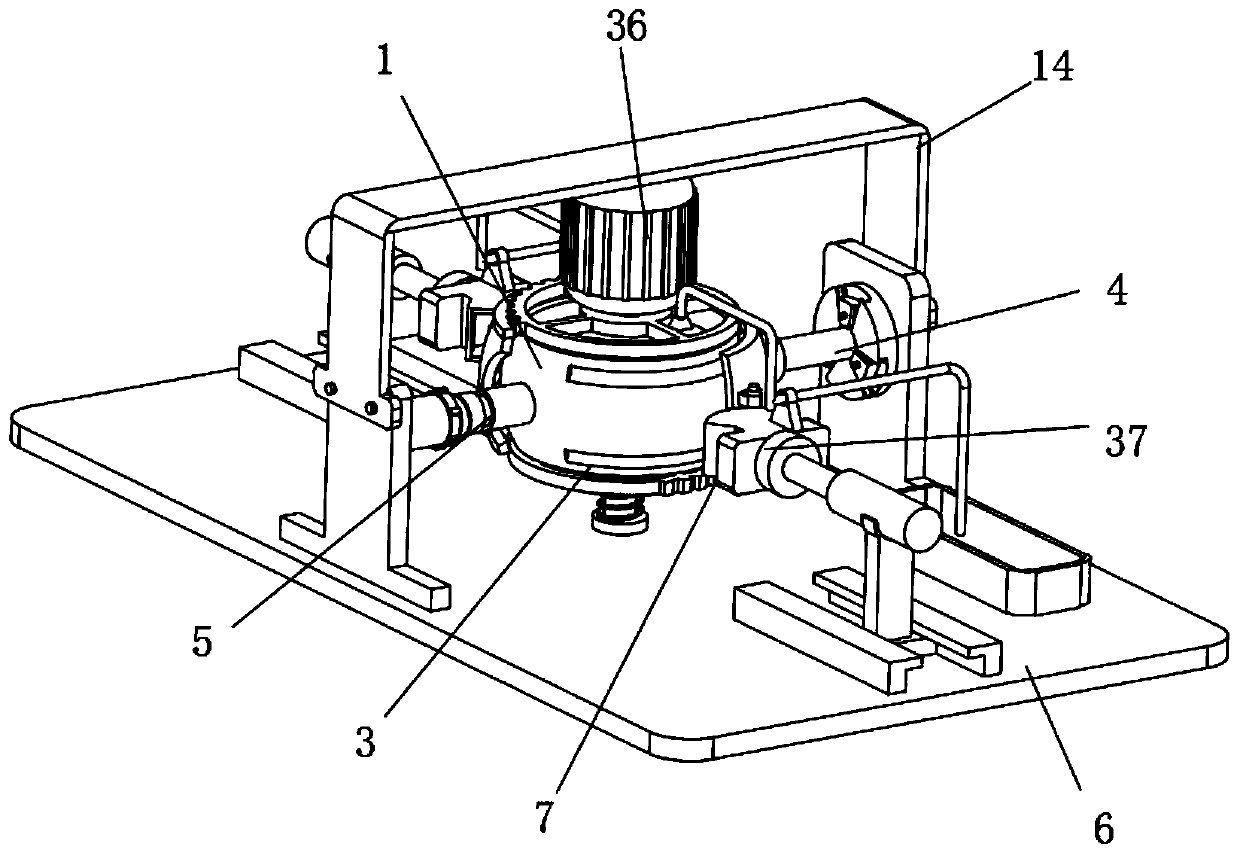

Ball valve and processing equipment thereof

A technology for processing equipment and ball valves, which is applied in the field of ball valves and their processing equipment, can solve the problems of inconvenient grinding at the same time, high grinding intensity, and easy slippage between the spherical edge and the sealing surface, and achieve the effect of improving the grinding efficiency and sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

