Apparatus and method for polishing semiconductor wafers

a technology of semiconductor wafers and polishing tools, applied in the direction of grinding machine components, manufacturing tools, lapping machines, etc., can solve the problem of greater operation cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

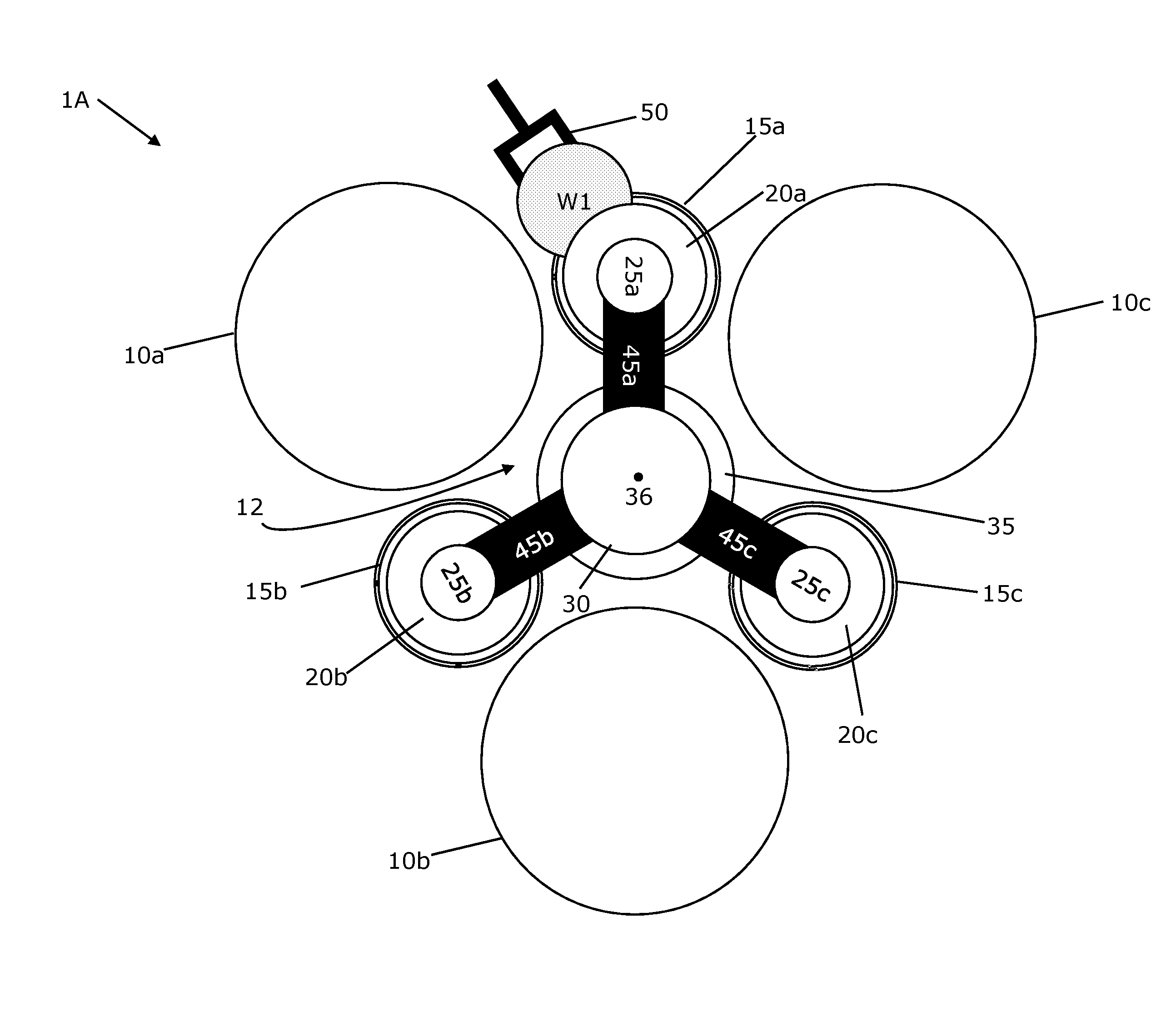

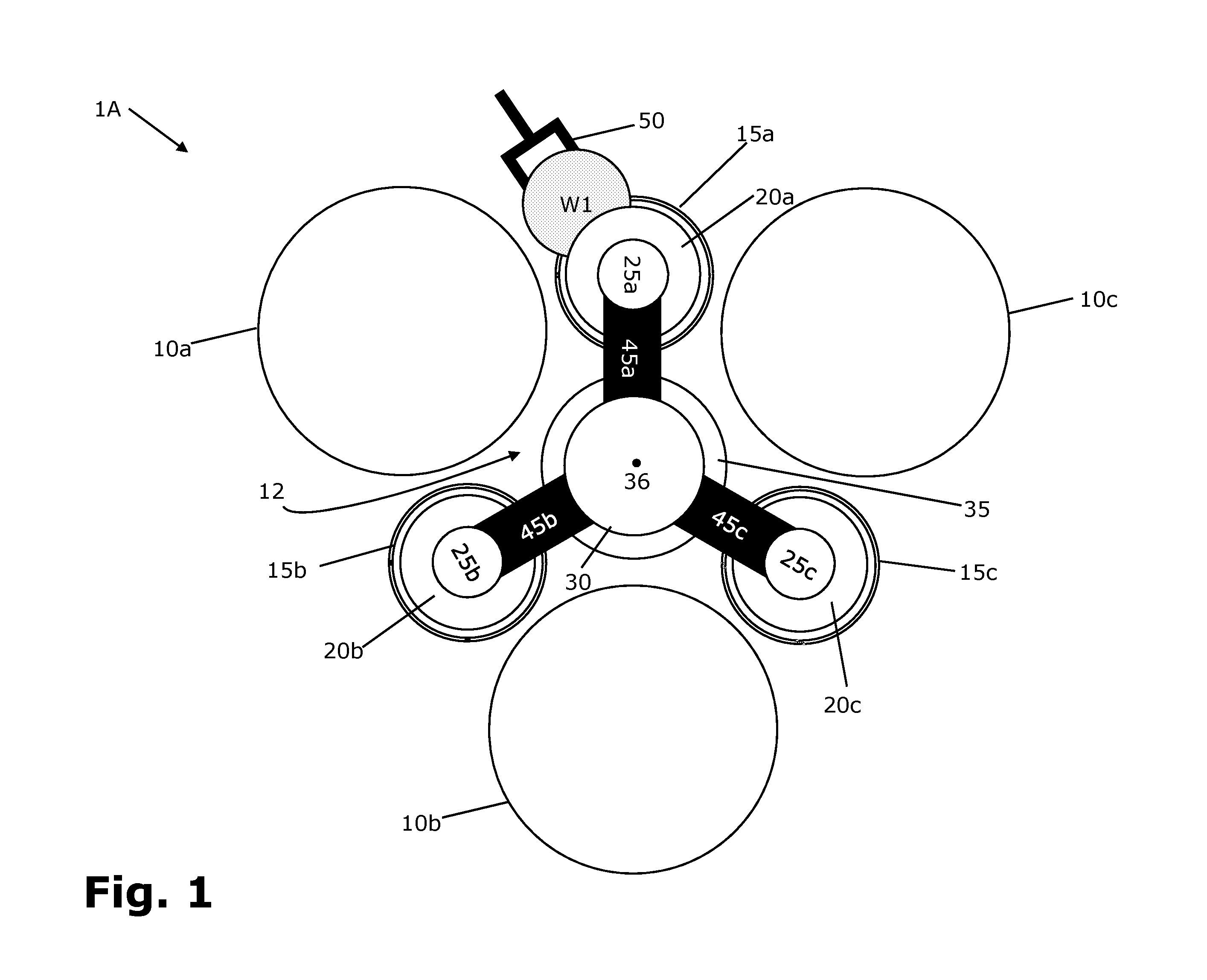

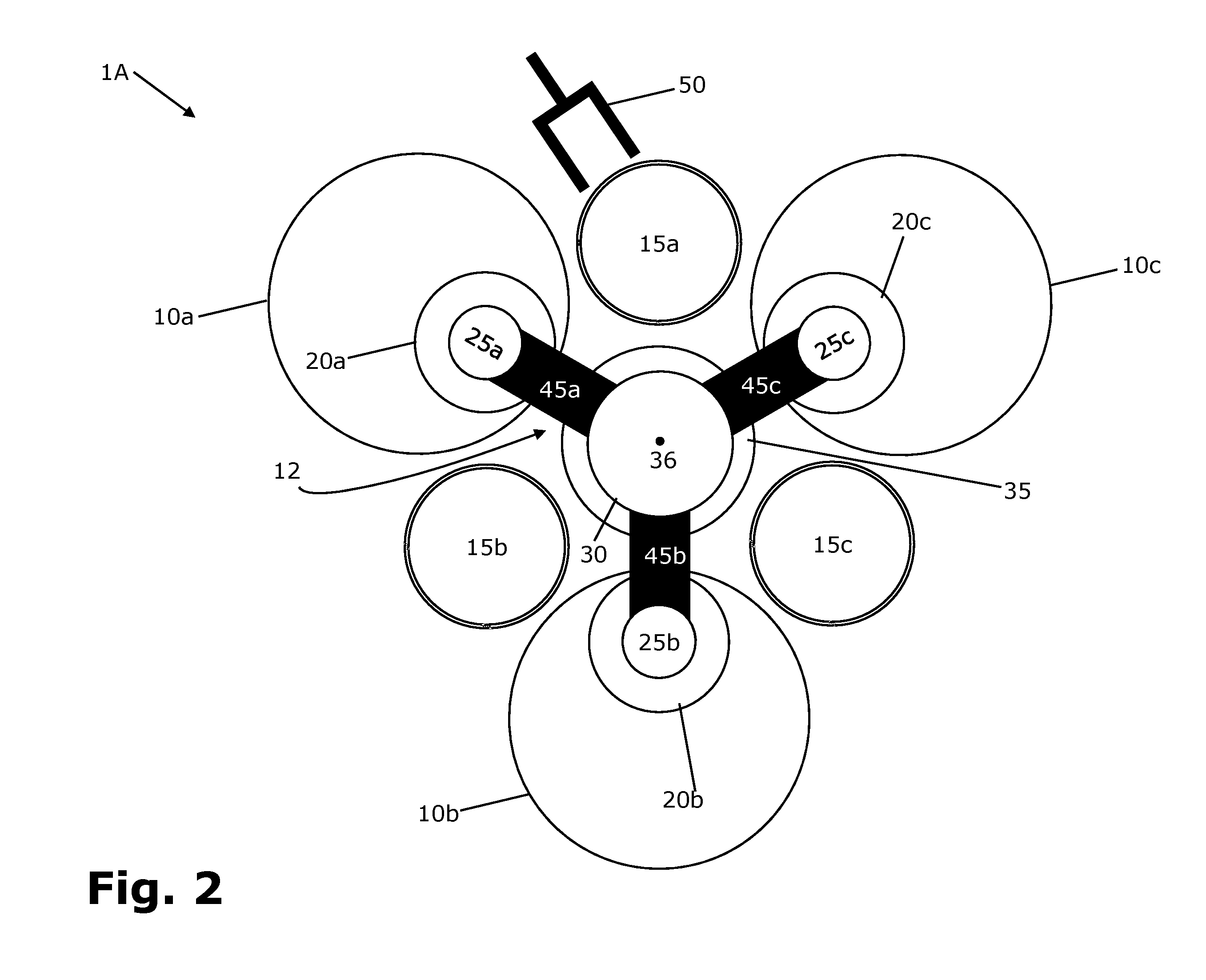

[0047]With reference to FIGS. 1-3, a polishing apparatus 1A according to an embodiment of the invention is described. The polishing apparatus 1A comprises three polishing surfaces 10a-10c, three polishing heads 20a-20c and three wafer load-unload stations 15a-15c. The polishing apparatus 1A can further comprise a wafer transfer device 50. The polishing apparatus 1A is capable of sequentially processing multiple semiconductor wafers, as described in more detail below.

[0048]FIG. 1 shows the polishing apparatus 1A when the first, second and third polishing heads 20a-20c are positioned over the first, second and third wafer load-unload stations 15a-15c, respectively. FIG. 2 shows the polishing apparatus 1A when the first, second and third polishing heads 20a-20c are positioned over the first, second and third polishing surfaces 10a-10c, respectively. FIG. 3 shows the polishing apparatus 1A when the first, second and third polishing heads 20a-20c are positioned over the second, third and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com