Tensioning feeding mechanism and ink jet printer

A feeding mechanism and tensioning technology, applied in printing devices, printing, thin material processing, etc., can solve the problems of not being able to maintain the tension of materials at all times, loose wrinkles, etc., and achieve the effect of avoiding wrinkles and ensuring printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is described in detail below in conjunction with accompanying drawing:

[0043] The first application structure:

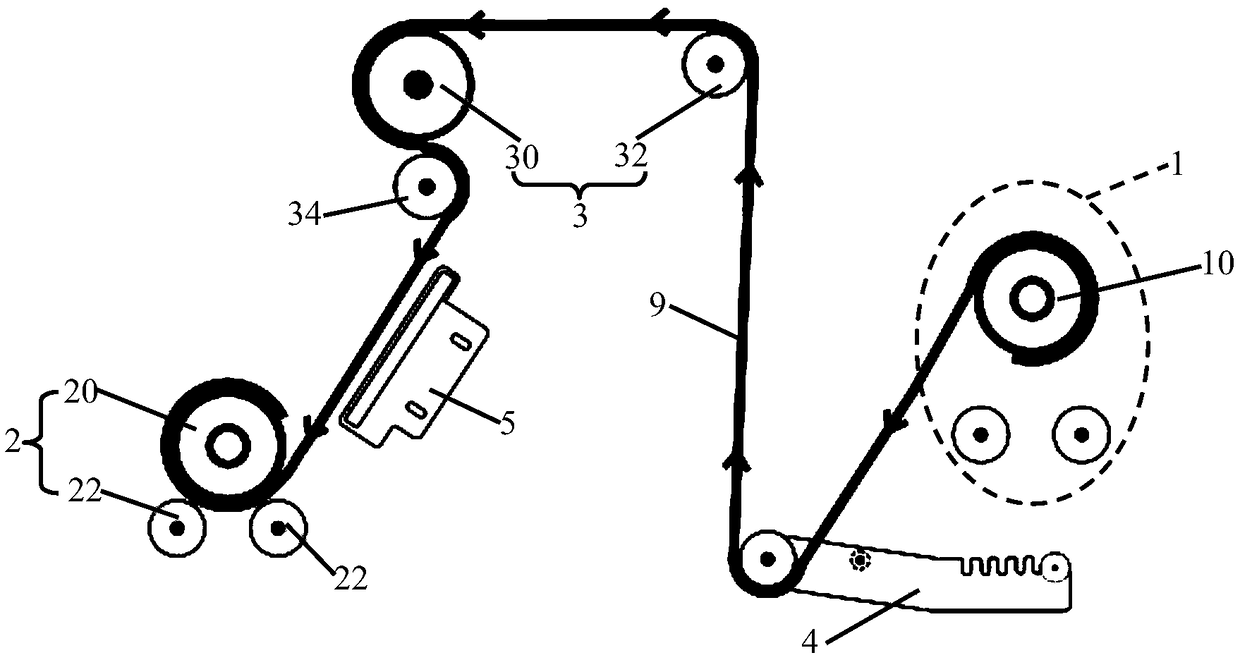

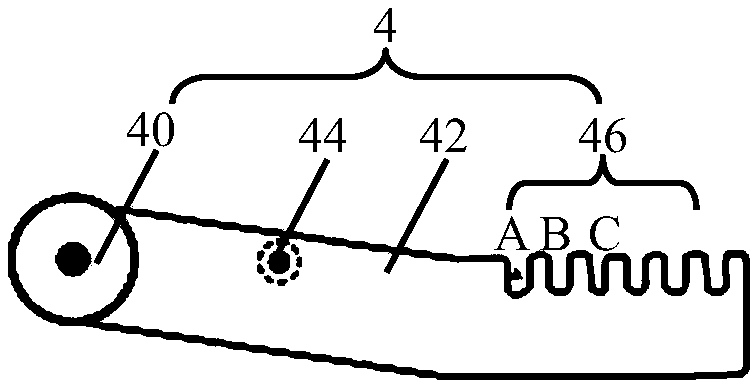

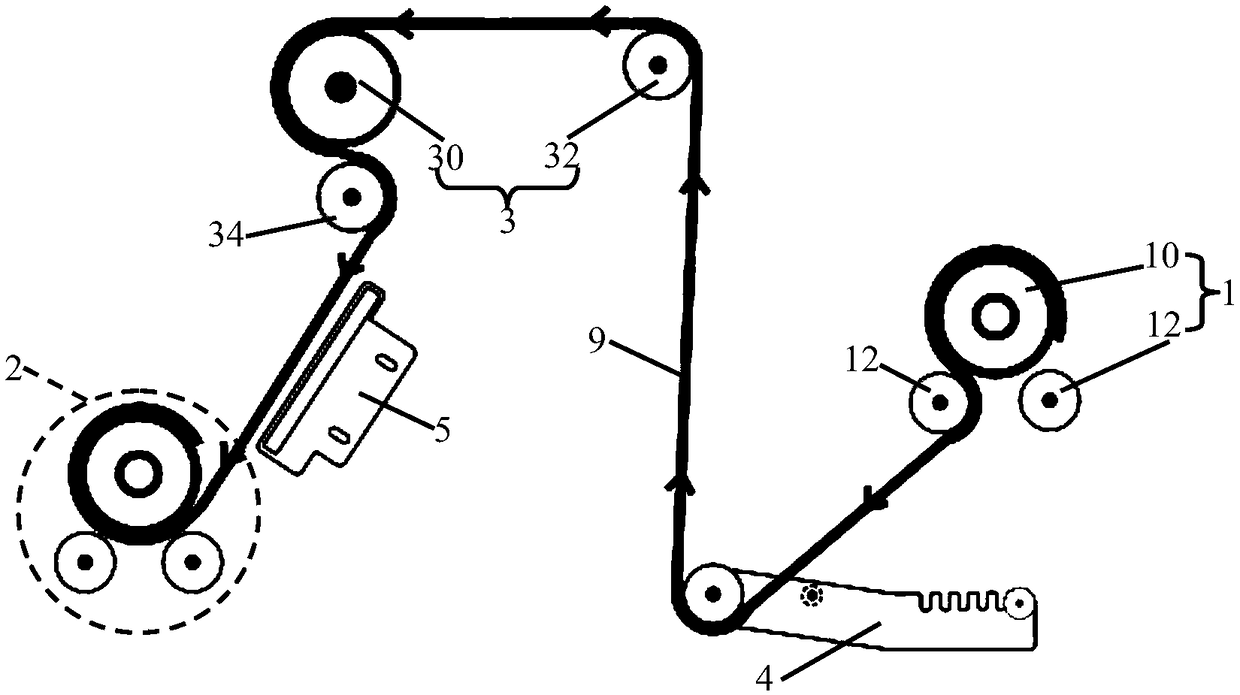

[0044] Such as figure 1 As shown, a tension feeding mechanism includes a rotatable discharge roller unit 1 and a take-up roller unit 2, a tension unit 3 is arranged between the discharge roller unit 1 and the take-up roller unit 2, The tensioning unit 3 includes a main roller 30 and a resistance member 32, the main roller 30 is rotatably arranged to drive the conveying material 9, the resistance member 32 is arranged at intervals on the main roller 30 and acts to hinder the progress of the material 9 resistance. Among them, specifically:

[0045] There are several setting methods for auxiliary rollers:

[0046] a. The resistance member 32 is an auxiliary roller, the auxiliary roller 32 is driven by a motor to rotate and its rotation direction is opposite to that of the main roller 30, the driving force between the main roller 30 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com