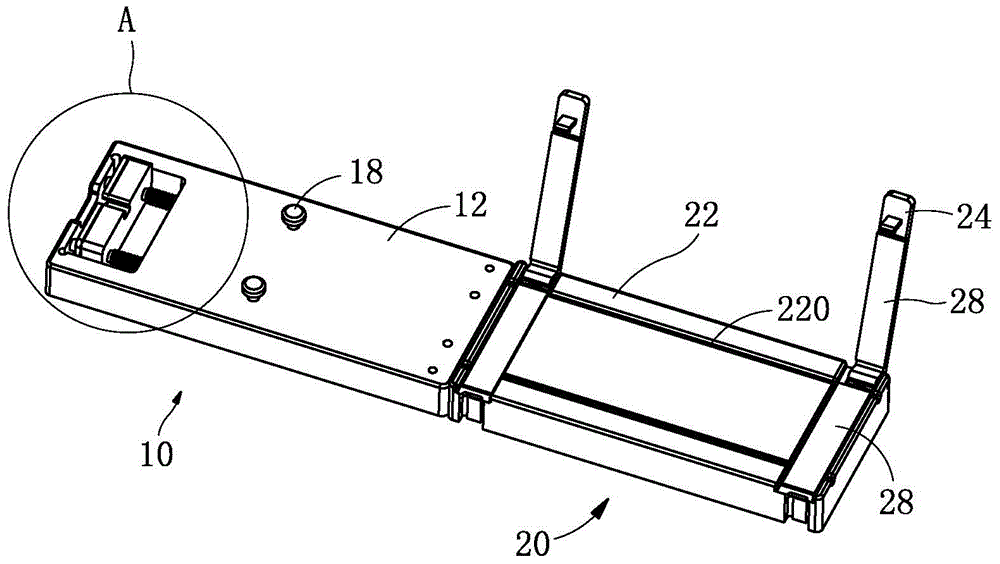

Tensioning feeding mechanism and ink jet printer

PendingCN109291642APrevent deviationAvoid wrinklesOther printing apparatusWebs handlingMechanical engineeringEngineering

Owner:浙江昱荣数码喷印技术有限公司

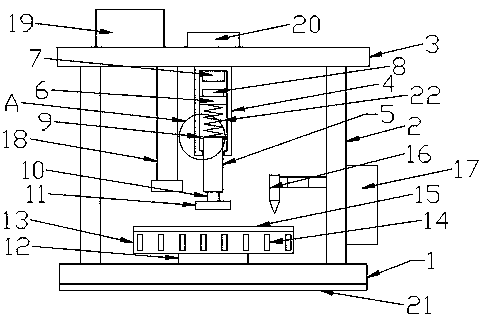

Fixing device for spot welding of circuit boards of household appliances

InactiveCN107838519AImprove maintenance efficiencyEasy to operatePrinted circuit assemblingMetal working apparatusSolderingSpot welding

The invention discloses a spot welding fixing device for a home appliance circuit board, which comprises a base, a column, a beam and a placing table; Straight down the sleeve, the lower end of the sleeve is inserted with a telescopic rod; the sleeve is slidably provided with a slider, a spring is fixedly connected between the slider and the telescopic rod, and a permanent magnet is fixedly installed on the upper side of the slider. An electromagnet is fixedly installed on the top of the corresponding sleeve above the permanent magnet; a rotating shaft is installed at the lower end of the telescopic rod, and the rotating shaft is installed on the pressing plate through a bearing. The present invention can ensure that the circuit rotates in the spot welding process and faces different directions through the provided rotating table and the rotating pressing plate, which not only ensures that the circuit board is not pressed during welding, but also ensures that the circuit board is rotated conveniently, which brings convenience to the operation of the maintenance personnel. Improve maintenance efficiency and avoid inaccurate spot welding positions affecting maintenance results.

Owner:束春花

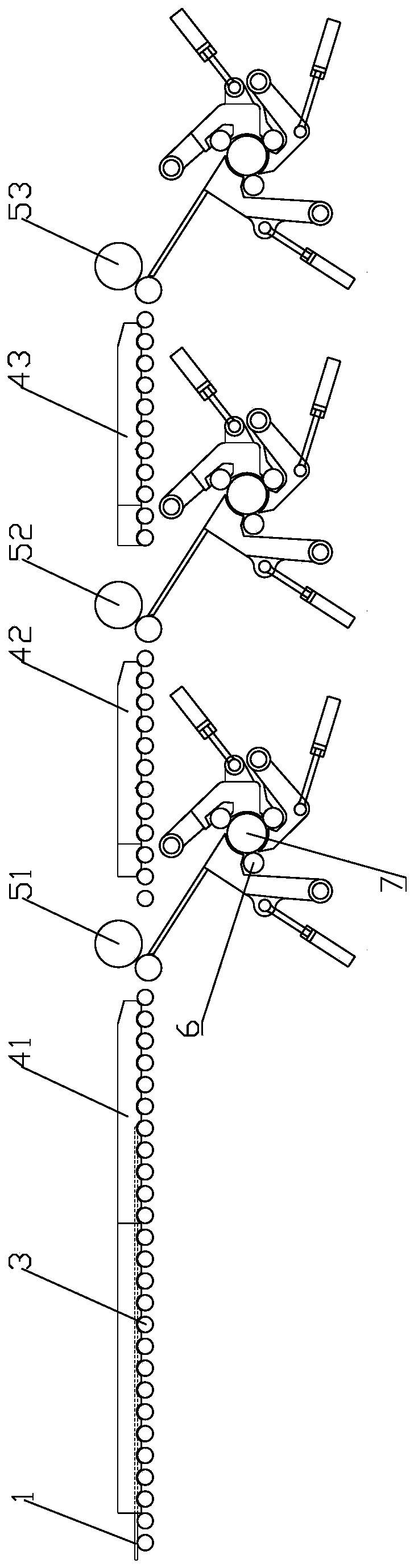

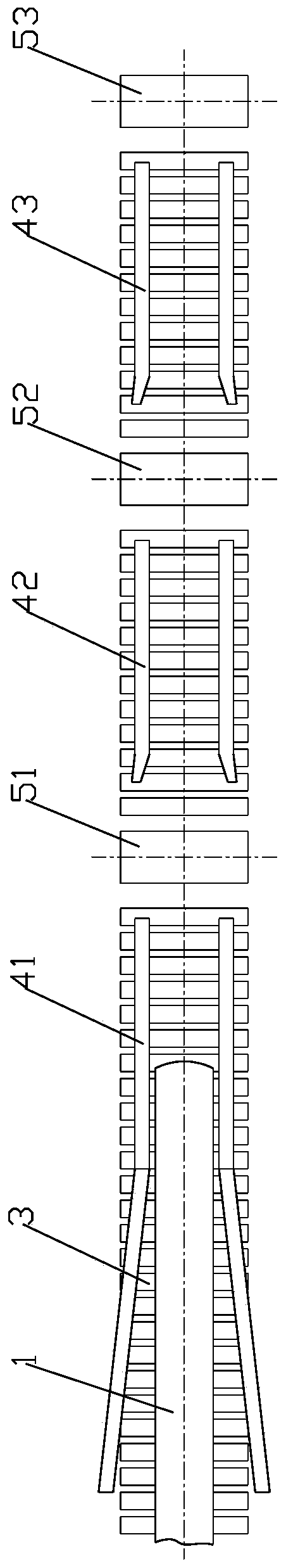

Method for improving strip steel tail part coiling quality

The invention provides a method for improving strip steel tail part coiling quality. The method is based on coiling equipment arranged behind a hot rolling unit, and the coiling equipment comprises afirst coiling machine and a second coiling machine which are arranged in sequence along the running direction of strip steel, and further comprises a pair of first side guide plates and a pair of second side guide plates. The method comprises the steps that during coiling of the strip steel by the second coiling machine, when the head part of the strip steel reaches an inlet of a pinch roller of the second coiling machine, the pair of second side guide plates are folded to clamp the strip steel; and before the tail part of the strip steel is transported out of a tail frame of a finish rollingunit, the pair of first side guide plates are folded to clamp the strip steel. According to the method for improving the strip steel tail part coiling quality, the side guide plates of the upstream coiling machines are used for clamping the strip steel, and two or more side guide plates are adopted to clamp the strip steel at the same time, so that the friction force between the side guide platesand the edge of the strip steel are improved, the tail part of the strip steel is ensured to be tightened, and the coiling quality of the tail part of the strip steel is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

