Leveling device for plastic films

A technology of leveling device and plastic film, which is applied in thin material processing, transportation and packaging, and winding strips, etc., can solve the problems of inability to level multi-layer plastic films and low leveling efficiency, and achieve convenient leveling work. , Improve the leveling efficiency, the effect of convenient contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

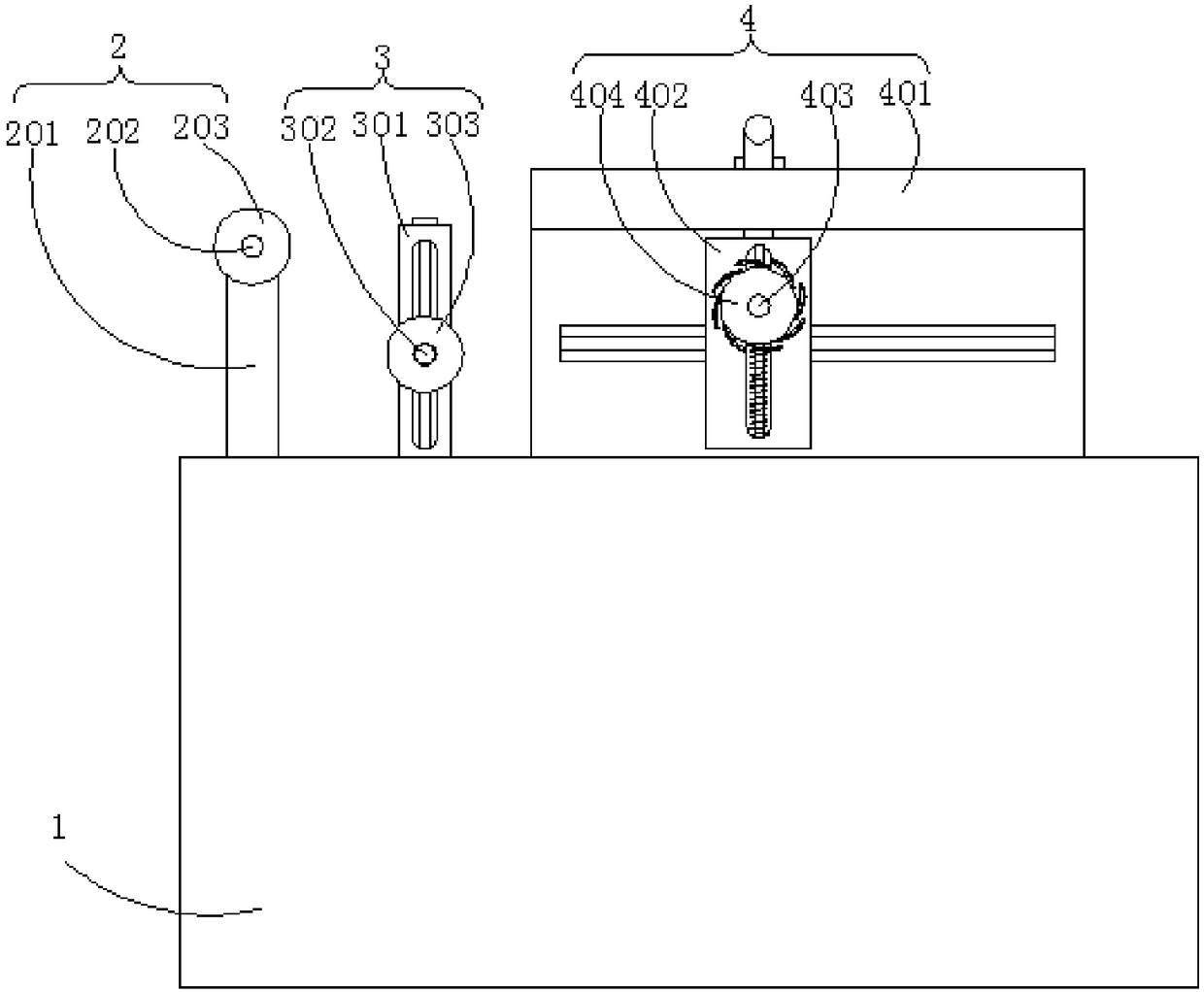

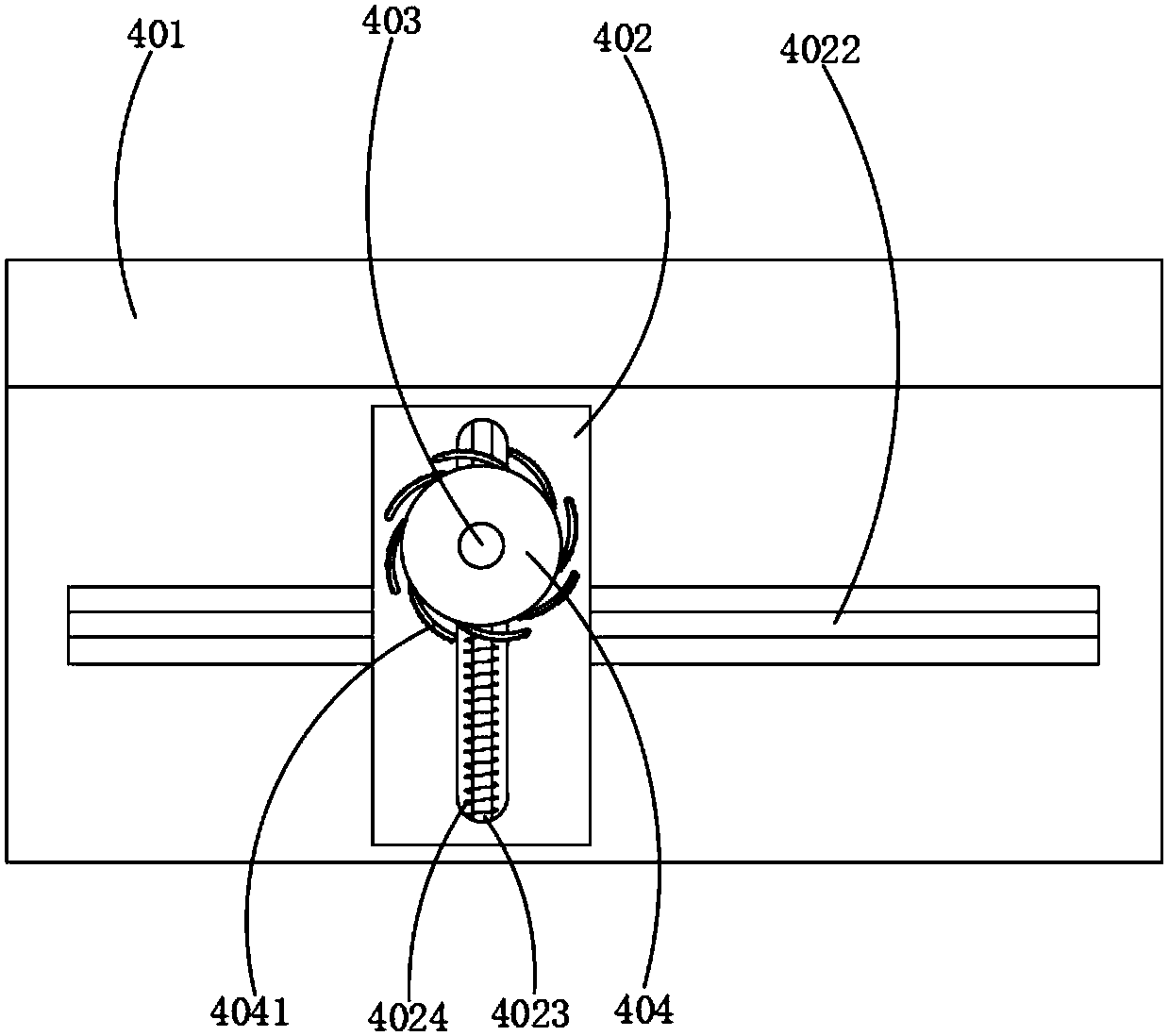

[0028] Embodiment 1: refer to Figure 1-5 , a flattening device for plastic film, including an operating table 1 arranged on one side of the film blowing machine discharge port, the upper side of the operating table 1 is provided with a support mechanism 2 and a pressing mechanism 3 from near to far from the film blowing machine , The leveling mechanism 4, the film blowing machine outlet, the support mechanism 2, the pressing mechanism 3, and the leveling mechanism 4 are located on the same straight line to ensure that the plastic film remains straight and prevent the plastic film from being bent and wrinkled.

[0029] The support mechanism 2 includes two symmetrically arranged first vertical plates 201 , and a supporting roller 203 is rotatably connected between the two first vertical plates 201 through a rotating shaft 202 .

