High-temperature-resistant self-adhesive pure polyethylene protective film and preparation method thereof

A polyethylene protective film, high-density polyethylene technology, applied in chemical instruments and methods, flat products, other household appliances, etc., can solve the problems of easy delamination, high processing temperature, large temperature difference, etc., to improve uniformity and The effect of flatness, uniform flatness and uniform film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

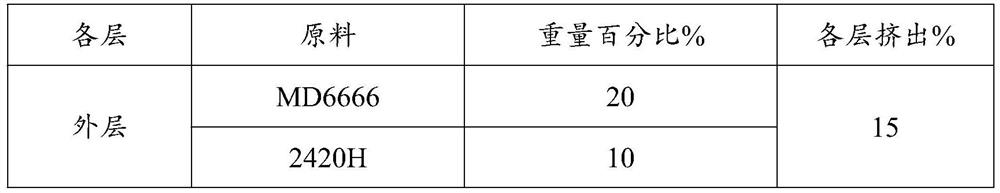

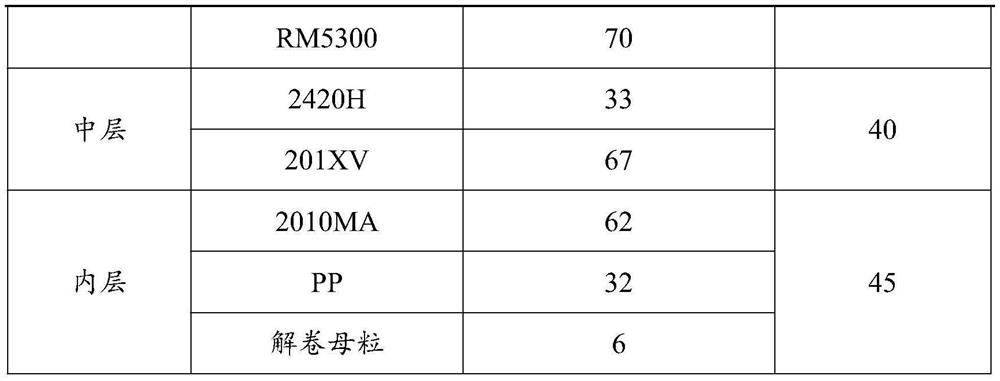

[0029] The raw materials for the preparation of the outer layer include: metallocene low-density polyethylene and polyolefin plastomer; the mass ratio of the metallocene low-density polyethylene and polyolefin plastomer is 4-8:2-6;

[0030] The preparation raw materials of the middle layer include: high-pressure low-density polyethylene, metallocene medium-density polyethylene and high-density polyethylene; the mass ratio of the high-pressure low-density polyethylene, metallocene medium-density polyethylene and high-density polyethylene is 1 ~4:3~8:2~5;

[0031] The raw materials for preparing the inner layer include: high-pressure low-density polyethylene and high-density polyethylene; the mass ratio of the high-pressure low-density polyethylene to high-density polyethylene is 5-16:4-25.

[0032] In the present invention, the outer layer is a self-adhesive layer; in the raw materials for the preparation of the outer layer, the mass ratio of metallocene low-density polyethylen...

Embodiment 1

[0054] The self-adhesive pure polyethylene protective film with a temperature resistance of 120°C prepared in this example has a three-layer structure, which is an outer layer, a middle layer and an inner layer, and the weight ratio of the outer layer, middle layer and inner layer is 8:65:27; The ingredients of each layer are as follows:

[0055] Outer layer: metallocene low density polyethylene 5210G, POP K8852G, the mass ratio of metallocene low density polyethylene to POP is 7.3:2.6;

[0056] Middle layer: high pressure low density polyethylene 450E, metallocene medium density polyethylene SP4020, high density polyethylene 5960G, the mass ratio of high pressure low density polyethylene, metallocene medium density polyethylene and high density polyethylene is 1.5:7.2:2.2;

[0057] Inner layer: High-pressure low-density polyethylene 450E, high-density polyethylene 5960G, the mass ratio of high-pressure low-density polyethylene to high-density polyethylene is 5.5:22.3;

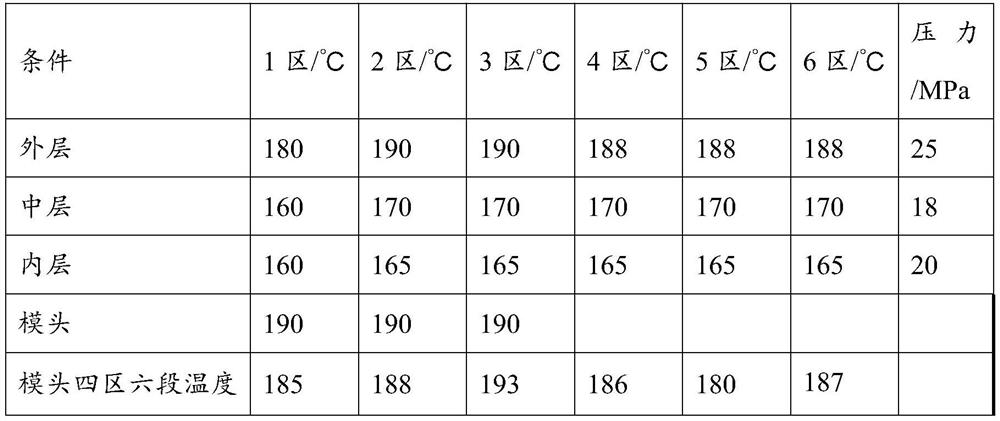

[005...

Embodiment 2

[0065] Change the extrusion mass ratio of the outer layer, middle layer and inner layer to 10:60:30, other conditions are consistent with Example 1, and the preparation method is the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com