Vibration sieve and method for adopting thick glue to compress and tighten screen

A vibrating screen and vibrating body technology, applied in chemical instruments and methods, filter screens, solid separation, etc., can solve the problems of high viscosity of materials, prolonged vibration time, time-consuming and laborious screen tension, and simplify the operation procedure, Prolonged service life, fast tightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

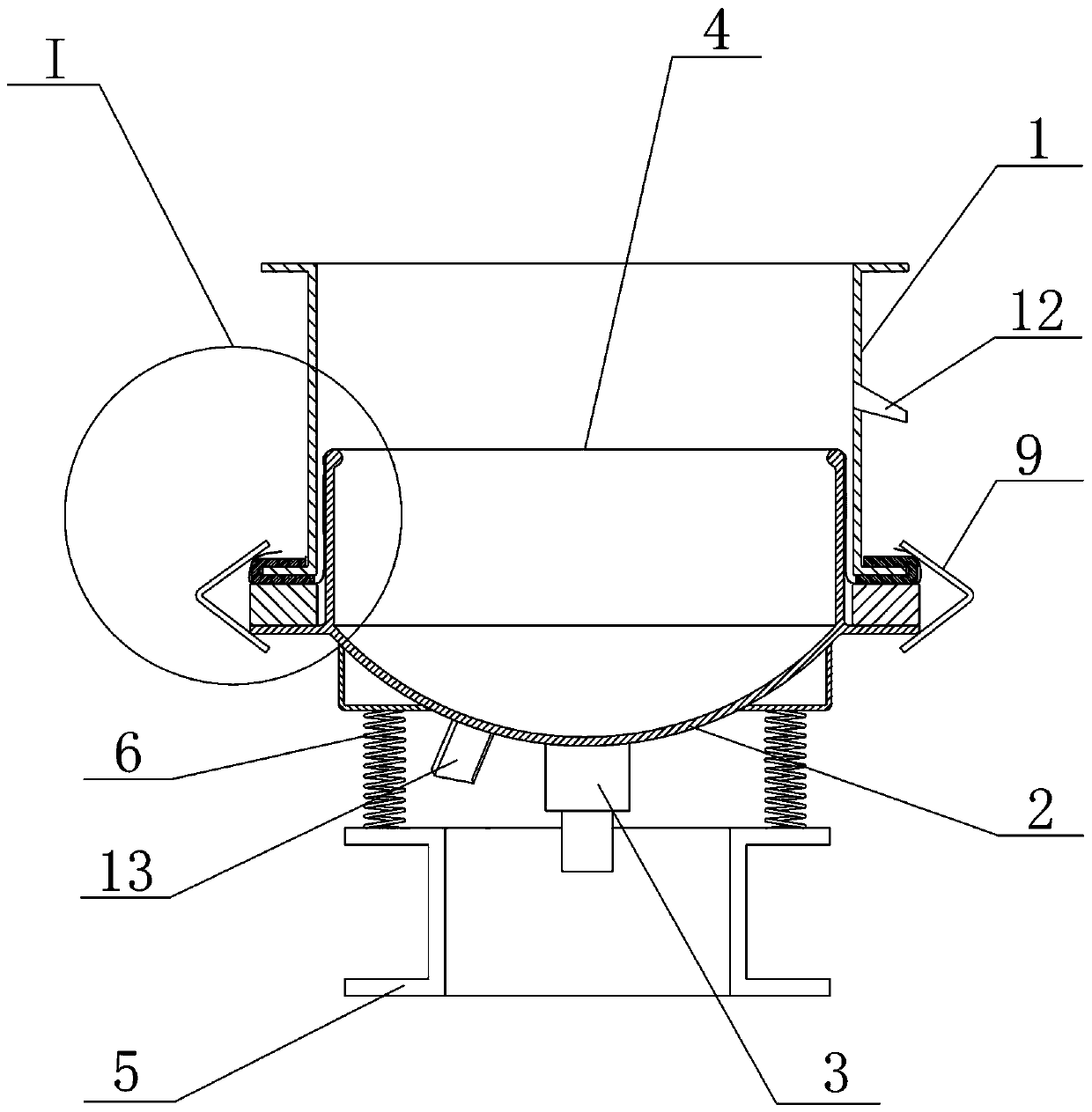

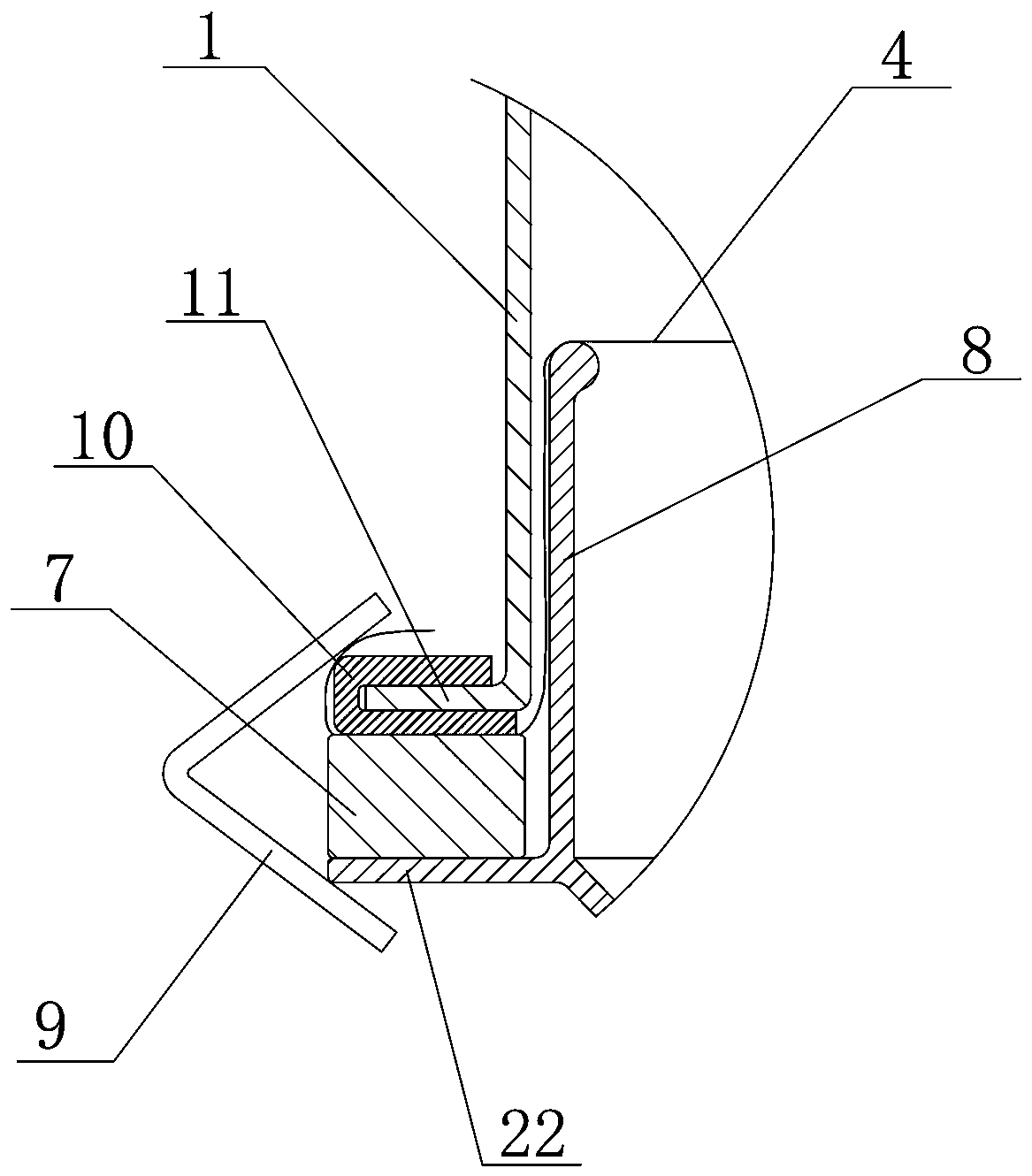

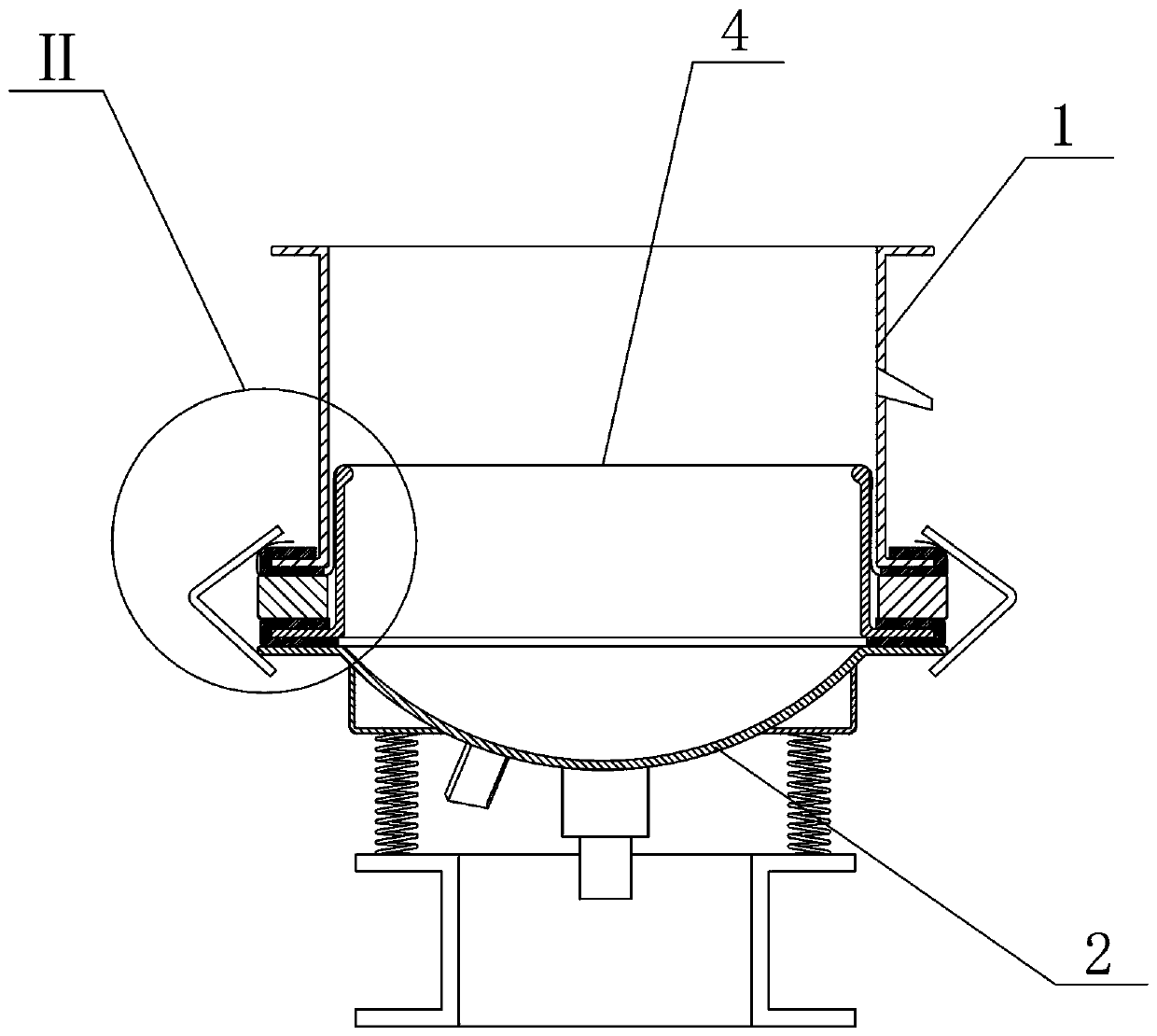

[0036] like figure 1 , 2 As shown, the present embodiment provides a vibrating screen using thick glue to compress and tighten the mesh, which is mainly composed of a screen frame 1, a screen mesh 4, a vibrating body 2, a vibrating motor 3, a base 5, a vibrating spring 6, etc., and the vibrating body 2 It is fixed with the base 5 by the vibration spring 6 . First, an elastic member 7 is placed on the vibrating body locking plate 22, and the elastic member 7 has a sufficient upper and lower elastic compression margin. The vibrating body 2 is provided with a grid 8, and the grid 8 can be