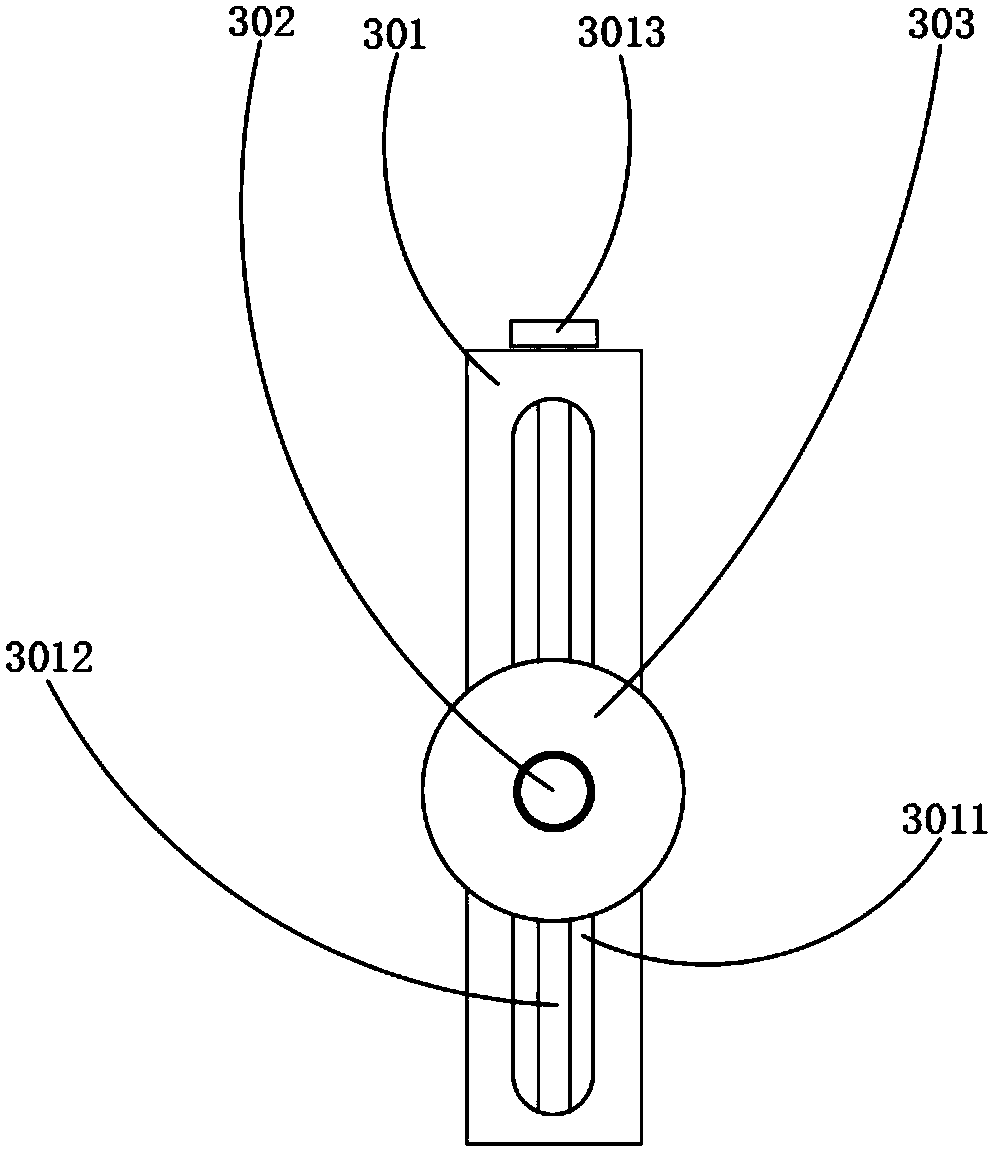

[0030] The pressing mechanism 3 includes two symmetrically arranged second vertical plates 301, between which the first connecting shaft 302 is rotata...

Embodiment 2

[0034] Embodiment 2: refer to Figure 2-8 , the present invention is applied to a plastic bag production equipment with the function of flattening plastic bags, including an operation table 1 arranged on the discharge port side of the film blowing machine, and the upper side of the operation table 1 is arranged in sequence from near to far from the film blowing machine There are supporting mechanism 2, pressing mechanism 3, leveling mechanism 4 and end tightening and fixing mechanism 5, film blowing machine outlet, supporting mechanism 2, pressing mechanism 3, leveling mechanism 4 and end tightening and fixing mechanism 5 are located on the same straight line to ensure that the plastic film remains straight and prevent the plastic film from bending to produce wrinkles.

[0035] The support mechanism 2 includes two symmetrically arranged first vertical plates 201 , and a supporting roller 203 is rotatably connected between the two first vertical plates 201 through a rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com