Furnace top seal device

A sealing device and furnace roof technology, which is applied in the combustion method, combustion chamber, outer cover/lining, etc., can solve the problems of huge thermal alternating stress and maintain the validity period of 1-3 years, so as to avoid cracking and prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

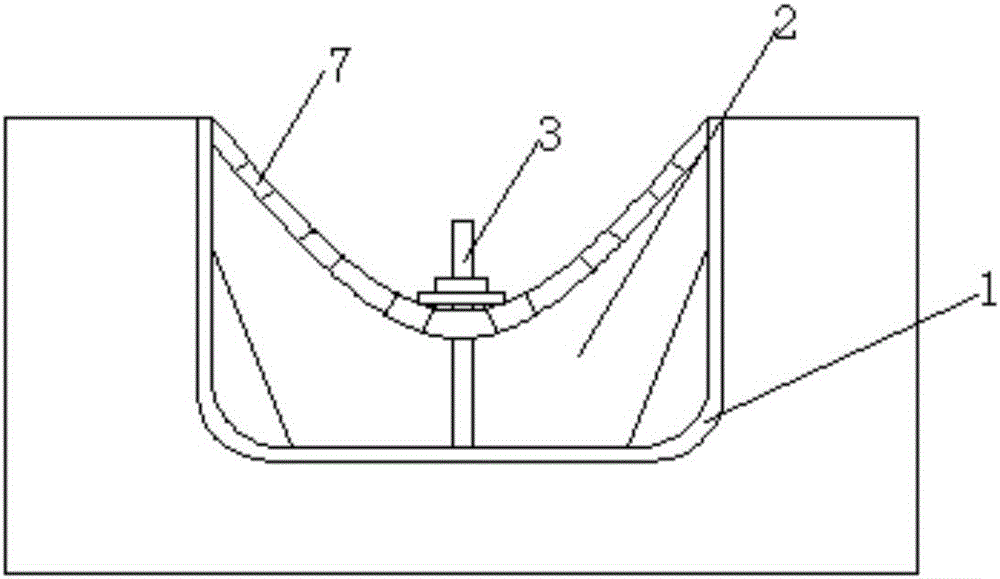

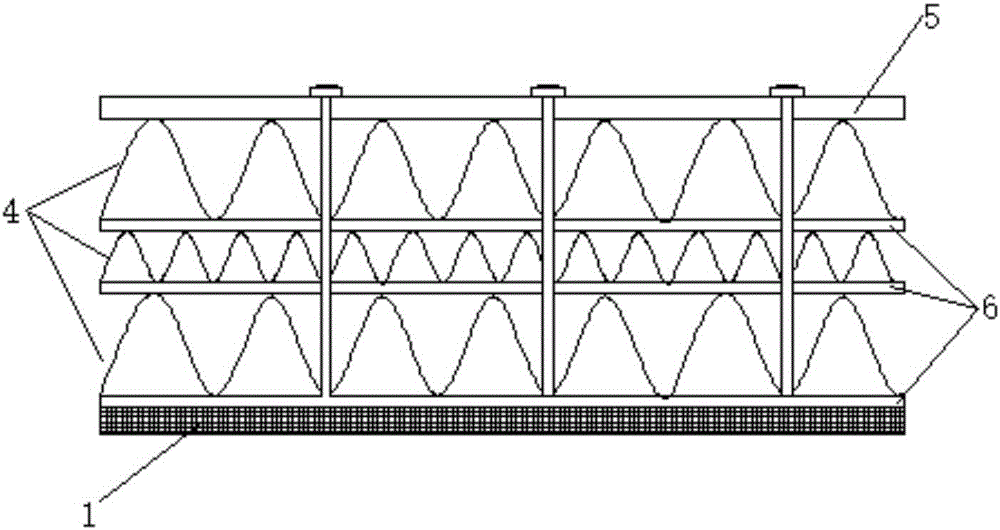

[0019] A furnace roof sealing device as shown in the accompanying drawings, includes a refractory layer 1 poured between the tube rows on the furnace roof, a plastic film leak-proof sealing layer 2 surrounded by the refractory layer 1 and welded on the furnace roof through Steel nails 3 extending from refractory layer 1 and plastic film leak-proof sealing layer 2; said refractory layer 1 includes a compacted and leveled bottom layer and an upper layer that is supplemented and repaired to realize that said refractory layer 1 is flat and smooth without cracks, and said plastic film The leak-proof sealing layer 2 is provided with three layers of ceramic fibers 4 and diamond-shaped stainless steel mesh 5 in sequence from bottom to top, and the ceramic fibers 4 are uniformly coated with high-temperature resistant adhesive 6 of uniform thickness, and the plastic film leak-proof sealing layer A layer of nickel-chromium-manganese steel soft mesh is evenly laid on the bottom layer of 2,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com