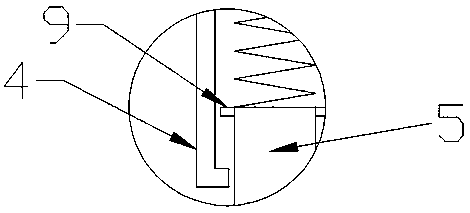

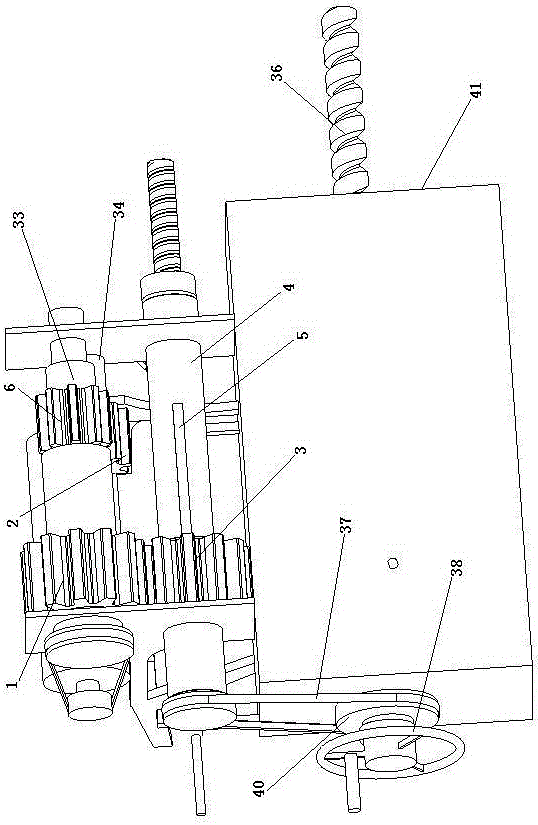

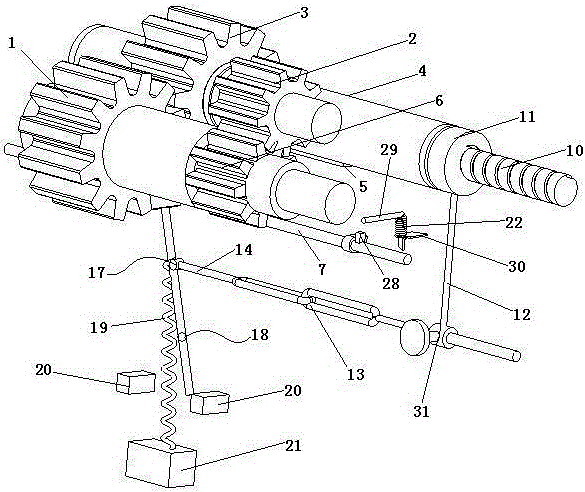

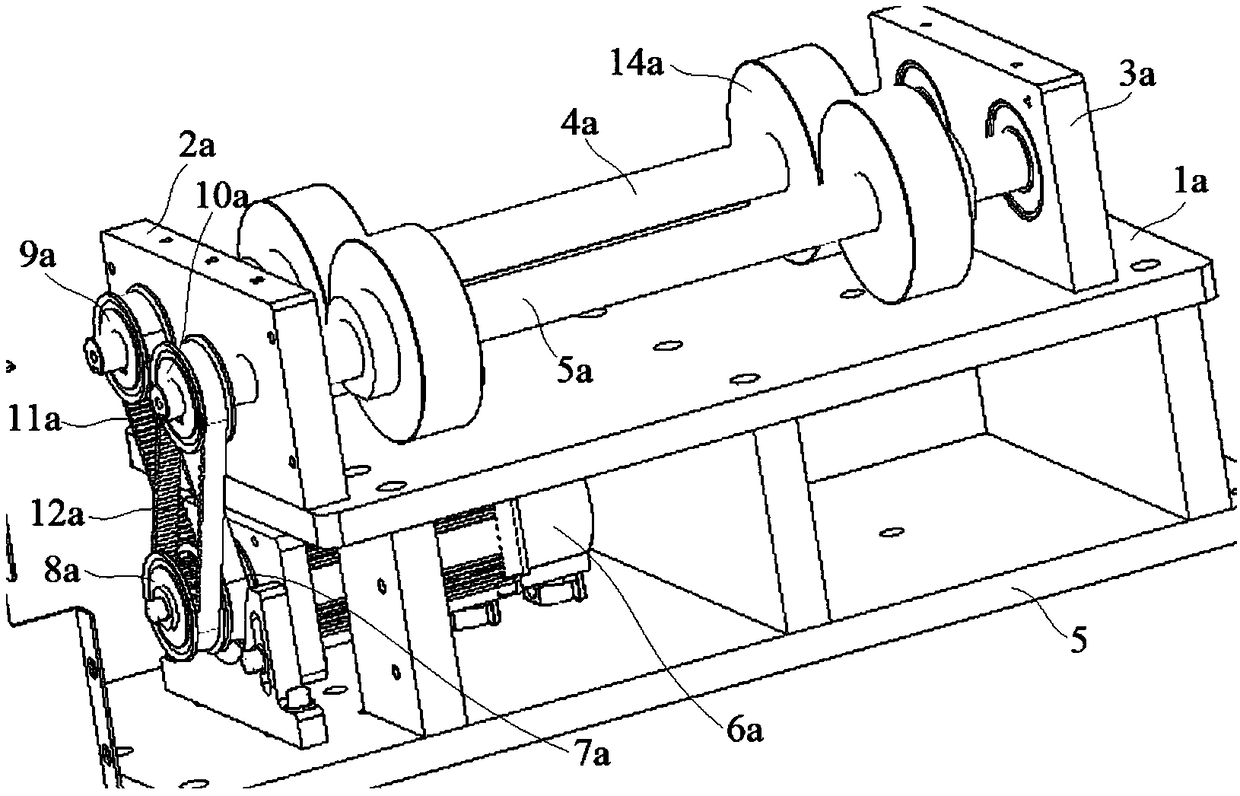

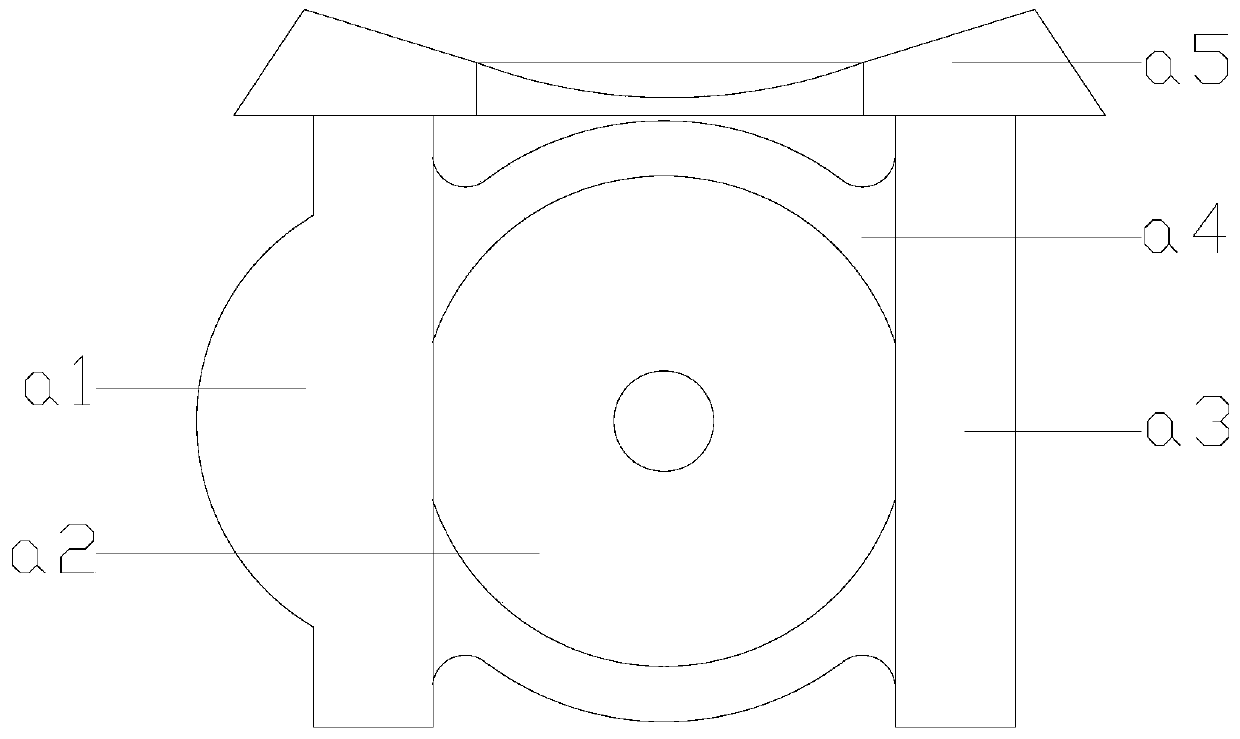

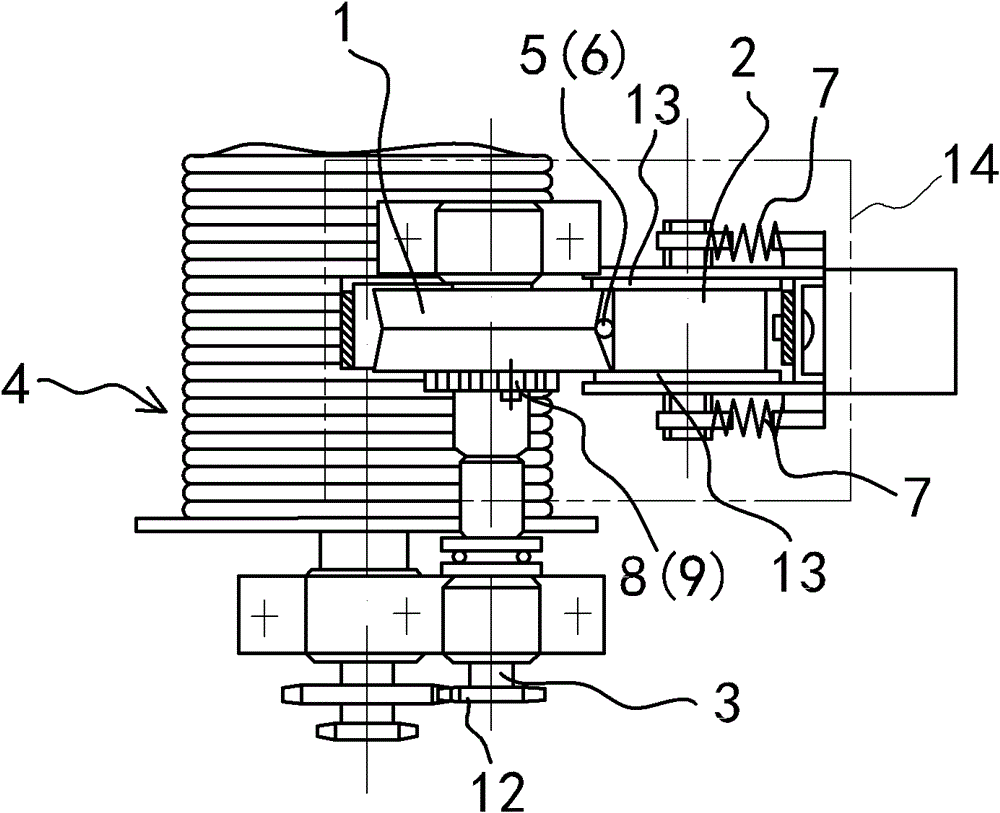

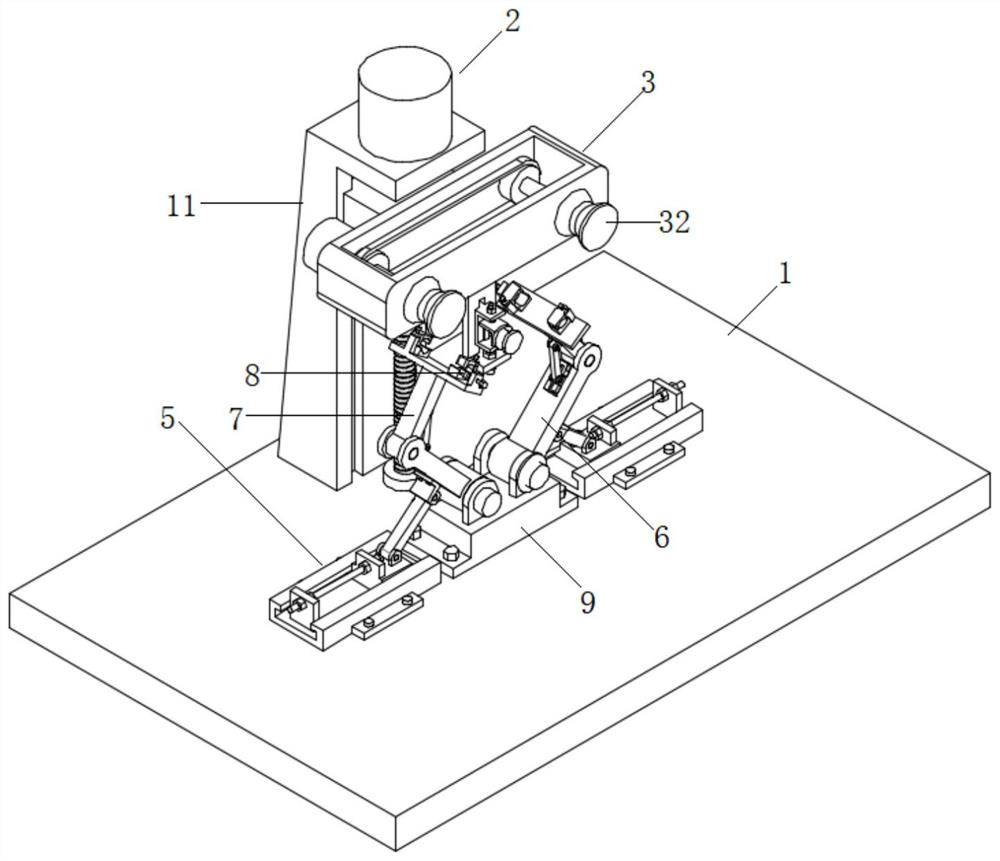

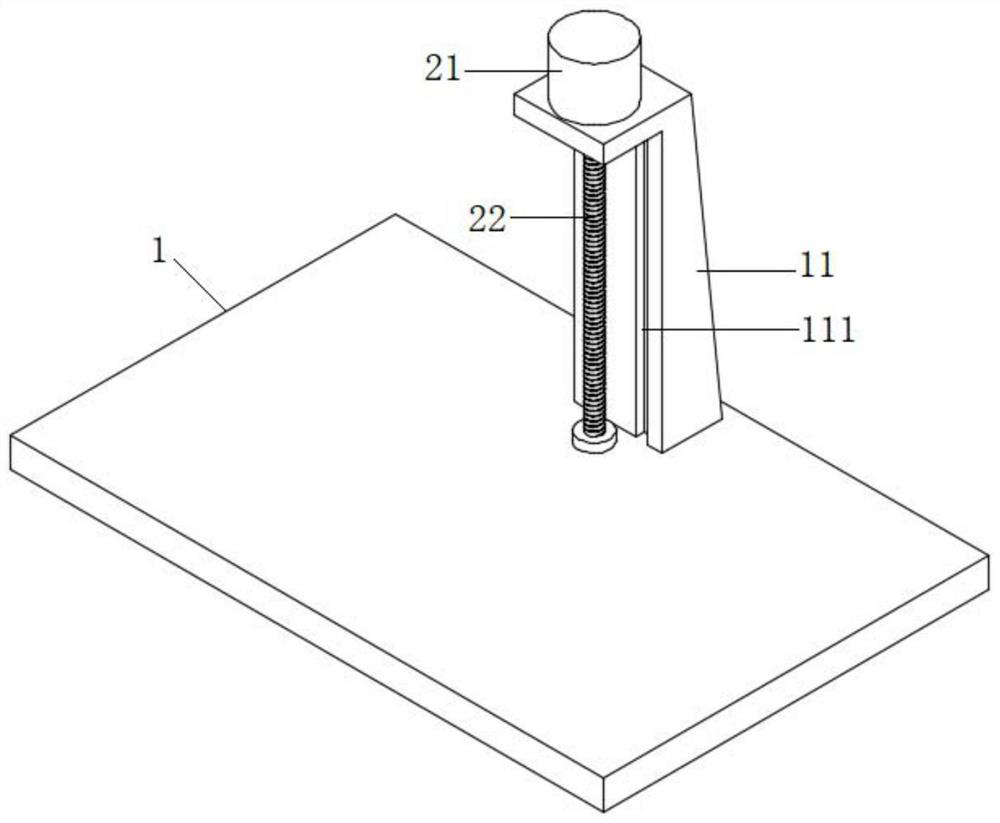

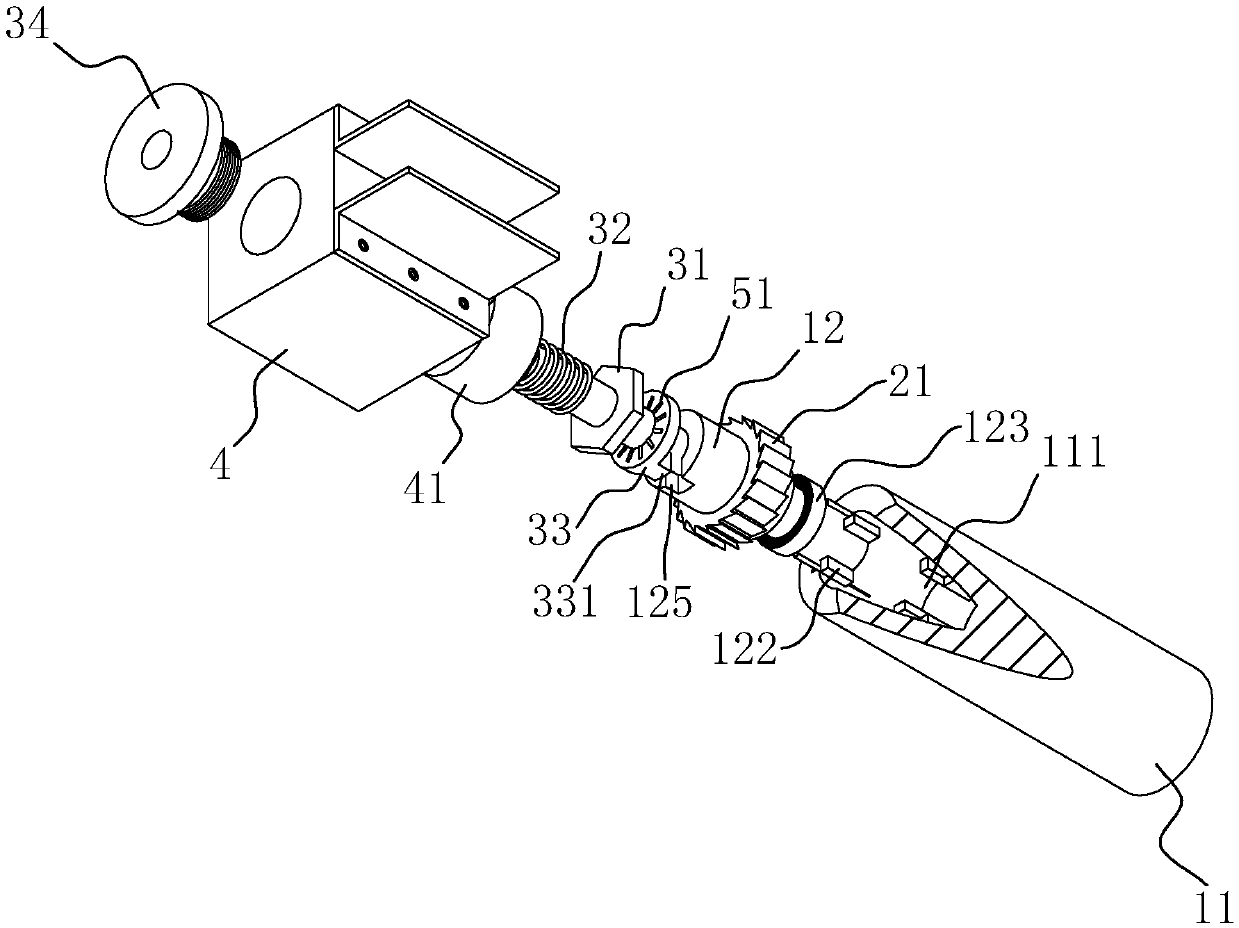

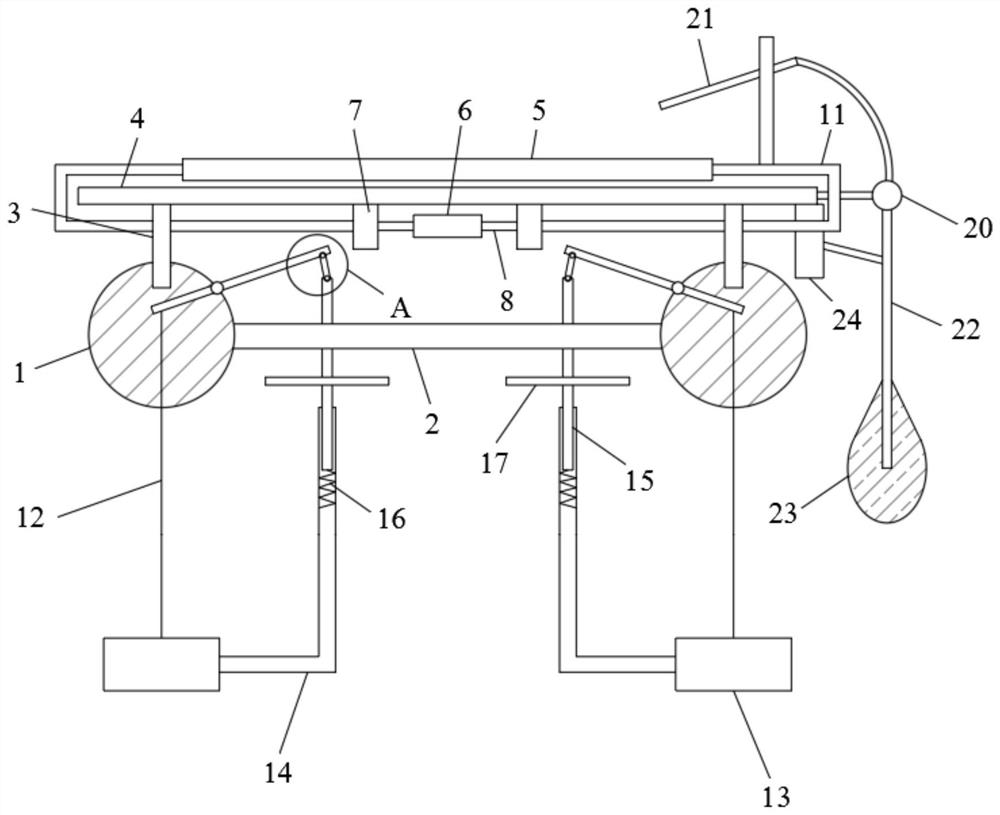

Automatic-feeding lathe tailstock mechanism

ActiveCN105057714APlay the role of meshing objectGuaranteed normal movementTailstocks/centresDrive shaftTailstock

The invention relates to an automatic-feeding lathe tailstock mechanism. The automatic-feeding lathe tailstock mechanism comprises a frame body and a driving mechanism and a pushing mechanism which are installed on the frame body; the driving mechanism and the pushing mechanism are linked through pushing fork rods, the driving mechanism is driven by a power device and drives a drill bit to act, and the driving mechanism can drive a driving gear to conduct forward rotation and reverse rotation; the pushing mechanism comprises a pushing rod which is arranged in a sliding mode, and the two pushing fork rods are located on the out sides of the two ends of the driving gear respectively; one end of a driving shaft is provided with a screw, and a thread sleeve connected with a curved rod is connected to the screw in a sleeving mode; an oscillating rod is connected with the pushing rod through a first rotating shaft and connected with a chain rod through a second rotating shaft, and the oscillating rod rotates through a third rotating shaft; the two ends of a chain are connected with the free end of the chain rod and the free end of the curved rod, and the free end of the chain rod and the free end of the curved rod can be in butt joint; one end of a first spring is fixedly connected to the portion, located on the position of the second rotating shaft, of the oscillating rod, and the other end of the first spring is fixedly connected to a fixing block; the pushing rod is further provided with a protruding block, and the protruding block is linked with a stopping mechanism.

Owner:扬州高力机械有限公司

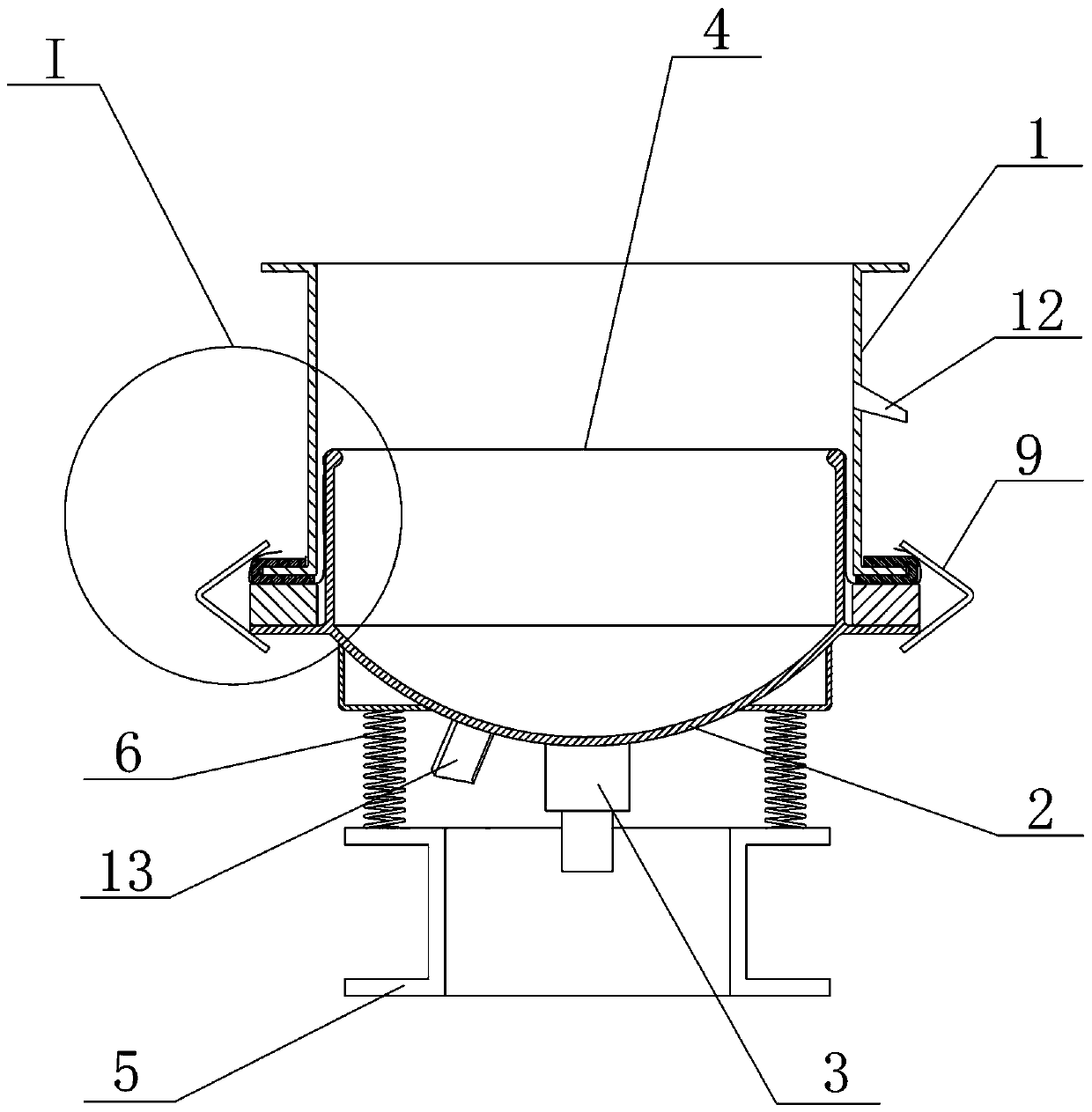

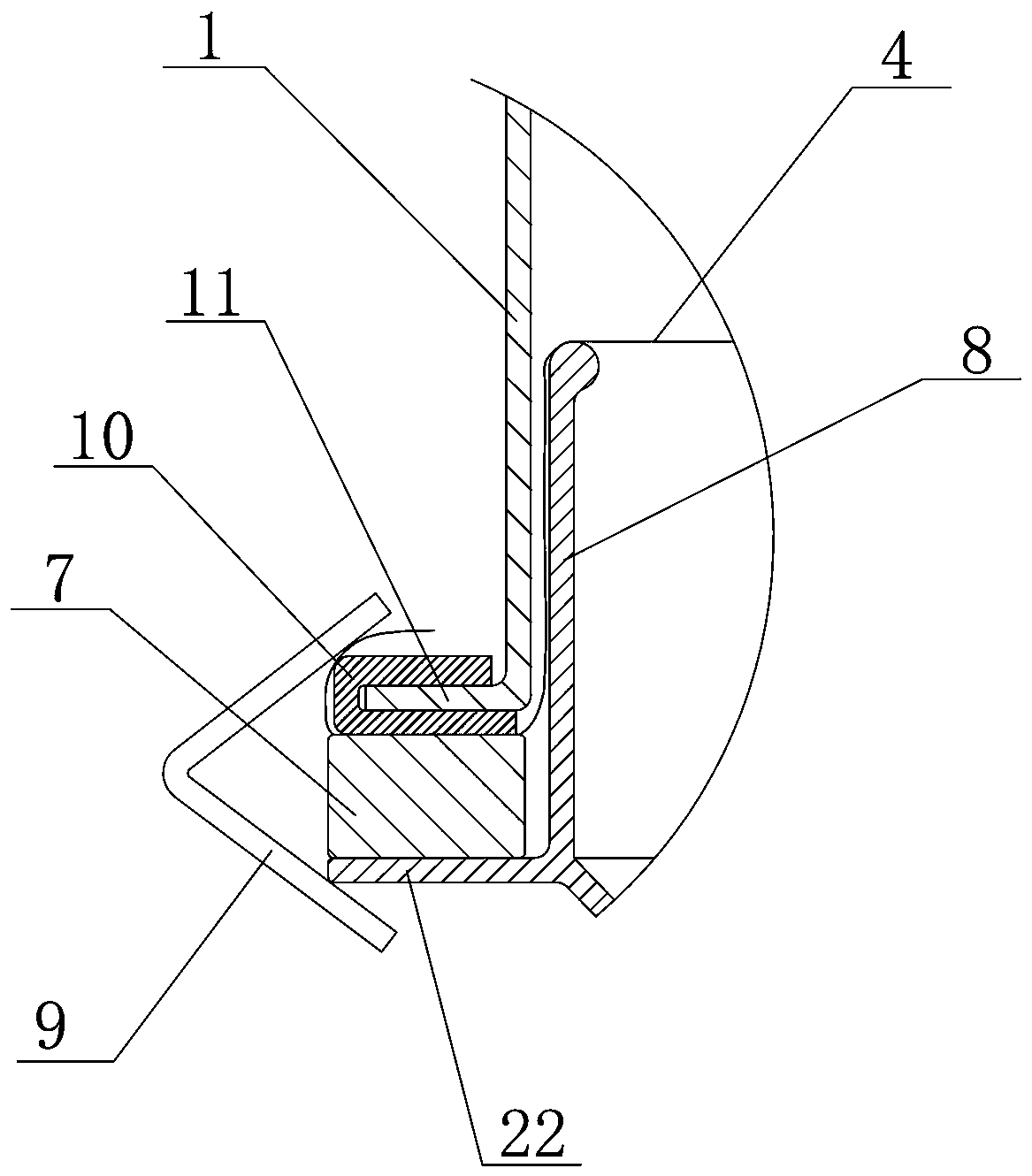

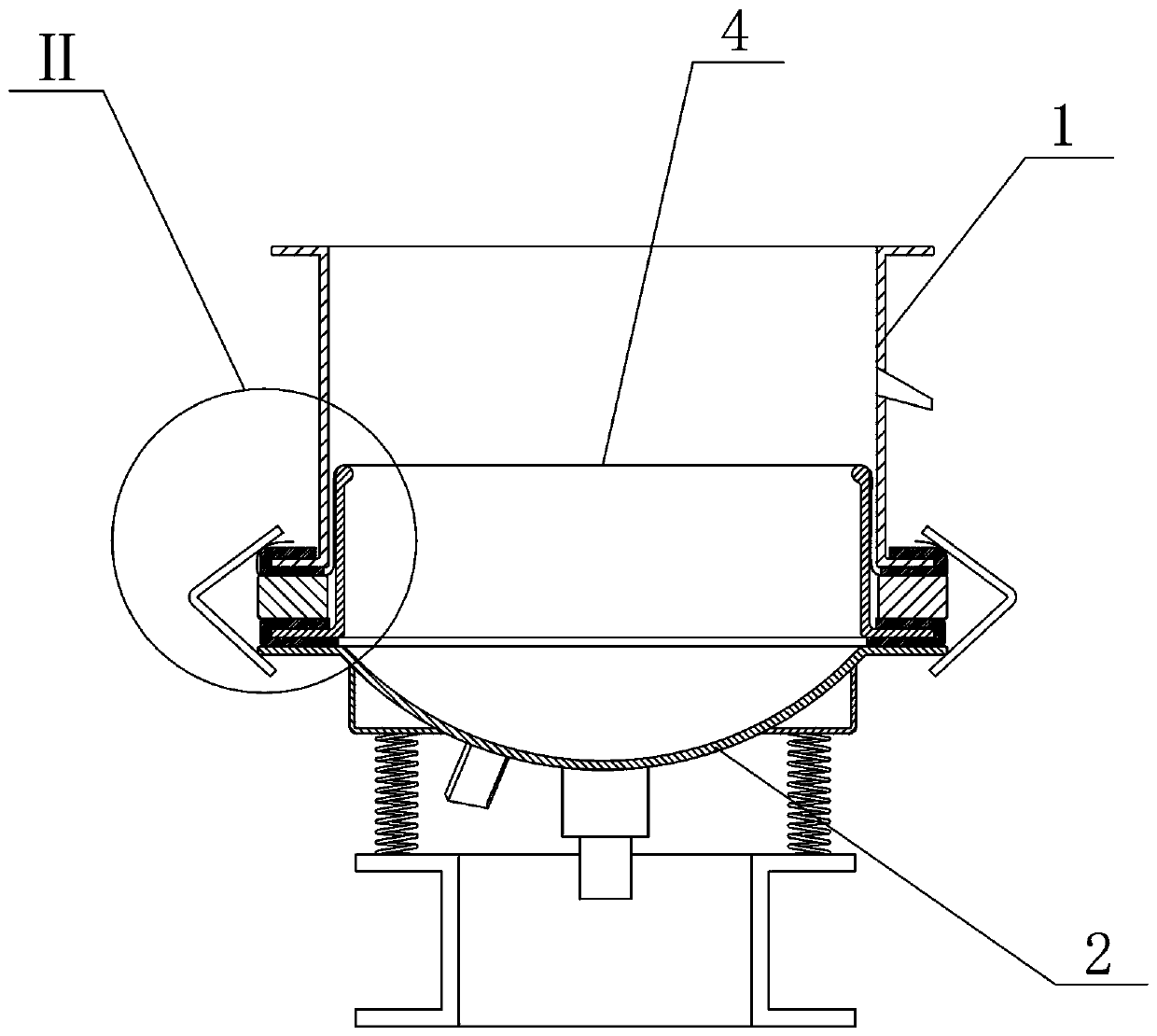

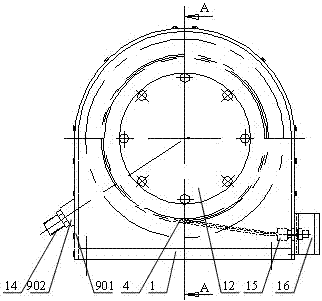

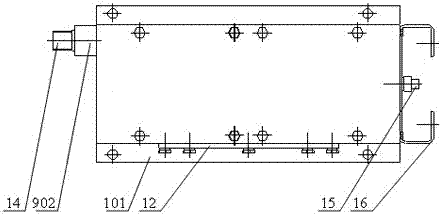

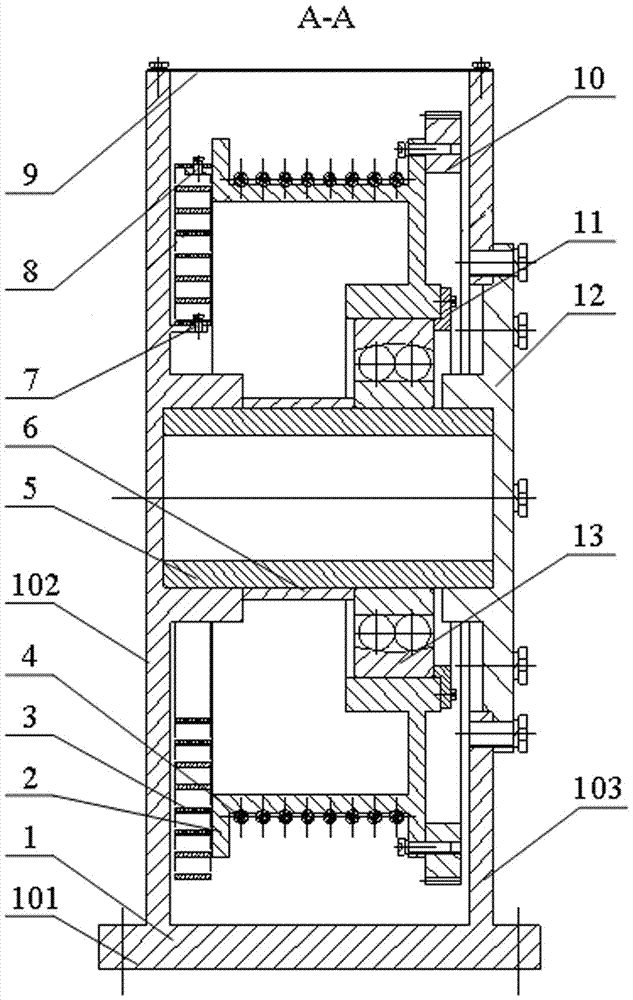

Vibration sieve and method for adopting thick glue to compress and tighten screen

The invention belongs to the technical field of material screening, and particularly relates to a vibration sieve and a method for adopting thick glue to compress and tighten a screen. A sieve frame,a screen, a screen frame and a vibration body are included. Locking discs are arranged on the edge of the sieve frame and the edge of the vibration body. The screen is laid on the screen frame, and the edge of the screen is tightly pressed below the sieve frame locking disc. The sieve frame, the screen frame, the screen and the vibration body are fixed together at the outer portion through fasteners. The vibration sieve and the method for adopting the thick glue to compress and tighten the screen are characterized in that elastic pieces with upper and lower elasticity are further included, andthe elastic pieces are arranged below the part, above the vibration body locking disc, of the screen. According to the vibration sieve and the method, the screen can be tightened directly through locking of the fasteners at the outer portion, and operation is simple and convenient.

