Cloth rolling frame and cloth rolling roller

A technology of cloth rolling roller and winding roller, which is applied in the directions of winding strips, thin material processing, transportation and packaging, etc. It can solve the problems of a large number of manpower operations and inaccurate adjustments, so as to improve the aesthetics and avoid inaccurate accuracy. High and low deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

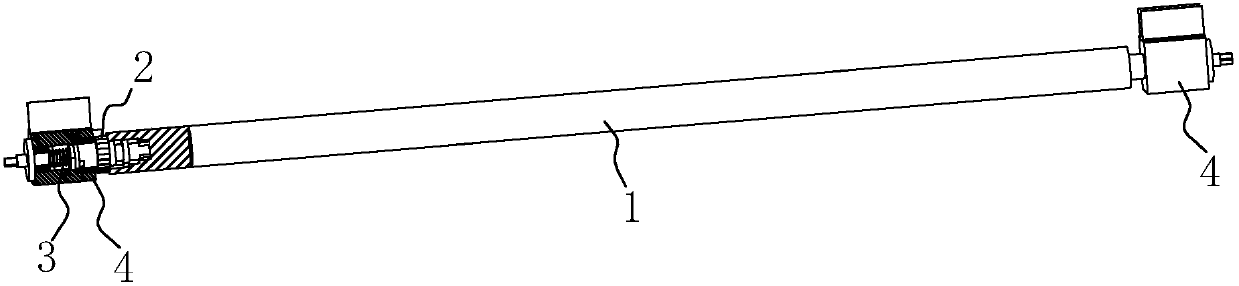

[0048] Embodiment 1: a kind of cloth roll, as figure 1 and figure 2 As shown, it includes a roller shaft 1, a claw mechanism 2 and a damping mechanism 3. The claw mechanism 2 is one in number and is arranged at one end of the roller shaft 1. The claw mechanism 2 includes a ratchet 21 and a pawl 22, and the ratchet 21 is fixed On the roller shaft 1; two damping mechanisms 3 are arranged on the two ends of the roller shaft 1 respectively.

