Semi-circulating ball type chain wheel position adjusting device and adjusting method

An adjustment device, semi-circulation technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of increasing the cost and instability of chain transmission, achieve rich use scenarios, reduce occupied space, guarantee Effects of stability and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

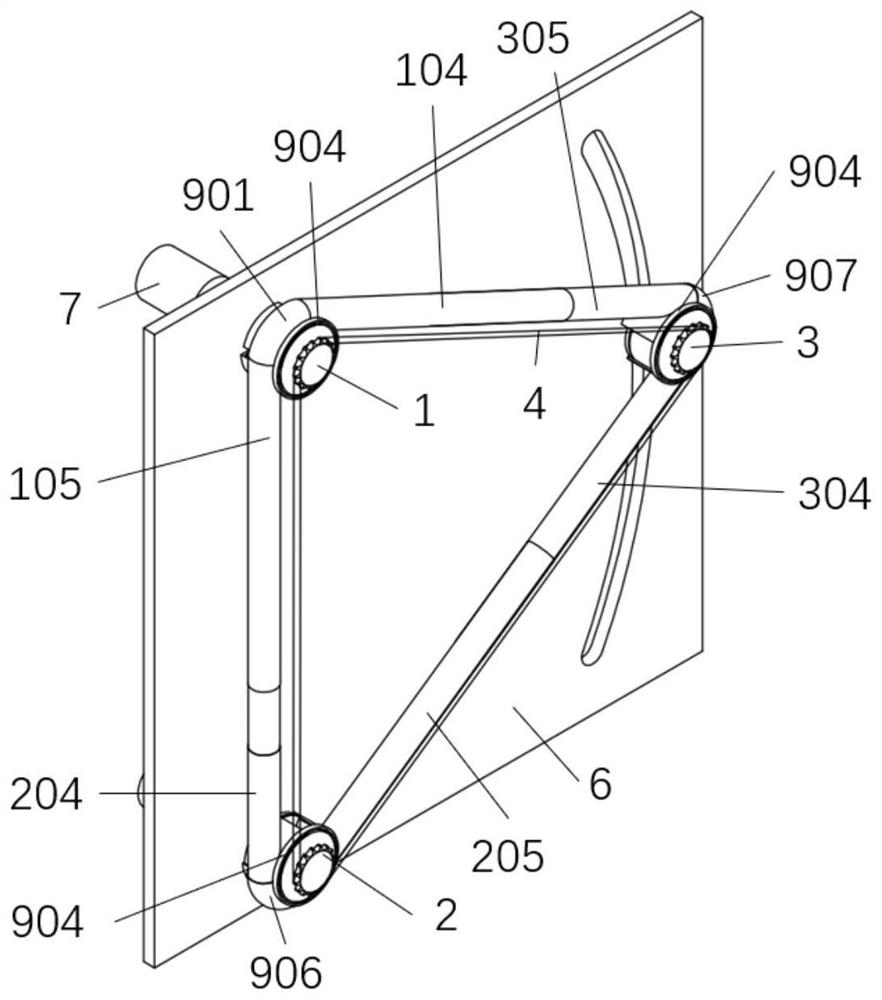

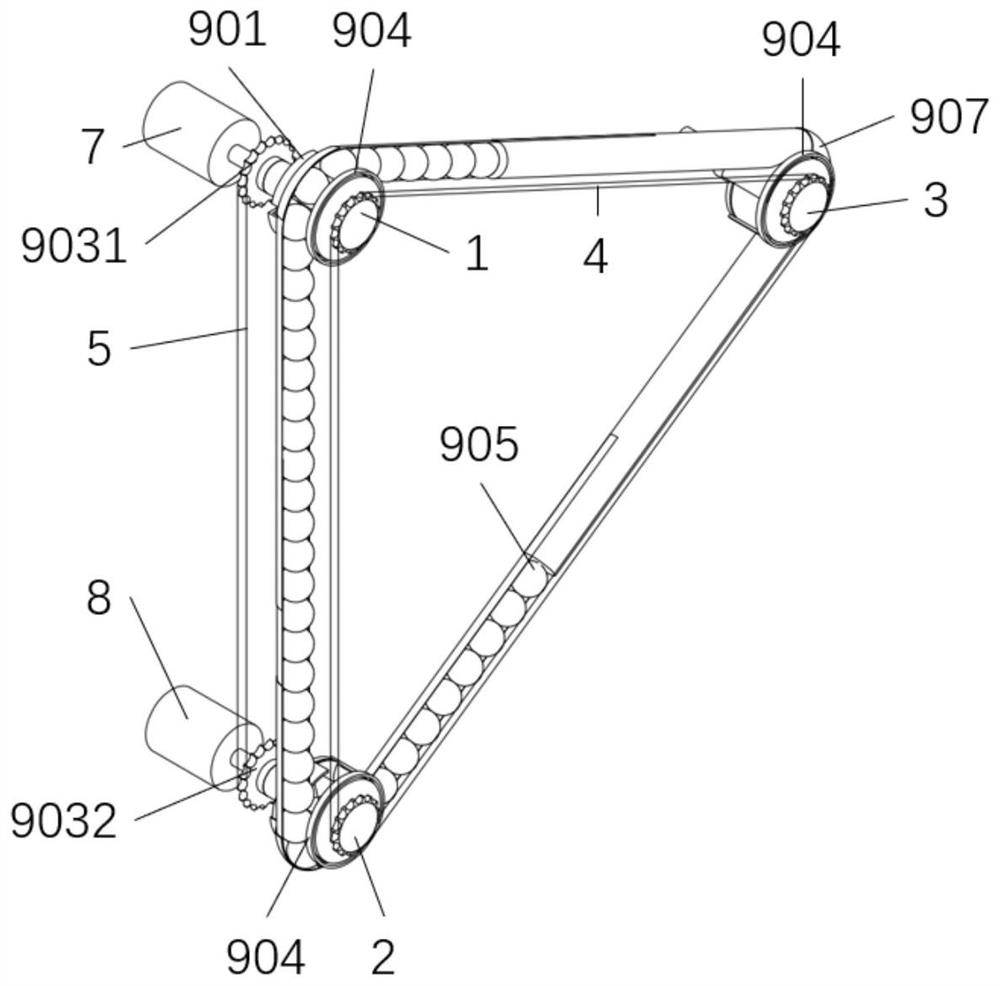

[0094]A semi-circulating ball type sprocket position adjustment device, comprising: a first wheel assembly 1, a second wheel assembly 2, a third wheel assembly 3, a transmission chain 4, an adjustment chain 5, a base plate 6, a transmission motor 7, Adjust the motor 8 and the steel ball 905.

