Glue overflowing wire automatic glue wiping machine after gluing of mobile terminal equipment display module

A device display and mobile terminal technology, which is applied in coatings, devices for coating liquid on the surface, etc., can solve the problem of manual wiping schemes that cannot accurately control wiping pressure, wiping time or wiping times, manual wiping has leakage, wiping dead ends, Unable to control the wiping effect, etc., to achieve high wiping efficiency, reduced glue wiping path, and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

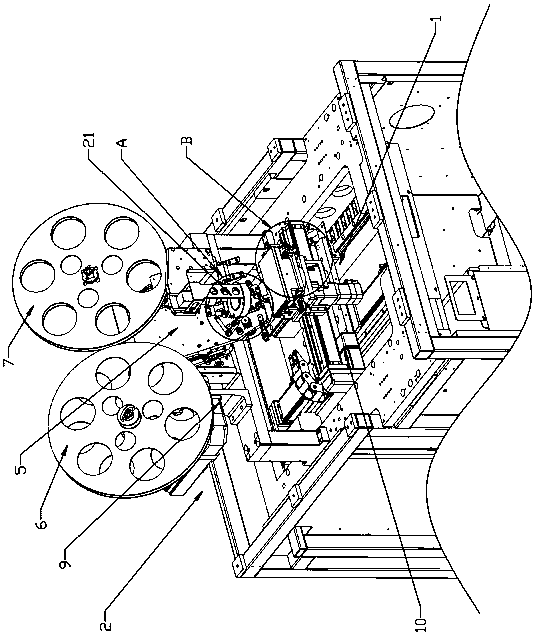

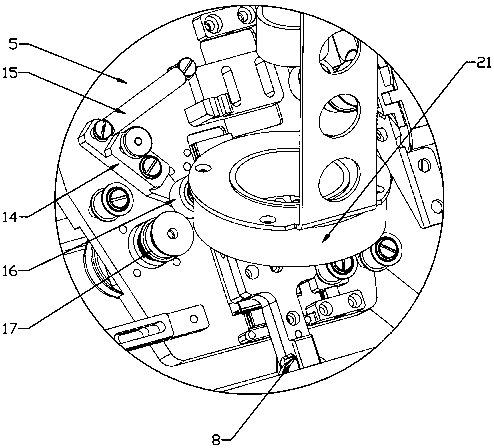

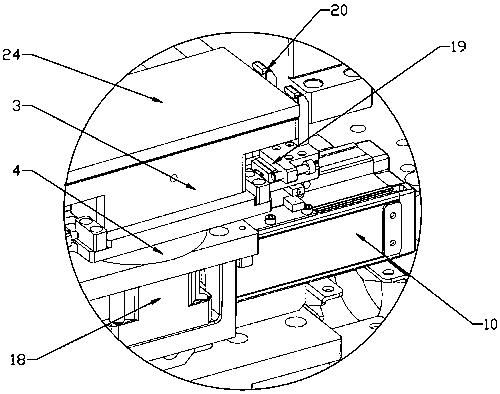

[0031] Such as Figure 1 to Figure 4 As shown, the specific embodiment of the present invention is: the present invention comprises carrier module 1, glue rubbing module 2 and the numerical control system of linear or rotary motion of driving device action parts, and described carrier module 1 includes carrier 3 and described The vertical rotation shaft 4 matched with the carrier 3, the glue wiping module 2 includes a mounting plate 5 arranged obliquely, the mounting plate 5 is aligned downward to the carrier 3, and the end of the mounting plate 5 A rubber rubbing wheel 8 is provided, and a winding wheel 6 and a discharge wheel 7 are respectively arranged on both sides of the mounting plate 5, and a material belt is connected between the winding wheel 6 and the discharge wheel 7, and the material The belt bypasses the rubber wiping wheel 8, and the glue wiping module 2 also includes a horizontal rotation shaft 9 matched with the mounting plate 5, and the axes of the vertical r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com