Owner:山东润科机电设备有限公司

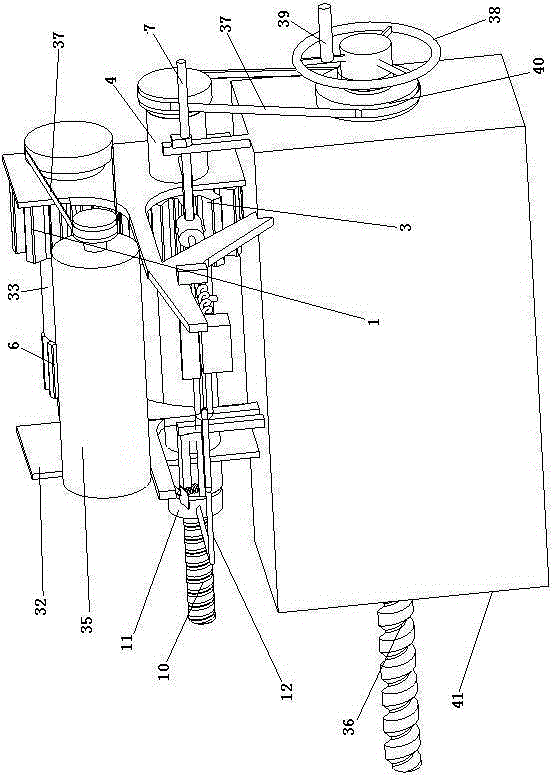

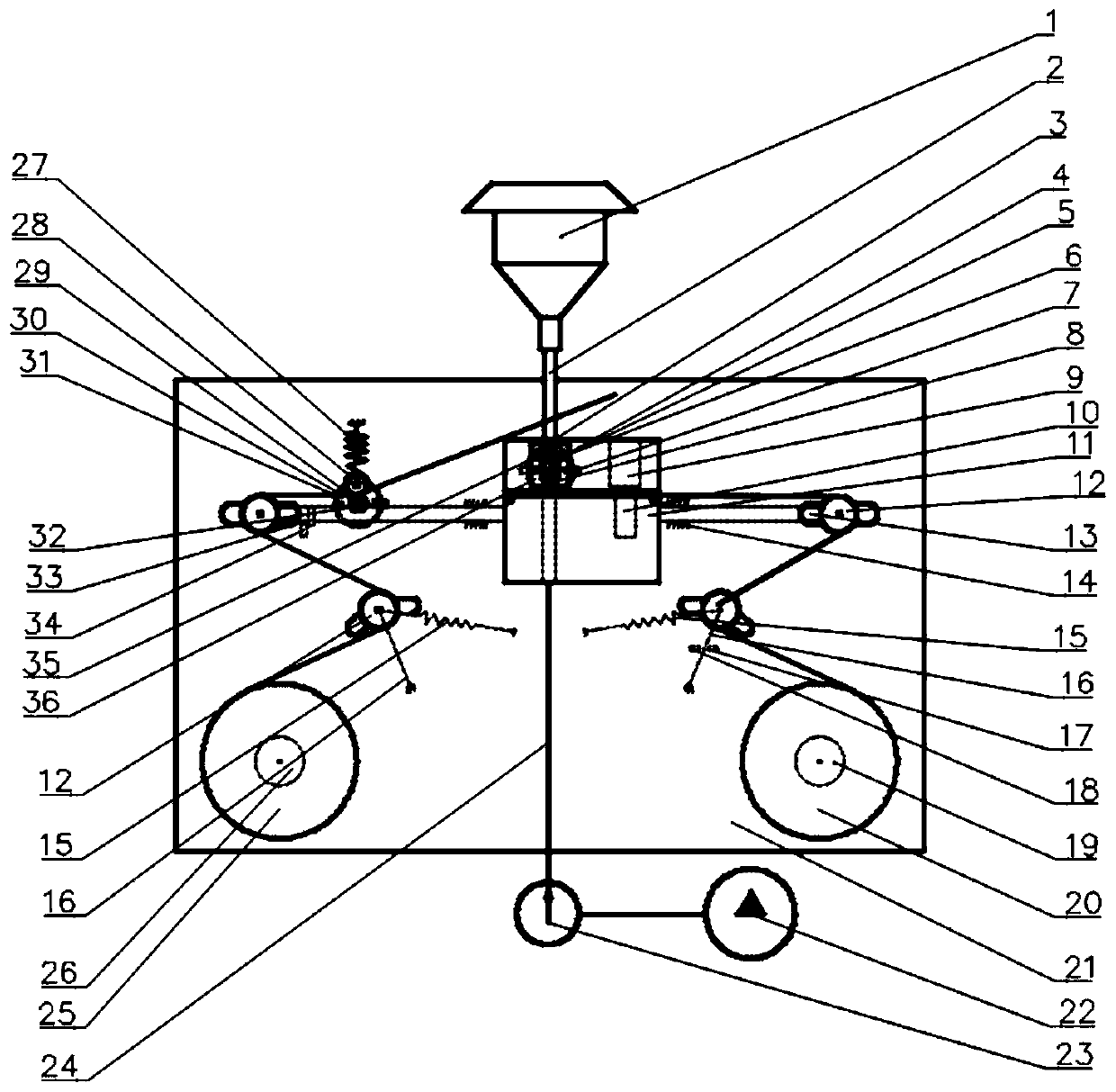

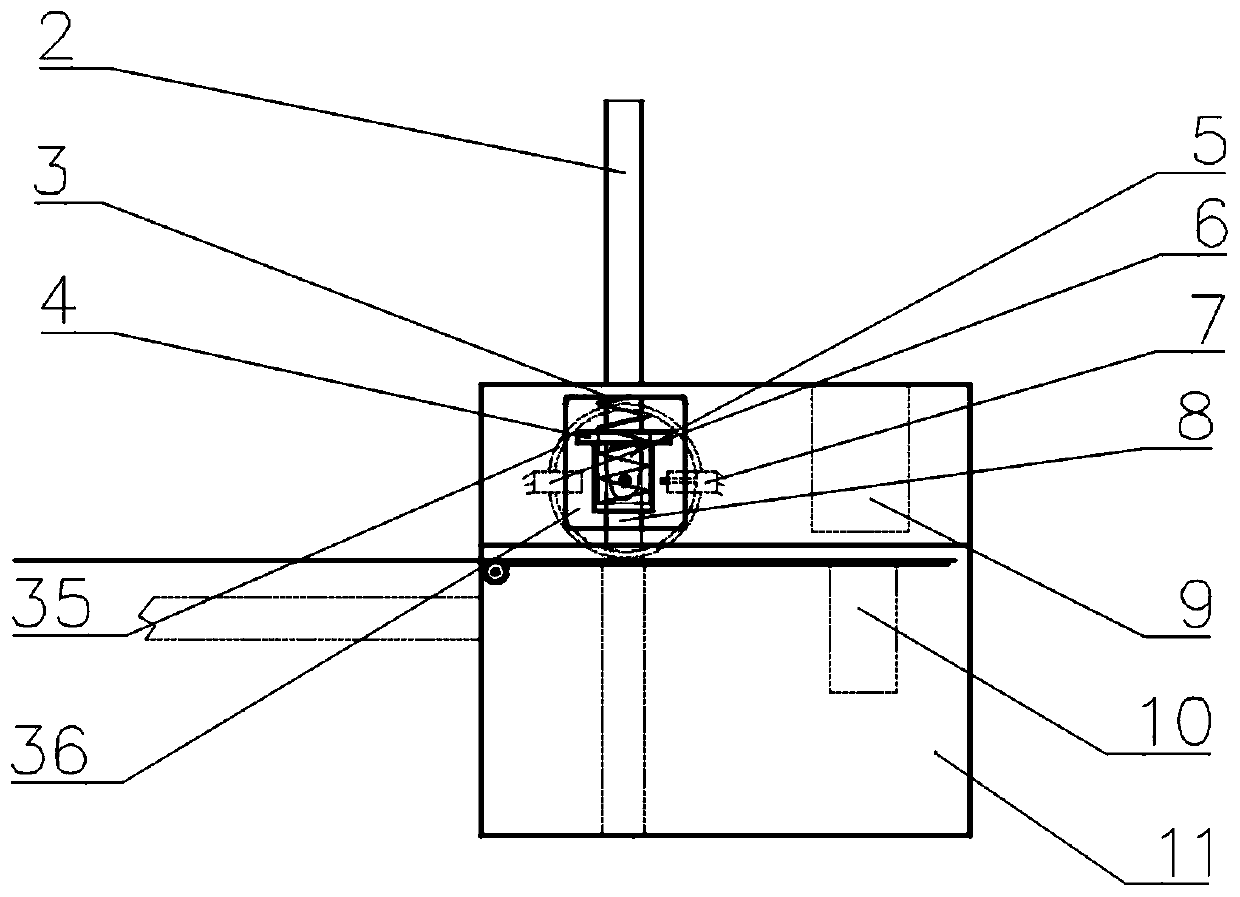

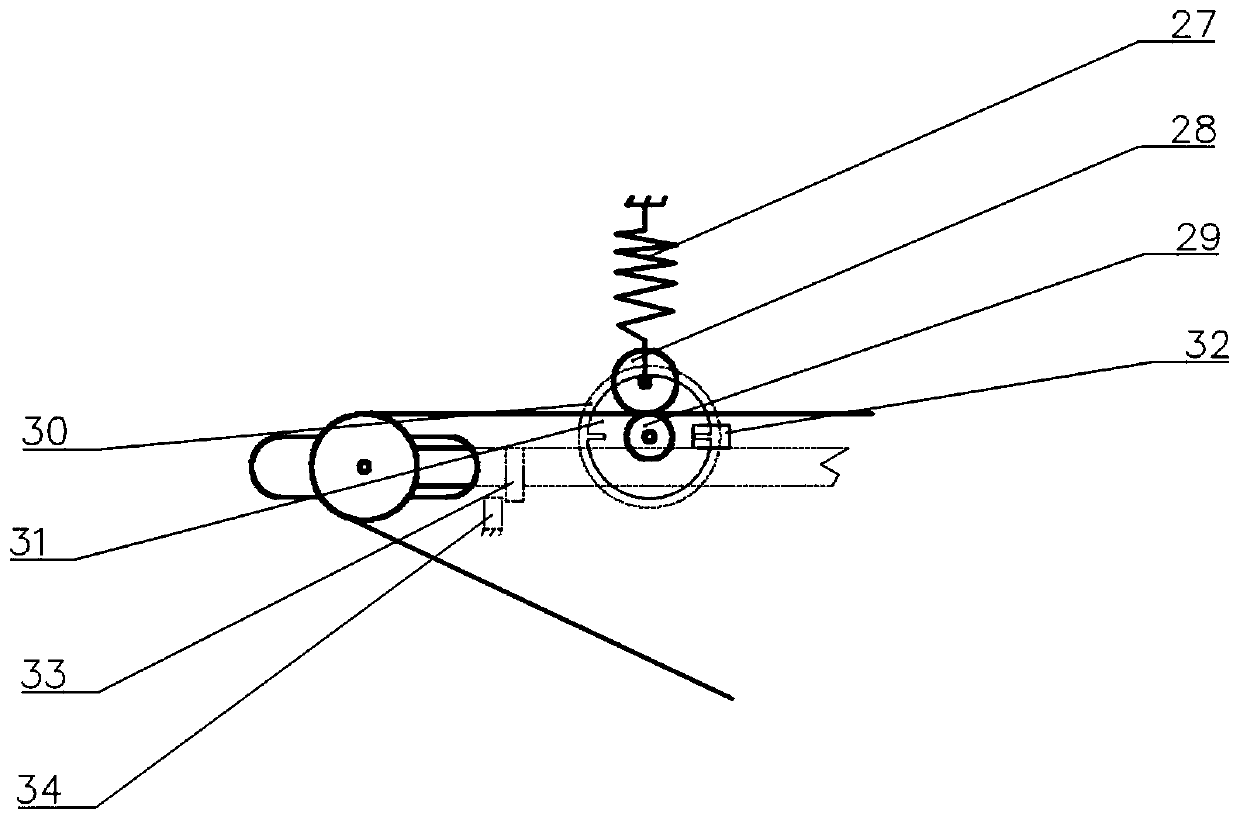

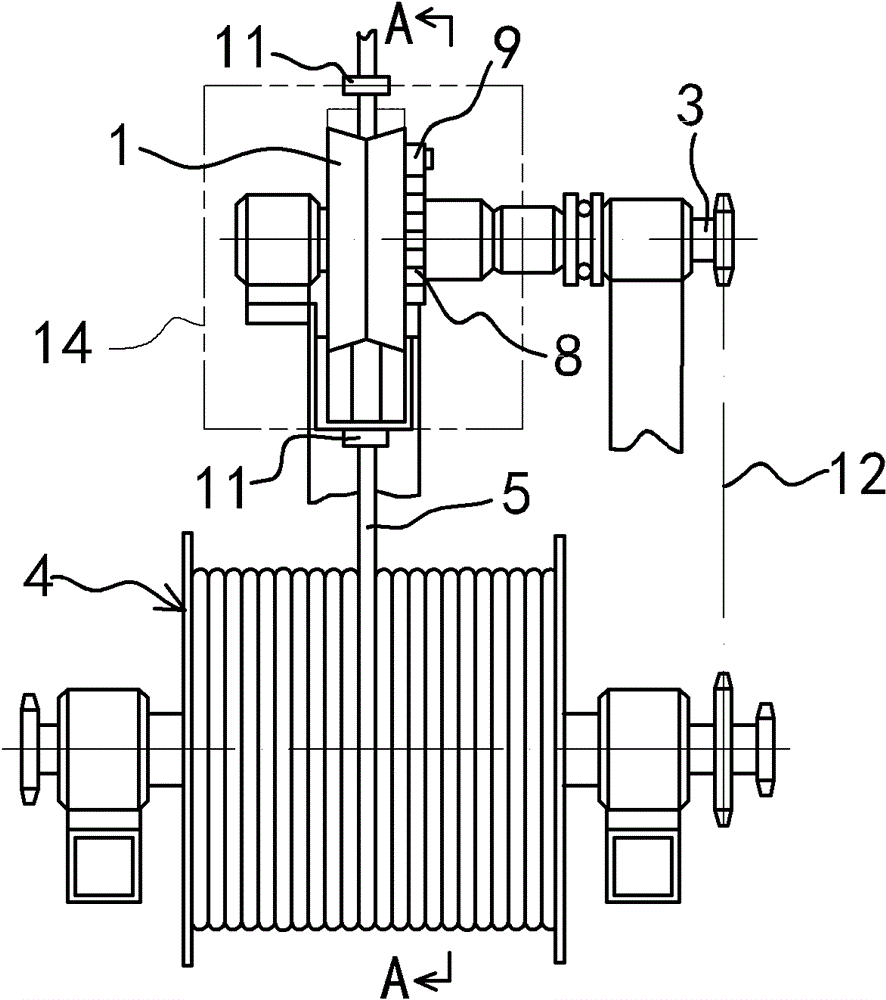

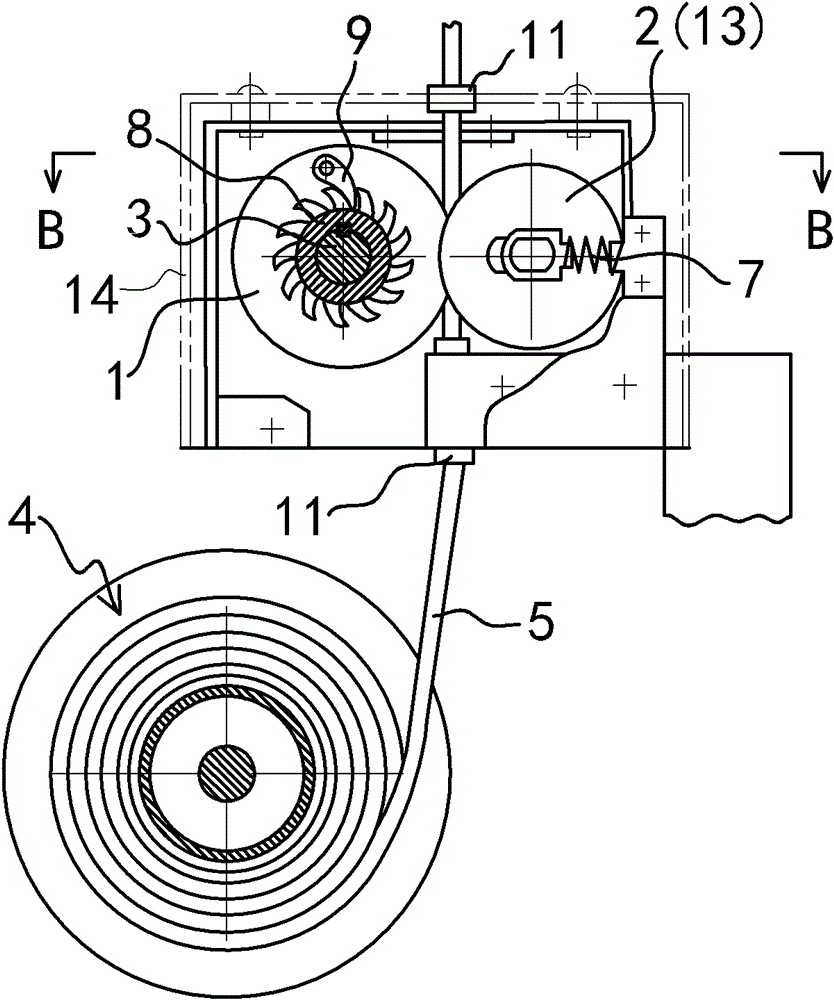

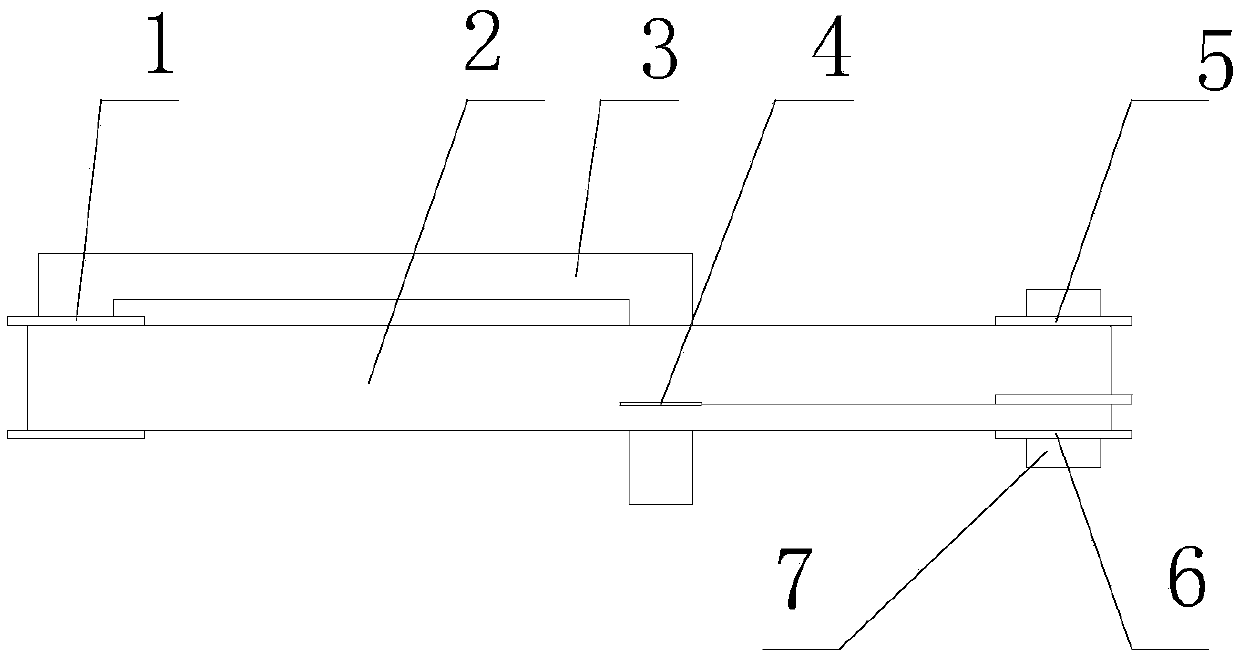

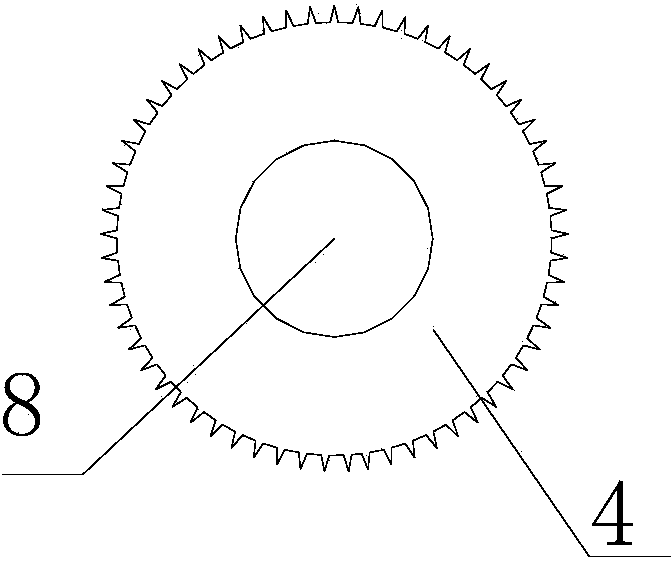

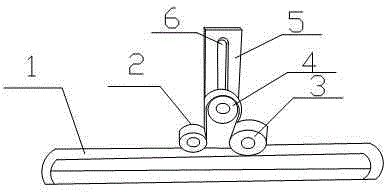

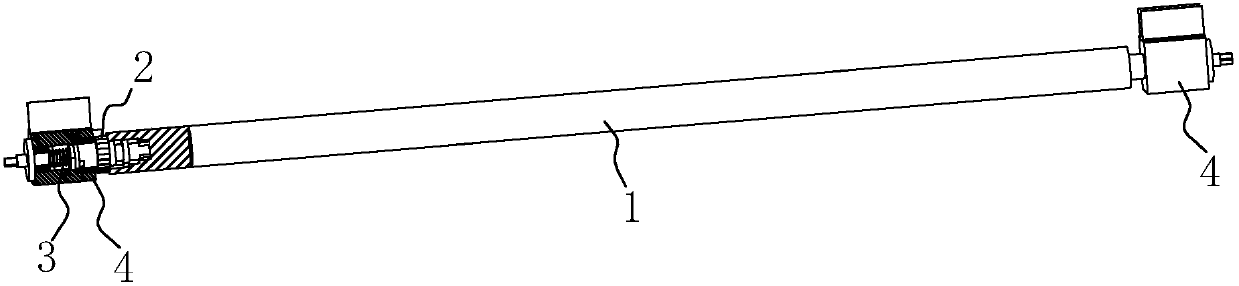

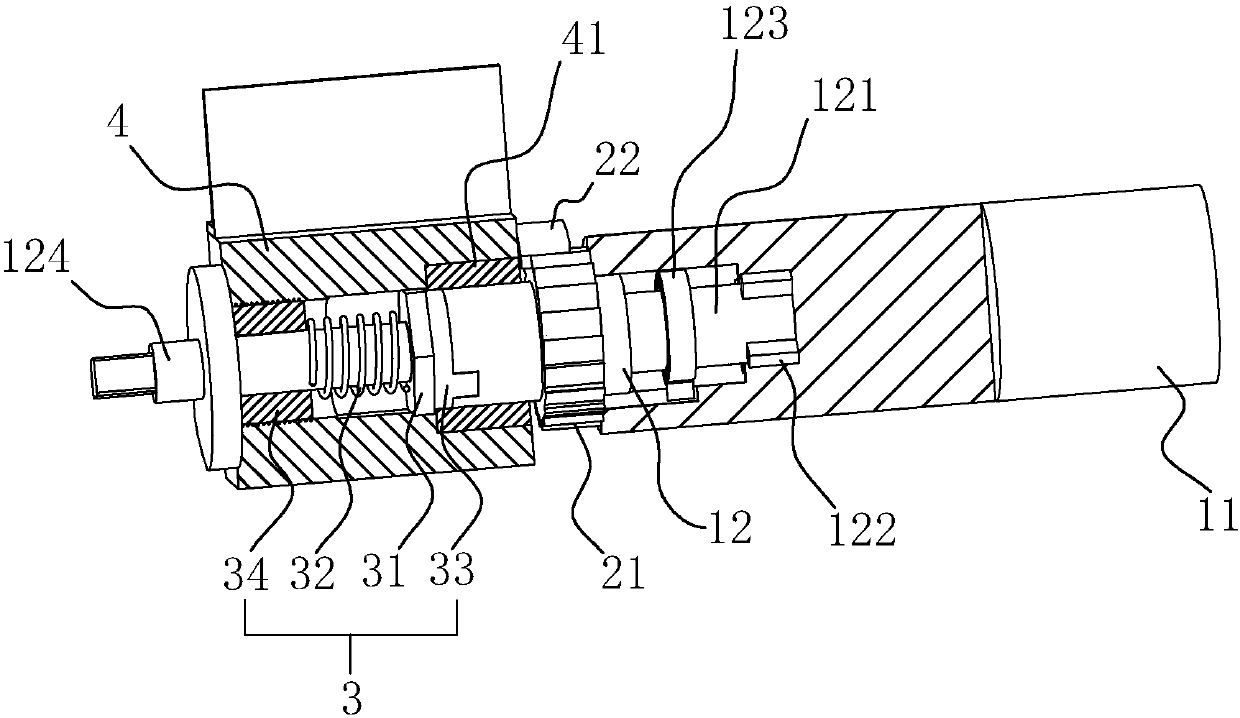

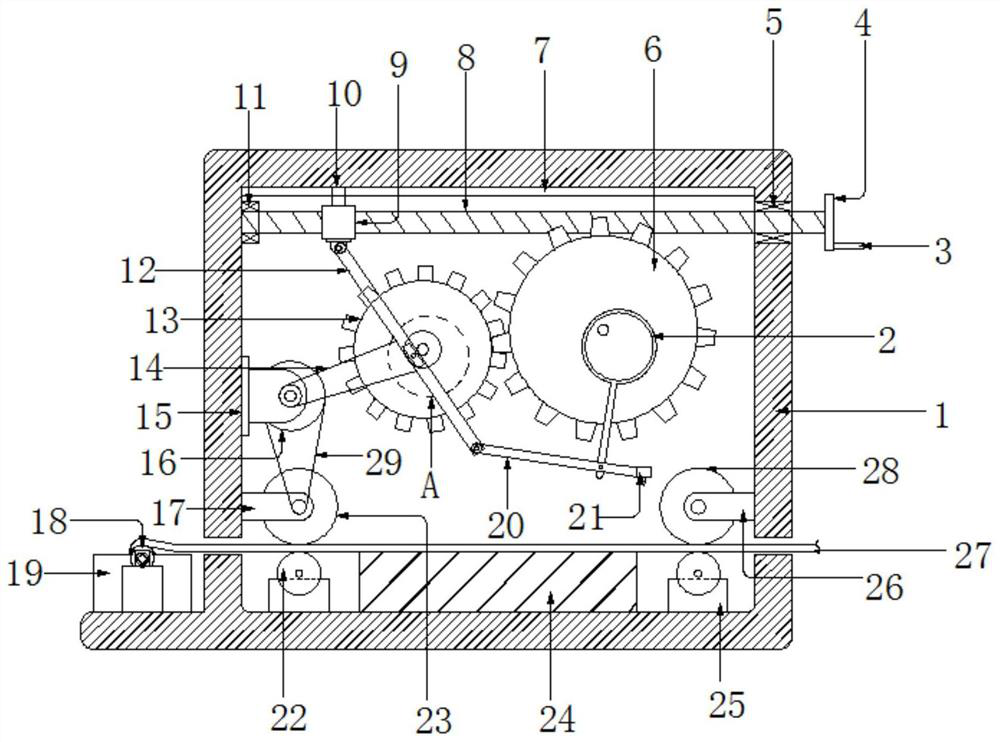

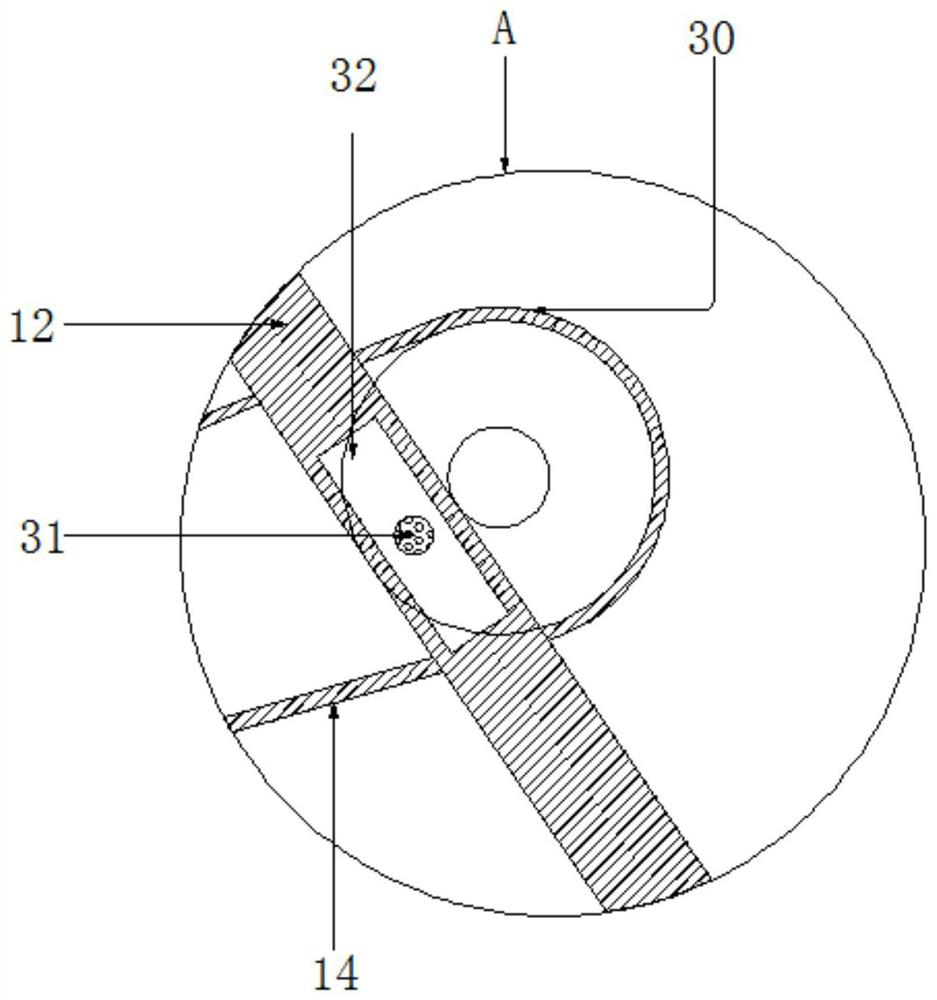

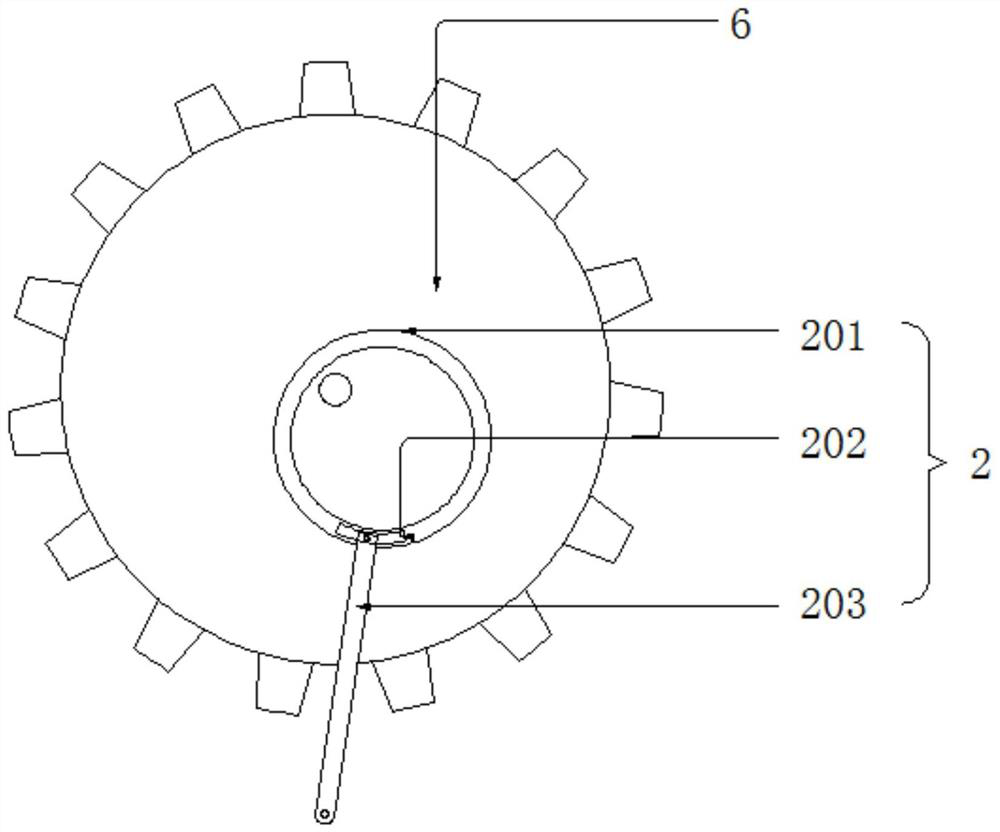

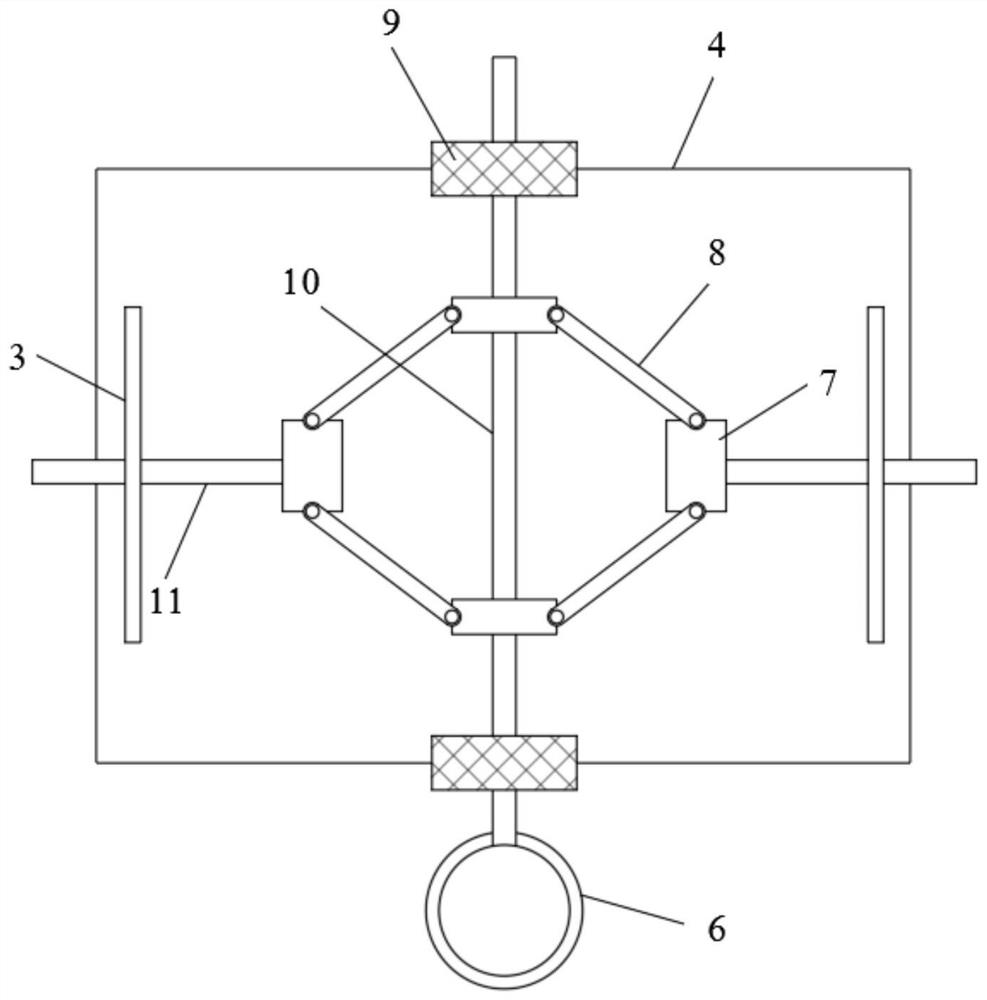

Movement speed and displacement integrated testing device and method of cable arranging device of marine winch

ActiveCN106865437ALarge measuring displacement rangeGuaranteed to be tightMeasurement devicesWinding mechanismsGear wheelCoil spring

The invention discloses a movement speed and displacement integrated testing device and method of a cable arranging device. The testing device comprises a supporting seat, a coil spring, a rope storing drum, a supporting shaft, a testing gear and a two-way hall switch, wherein the supporting shaft is mounted on a bracket, and the rope storing drum is mounted on the supporting shaft through a bearing; one end of the coil spring is fixedly connected with the bracket, and the other end of the coil spring is fixed to the rope storing drum; the testing gear which is coaxially fixedly mounted on the rope storing drum; the two-way hall switch corresponding to the testing gear is mounted on the bracket, and an axis of the two-way hall switch passes through the center of the gear; a steel wire rope end head locking device corresponding to the rope storing drum is arranged on the bracket. According to the testing device, the movement speed and displacement are measured in a way of pulling a coiling drum to test the contact mode of a steel wire rope, so that the measurement moving range is wide; a vortex type coil spring is arranged and can provide a certain tensioning force and returning force so as to ensure that the testing steel wire rope is tensioned as well as avoid disordering of the rope, and as a result, the tracking measuring accuracy is high.

Owner:HUNAN UNIV OF SCI & TECH

Device for on-line measurement of atmospheric particulate matter concentration

InactiveCN110849784ASimple structureQuantitative movementParticle suspension analysisEngineeringAtmospheric sciences

The invention discloses a device for on-line measurement of atmospheric particulate matter concentration, which comprises a sampling system, a main mounting plate, a detection mechanism, a sampling head lifting mechanism and a filter paper tape quantitative moving mechanism, wherein the sampling system comprises a particulate matter cutter, a sampling tube, a PU tube, a gas flowmeter and a sampling pump; the detection mechanism comprises a measurement block, a beta ray source and a scintillation detector; the sampling head lifting mechanism comprises a cam, a compression spring, a sampling pressure head and a sampling pressure head sleeve; and the sampling pressure head sleeve is fixed on the sampling pressure head. The device relates to the technical field of atmospheric particulate matter concentration monitoring. The device for on-line measurement of atmospheric particulate matter concentration has modular design of each mechanism and simple structure. The sampling head lifting device can ensure the airtightness of a filter paper tape when the atmospheric particulate matter concentration monitoring device is sampling; and a driving shaft optically-coupled baffle and a driving shaft photoelectric switch are arranged on the filter paper tape quantitative moving mechanism, so that accurate and quantitative movement of the paper tape can be realized.