[0095] like figure 1 As shown, the first wheel assembly 1 , the second wheel assembly 2 and the third wheel assembly 3 are all mounted on the base plate 6 .

[0096] The bottom plate 6 is provided with a movement track, and the movement track is a part between the horizontal heights of two focal points of the ellipse.

[0097] Preferably, the ellipse has a focal length of 400mm and a long axis of 800mm.

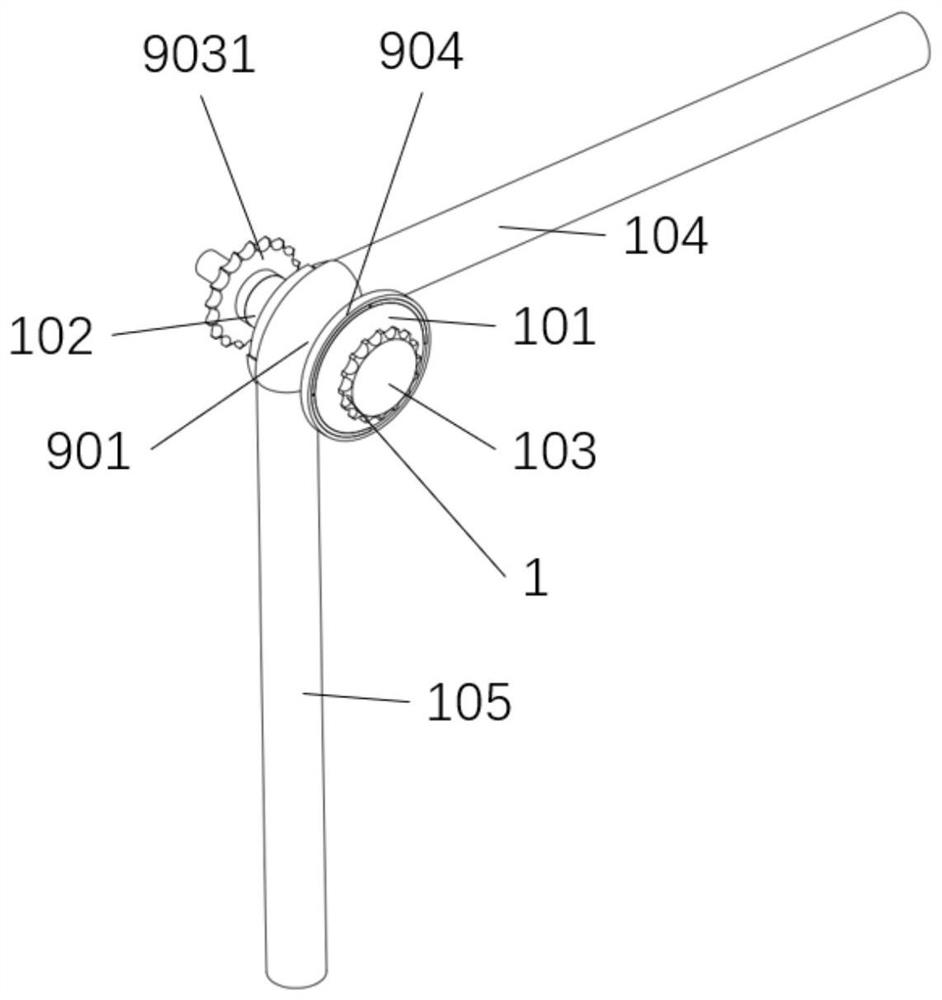

[0098] like Figure 3 to Figure 21 As shown, the first wheel assembly 1 includes: a first wheel 101 , a first wheel axle 102 , a first transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com