Adjustable leveling guide rail and leveling method thereof

An adjustable, flat guide rail technology, applied in construction, building structure, construction material processing and other directions, can solve the problems of wasting materials, difficult to level, affecting construction, etc., to achieve convenient use and disassembly, and enhance the ease of operation. , to ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

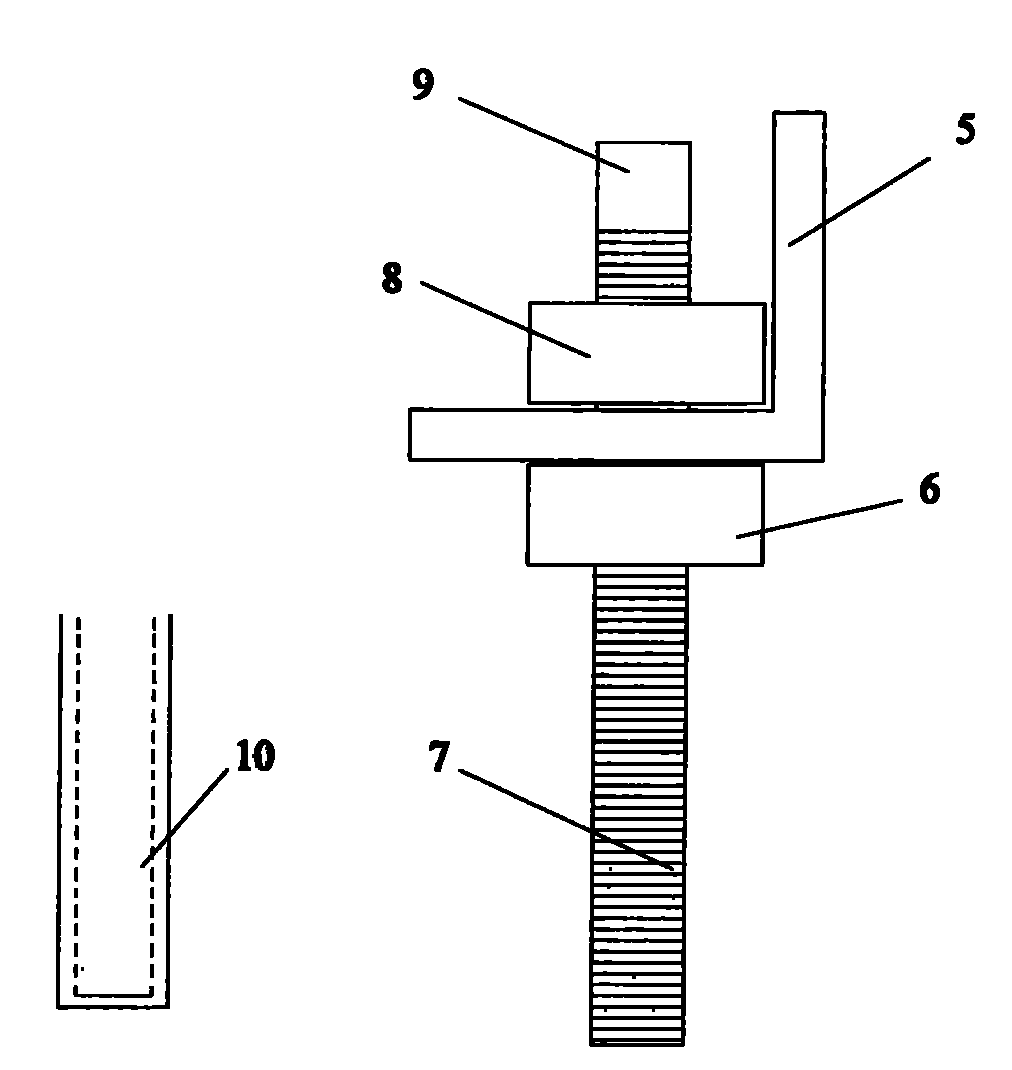

[0043] Figure 3 ~ Figure 4 shows the specific structure of this embodiment, such as image 3 As shown, the adjustable leveling guide rail includes a guide rail beam 5 and two supports, each support member includes a screw rod 7 and a nut, the screw rod 7 is connected with the guide rail beam 5 through a nut, and the end of the screw rod 7 is provided with Fixed block 9.

[0044] The fixed block 9 is integrally connected with the screw rod 7 and is an axial section at the upper end of the screw rod 7 . The fixing block 9 is hexagonal.

[0045] The supporting member also includes a locating member 10 , and the locating member 10 is matedly connected with the screw rod 7 . The positioning member 10 adopts an expansion bolt, and the lower section of the screw rod 7 is provided with threads, and the lower section of the screw rod is connected with the expansion bolt.

[0046] The section of the guide rail beam 5 is Shaped like Figure 5 (a) shown.

[0047] Such as image ...

Embodiment 2

[0059] This embodiment is the same as Embodiment 1 except for the following features: the adjustable leveling guide rail includes a guide rail beam and five supports, and the supports include positioning nuts, leveling nuts and screw rods, and the ends of the screw rods are provided with Fixed block. Such as Figure 7 As shown, the guide rail beam 5 is provided with five screw holes 11, and the screws pass through the screw holes and are connected with the guide rail beam through positioning nuts and leveling nuts.

[0060] The fixed block presents a quadrangular shape.

[0061] The positioning part adopts a screw sleeve.

Embodiment 3

[0063] This embodiment is the same as Embodiment 1 except the following features: the section of the guide rail beam is "]" or "I" shape, as shown in Figure (b) or Figure (c).

[0064] The fixing block is detachably connected to the screw rod, and the fixing block is engaged with the screw rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com