Device with well tightened conveyor belt

A technology of conveyor belts and rollers, applied in the field of conveyor belts, can solve problems such as waste, and achieve the effect of ensuring transmission speed and good tightening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

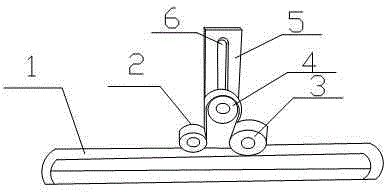

[0017] Such as figure 1 As shown, the present invention includes a transmission belt body 1, the top of the transmission belt body 1 is equipped with a first roller 2, a second roller 3 and a third roller 4, and the first roller 2, the second roller 3 and the third roller 4 are distributed in a triangle, the first roller 2 and the second roller 3 are located on the same straight line in the horizontal plane and below the third roller 4, and the third roller 4 can move up and down.

[0018] In this embodiment, a positioning mechanism is set. Three rollers are arranged on the positioning mechanism. After the three rollers are arranged, they form a triangular pattern. A waist-shaped hole moves up and down, and the conveyor belt is tightened by adjusting the rollers that can move up and down. In this way, the conveyor belt can be in a tight state after repeated use.

Embodiment 2

[0020] The preferred specific structure of this embodiment on the basis of embodiment 1 is as follows: the first roller 2 and the second roller 3 can only rotate and cannot be displaced. To ensure that the transmission track of the conveyor belt is fixed, it is better to control the third roller to realize that the conveyor belt can be in a tense state after repeated use, ensuring the transmission speed of the conveyor belt.

[0021] A steel plate 5 is installed on the vertical direction of the conveyor belt body 1 , and a waist-shaped hole 6 is installed on the steel plate 5 .

[0022] The third roller 4 is installed in the waist hole 6 and can slide up and down in the waist hole 6 . It is convenient to control the position of the third roller. When the conveyor belt becomes loose, the third roller can be moved up to ensure that the conveyor belt is always in a tight state.

[0023] The steel plate 5 is parallel to the third roller 4 and is located directly behind the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com