Owner:安徽曼德克环境科技有限公司

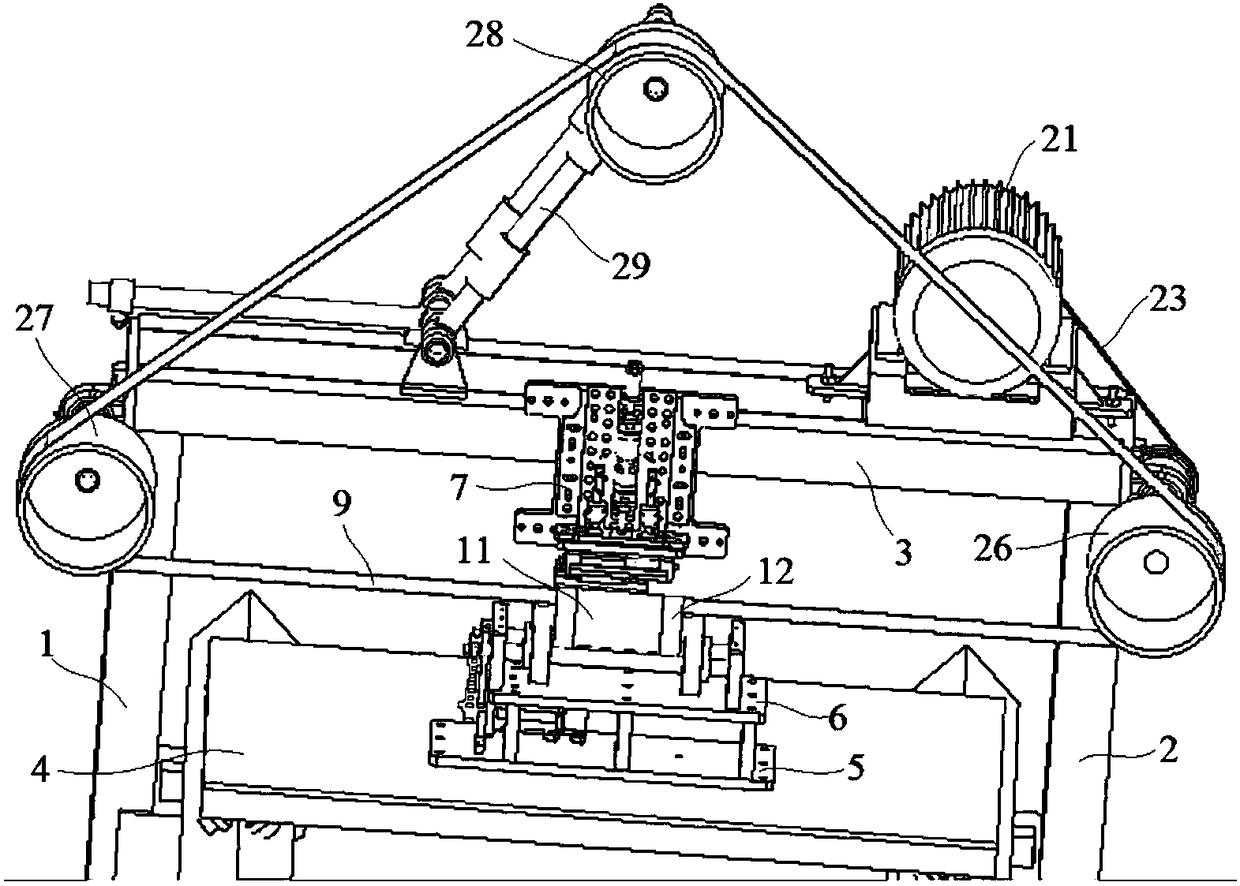

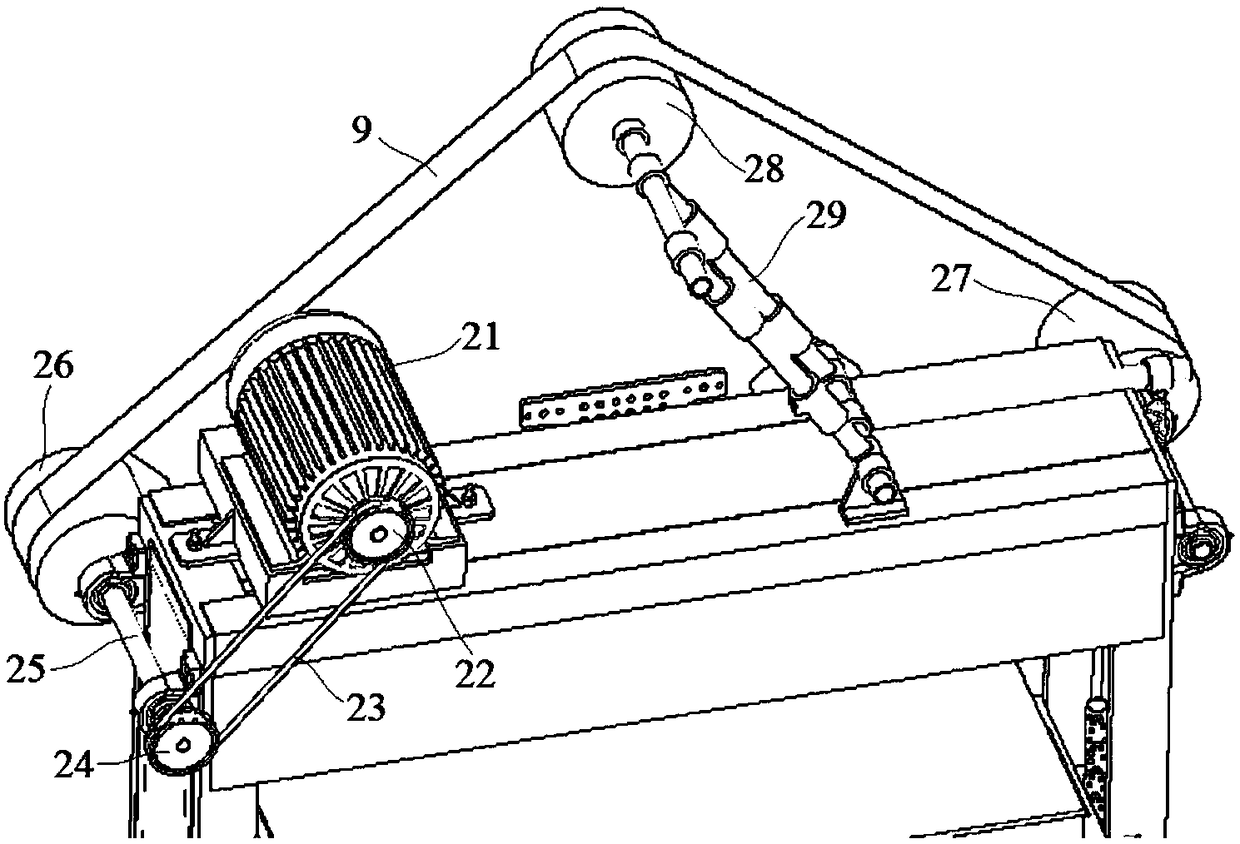

Automatic metal surface treatment device

ActiveCN108177061AAutomatic straight wire drawingGuaranteed drawing qualityGrinding drivesBelt grinding machinesDrive wheelPiston rod

The invention discloses an automatic metal surface treatment device which comprises a left vertical plate, a right vertical plate, a beam plate, a carrier plate, a base plate, a clamp base, a pressing-down mechanism and an abrasive belt. The left vertical plate and the right vertical plate are arranged in parallel. The beam plate is in bridging connection with the left vertical plate and the rightvertical plate. An output shaft of a motor is provided with a driving wheel, the driving wheel is in transmission connection with a driving auxiliary wheel through a belt, an air cylinder is vertically installed on the front surface of an installation plate, a piston rod of the air cylinder is fixedly connected with a pressing-down plate, a middle shaft is sleeved with a left fixing ring and a right fixing ring from the two ends of a supporting sleeve, the left fixing ring and the right fixing ring make close contact with the two end faces of the supporting sleeve correspondingly, and the supporting sleeve is sleeved with a circular pipe which is fixed through the left fixing ring and the right fixing ring. Straight wiredrawing operation of the metal surface can be automatically achieved,wiredrawing straightness, wire flow uniformity and wiredrawing efficiency are improved, the wiredrawing quality of the metal circular pipe is ensured, and the rate of finished products is improved.

Owner:苏州丰川电子科技有限公司

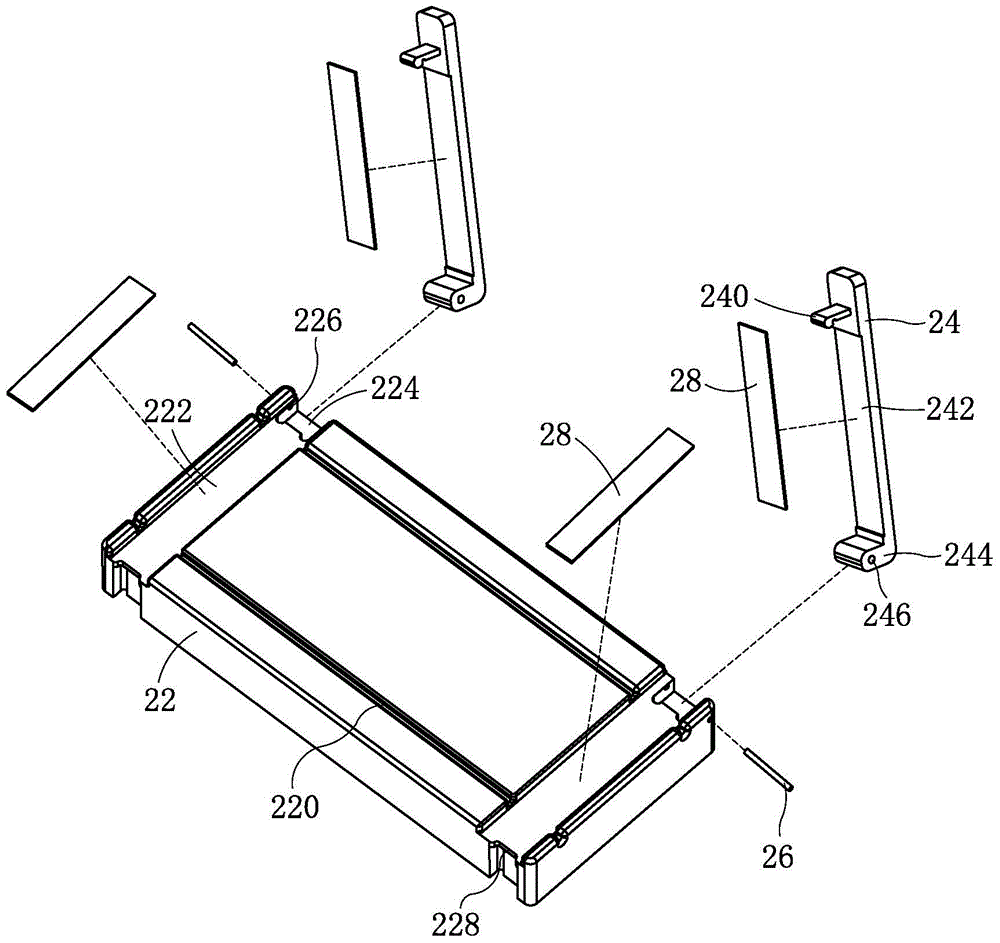

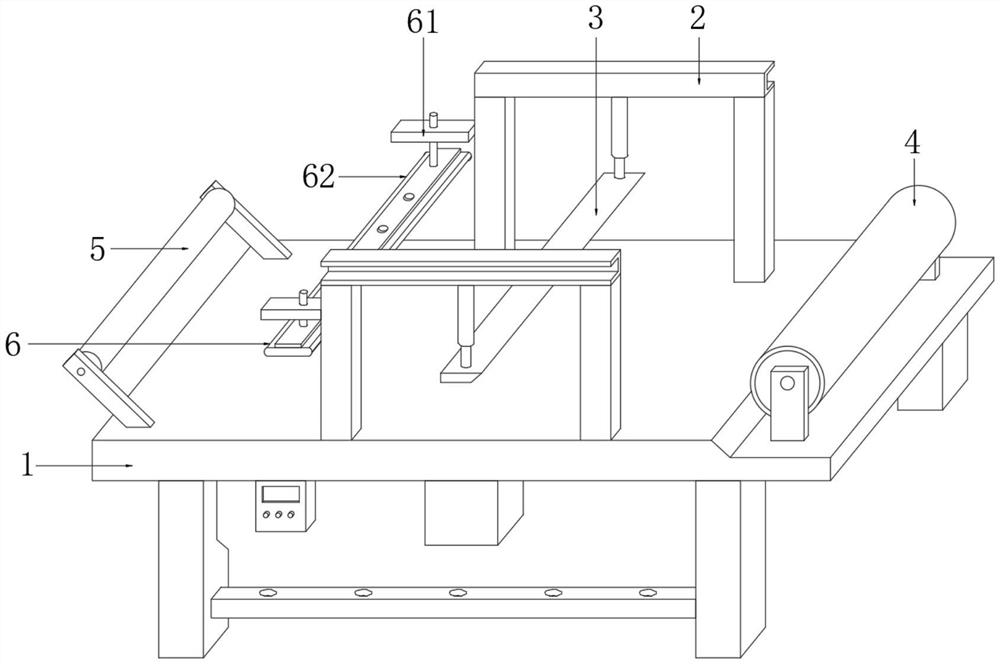

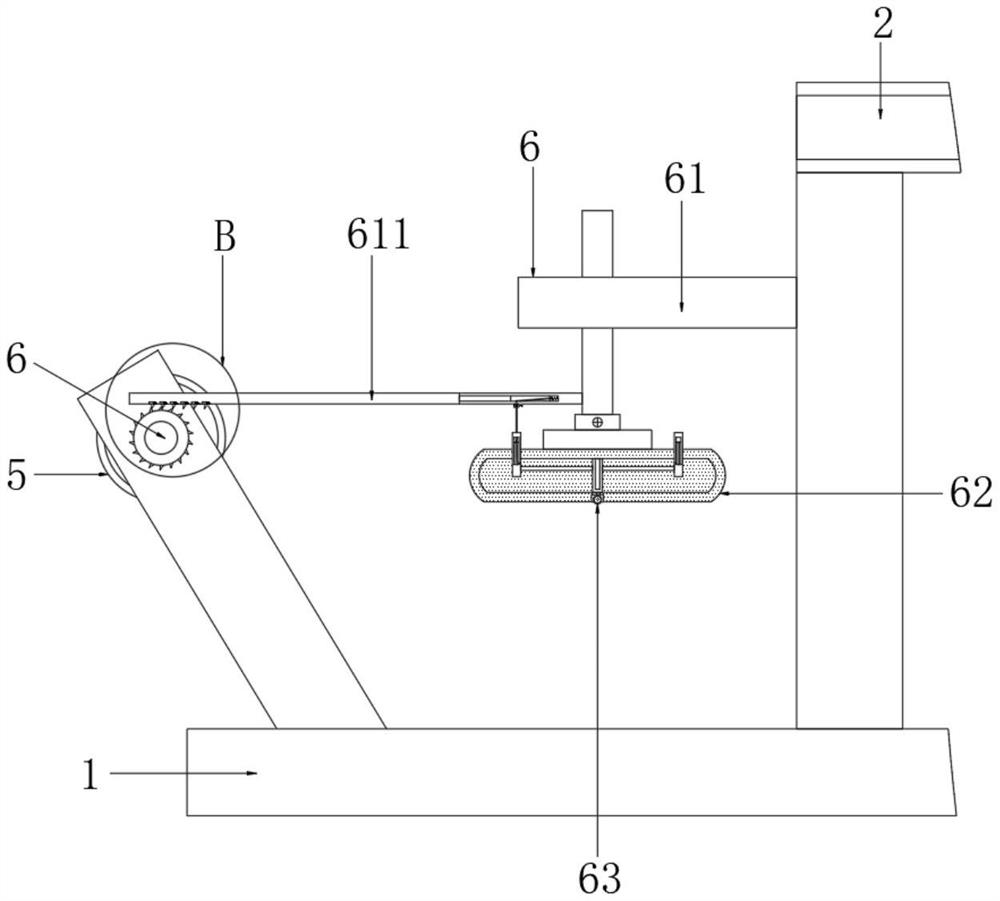

Glue overflowing wire automatic glue wiping machine after gluing of mobile terminal equipment display module

PendingCN108339726AGood wiping stabilityImprove stabilityLiquid surface applicatorsCoatingsTerminal equipmentGlue line

The invention discloses and provides a glue overflowing wire automatic glue wiping machine after gluing of a mobile terminal equipment display module, which is simple in structure, excellent in wipingstability, excellent in effect and high in wiping efficiency. The machine comprises a carrier module and a glue wiping module; the carrier module comprises a carrier, and a vertical rotating shaft cooperating with the carrier; the glue wiping module comprises a mounting plate aslant arranged; the mounting plate is downwards aligned to the carrier; a glue wiping wheel is arranged at the tail end of the mounting plate; a winding wheel and an unwinding wheel are arranged on the two sides of the mounting plate; a strip is connected between the winding wheel and the unwinding wheel, and is bypassed through the glue wiping wheel; and the glue wiping module further comprises a transverse rotating shaft cooperating with the mounting plate. The machine can be applied to the technical field of gluewiping machines.

