Rotary conveyer

A technology of rotary conveying and conveyor belts, which is applied in the direction of conveyors, cleaning devices, conveyor objects, etc., can solve the problems of insufficient conveying power, easy slipping, uneven conveying, etc., achieve stable conveying, stable conveying, and solve the problem of occupying land The effect of the area problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

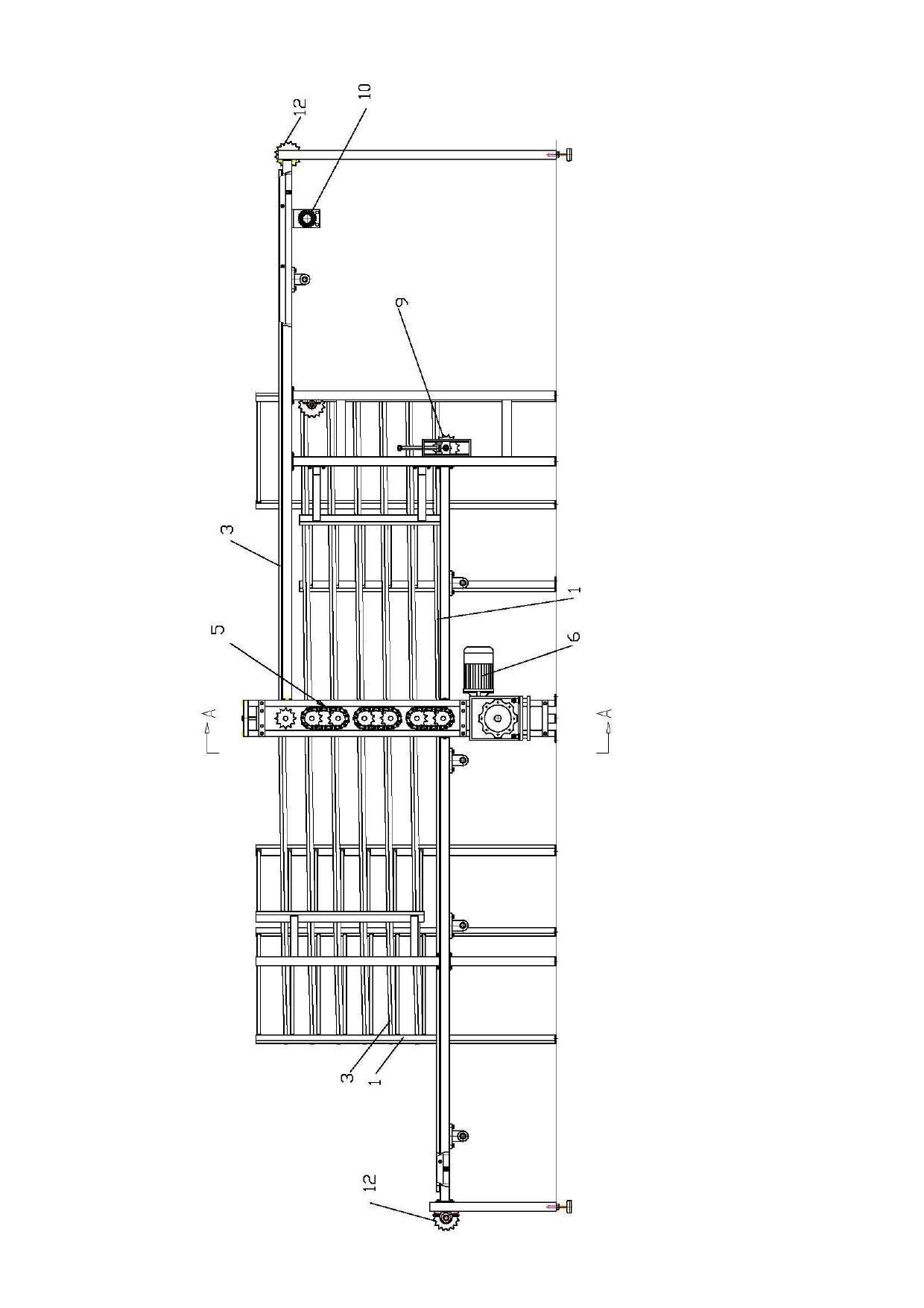

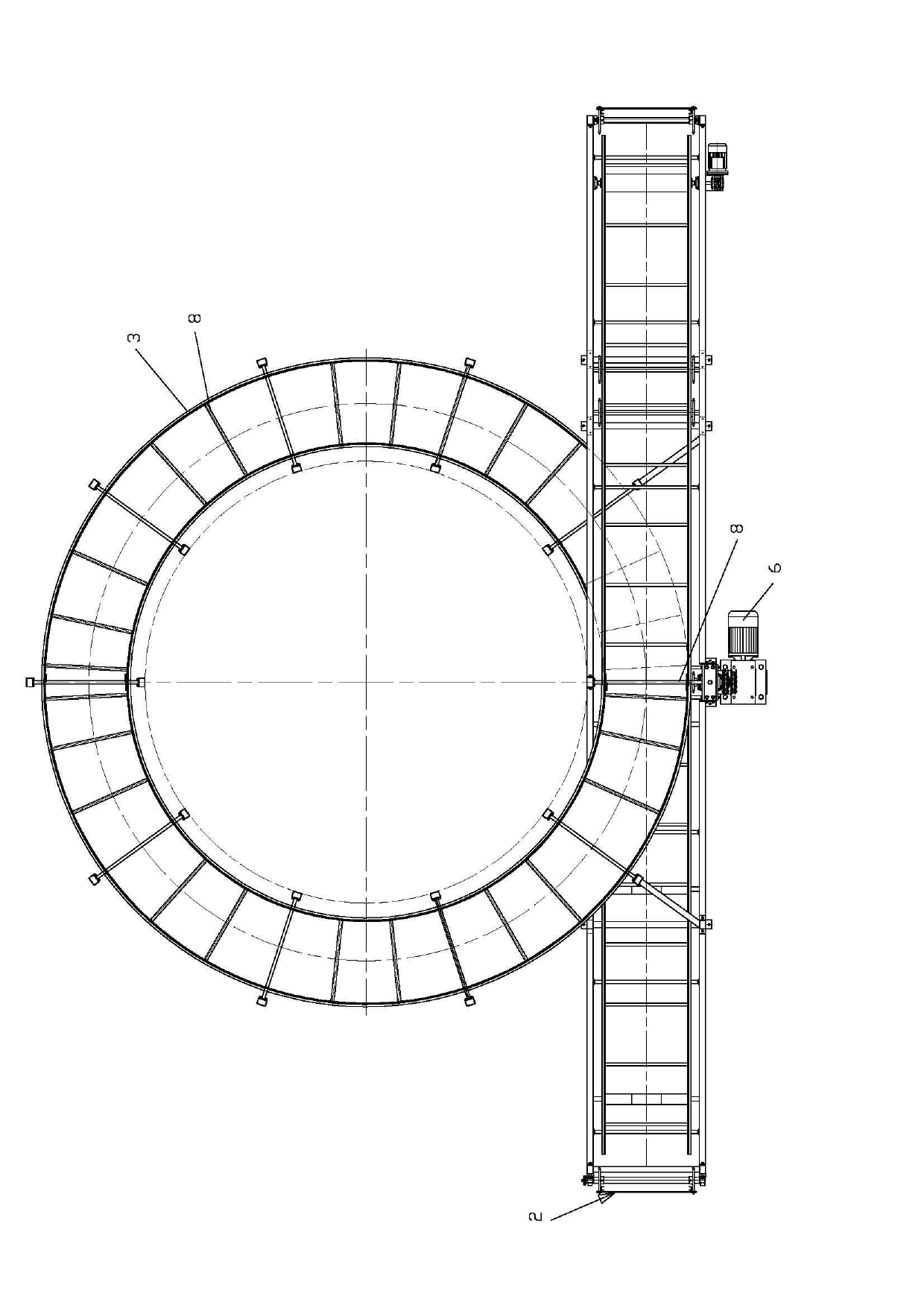

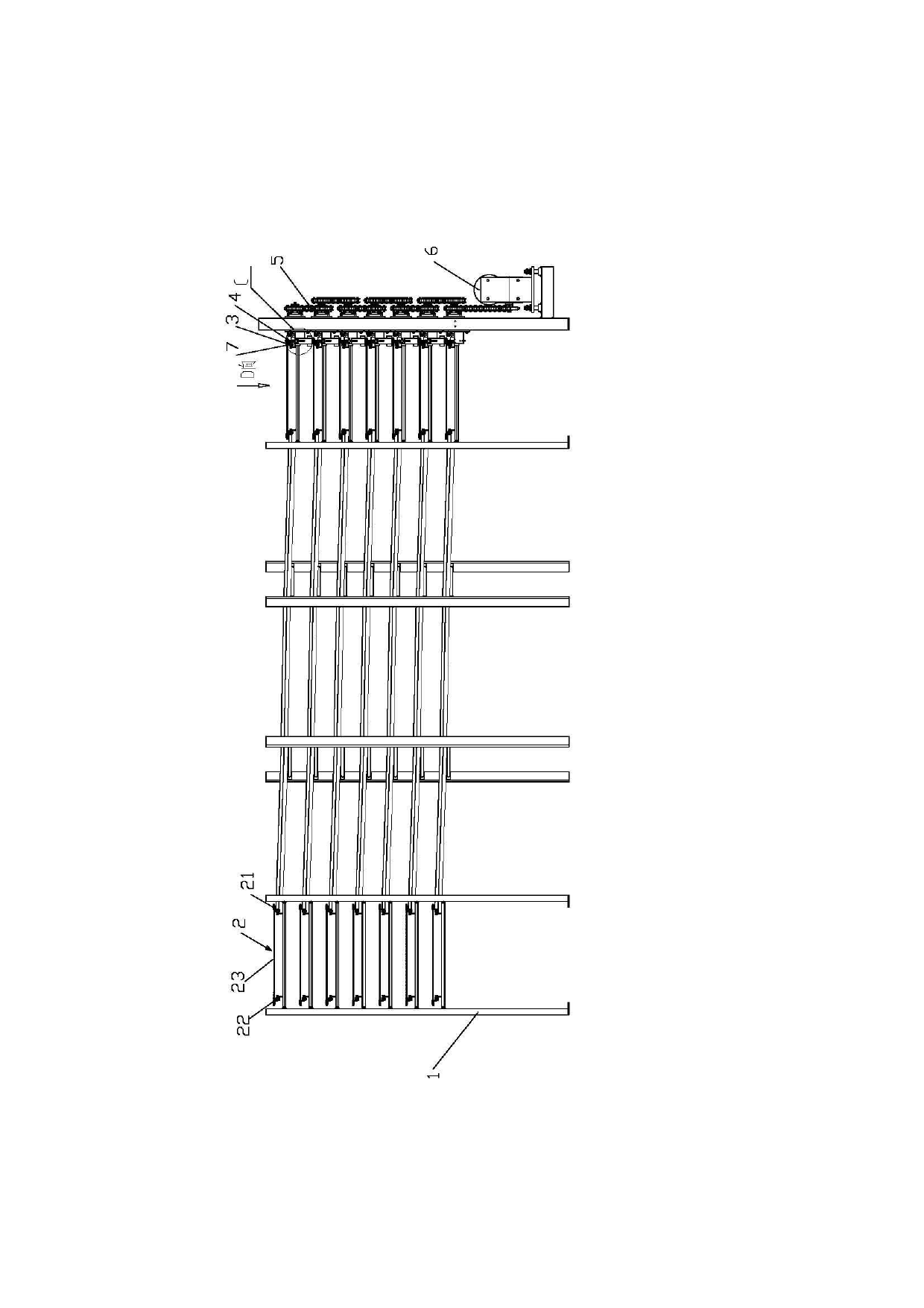

[0020] figure 1 , 2 , 3, 4 and 5, the rotary conveying device of the present invention includes a rotating frame 1 and a conveying mesh belt 2, wherein the conveying mesh belt is fixed inside and outside by inner and outer circulating conveyor belts 21, 22, The mesh belt 23 on the outer circulation conveyor belt 21, 22 is composed of a guide rail 3 on the rotating frame 1, and a mesh belt sprocket 4 matched with the outer circulation conveyor belt 22 is provided on each layer of the rotating frame 1. The belt sprocket 4 is connected to the motor 6 through the transmission mechanism 5; on the conveying mesh belt 2, there is also a limit block 7 that matches the guide rail 3, and the cross-sectional shape of the limit block 7 is an inverted U-shaped structure , The limiting block 7 is in contact with the inner upper surface and the inner surface on the annular guide rail 3, which not only plays a position limiting role, but also makes it slide on the smooth guide rail 3 surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com