Processing method of high-quality frozen lotus root slices

A processing method and technology for freezing lotus, which are applied in the fields of freezing/refrigerating preservation of fruits/vegetables, food preservation, climate change adaptation, etc. problems, to achieve the effect of retention of sensory and nutritional indicators, good fresh-keeping quality, and little damage to tissue structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

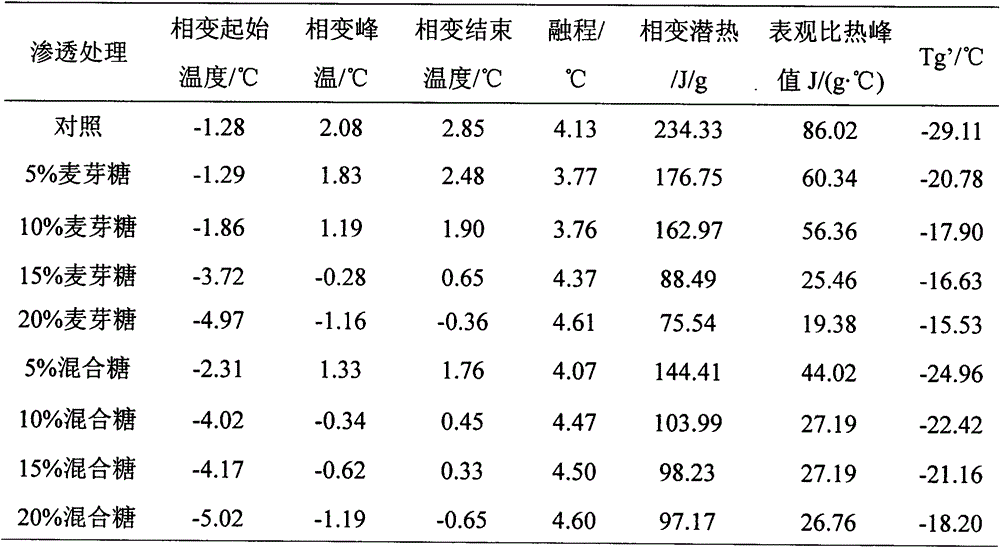

Embodiment 1

[0025] Select fresh, white, crisp and undamaged lotus roots, wash them, peel them, cut them into thin slices with a thickness of 4mm, and protect the color with a mixed solution of citric acid, Vc, and sodium hexametaphosphate for 30 minutes. The mass concentrations of the components are 0.4% citric acid, 2.0% Vc, and 0.2% sodium hexametaphosphate; the raw materials after color protection are added to a solution containing 0.1% citric acid, and microwave blanching is carried out for 60 seconds. The microwave power is 2450MHz, and the microwave power is 500W; the blanched lotus root slices are placed under a vacuum condition with a vacuum degree of 0.08-0.1MPa, and are infiltrated in a maltose conditioning solution with a mass concentration of 20% at 25°C for 30 minutes. The weight ratio to the conditioning solution is 1:2; the lotus root slices after vacuum infiltration are quickly frozen at -35°C until the center temperature of the lotus root slices reaches below -18°C. The f...

Embodiment 2

[0027] Select fresh, white, crisp and undamaged lotus roots, wash them, peel them, cut them into thin slices with a thickness of 5mm, and protect the color with a mixed solution of citric acid, Vc, and sodium hexametaphosphate for 30 minutes. The mass concentrations of the components are 0.4% citric acid, 2.0% Vc, and 0.2% sodium hexametaphosphate; the raw materials after color protection are added to a solution containing 0.1% citric acid, and microwave blanching is carried out for 40 seconds. The microwave power is 2450MHz, and the microwave power is 450W; the lotus root slices after blanching are placed under a vacuum condition with a vacuum degree of 0.08-0.1MPa, and at 25°C, the mass concentration is 10% maltose conditioning solution for osmosis treatment for 40 minutes, wherein the lotus root slices The weight ratio to the conditioning solution is 1:1.5; the lotus root slices after vacuum infiltration are quickly frozen at -30°C until the center temperature of the lotus r...

Embodiment 3

[0029] Select fresh, white, crisp and undamaged lotus roots, wash them, peel them, cut them into thin slices with a thickness of 6mm, and then use a mixed solution of citric acid, Vc, and sodium hexametaphosphate to protect the color for 30 minutes. The mass concentrations of the components are 0.4% citric acid, 2.0% Vc, and 0.2% sodium hexametaphosphate; the raw materials after color protection are added to a solution containing 0.1% citric acid, and microwave blanching is carried out for 80 seconds. The microwave power is 2450MHz, and the microwave power is 500W; the lotus root slices after blanching are placed under a vacuum condition with a vacuum degree of 0.08-0.1MPa, and are infiltrated in a maltose conditioning solution with a mass concentration of 20% at 25°C for 30 minutes, wherein the lotus root slices The weight ratio to the conditioning solution is 1:2; the lotus root slices after vacuum infiltration are quickly frozen at -40°C until the center temperature of the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com