Owner:深圳市运泰利自动化设备有限公司

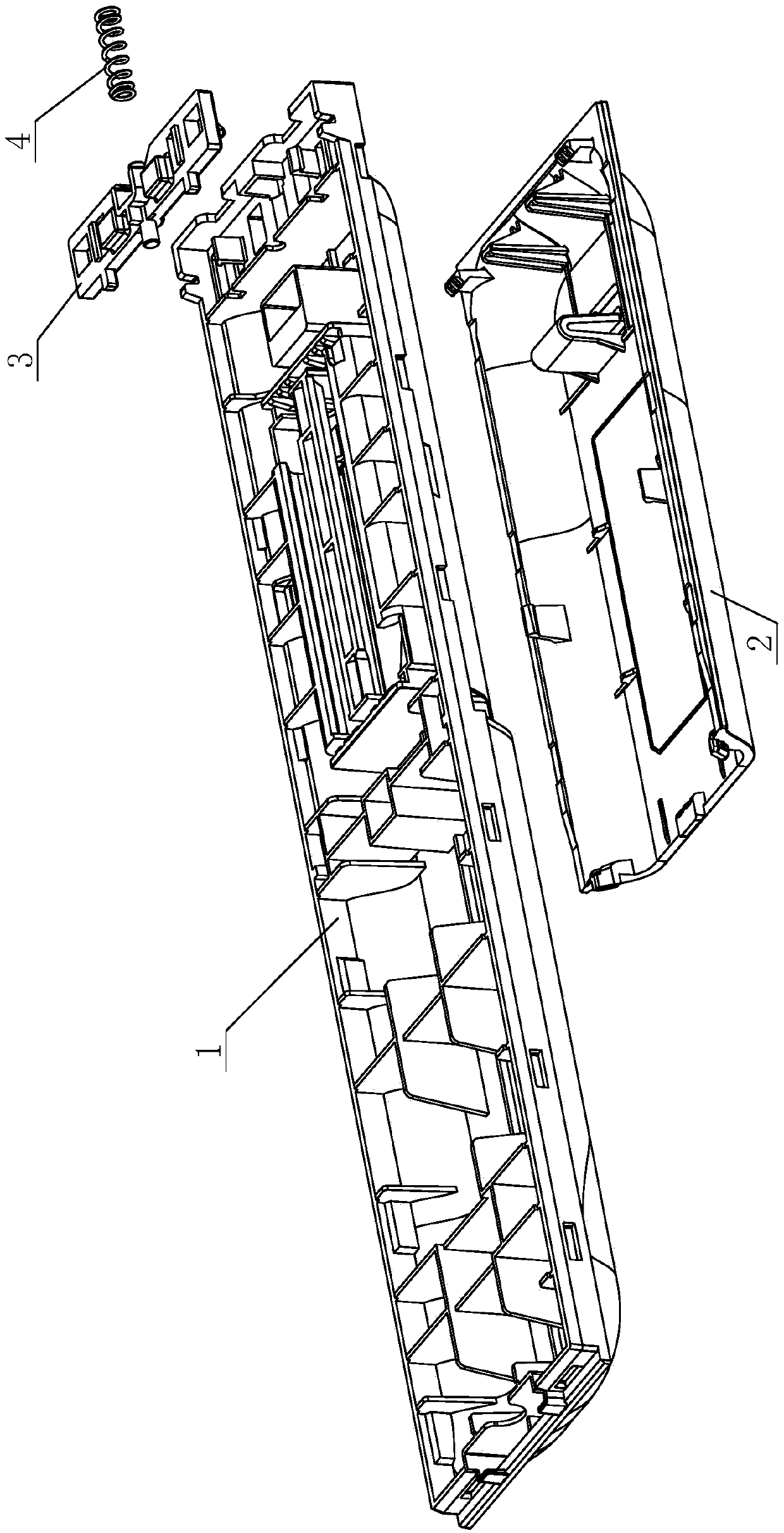

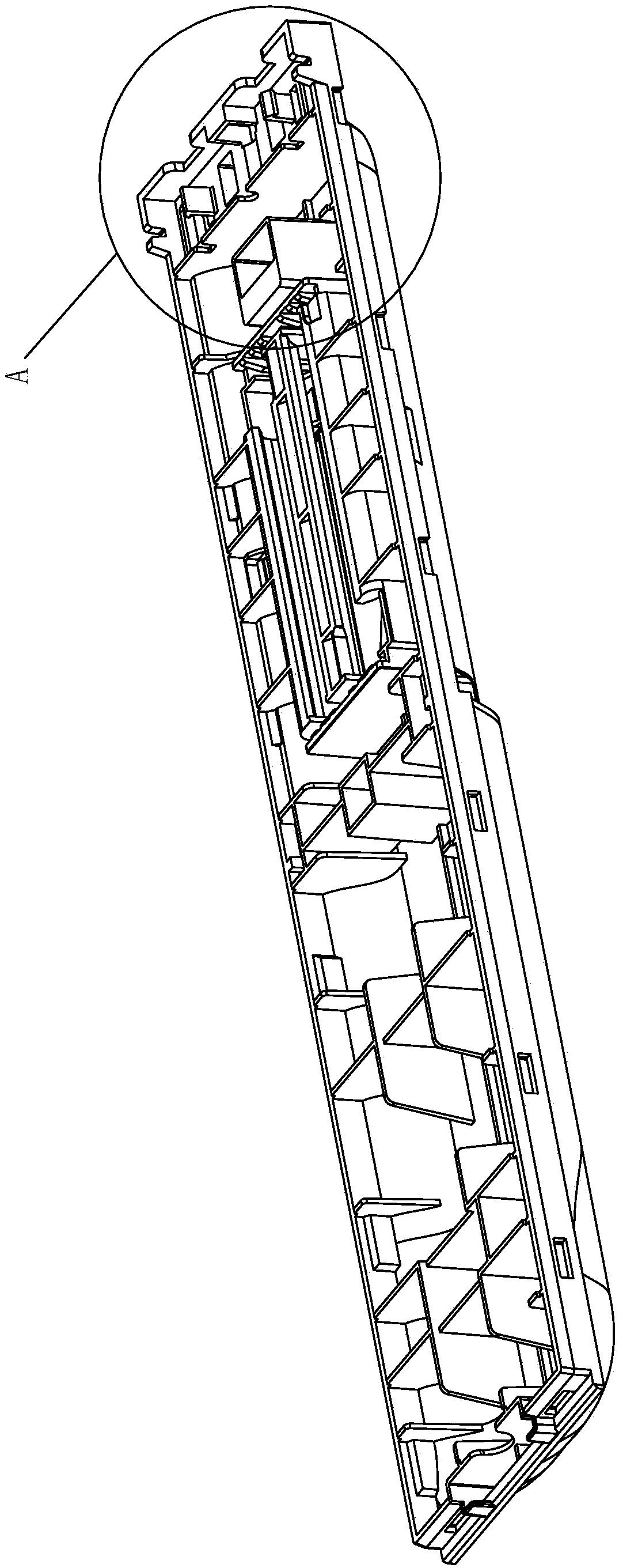

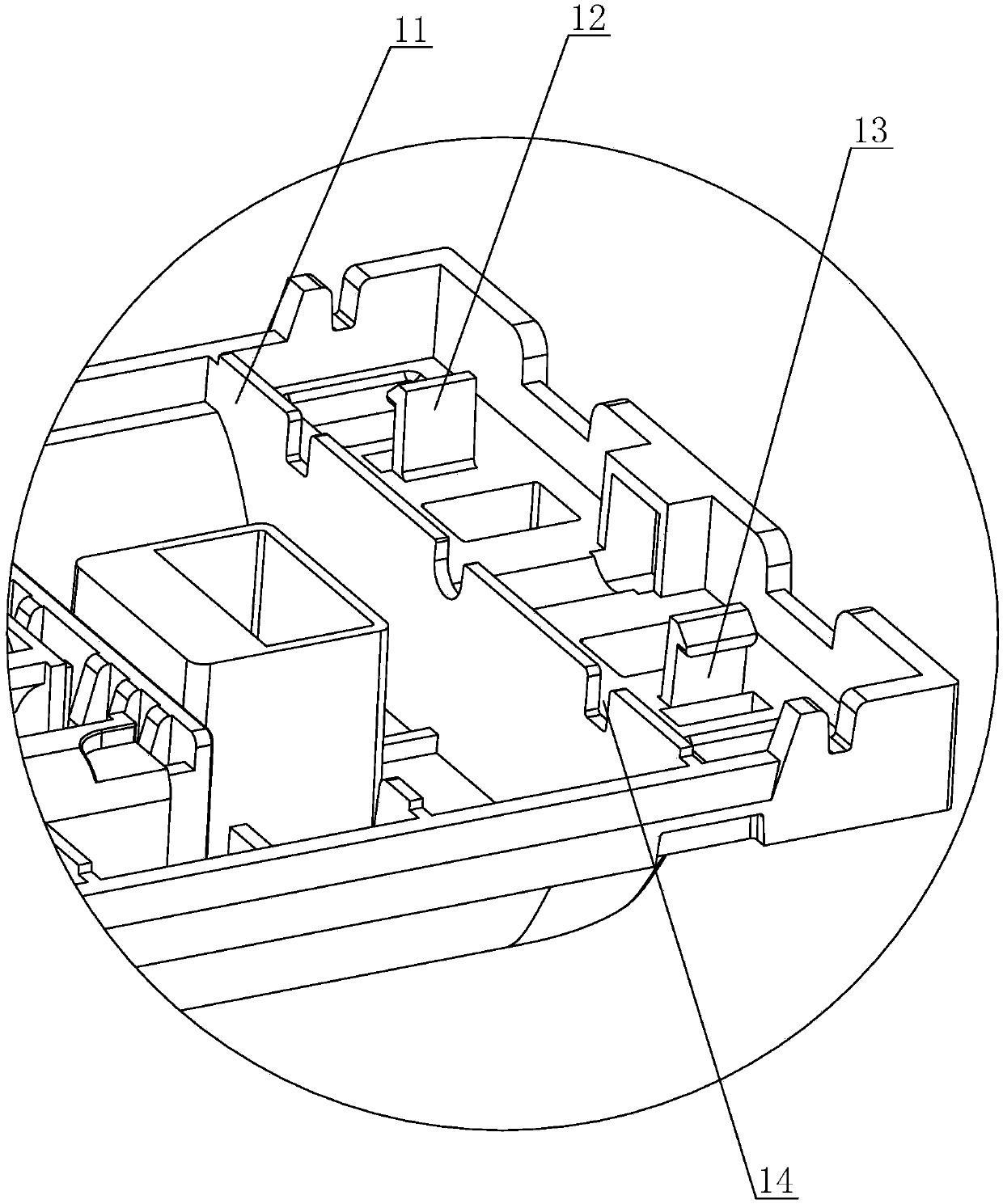

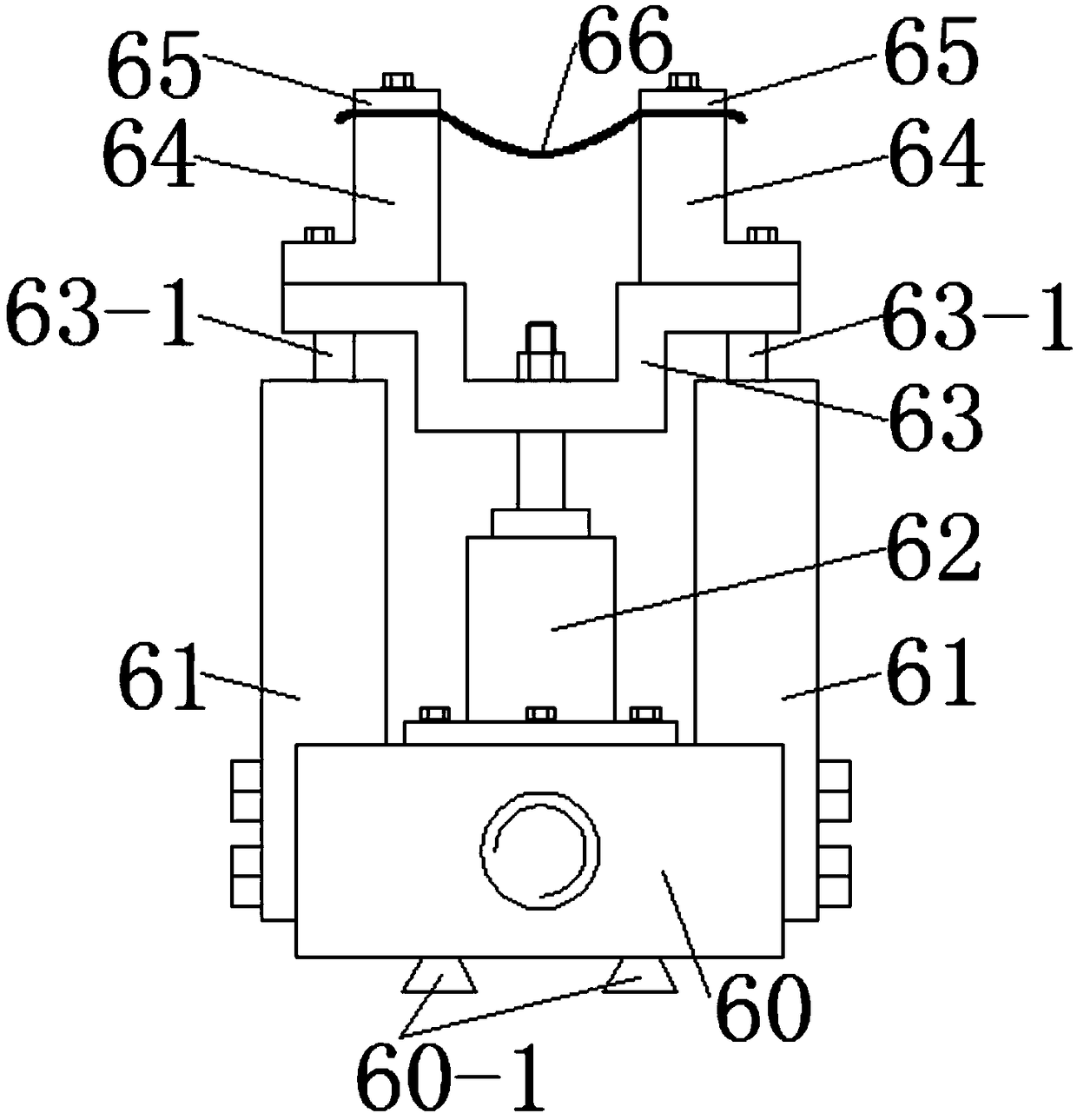

Wire fixing jig

The invention discloses a wire fixing jig, and relates to the technical field of wire processing molds. The wire fixing jig comprises a wire guide assembly and a wire clamp assembly. The wire guide assembly and the wire clamp assembly are connected with each other, the wire guide assembly comprises a wire guide base plate, the wire clamp assembly comprises a wire clamp base plate, and one end of the wire guide base plate is connected with an end of the wire clamp base plate; a slider is slidably mounted at the other end of the wire guide base plate, the sliding direction of the slider is consistent with the extending direction of the wire guide base plate, a clamp portion which is used for clamping a wire distributor for wires is arranged on the slider, and at least two wire distributing columns are arranged in the middle of the wire guide base plate; two wire clamp plates are respectively hinged to two ends of the wire clamp base plate, and the wires can be clamped between the wire clamp base plate and the wire clamp plates by the two wire clamp plates. The wire fixing jig has the advantages that the wire fixing jig is simple in structure and convenient to use, and the wires can be reliably fixed by the aid of the wire fixing jig and can be prevented from being damaged; the wire fixing jig is suitable for assembly line work, and the production efficiency of products can be effectively improved.

Owner:GOERTEK INC

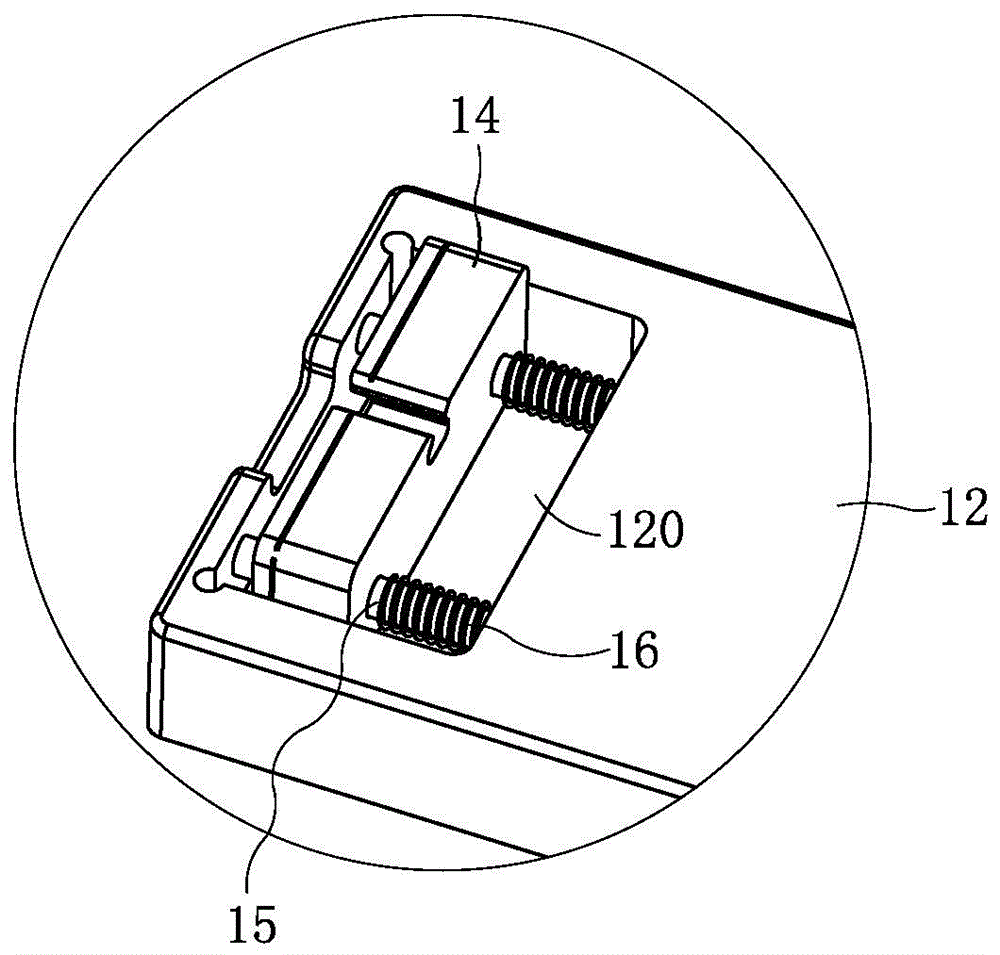

Cover closing mechanism for remote control battery cover

PendingCN107809870AHigh strengthGuaranteed to be tightCasings/cabinets/drawers detailsElectrical batteryRemote control

The invention discloses a cover closing mechanism for a remote control battery cover. The cover closing mechanism includes a remote control face casing and a remote control bottom casing. The outer side of the remote control bottom casing is provided with a battery compartment, and the battery cover is arranged on the remote control bottom casing and located at the position of the battery compartment. The cover closing mechanism further includes a cover closing clock. The cover closing clock includes a lock plate which can move in a front-rear mode and is arranged on the inner side of the remote control bottom casing and a wedge mechanism for driving the lock plate to move backwards. A limiting plate having a limiting effect is arranged on the inner side of the remote control bottom casingand located in the front of the lock plate, a spring is arranged between the lock plate and the rear end of the inner side of the remote control bottom casing, the inner side of the battery cover isfixedly connected with a clamping hook, the lock plate is provided with a clamping groove for the clamping hook to be inserted in, the length of the clamping groove in the front-rear direction is larger than that of the clamping hook in the front-rear direction, and the groove wall of the front end of the clamping groove is provided with a clamping surface matched with the clamping hook. The coverclosing mechanism for the remote control battery cover has the advantages of being simple in structure and convenient to dismantle and close and performing closing closely.