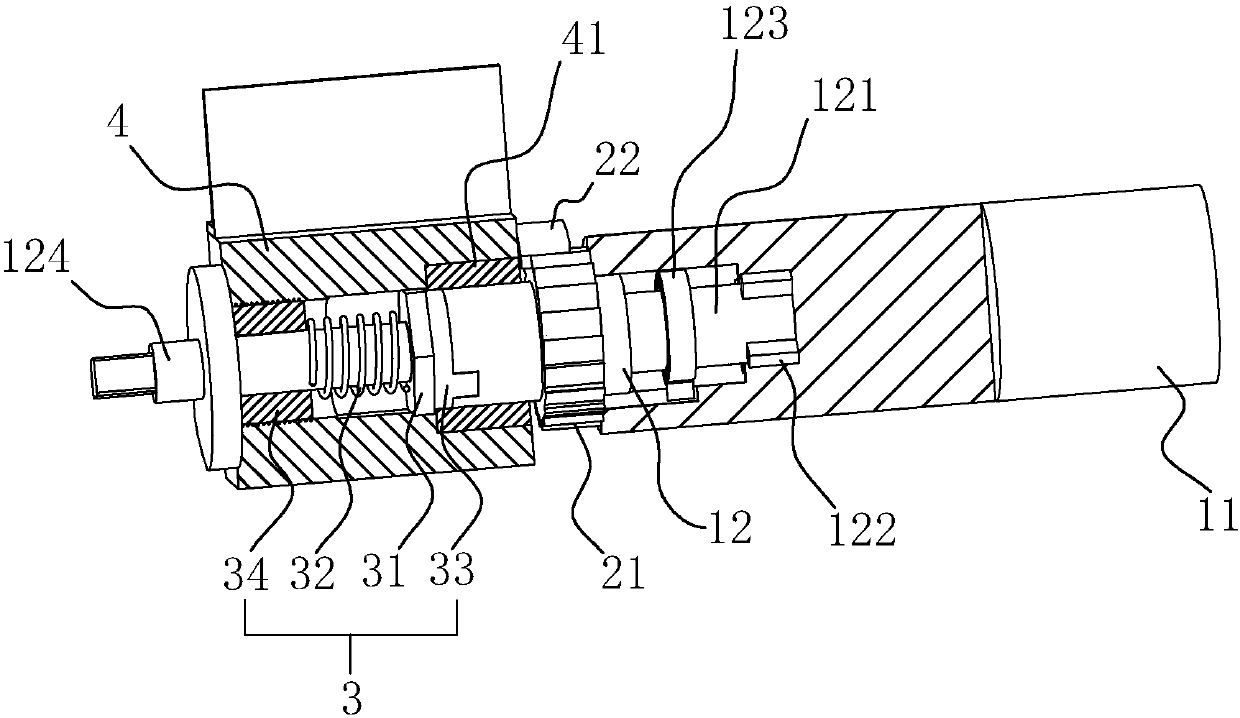

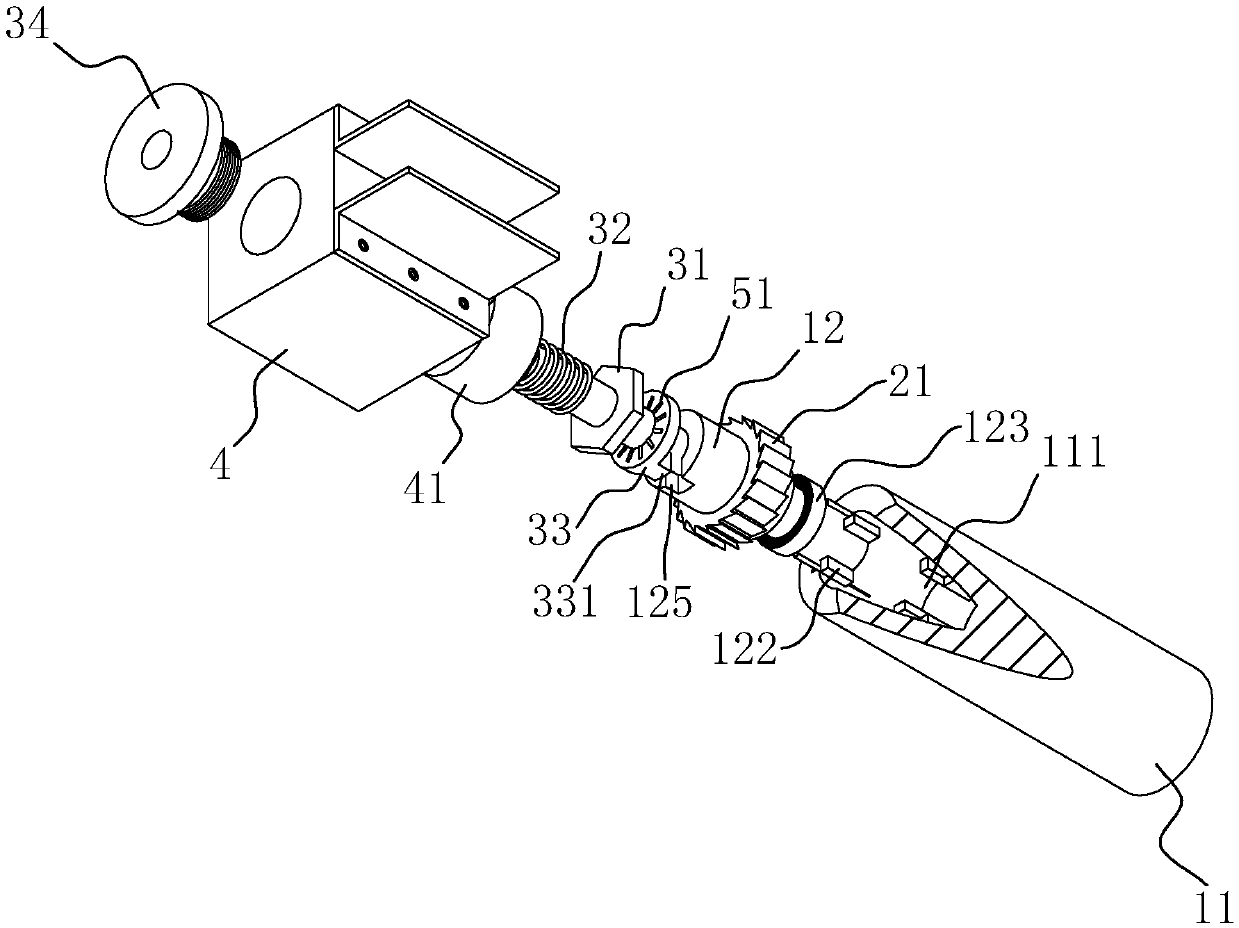

[0049] refer to figure 2 and image 3 The roller shaft 1 includes a roller body 11 and a connecting portion 12 arranged at both ends of the roller body 11, one end of the connecting portion 12 is inserted into the end of the roller body 11, and the other end is rotatably connected to a sliding block 4 through a bearing 41, The rotation of the roller shaft 1 is realized by two sliding blocks 4 . Wherein, one end of the connecting portion 12 is provided with an insertion portion 121, and a plurality of limit strips 122 are evenly distribu...

Embodiment 2

[0055] Embodiment 2: a kind of cloth rolling frame, such as Figure 5 and Figure 6 As shown, it includes: a winding roller 6, a cloth rolling roller of the first embodiment and two poles, one end of the winding roller 6 is provided with a claw device 8, and the claw device 8 and the claw mechanism 2 have the same structure , but the limited direction of the ratchet 22 on the pawl device 8 to the ratchet 21 is opposite to the limited direction of the ratchet 22 on the pawl mechanism 2 to the ratchet 21; The conveyance between the cloth roll and the winding roll 6; two poles connect the winding roll 6 and the cloth rolling roll to form a frame structure.

[0056] Wherein, two sliding blocks 4 are also arranged at both ends of the winding roller 6, and the struts are connected to the sliding blocks 4 on the winding roller 6 and the cloth rolling roller.

[0057] Working principle: first install the base cloth roll on the cloth roll, then pull the base fabric out from the roll ...

Embodiment 3

[0058] Embodiment 3: as Figure 7 As shown, the difference from Embodiment 2 is that two guide rollers 9 located on the same vertical surface are arranged on the pole, the guide rollers 9 are parallel to the cloth rolling roller, and the winding roller 6 and the cloth rolling roller are parallel and not Intersect at the plane where the guide roller 9 is located. The cloth for embroidery is kept on the same vertical plane by the setting of the two guide rollers 9, avoiding that the base cloth between the winding roller 6 and the cloth roll cannot be kept on the same plane because the diameter of the base cloth roll changes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com