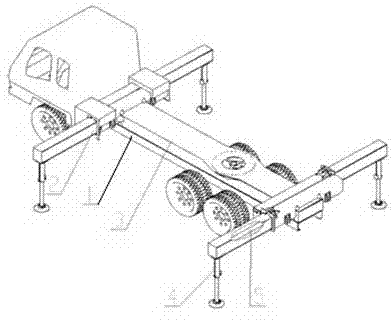

Chassis leveling system for mixture arm high-altitude operation vehicle

A high-altitude work vehicle and chassis technology, which is applied in vehicle maintenance, lifting vehicle accessories, transportation and packaging, etc., can solve the problem of inability to meet the needs of chassis leveling, and achieve the effect of improving leveling accuracy and leveling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

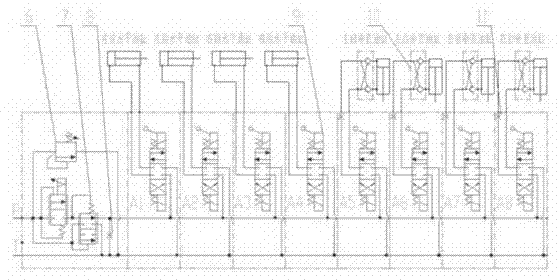

Method used

Image

Examples

Embodiment

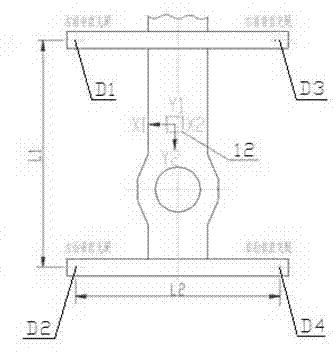

[0034] Example: such as image 3 As shown, the biaxial inclination sensor 12 judges the highest support point D1, the adjacent two low support points D2 and D3, the inclination angle in the Y1-Y2 direction measured by the biaxial inclination sensor 12 is α, and the inclination angle in the X1-X2 direction is β. The distance between point D1 and support point D2 is L1, and the distance between support point D1 and support point D3 is L2. According to the lifting and leveling method, the height of support point D2 needs to be raised h1=L1*sinα, the support point D3 needs to raise the height h2=L2*sinβ; the PLC controller will use the pre-stored formula to calculate the number of pulses n1 and n2 required for the support points D2 and D3 to raise h1 and h2. The calculation formula is: number of pulses n = hΔT, where: h represents the height that needs to be raised, and the unit is mm, and ΔT is a fixed pulse that produces a displacement of 1mm, and the time required for the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com