Owner:无锡迪富智能电子股份有限公司

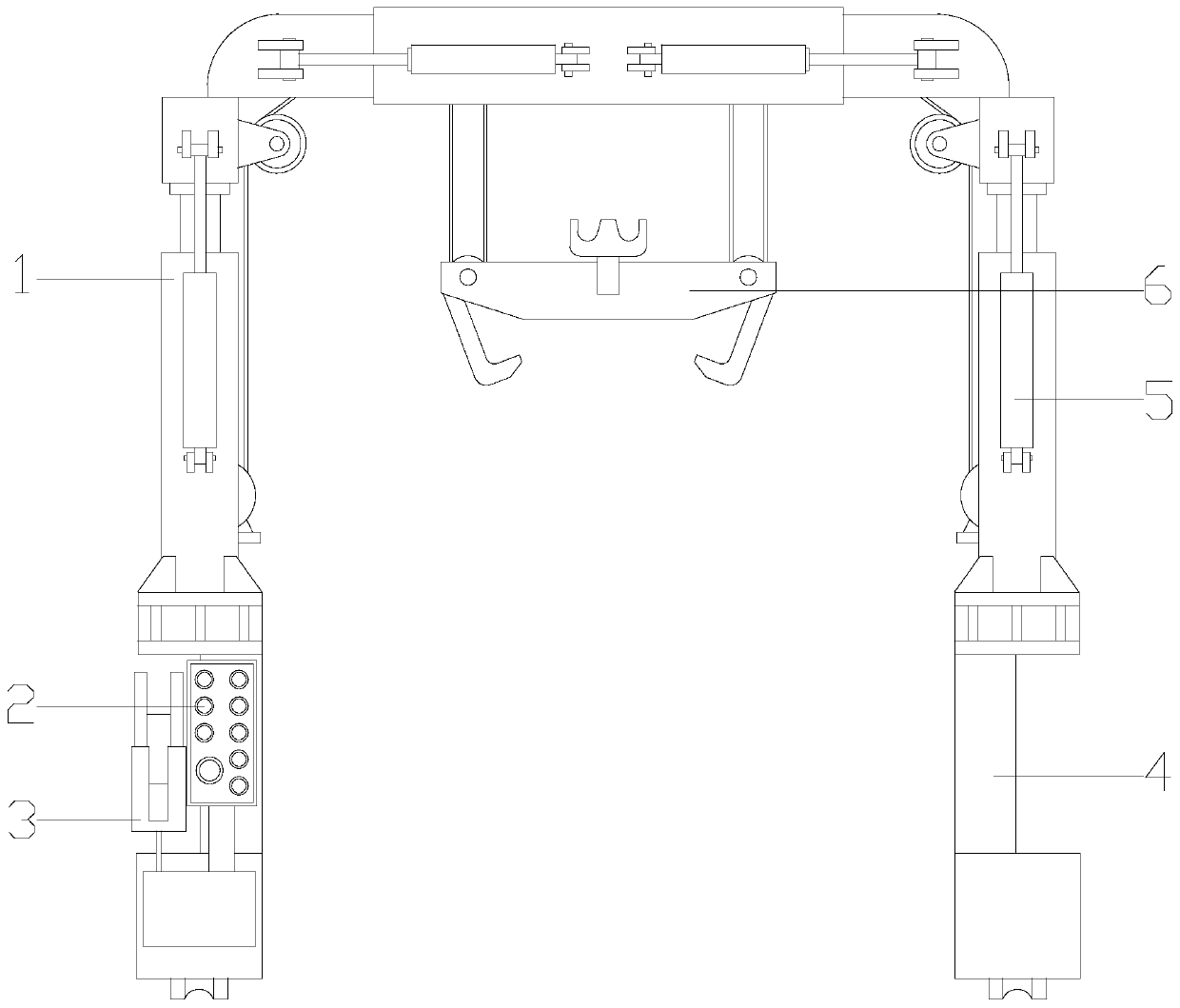

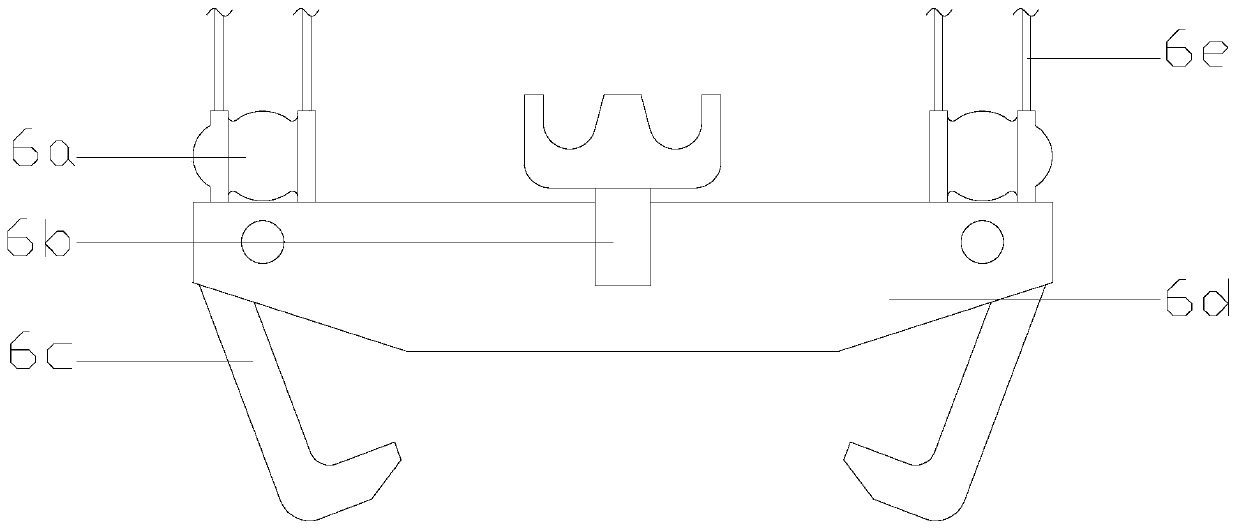

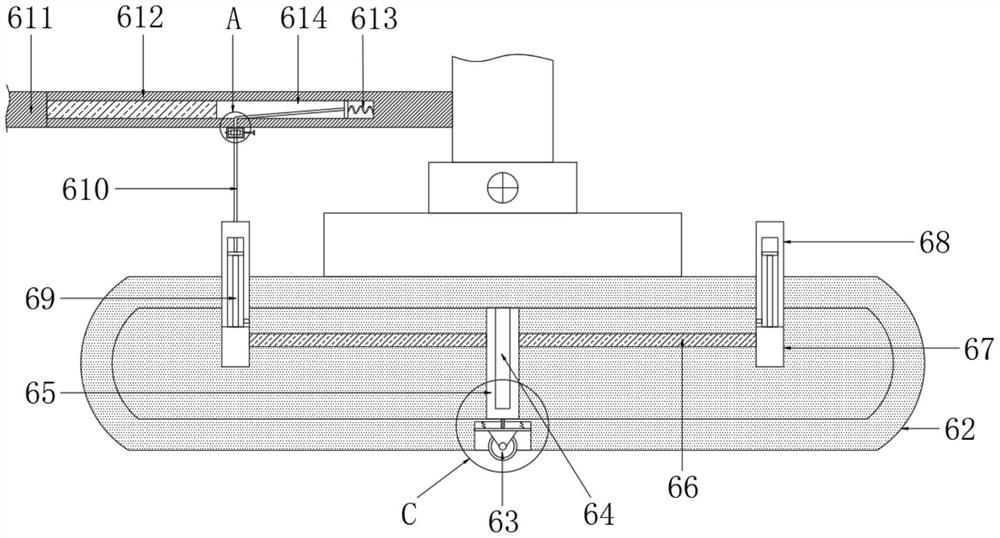

Anti-slot-disorder hoisting machine special for railway track laying

ActiveCN111348569AAvoid messAvoid rattling or fraying and jammingBase supporting structuresBraking devices for hoisting equipmentsTrackwayWire rope

The invention discloses an anti-slot-disorder hoisting machine special for railway track laying. The anti-slot-disorder hoisting machine structurally includes a supporting beam frame, a control panel,a cable winding tray, walking mechanisms, telescopic hydraulic cylinders and a sleeper hoisting mechanism, the walking mechanisms are vertically installed and close to a preset track, the control panel is fixed to the upper part of the left walking mechanism through bolts, and the cable winding tray is located on the left side of the control panel. The hoisting machine special for railway track laying is provided with steel rope tighteners, when a lifting hanging bracket abuts against debris or the hanging bracket falls to the ground during the downward movement, it can be effectively ensuredthat steel wire ropes are in a tight state, and the slot-disorder phenomenon of the steel wire ropes and pulleys is avoided; and meanwhile, impurities such as sand and stone adhering to the surface of the ropes are removed in the sliding process of the steel wire ropes, abnormal noise or abrasion and jamming of the steel wire ropes in the sliding process are avoided, and the service life of a track laying machine is prolonged and the construction efficiency of track laying is improved.

Owner:山东万力起重机械有限公司

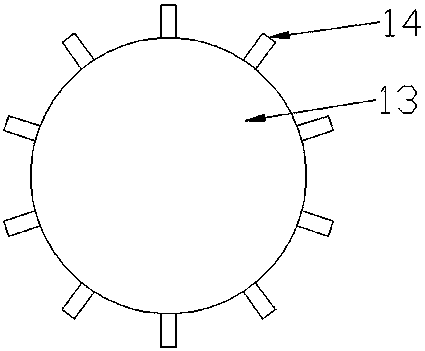

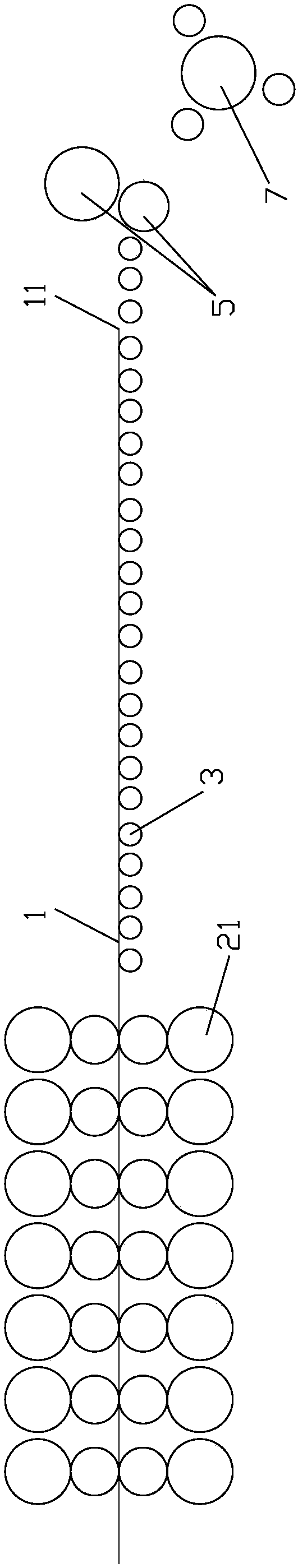

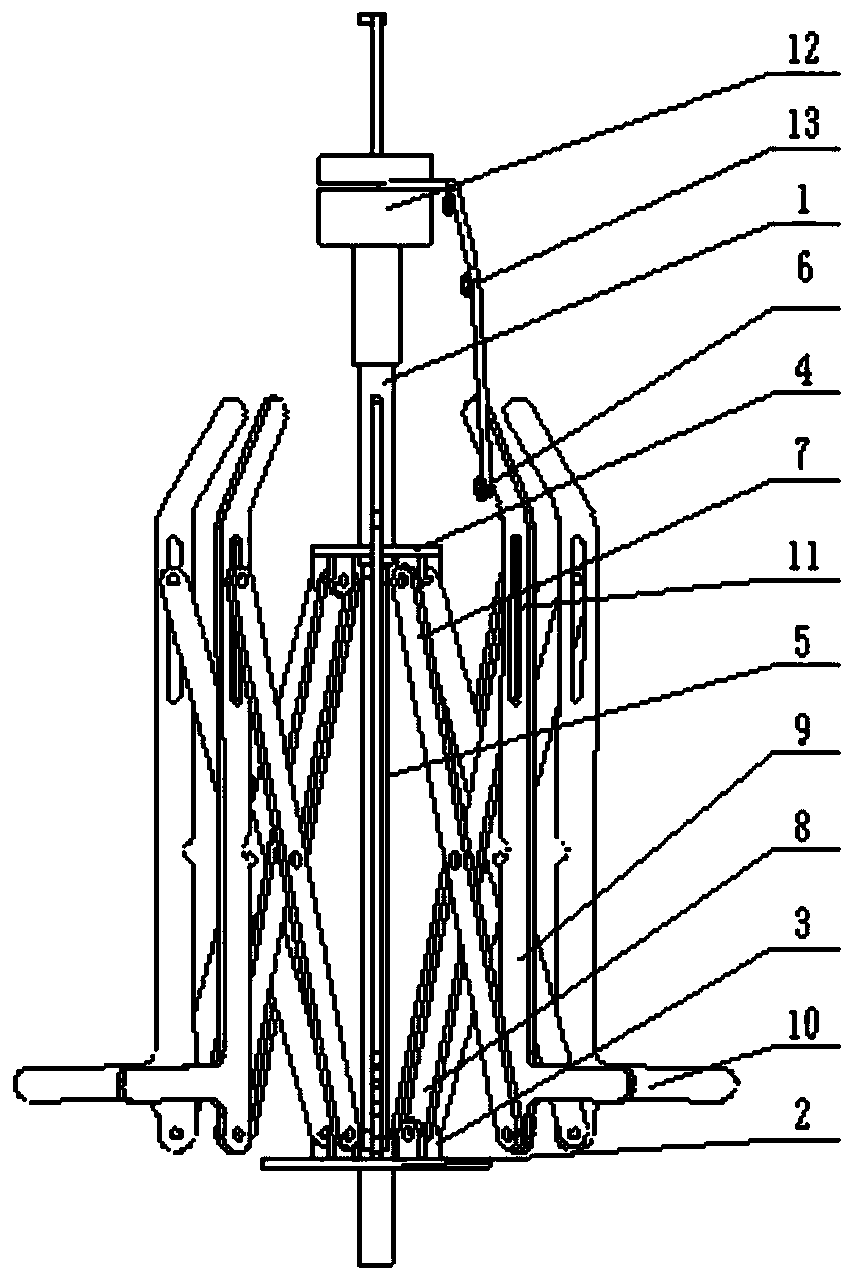

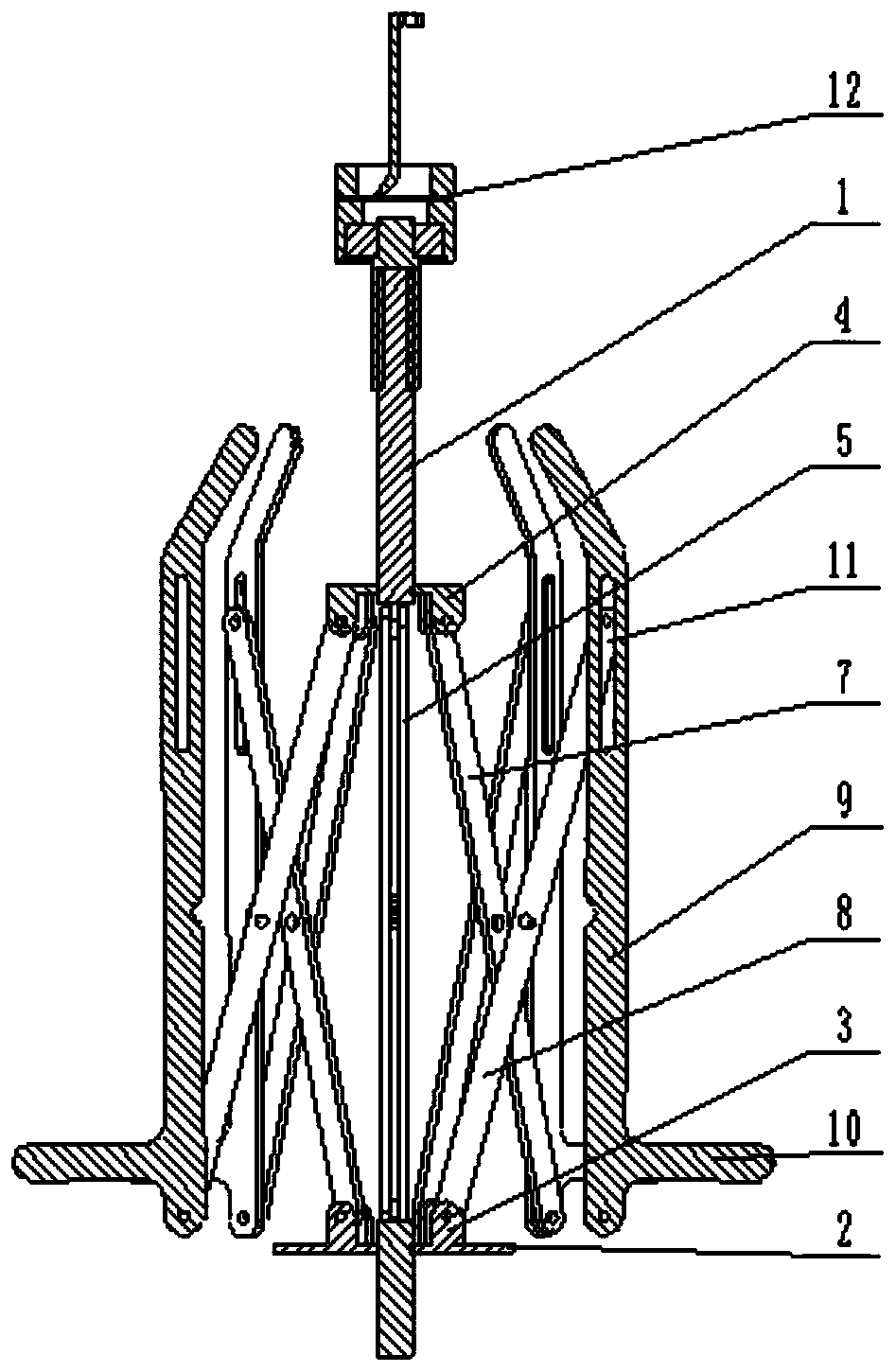

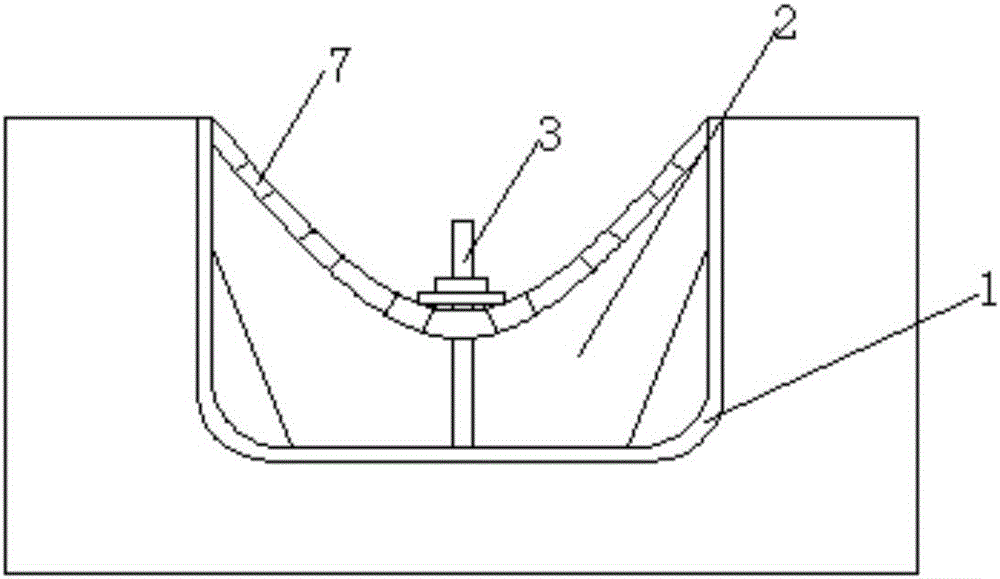

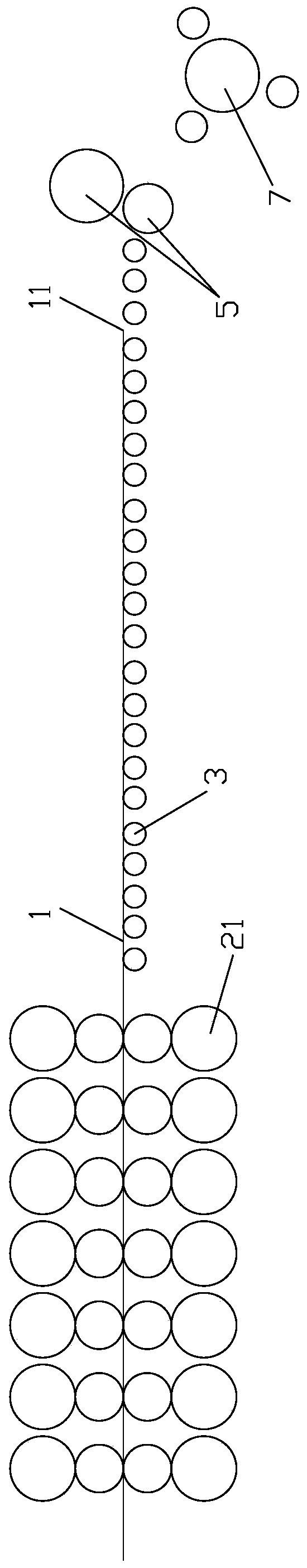

Yarn supporting device for skein rewinding and elastic yarn thermal shrinkage or expansion processing and yarn dyeing method based on yarn supporting device

PendingCN110644098ASolve the problem of messy yarnIncreased skein capacityYarnLiquid/gas/vapor yarns/filaments treatmentYarnEngineering

The invention discloses a low-cost yarn supporting device for skein rewinding, which can accommodate a cone of yarn without yarn messing. The yarn supporting device comprises a main rod, a lower baseis movably arranged at the bottom of the main rod, an avoiding hole for admitting penetration of the main rod is movably arranged in the middle of the lower base, a single lug is arranged on the upperside of the lower base, an upper base is fixedly arranged in the middle of the main rod. a single lug is arranged on the lower side of the upper base, a spring is movably arranged on the main rod between the upper base and the lower base, the single lug inside the upper base is movably connected with one end of a fixed inner supporting plate, the single lug inside the lower base is movably connected with one end of a movable inner supporting plate, the fixed inner supporting plate is hinged to the middle of the movable inner supporting plate, the other end of the fixed inner supporting plateis movably connected with the bottom end of an outer supporting plate, a yarn retaining plate is horizontally and fixedly arranged on the outward side of the outer supporting plate, a sliding groove is formed in the upper part of the outer supporting plate, and the other end of the movable inner supporting plate is slidably connected with the outer supporting plate through the sliding groove. Theinvention also discloses an elastic yarn thermal shrinkage or expansion processing and yarn dyeing method based on the yarn supporting device.

Owner:苏州济洋纺织机械有限公司

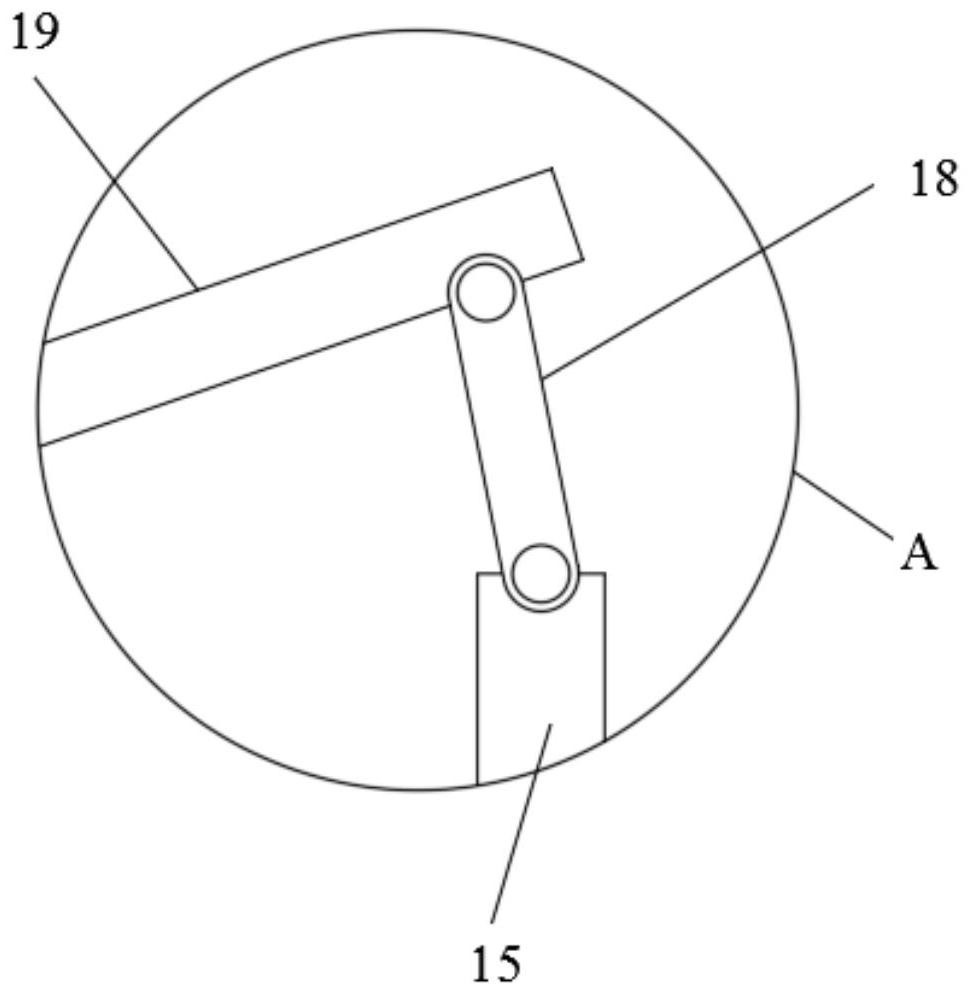

Silk cloth ironing equipment with compensation function for garment production

InactiveCN112981831AGuaranteed to be tightExtension of timeTextile shapingSilk clothMechanical engineering

The invention discloses silk cloth ironing equipment with a compensation function for garment production, and belongs to the technical field of garment processing equipment. The silk cloth ironing equipment comprises a workbench, a rack, an ironing device, a discharging roller and a receiving roller, wherein the receiving roller, the rack and the discharging roller are sequentially mounted on the outer wall of the top of the workbench; the inner wall of the top of the rack is fixedly connected with the ironing device through an electric telescopic rod; and a compensation device is arranged on the outer wall of the left side of the rack. In the device, air in an air bag is extruded, so that the air bag is raised and drives a guide roller to move downwards; the guide roller continues to apply pressure to drooping cloth, so that it is guaranteed that the drooping cloth continues to be tightened; and the extending cloth is compensated, so that the situation that the cloth below the ironing device cannot be moved away by the receiving roller according to the specified time due to the fact that the cloth extends and droops is avoided, the cloth ironing time is prevented from being prolonged, and the probability that the silk cloth is damaged is reduced.

Owner:杨梅

Reinforced concrete steam turbine platform beam bolt casing pipe top template construction method

The invention particularly relates to a reinforced concrete steam turbine platform beam bolt casing pipe top template construction method which is characterized by including (1) a step of installing a steam turbine platform beam bottom template, (2) a step of manufacturing a circular template, (3) a step of flicking lines and lofting, (4) a step of fixing the circular template, (5) a step of conducting platform beam steel bar and template construction, installing longitudinal steel bar and transverse steel bars by avoiding the circular template according to a position of the installed circular template in the process of installation of the steel bars, installing a side template of a platform beam and an edge template of a reserved opening after installation of the steel bars are examined and received, (6) a step of installing bolt casing pipes, (7) a step of pouring concrete, (8) a step of vibrating and pounding the concrete, and (9) a step of removing the templates, and then removing the steam turbine platform beam side template and the bottom template after strength grade of the concrete meets requirements of the design, wherein the circular template can automatically drop along with the bottom template and the bolt casing pipes are communicated. The circular template is simple in structure, convenient to manufacture and install, low in cost and convenient to construct. The bolt casing pipes are high in installation accuracy.

