Yarn supporting device for skein rewinding and elastic yarn thermal shrinkage or expansion processing and yarn dyeing method based on yarn supporting device

A technology of yarn support and rewinding, which is applied in the field of yarn support for skein rewinding, which can solve the problems of uniform dyeing of internal yarns, difficult rewinding operation, and scattered yarns, and achieve direct economic benefits, saving and economical The effect of benefit saving and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

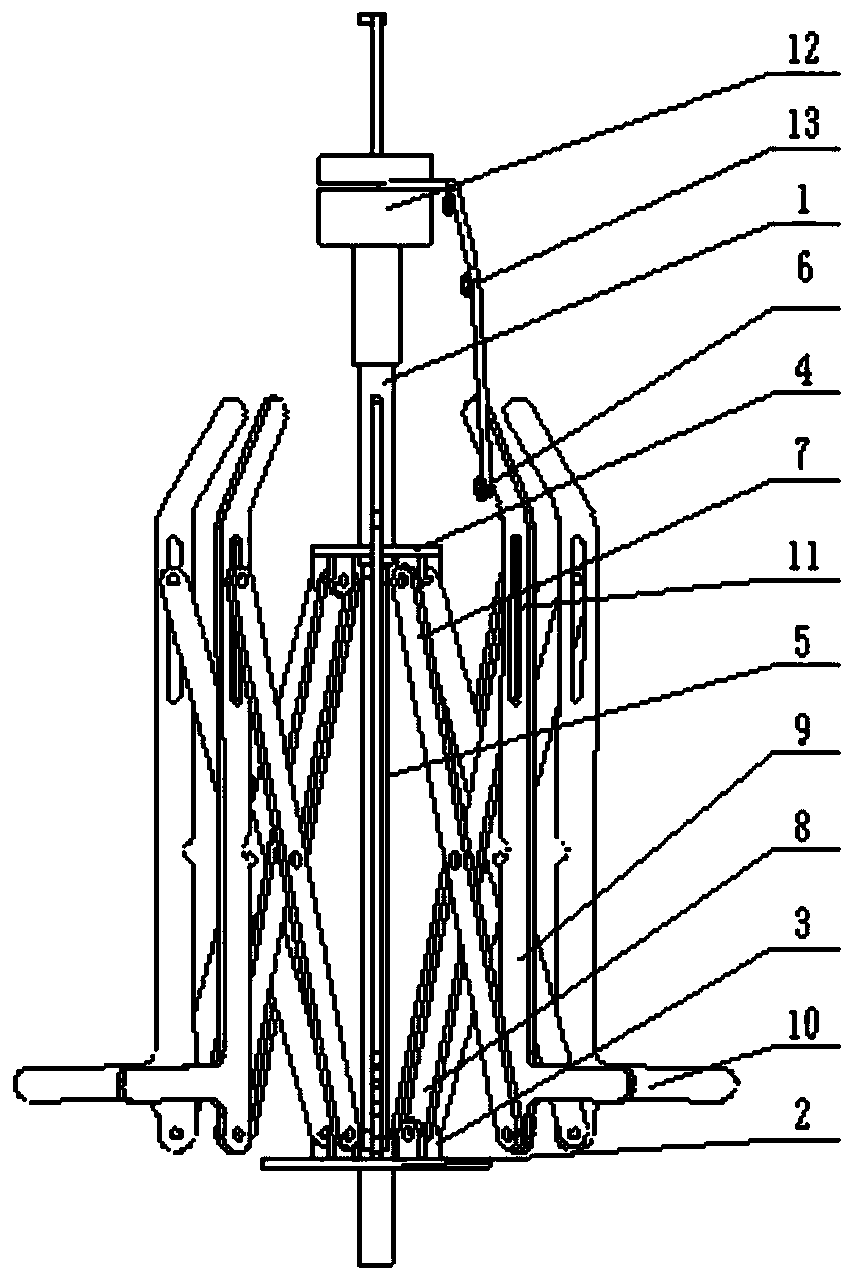

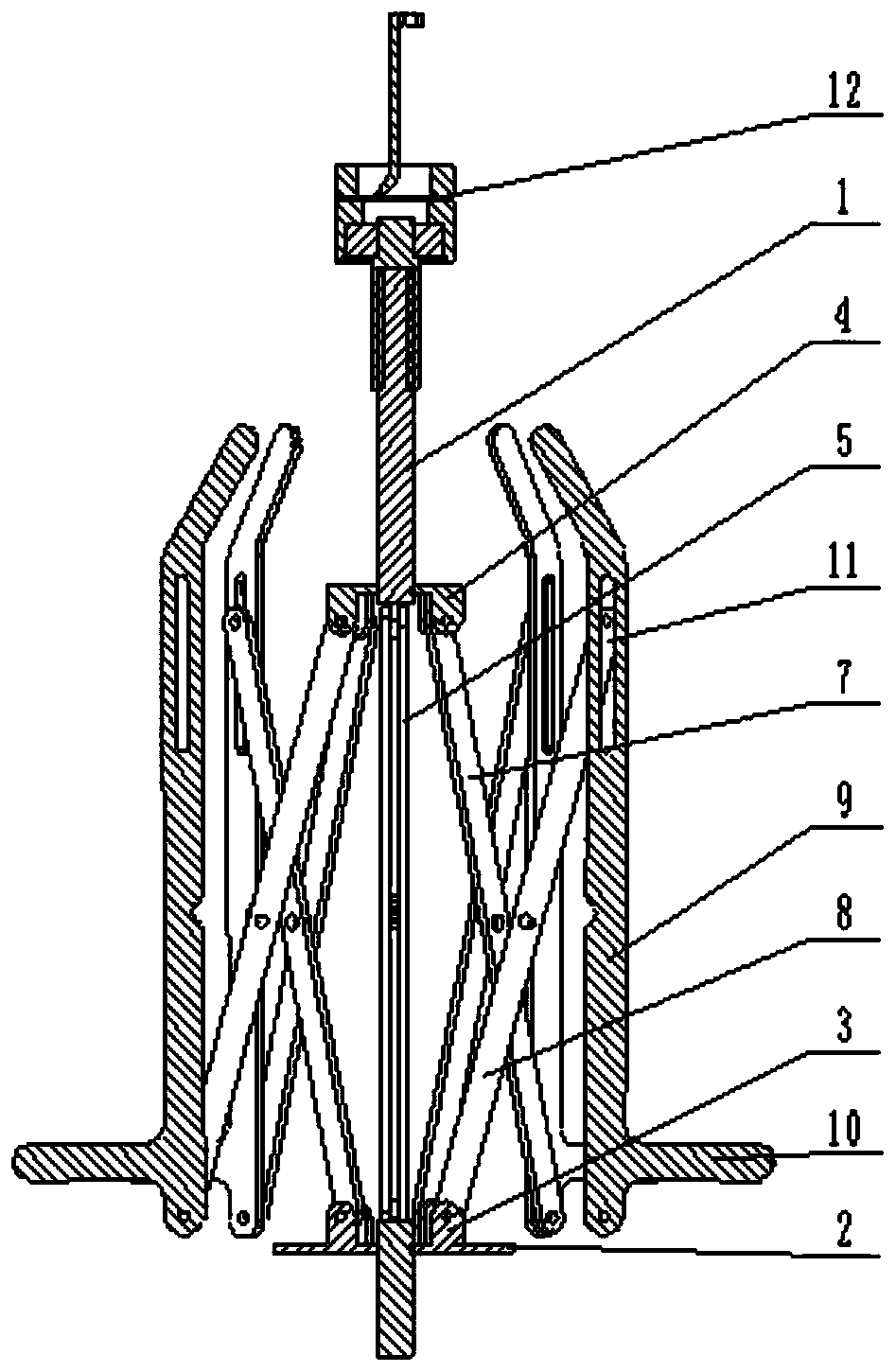

[0029] The specific implementation of the yarn supporter in the present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] Such as Figure 1-2 As shown, a yarn supporter for skein rewinding includes a vertically arranged main rod 1, a lower base 2 is movable at the bottom of the main rod 1, and an escape hole for passing through the main rod 1 is provided in the middle of the lower base 2. The upper side of the lower base 2 is evenly distributed with at least three groups of single ear seats 3 in the circumferential direction, the middle part of the main rod 1 is fixedly set with an upper base 4, and the lower side of the upper base 4 is uniformly distributed with the same number of single ear seats 2 on the lower base. Seat 3.

[0031] The main rod 1 is located between the upper base 4 and the lower base 2, and is provided with a compression spring 5 for pulling the lower base 2 in the direction of the upper base 4, and the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com