fixed on the inner wall of the vibrating body 2 by welding; The locking plate 11 and the vibrating body locking plate 22 have a certain margin. The edge of the screen frame locking plate 11 is wrapped with a U-shaped rubber ring 10, and the screen frame locking plate 11 presses the edge of the screen 4 on the vibrating body locking plate 22, and at the same time tries to ensure that the scree...

Embodiment 2

[0041] Compared with the first embodiment, the grid frame in this embodiment can adopt the finished grid frame 14 currently on the market. like image 3 , Figure 4 As shown, the finished mesh frame 14 has a bottom edge. First, the bottom edge of the finished mesh frame 14 is wrapped with a U-shaped rubber ring 15 to avoid material leakage, and then the bottom edge of the mesh frame 8 is placed on the vibrating body locking plate 22. Then, the elastic member 7 is placed on it, and other structures are the same as those of the first embodiment.

[0042] The grid 8 in the first embodiment is prone to problems such as skew and poor welding when it is fixed with the inner wall of the vibrating body 2, which requires welding technology, and the present embodiment adopts the existing finished grid 14 on the market, which is convenient for production. It can also ensure the flatness of the support end of the grid.

Embodiment 3

[0044]Compared with Embodiment 1, the elastic member in this embodiment can be replaced by a spring 16 and an annular sealing ring 17 . like Figure 5 , Image 6 As shown, a coil of spring 16 is arranged on the vibrating body locking plate 22. The function of the spring 16 is the same as that of the elastic member 7 in the first embodiment, and both have a certain upper and lower elastic compression margin. An annular sealing ring 17 is arranged above the spring 16, and the inner wall of the annular sealing ring 17 is closely attached to the outer wall of the network frame 8 to prevent material from leaking. Subsequently, the screen cloth 4, the screen frame 1, etc. are set above the annular sealing ring 17, the same as in the first embodiment.

[0045] In this embodiment, the elastic part is replaced by a spring, which provides another solution to the elastic compression margin, and can also realize the tightening of the screen only through the locking of the screen frame a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com