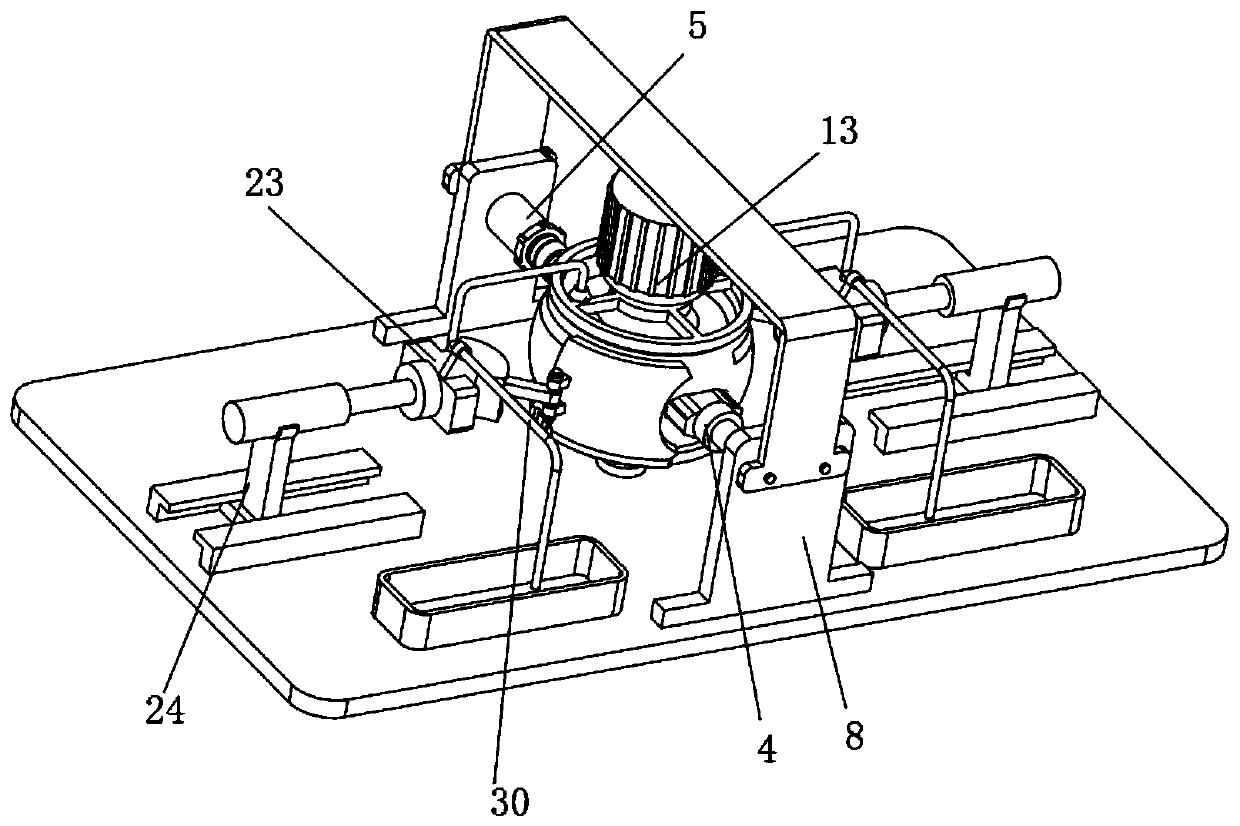

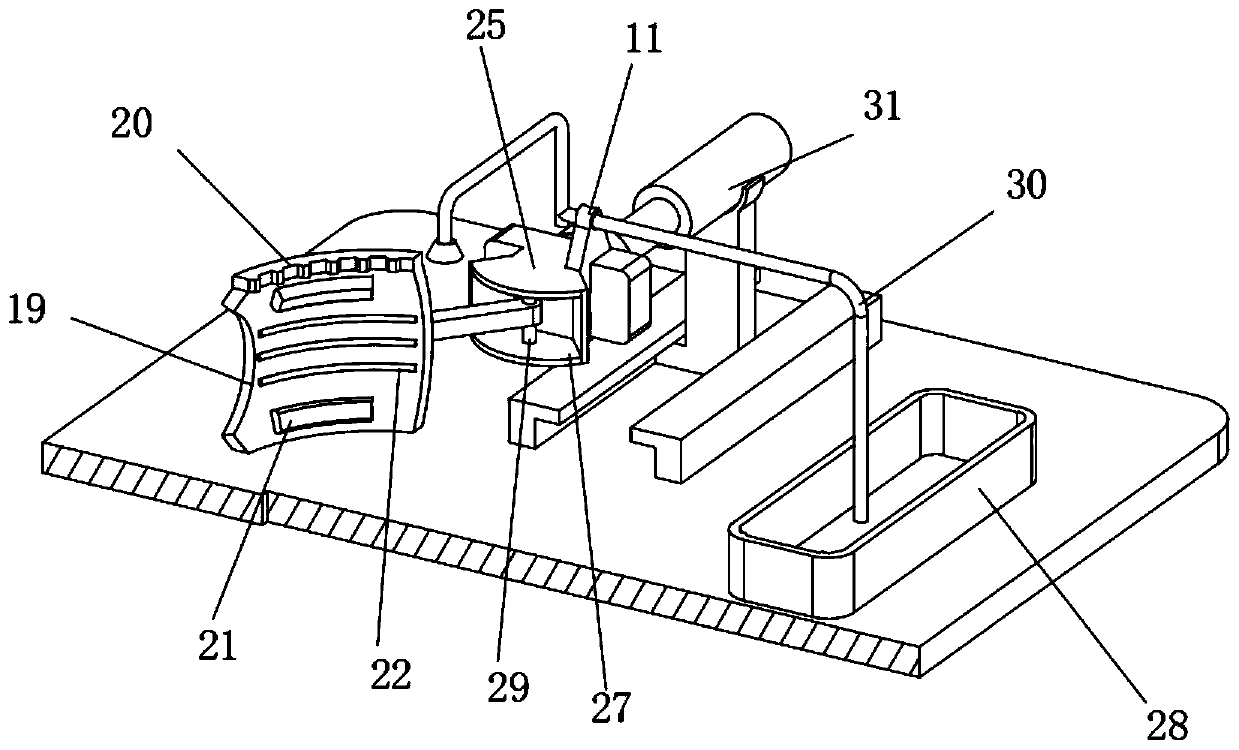

[0031] Specific implementation method: when the ball valve ball 1 is polished, after the ball valve ball 1 is installed on the workbench 6, by starting the cylinder 31, since the bottom of the cylinder 31 is socketed inside the chute 33 through the support seat 32, it can be adjusted according to the ball valve ball. 1. The diameter adjusts the position of the cylinder 31. Under the output power of the cylinder 31, the push plate 25 moves forward. At the same time, the push plate 25 is connected to the connecting plate 35 through the rotating shaft 29, and the connecting plate 35 is in contact with the contact plate 19. Because the contact plate 19 is a spherical arc surface, which is convenient to contact with the outside of the ball valve ball 1. When the friction groove bar 21 on the inner side of the contact plate 19 contacts with the sealing groove 3, the movement of the cylinder 31 is stopped. At this time, the grinding bar 22 on the contact plate 19 and The outer sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com