Active rope tensioning device for wire rope

A technology of steel wire rope and rope tensioner, which is applied in hoisting device, clockwork mechanism, etc. It can solve the problems of wire rope slack and random buckling, and achieve the effect of avoiding random buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

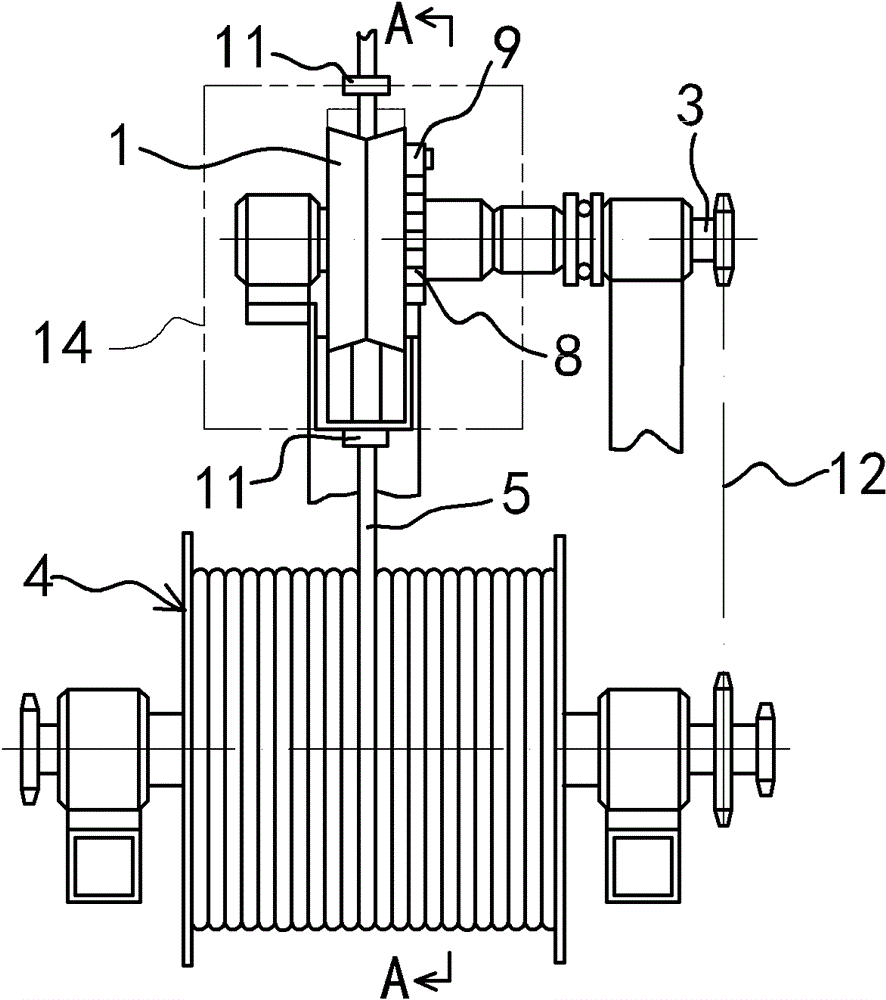

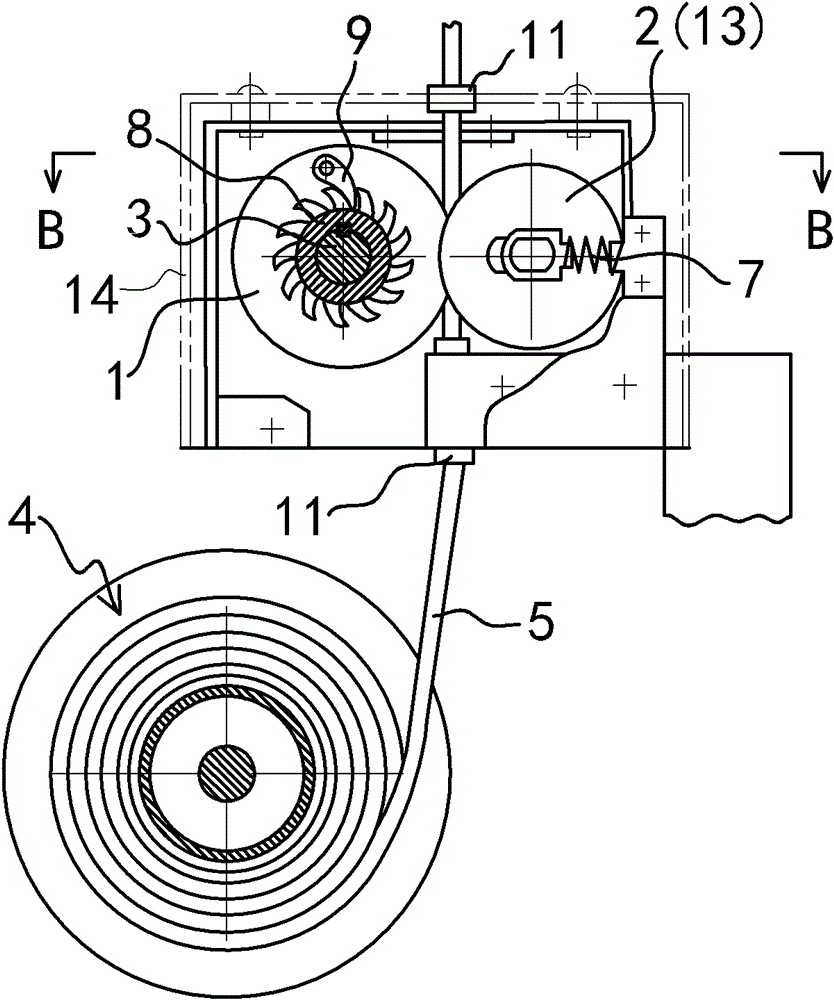

[0025] Embodiment one: see attached Figure 1~3 Shown:

