Wire fixing jig

A technology for fixing jigs and wires, which is applied in the direction of sensors and electrical components, can solve the problems of affecting the production efficiency of earphones, prone to pinching or pinching, unfavorable assembly line operations, etc., and achieves small deformation, simple structure, and reliable fixation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention.

[0033] The longitudinal direction referred to in this specification refers to the extending direction of the wiring substrate and the wiring substrate, and the transverse direction refers to the direction perpendicular to the extending direction of the wiring substrate and the wiring substrate.

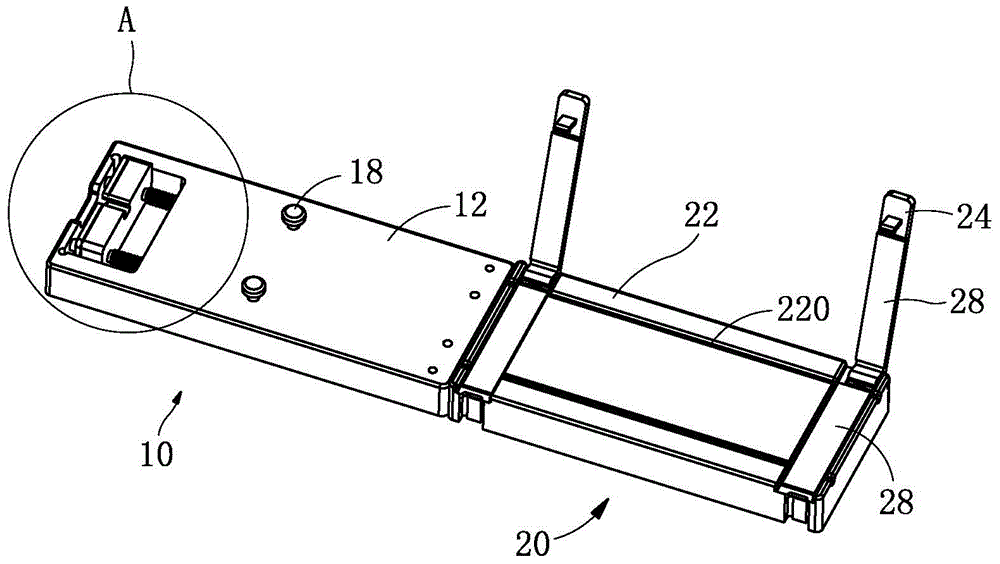