Owner:SHANDONG ZIJIAN GRP

Belt cutting machine

InactiveCN103433952AGuaranteed to be tightGuaranteed smoothMetal working apparatusDrive shaftEngineering

The invention discloses a belt cutting machine. The belt cutting machine comprises a belt releasing disc, a first belt collecting disc, a second belt collecting disc and a cutter with teeth, wherein the belt releasing disc is located at a feeding end of a machine frame, the first belt collecting disc and the second belt collecting disc are located at a discharging end of the machine frame and jointly utilize the same rotation shaft, and the cutter with the teeth is fixed to the machine frame in a rotary mode through a transmission shaft. According to the belt cutting machine, the two belt collecting discs are used for recycling cut wrapping belts, so that the wrapping belts are guaranteed to be always tensioned before and after being cut. In addition, the cutter with the teeth is used for cutting materials, so that the cutter with the teeth can smoothly cut the wrapping belts, and the edges of the materials are guaranteed to be flat after the materials are cut.

Owner:ANHUI HOBO CABLE GRP

Furnace top seal device

The invention discloses a furnace top seal device. The device comprises a fireproof layer, a plastic film leakage-proof seal layer and a steel nail; the fireproof layer is cast between tube rows on a furnace top, the plastic film leakage-proof seal layer surrounds the fire-proof layer, and the steel nail is welded to the furnace top, penetrates the fireproof layer and the plastic film leakage-proof seal layer and extends out, and the fireproof layer comprises a compacted and leveled bottom layer and an upper layer carrying out complementing and leveling to achieve the aim that the fireproof layer is flat, smooth and free of cracks, the plastic film leakage-proof seal layer is sequentially provided with three layers of ceramic fibers and a rhombus stainless steel net from bottom to top, the positions among the ceramic fibers are evenly coated with high-temperature-resisting bonding agents with the consistent thickness, a nickel chromium manganese steel soft net is flatly laid above the bottom layer of the plastic film leakage-proof seal layer, and a fixing assembly is arranged in a manner of penetrating the steel nail and being fixed to the rhombus stainless steel net; and compared with the existing technical scheme, the furnace top seal device has the plasticity, the phenomena of cracking and air leakage caused by heat alternating stress of a boiler are effectively avoided, it is ensured that the portion of the furnace top is tight and free of leakage, and the service life of the device is greatly prolonged.

Owner:江苏兴鼎力炉窑工程有限公司

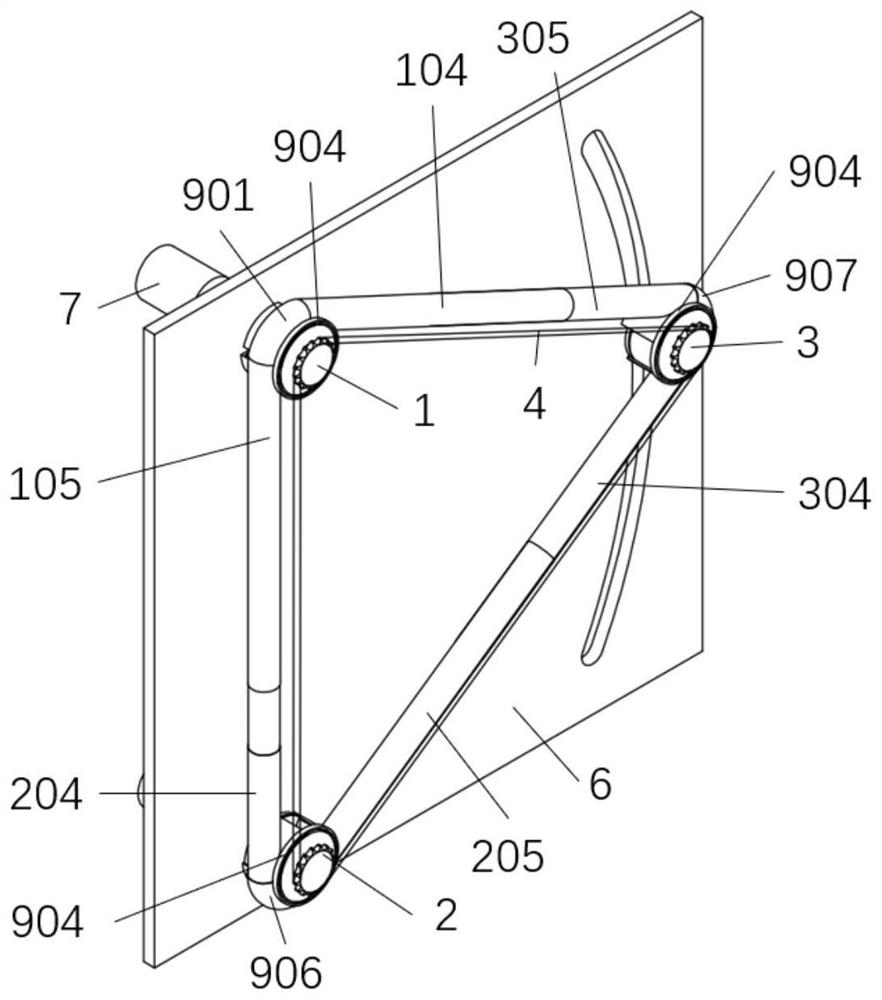

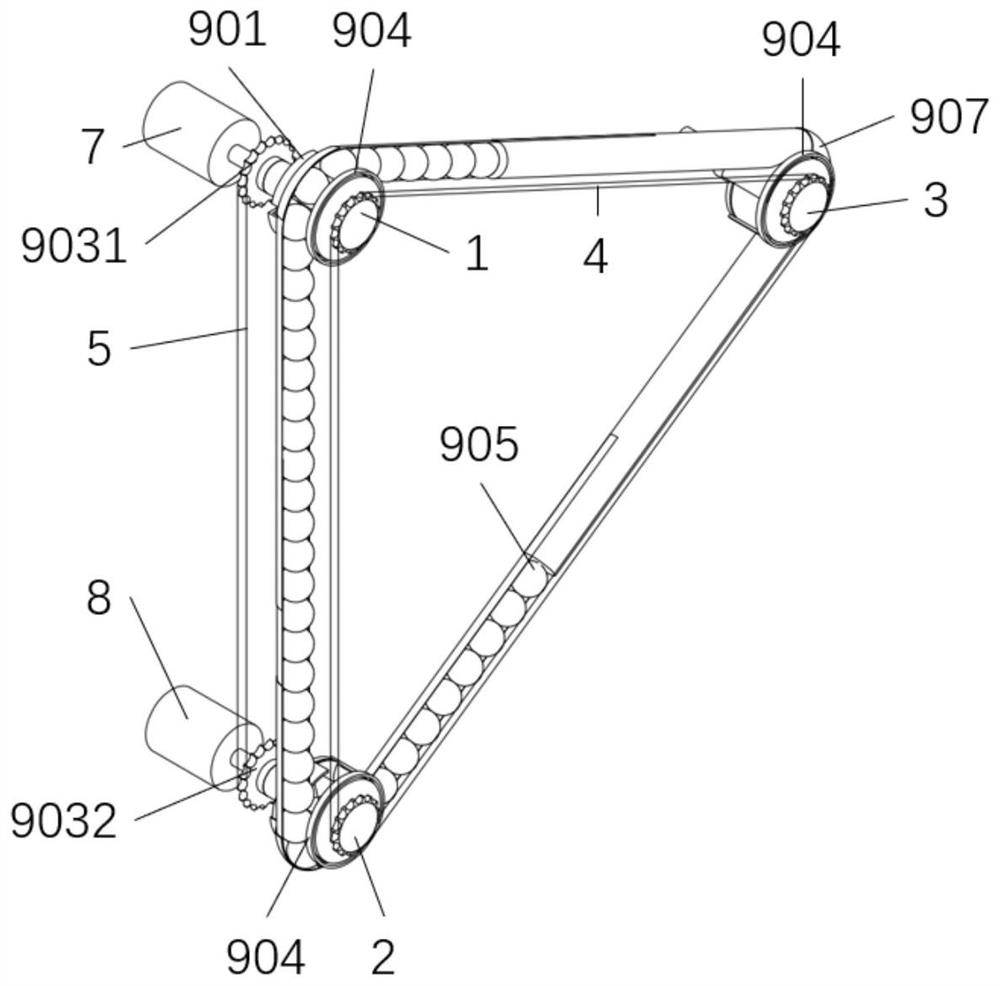

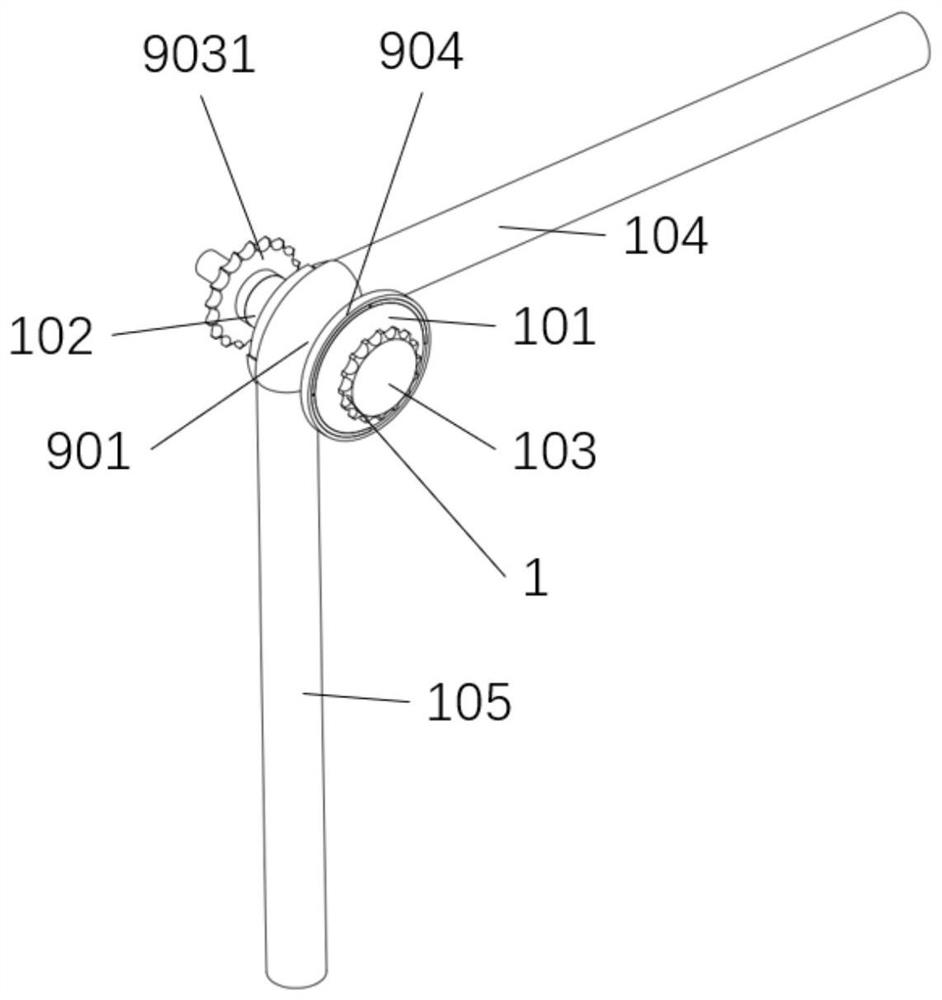

Semi-circulating ball type chain wheel position adjusting device and adjusting method

The invention belongs to the technical field of mechanical transmission devices, and relates to a semi-cycle ball type chain wheel position adjusting device and method. The device comprises a first wheel assembly, a second wheel assembly, a third wheel assembly, a transmission chain, an adjusting chain, a bottom plate, a transmission motor, an adjusting motor and a steel ball, position adjustment of the chain wheels and chain transmission are integrated into one set of device, so that the occupied space of the device is effectively reduced; the track of the third transmission chain wheel is oval, and it is guaranteed that the transmission chain is always tightened in the position adjusting process of the third transmission chain wheel. The rigid action among the steel balls, the third wheel first track and the third wheel second track can ensure the stability and precision of position adjustment of the chain wheel; different motors are adopted for position adjustment of the chain wheel and chain transmission, transmission routes of the motors are completely separated, it can be guaranteed that position adjustment of the chain wheel and chain transmission are independently controlled to operate, a controller can be externally connected to enable the two actions to operate in a coordinated mode, and the use scene of the device is greatly enriched.

Owner:CHINA AGRI UNIV

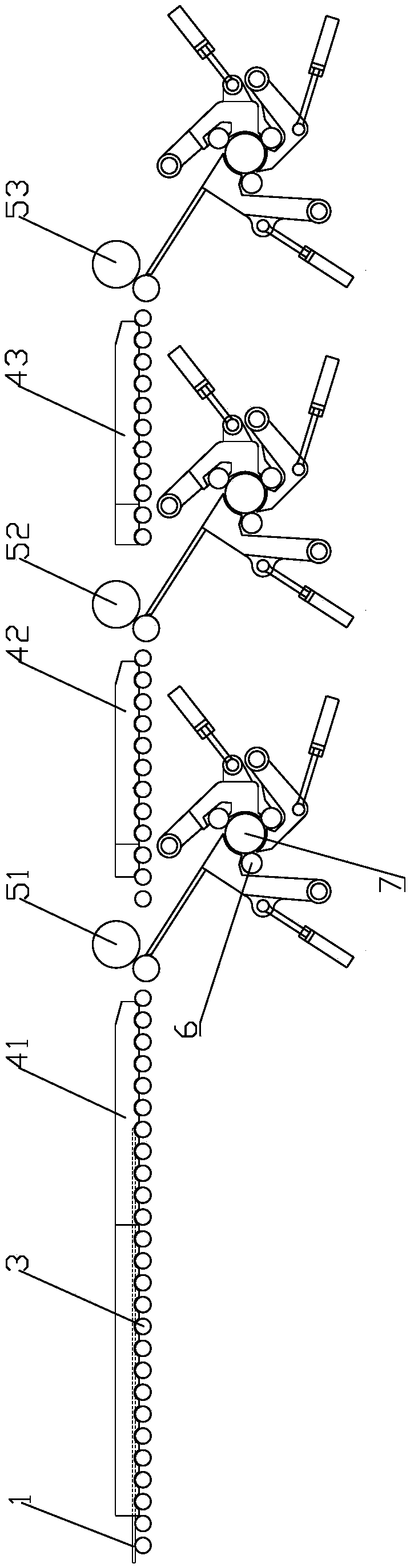

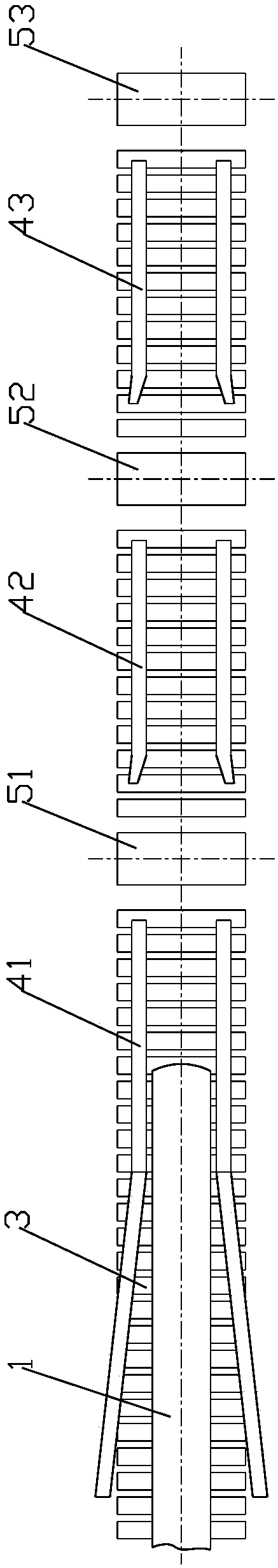

Sapphire multi-wire cutting device

ActiveCN114311353AImprove cutting accuracyImprove cutting efficiencyWorking accessoriesFine working devicesPhysicsWire cutting

The invention discloses a sapphire multi-wire cutting device, and belongs to the technical field of sapphire machining. The wire cutting device comprises a base and a wire cutting mechanism. The base is fixedly connected with a fixed beam, and the fixed beam is fixedly connected with a lifting driving mechanism used for driving the wire cutting mechanism to ascend and descend. The cutting line mechanism comprises a lifting frame and a pair of cutting rollers rotationally connected to the lifting frame, and a cutting line is wound between the two cutting rollers. The base is fixedly connected with a connecting seat, the connecting seat is symmetrically and rotationally connected with a pair of swinging arms arranged in a V shape, one end of each swinging arm is rotationally connected with a rotating arm, and the end part of each rotating arm is fixedly connected with a clamping mechanism for fixing sapphire; and the base is fixedly connected with a fixing mechanism for fixing the swinging arm. The cutting device can achieve the function of always tightly supporting the cutting line, improves the cutting precision, can adjust the sapphire cutting position angle, and is wide in application range.

Owner:江苏天晶智能装备有限公司

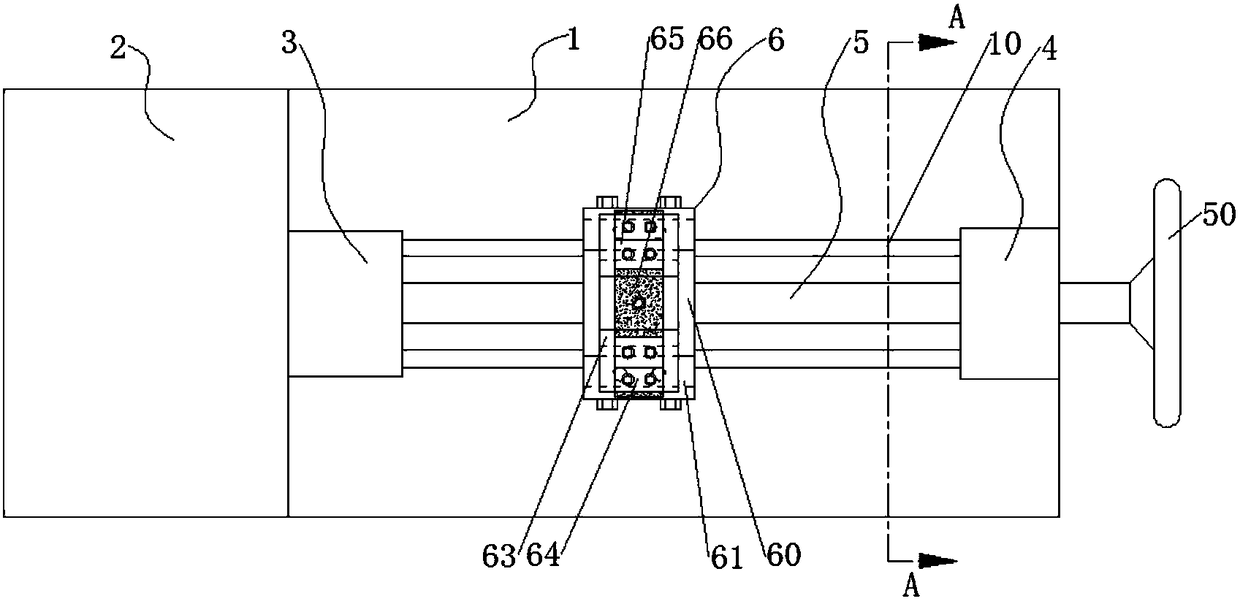

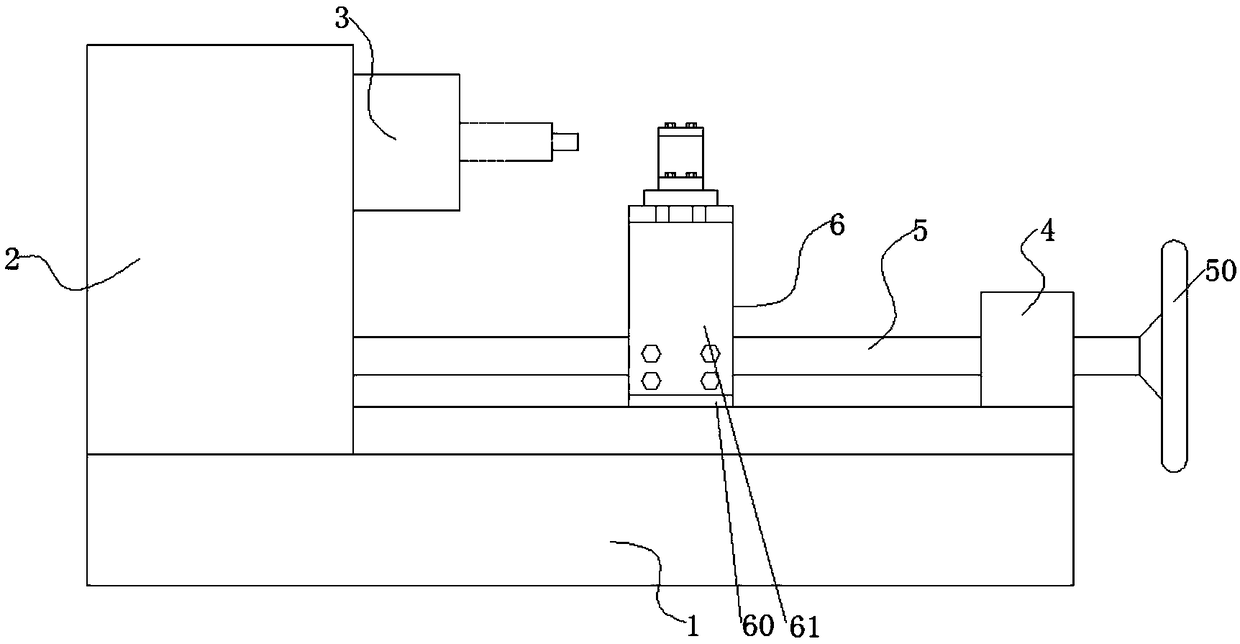

Grinding device for producing shaft type part by using round steel

InactiveCN108145546AAchieve direct grindingAvoid insecurityRevolution surface grinding machinesGrinding work supportsEngineeringCushion

The invention discloses a grinding device for producing a shaft type part by using round steel. The grinding device comprises a pedestal, a main machine box, a three-jaw chuck, a bearing seat, a screwrod and a grinding device part; the main machine box is connected with the pedestal; the three-jaw chuck is rotationally connected with the main machine box; the bearing seat is connected with the pedestal; one end of the screw rod is rotationally connected with the bottom of the main machine box; the other end of the screw rod penetrates through the bearing seat and is rotationally connected with the bearing seat; the grinding device is connected with the screw rod through a screw pair; and the grinding device part consists of a slider, a side frame plate, an electric push rod, a push block,a cushion block, a pressing block and abrasive paper. The grinding device disclosed by the invention realizes direct grinding of the shaft type part after the shaft type part is machined on a machinetool, prevents insecurity caused by manually holding the abrasive paper to implement grinding operation, and also reduces the labor intensity of a worker.

Owner:马鞍山市鑫龙特钢有限公司

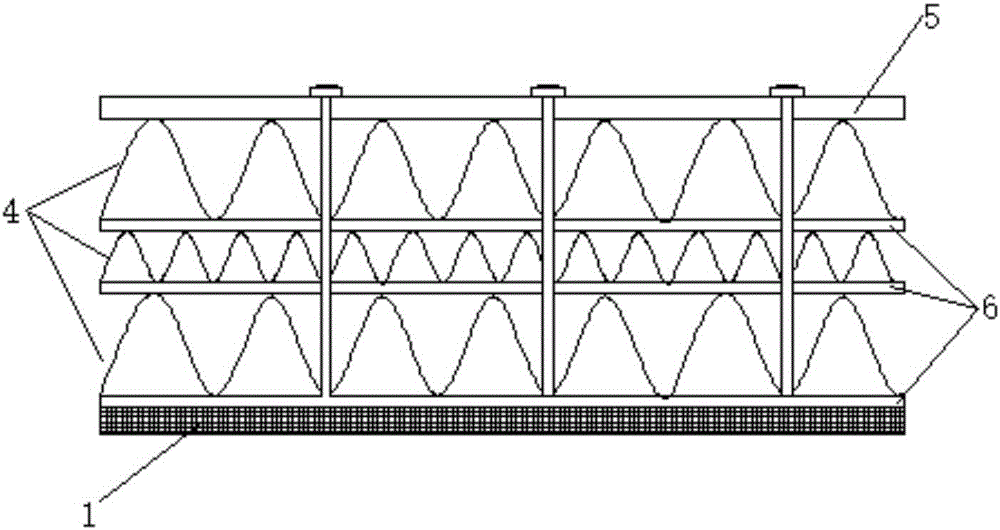

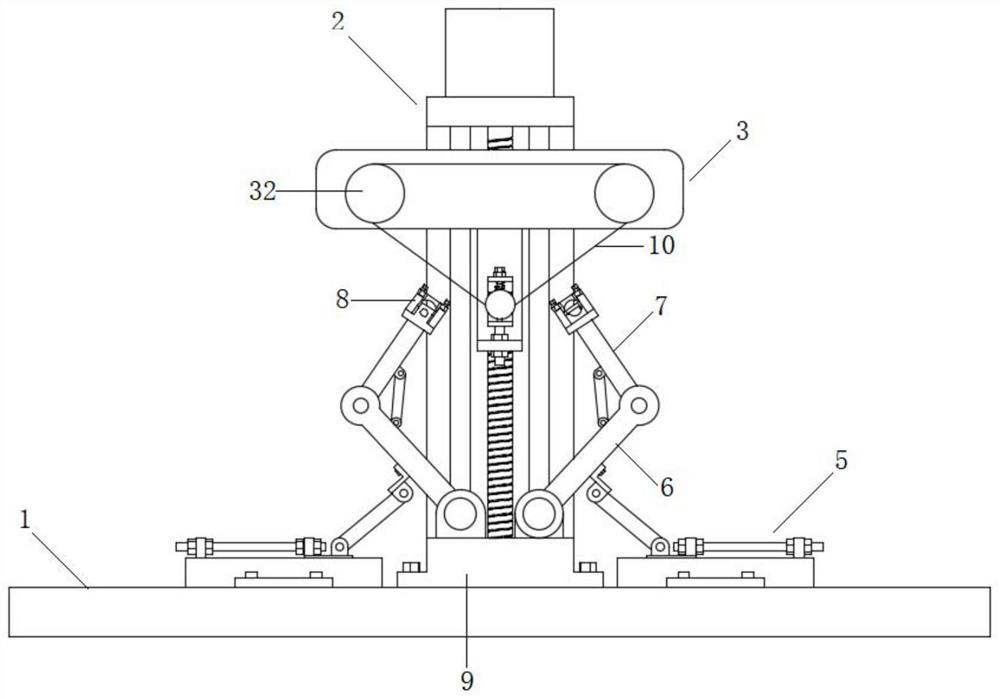

Device with well tightened conveyor belt

InactiveCN104097903AGuaranteed transmission speedGuaranteed to be tightConveyorsEngineeringConveyor belt

The invention discloses a device with a well tightened conveyor belt. The device comprises a conveyor belt body (1); a first roller (2), a second roller (3) and a third roller (4) are mounted at the top of the conveyor belt body (1); the first roller (2), the second roller (3) and the third roller (4) are arranged triangularly; the first roller (2) and the second roller (3) are located in the same straight line of the horizontal plane and under the third roller (4); the third roller (4) is capable of moving up and down. Due to such a structure, the device is capable of guaranteeing that the conveyor belt is still in the tightened state after being used repeatedly, thereby ensuring the conveying speed of the conveyor belt.

