Automatic welding method for realizing drop properties of submerged arc welder by field digital preset mode

A digital preset, automatic welding technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as unfavorable welding process formulation and implementation, anti-interference ability limitation, data transmission speed and distance limitation, etc. The effect of transmission speed and real-time performance, improvement of workers' working conditions, and improvement of anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

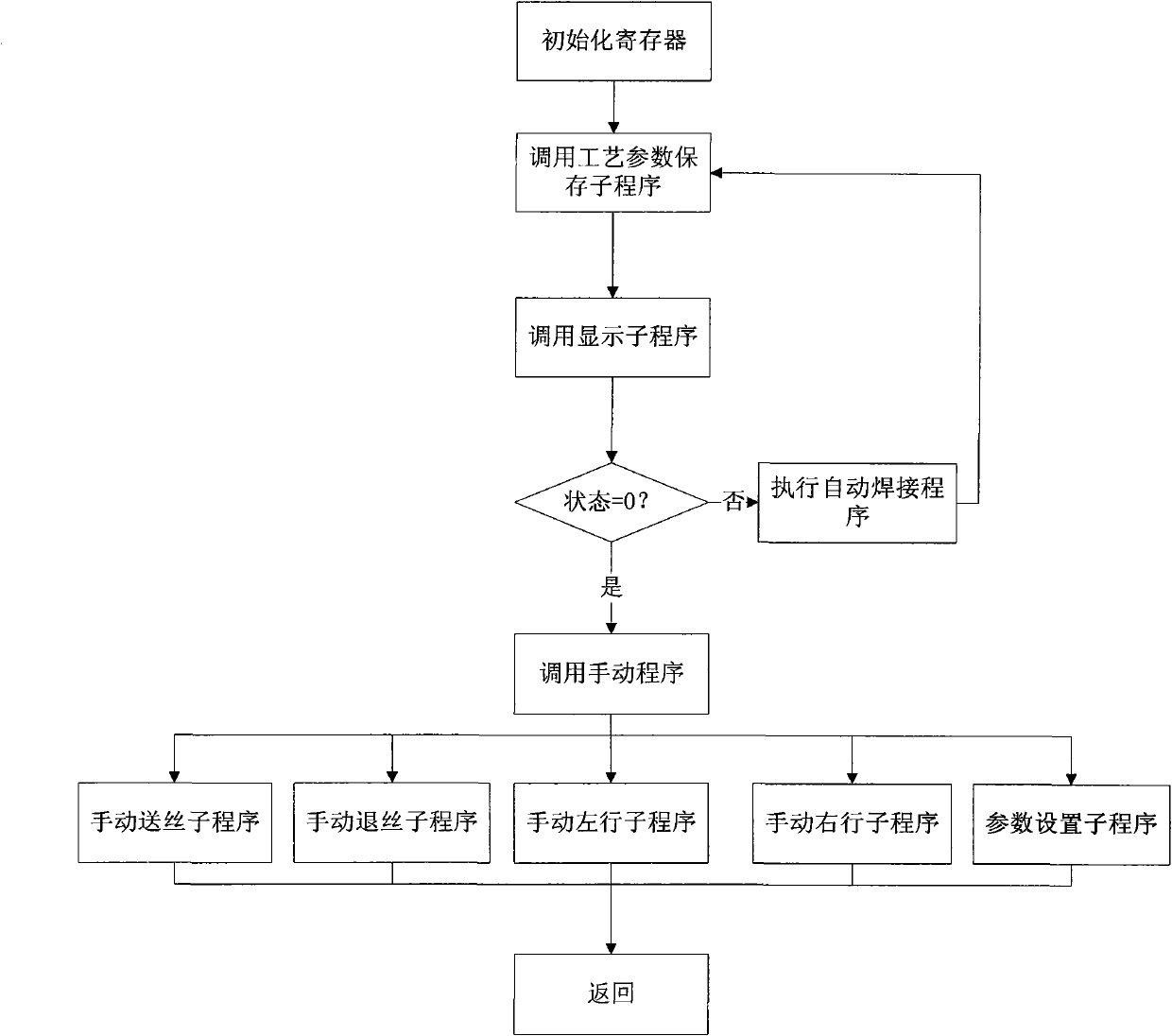

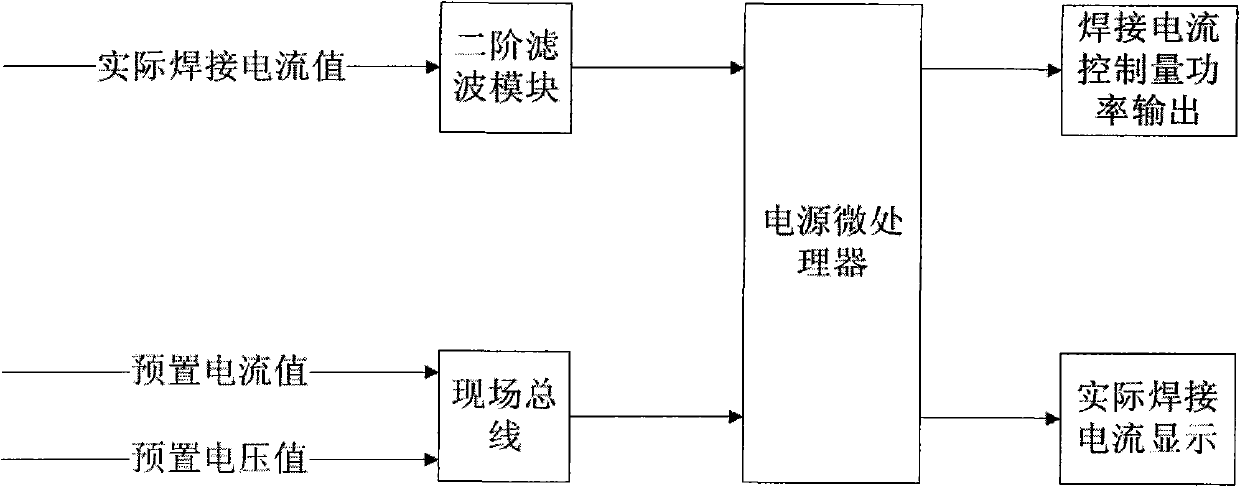

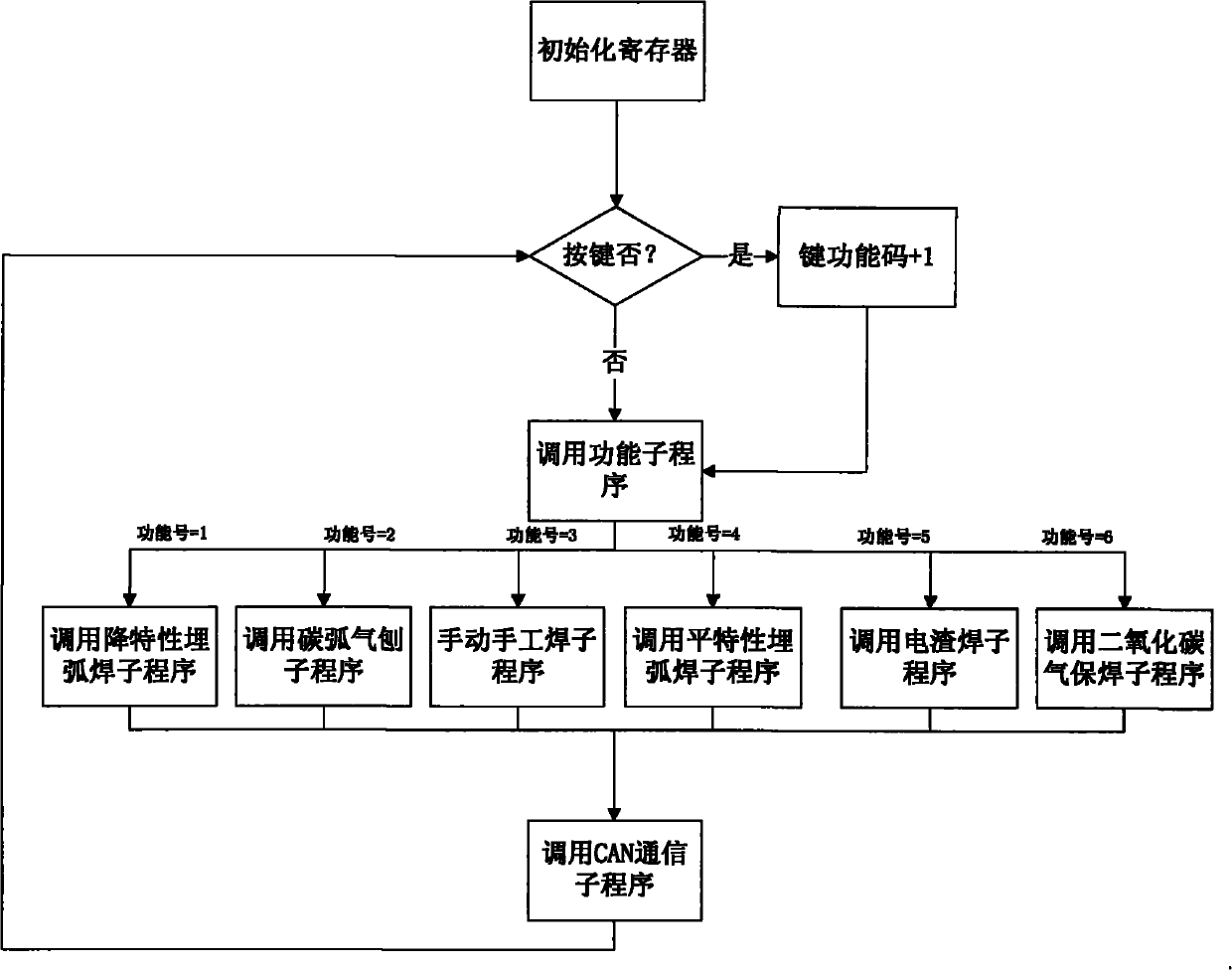

[0038]The on-site digital preset method provided by the present invention realizes the automatic welding method of submerged arc welding machine with reduced characteristics, including the following steps: A, configuring a submerged arc welding machine power supply control system and a welding trolley control system on the submerged arc welding machine; B, The preset welding process parameters are input through the man-machine interface of the welding trolley control system, and the welding trolley control system transmits the preset current value and preset voltage value to the microprocessor of the submerged arc welding machine power supply control system through the field bus; The preset welding process parameters include at least a preset current value, a preset voltage value and a preset welding speed value; C, the actual welding current v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com