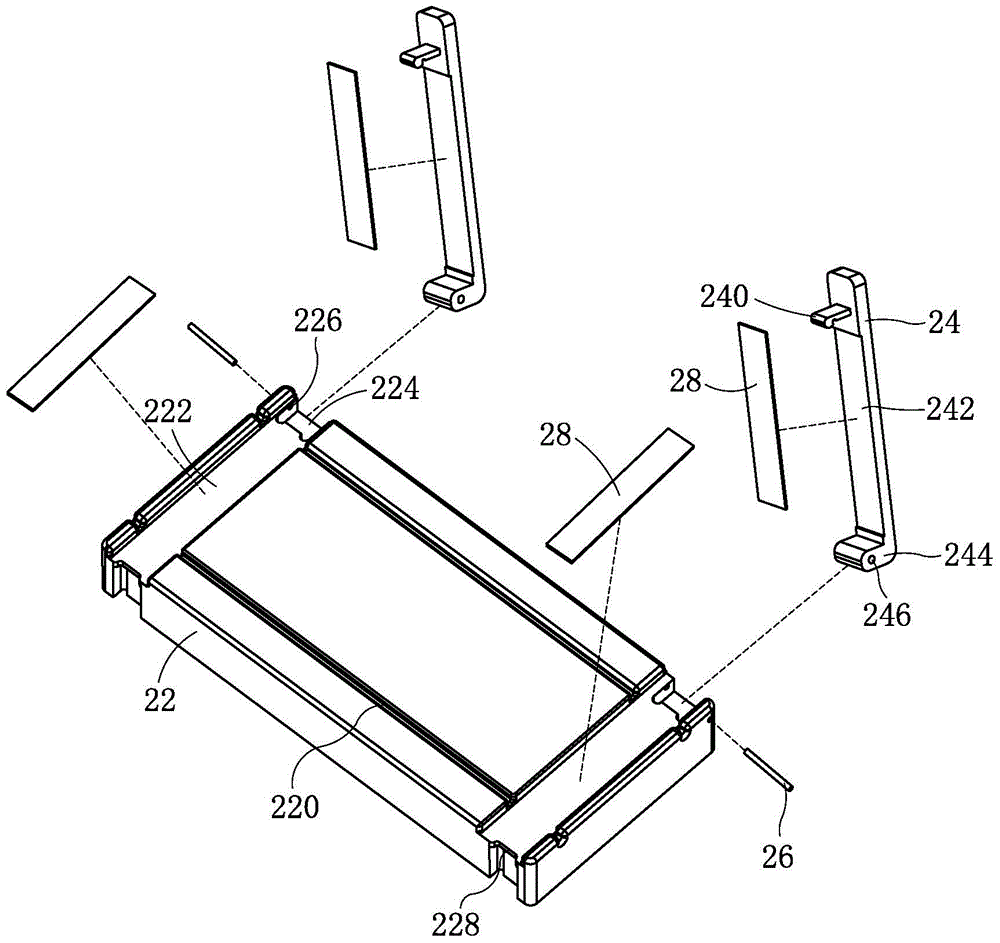

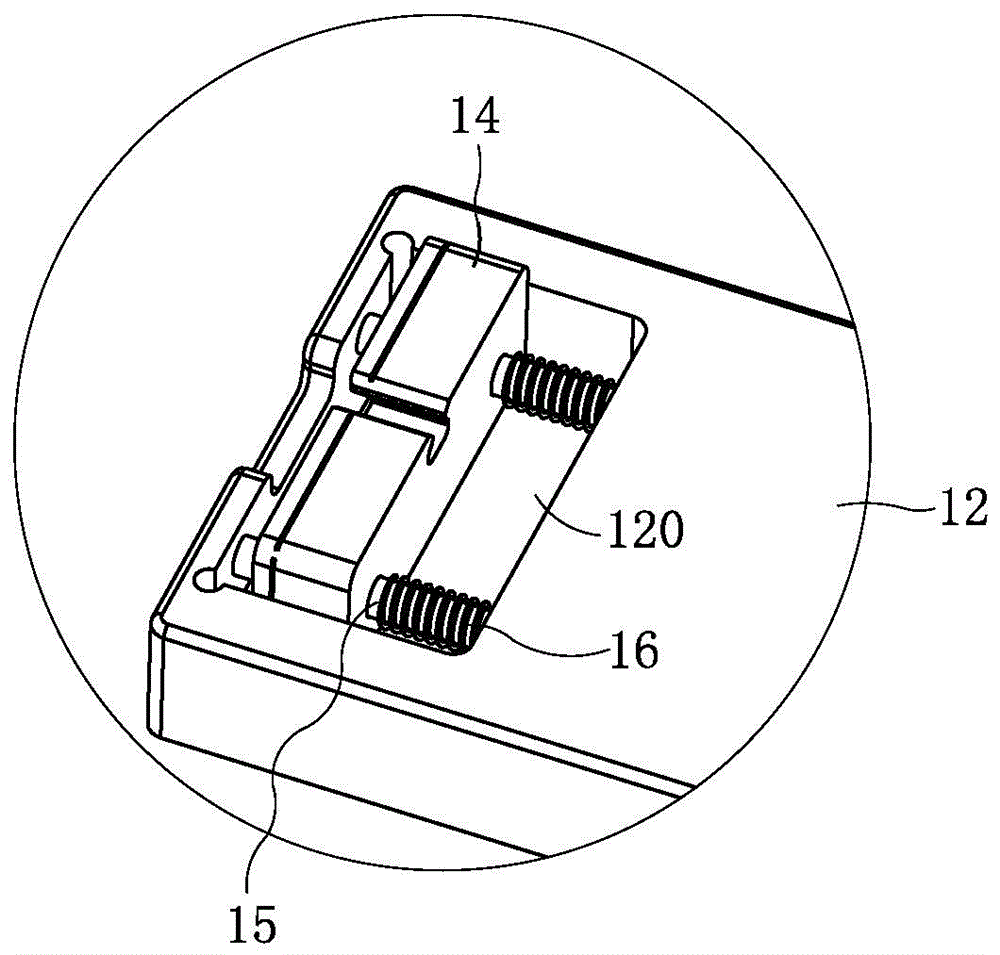

[0034] Such as figure 1 As shown, a wire fixing jig includes a wire assembly 10 and a clamping assembly 20 connected together. The wire assembly 10 includes a rectangular wire substrate 12. The wire clamping assembly 20 includes a rectangular wire clamping substrate 22. The wire substrate 12 is consistent with the width of the wiring substrate 22, and one end of the wiring substrate 12 is connected to one end of the wiring substrate 22, that is, the short side of one side of the wiring substrate 12 is connected to the short side of one side of the wiring substrate 22, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com