Owner:成都昱阳鑫达实业有限公司

Cloth rolling frame and cloth rolling roller

The invention discloses a cloth winding frame and a cloth winding roller thereof. The cloth winding roller comprises a roller shaft and a ratchet-pawl mechanism, and the ratchet-pawl mechanism is arranged at one end of the roller shaft and comprises a ratchet and a pawl. A damping mechanism for increasing the rotation resistance of the roller shaft is arranged at least one end of the roller shaft. Each damping mechanism comprises an elastic pressing piece and a damping piece, wherein the damping piece is fixedly arranged at the end of the roller shaft; the elastic pressing piece is pressed on the end face of the damping piece in the axis direction of the roller shaft under the action of elastic force; and a resistance increasing mechanism is arranged on the abutting surface between the damping piece and the elastic pressing piece. According to the cloth winding frame and the cloth winding roller, the damping mechanism is arranged based on the ratchet-pawl mechanism, thus, rotation of the roller shaft can overcome resistance generated by the resistance increasing mechanism by applying certain force, accordingly, the roller shaft is driven to rotate, that is, when base cloth is pulled out from the cloth winding roller, the force for pulling the base cloth can overcome the resistance, the cloth winding roller is driven to rotate, the base cloth is in the tightened state all the time in the process, and tightening is achieved automatically after replacement is completed.

Owner:HAINING JBL TEXTILE

Embroidery machine for spinning and using method

The invention discloses an embroidery machine for spinning and a using method in the technical field of textile equipment. The embroidery machine comprises a shell, wherein a sliding groove is formedin the transverse center axis of the top end of an inner cavity of the shell, a supporting bearing is arranged at the upper end of the longitudinal center axis of the left side face of the inner cavity of the shell, a threaded rod is installed in an inner cavity of the supporting bearing, the right end of the threaded rod penetrates through the upper portion of a right side panel of the shell to the right side of the shell, a rotating bearing is arranged on the upper portion of the central axis of the right side panel of the shell, the inner ring of the rotating bearing is connected with the threaded rod in a sleeving mode, a disc is arranged at the right end of the threaded rod, a rocker is arranged on the upper end face of the disc, a sleeve sleeves the left side of the outer portion ofthe threaded rod, a sliding block is arranged on the upper end face of the sleeve, the sliding block is arranged on the left side of an inner cavity of the slide groove, a driving motor is arranged inthe middle of a left side panel of the inner cavity of the shell, a belt wheel is arranged in the middle of a motor shaft of the driving motor, and a driving gear is movably connected to the front end face and the rear end face of the inner cavity of the shell. The embroidering machine is simple in structure and convenient to operate, the embroidering efficiency can be effectively improved, and the embroidering quality of textile fabrics can be improved.

Owner:王玉立

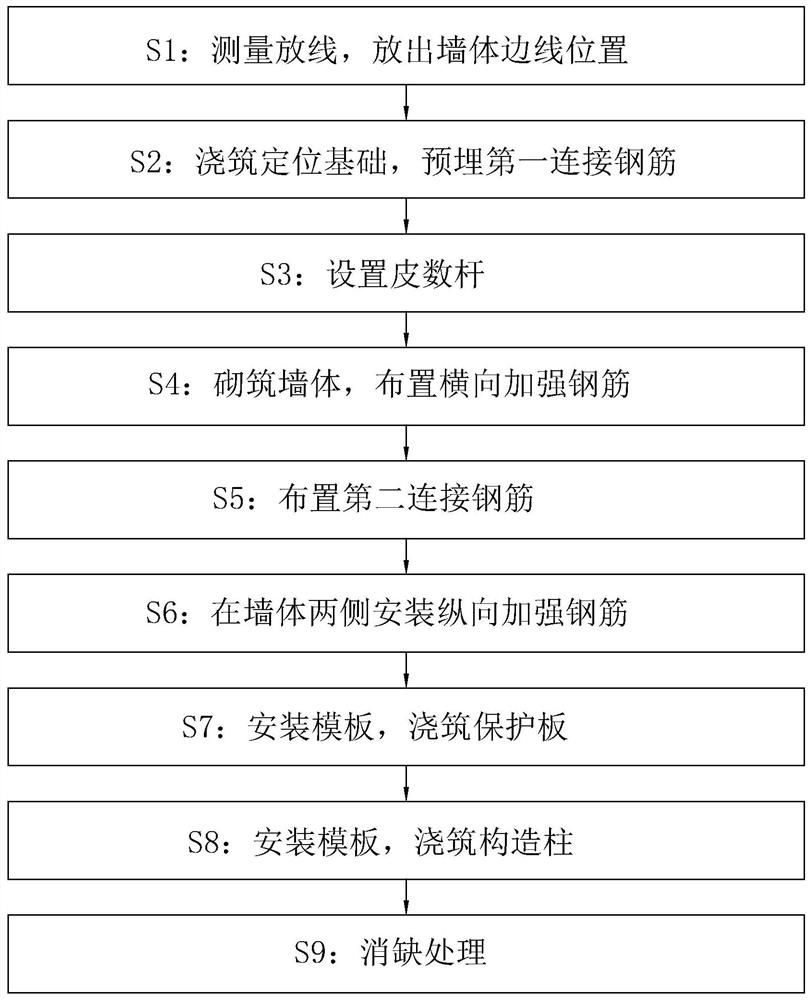

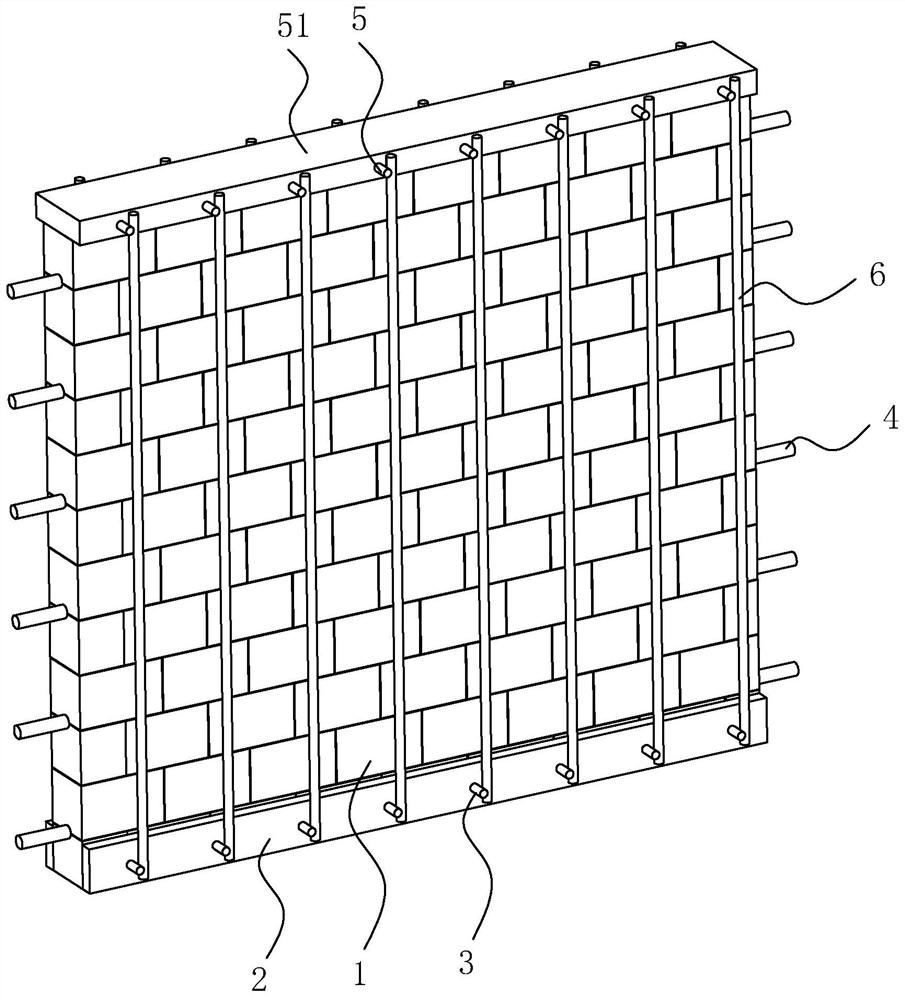

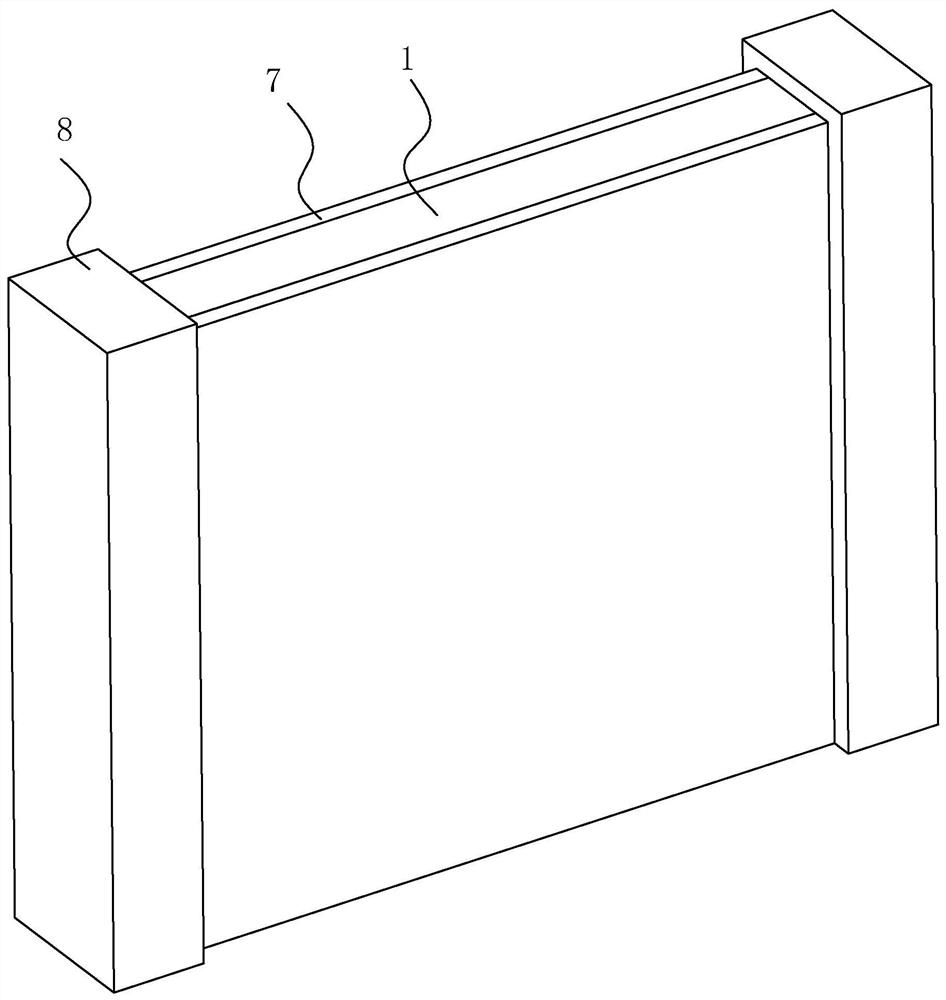

A kind of masonry engineering construction technology

ActiveCN111719869BImprove mechanical performanceLess damageWallsBuilding material handlingArchitectural engineeringRebar

The invention relates to a masonry engineering construction process, which belongs to the field of building construction, and comprises the following steps: S1: measuring and setting out the line; S2: pouring the positioning foundation and arranging the first connecting steel bars; S3: setting the skin number at both ends of the positioning foundation S4: Masonry wall and arrangement of transverse reinforcement bars; S5: Arrangement of second connection reinforcement bars; S6: Installation of longitudinal reinforcement bars; S7: Pouring protection panels; S8: Pouring structural columns; The invention has the effect of improving the mechanical performance of the wall body.

Owner:中能建西北城市建设有限公司

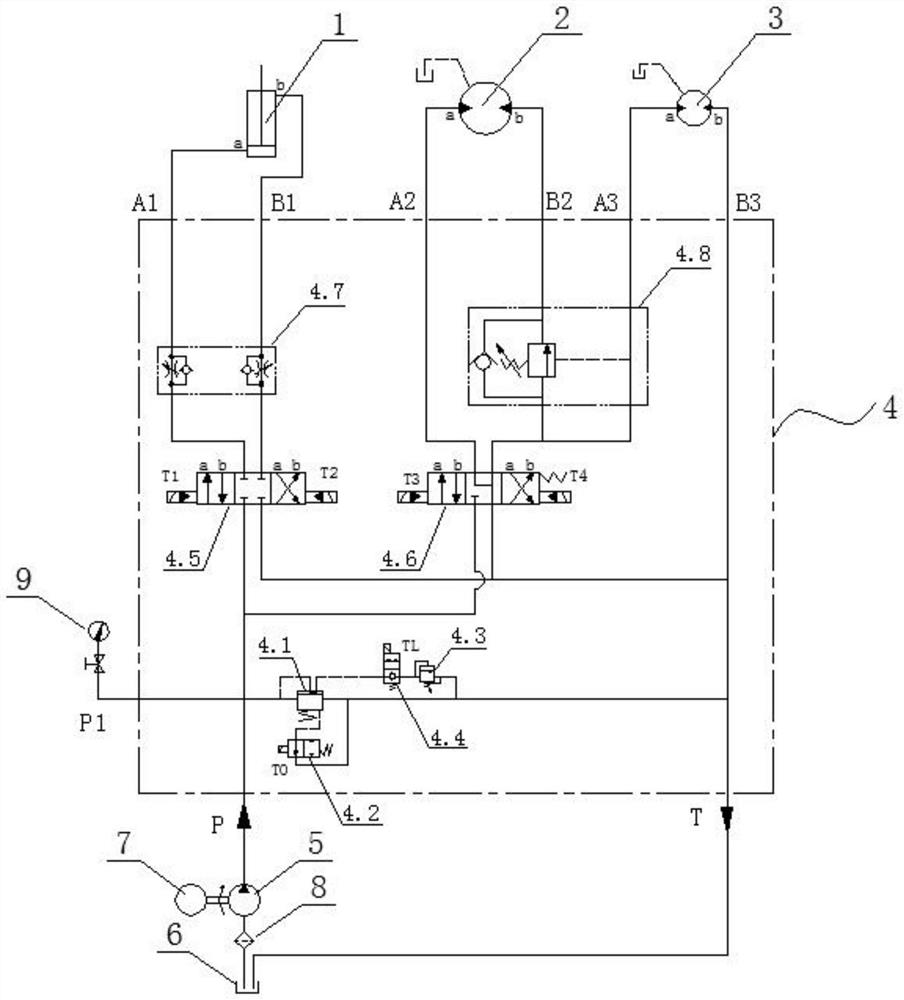

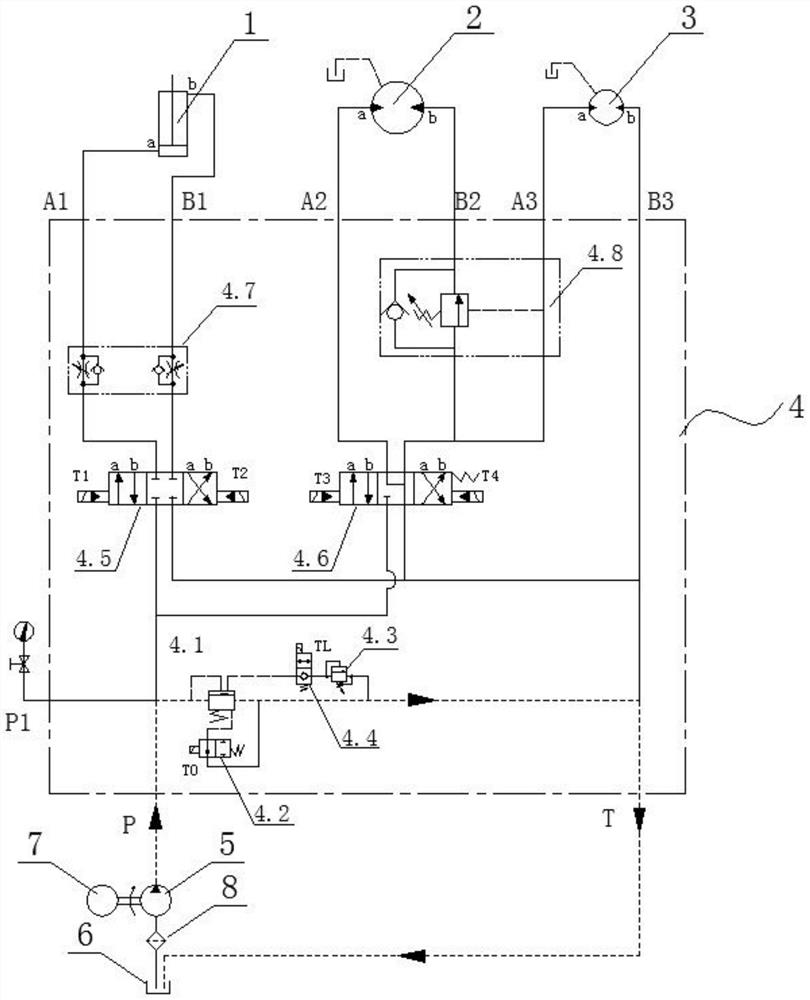

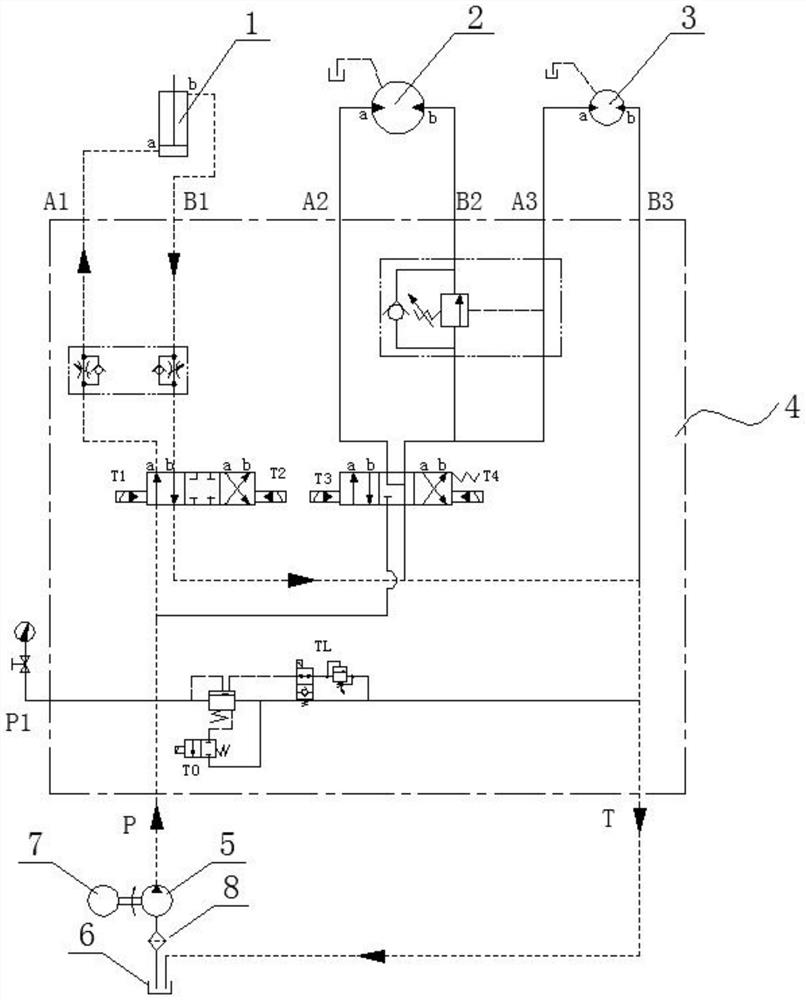

Hydraulic control system of low-density material transportation semitrailer

PendingCN114198352AReduce feverLow failure rateServomotor componentsServomotorsHydraulic motorControl system

The invention discloses a hydraulic control system of a low-density material transportation semitrailer. The rear door opening and closing oil cylinder is used for controlling a rear door opening and closing of the low-density material transportation semitrailer, the roller hydraulic motor is used for controlling a discharging roller of the low-density material transportation semitrailer to rotate, the winch hydraulic motor is used for controlling a discharging push plate of the low-density material transportation semitrailer to return, and the oil cylinder is used for controlling the rear door opening and closing. The hydraulic oil pump and the hydraulic oil tank are used for providing power for the whole hydraulic control system. The hydraulic system has the advantages of simplicity in control, low manufacturing cost and capability of well solving the problems of heating and system faults of the hydraulic system.

Owner:中国重汽集团湖北华威专用汽车有限公司

The Method of Improving the Rolling Quality of Strip Tail

The invention provides a method for improving strip steel tail part coiling quality. The method is based on coiling equipment arranged behind a hot rolling unit, and the coiling equipment comprises afirst coiling machine and a second coiling machine which are arranged in sequence along the running direction of strip steel, and further comprises a pair of first side guide plates and a pair of second side guide plates. The method comprises the steps that during coiling of the strip steel by the second coiling machine, when the head part of the strip steel reaches an inlet of a pinch roller of the second coiling machine, the pair of second side guide plates are folded to clamp the strip steel; and before the tail part of the strip steel is transported out of a tail frame of a finish rollingunit, the pair of first side guide plates are folded to clamp the strip steel. According to the method for improving the strip steel tail part coiling quality, the side guide plates of the upstream coiling machines are used for clamping the strip steel, and two or more side guide plates are adopted to clamp the strip steel at the same time, so that the friction force between the side guide platesand the edge of the strip steel are improved, the tail part of the strip steel is ensured to be tightened, and the coiling quality of the tail part of the strip steel is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Processing method of green tea

ActiveCN102960482BPromote sustainable developmentImprove tree down ratePre-extraction tea treatmentGreen teasEngineering

In order to solve the problem of bitterness and astringency of bulk green tea in Sichuan, the present invention provides a processing method of green tea, which is characterized in that: the method steps include fresh leaves, spreading green, killing green, rolling, baking second green, secondary rolling, deblocking, The two kneading processes of roasting three greens, spreading, frying, spreading, drying and enhancing fragrance all adopt the method of hot kneading. The green tea processing method of the invention can effectively reduce the bitterness and astringency of Sichuan bulk green tea, improve the tea quality, increase the concentration and freshness, and lay a good foundation for expanding the market of Sichuan tea and promoting the export of Sichuan tea.

Owner:YIBIN CHUANHONG TEA IND GRP

Anchoring system of floating type photovoltaic power generation platform and construction method of anchoring system

PendingCN113879465AEasy to fixEasy to disassembleFloating buildingsAnchoring arrangementsBuoyMechanical engineering

The invention discloses an anchoring system of a floating type photovoltaic power generation platform, and the anchoring system comprises two buoys, a platform and a photovoltaic panel; the platform is fixed between the two buoys, a support plate is fixed on the upper side wall of each buoy, a mounting plate is fixed at the upper ends of the two support plates, and the photovoltaic panel is mounted on the mounting plate. The construction method of the anchoring system of the floating type photovoltaic power generation platform comprises the following steps that S1, the buoy and the platform are fixed, and the photovoltaic panel is placed on the mounting plate to be fixed; S2, the end of the rotating plate is fixed to the anchor rope, the buoy is placed on the water surface, and the anchor block sinks into the water surface to be fixed. The system has the advantages that the position of the upper end of the anchor rope is adjusted to ensure that the anchor rope is always in a tightened state, on one hand, the buoy and the platform are prevented from moving when the water level is too low, on the other hand, the buoy and the platform are prevented from being affected by large resistance when the water level is too high, and the photovoltaic efficiency is ensured by regularly cleaning the photovoltaic panel.

Owner:华能黑龙江发电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com