[0026] An active rope tightening device for steel wire ropes, comprising a rope tightening wheel 1, a pressure roller 2, a transmission shaft 3 and a ratchet mechanism.

[0027] The rope tightening wheel 1 and the pressing roller 2 are arranged side by side for rotation and support, and the central axes of the rope tightening wheel 1 and the pressing roller 2 are parallel to each other. The wheel surface of described tight rope wheel 1 and the wheel surface of pressure roller 2 match, and the wheel surface section of concrete tight rope wheel 1 is concave V shape, and the wheel surface of pressure roller 2 is plane, and the two sides of pressure roller 2 The side is provided with positioning plate 13, and this positioning plate 13 plate edges protrude on both sides of the pressure roller 2, and the tight rope wheel 1 just embeds between the two positioning plate 13 plate edges, so that the tight rope wheel 1 wheel surfa...

Embodiment 2

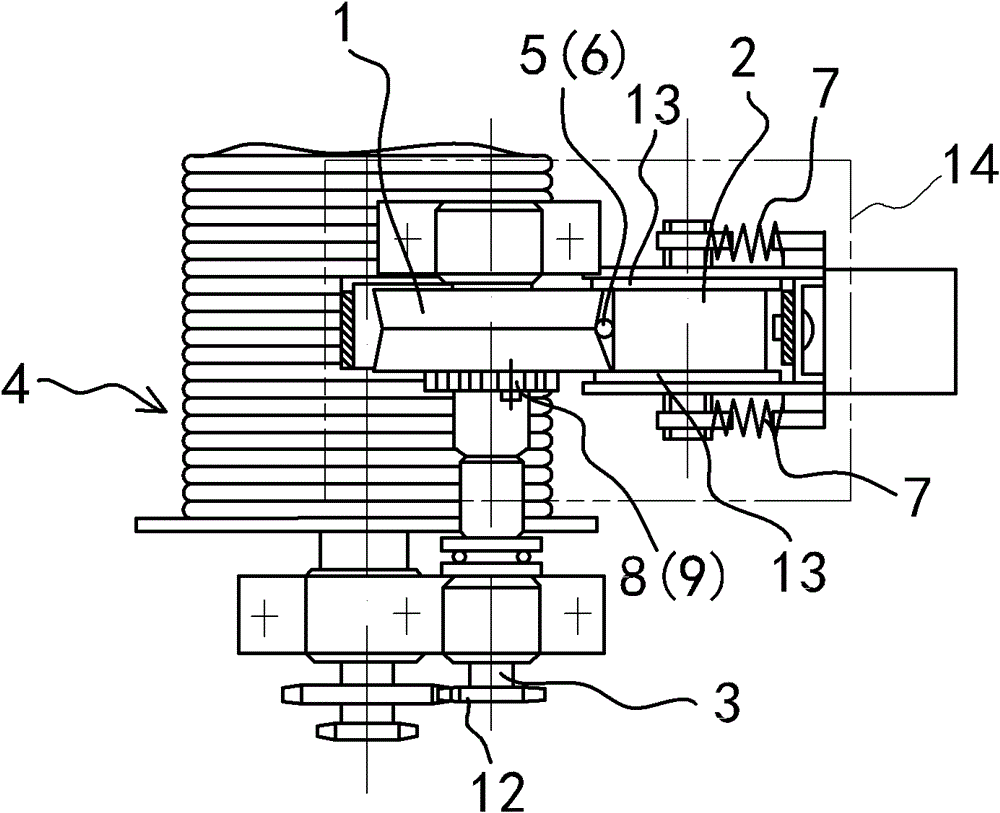

[0034] Embodiment two: see attached Figure 4 Shown:

[0035]An active rope tensioner for a steel wire rope, comprising a rope tightening wheel 1, a pressure roller 2, a transmission shaft 3 and a ratchet mechanism, the only difference from Embodiment 1 is that the ratchet mechanism is an internally connected ratchet mechanism, which includes Ratchet, transmission wheel 10, ratchet 9 and spring; Establish teeth on the inner edge of described tight rope wheel 1 to form described ratchet, described transmission wheel 10 is embedded in the center of tight rope wheel 1 on the described transmission shaft 3, The transmission wheel 10 is fixed or keyed to the transmission shaft 3; the teeth of the corresponding ratchet of the ratchet 9 are hinged on the transmission wheel 10, and the spring acts on the ratchet 9 to make the ratchet 9 and the teeth of the ratchet match.

[0036] Others are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com