Surface defect detection equipment based on machine vision

A defect detection and machine vision technology, applied in the direction of optical testing defects/defects, instruments, measuring devices, etc., can solve the problems of film product image capture distortion, uneven film roll tension, film product warping and other problems, to achieve uniform flatness , Reduce production costs, avoid the effect of warping or denting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

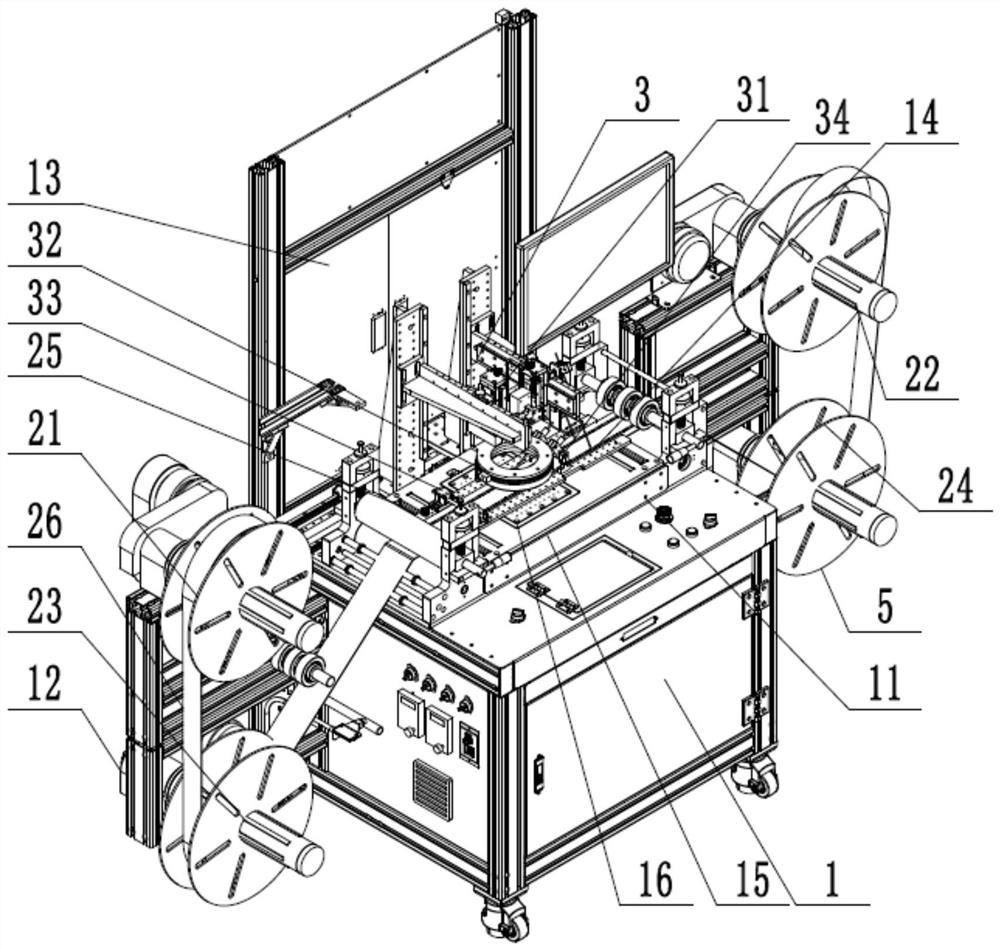

[0022] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

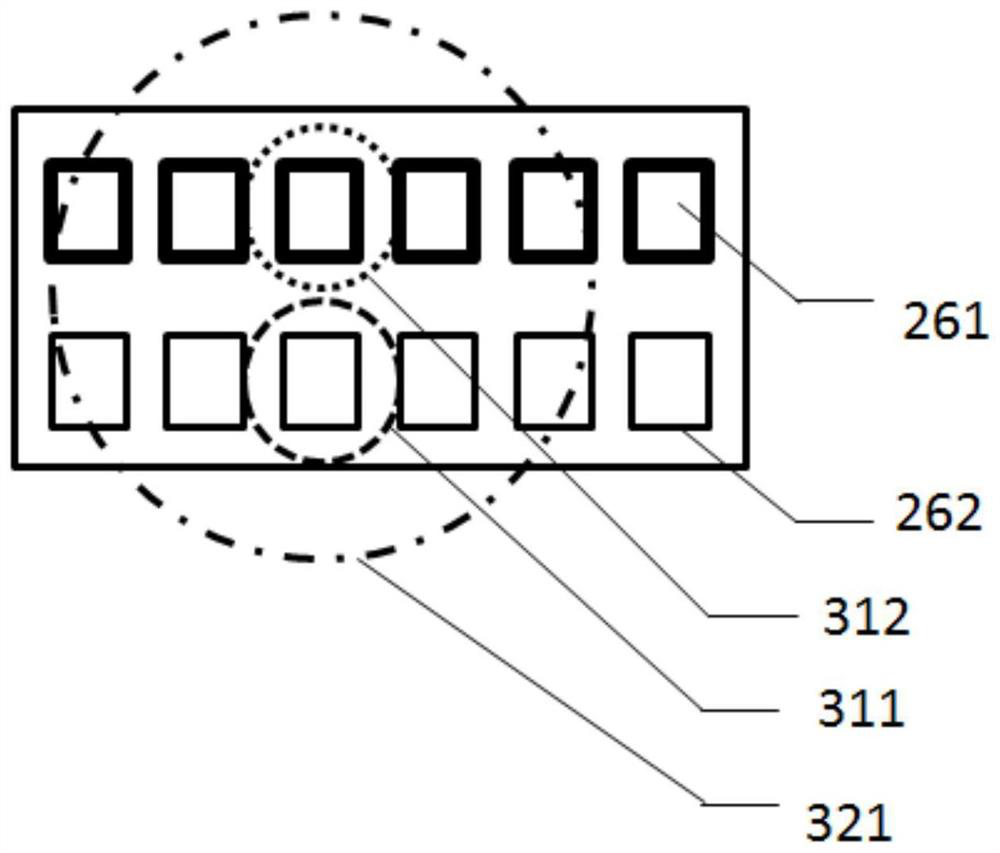

[0023] like figure 1 , 2 As shown, the technical solution adopted in the present invention is a machine vision-based surface defect detection device for surface defect detection of film roll 26, which includes carrier tape roll, film product and attached to the film roll 26. The release paper used to protect the film product on the carrier tape roll includes a frame 1, a film roll 26 assembly 2 for conveying the film roll 26 and a visual inspection system 3 for detecting the film roll 26, The frame 1 includes an operating table 11, side supports 12 arranged on both sides of the operating table 11 and an upper frame 13 arranged above the operating table 11, and the operating table 11 includes a detection area; The film roll 26 winding is used to transport the film roll 26, including the feeding roller 21, the release paper receiving roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com