Method for preparing ceramic sheet

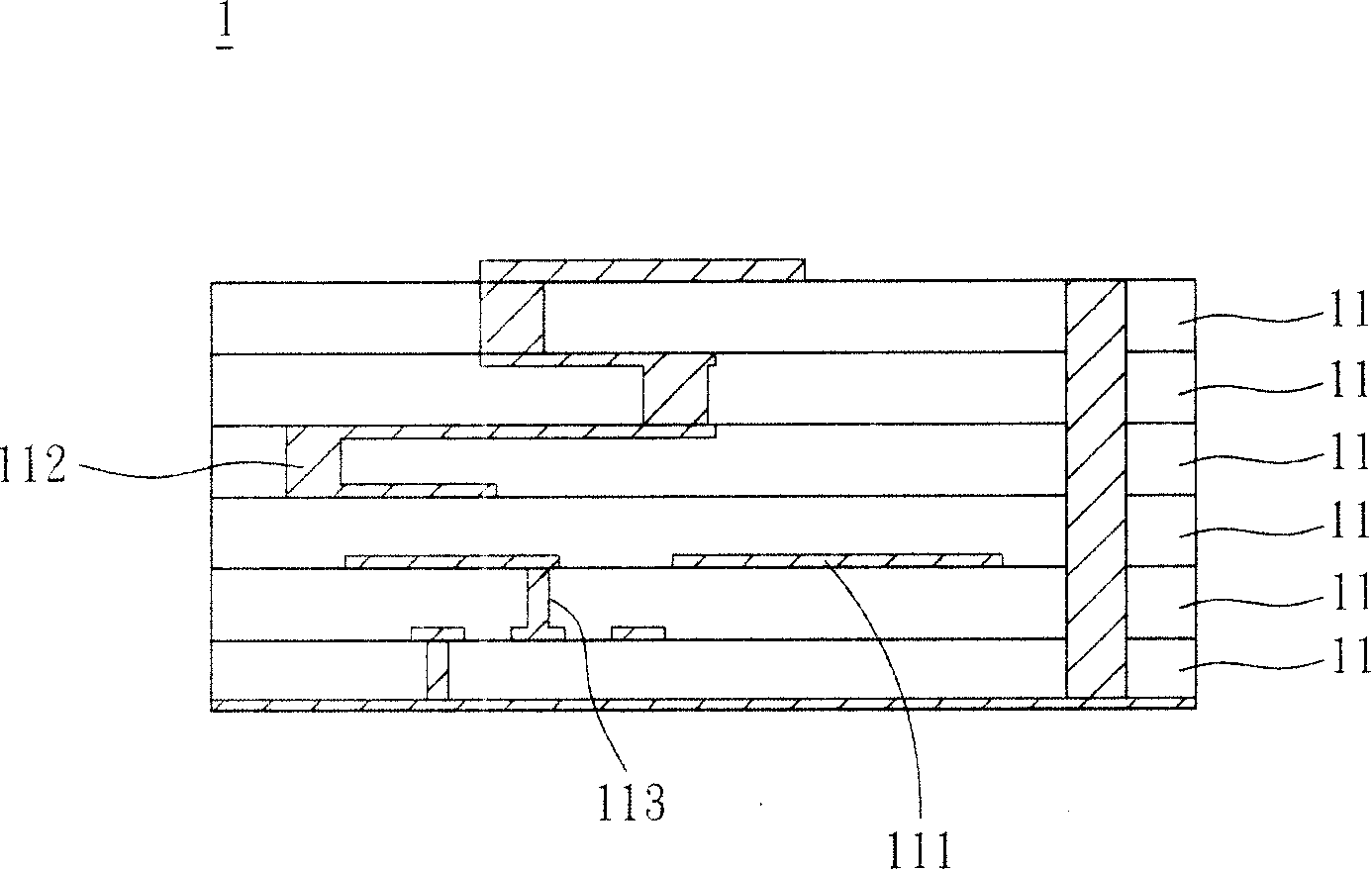

A manufacturing method and technology of ceramic thin plates, applied in the direction of manufacturing tools, ceramic molding machines, ceramic layered products, etc., can solve the distortion and warping of ceramic thin plates 11, which is not suitable for mass production of tunnel kilns, and affects low-temperature co-fired ceramics Substrate 1 yield and reliability issues, to achieve good densification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A method for manufacturing a thin ceramic plate according to a preferred embodiment of the present invention will be described below with reference to related drawings, wherein the same elements will be described with the same reference symbols.

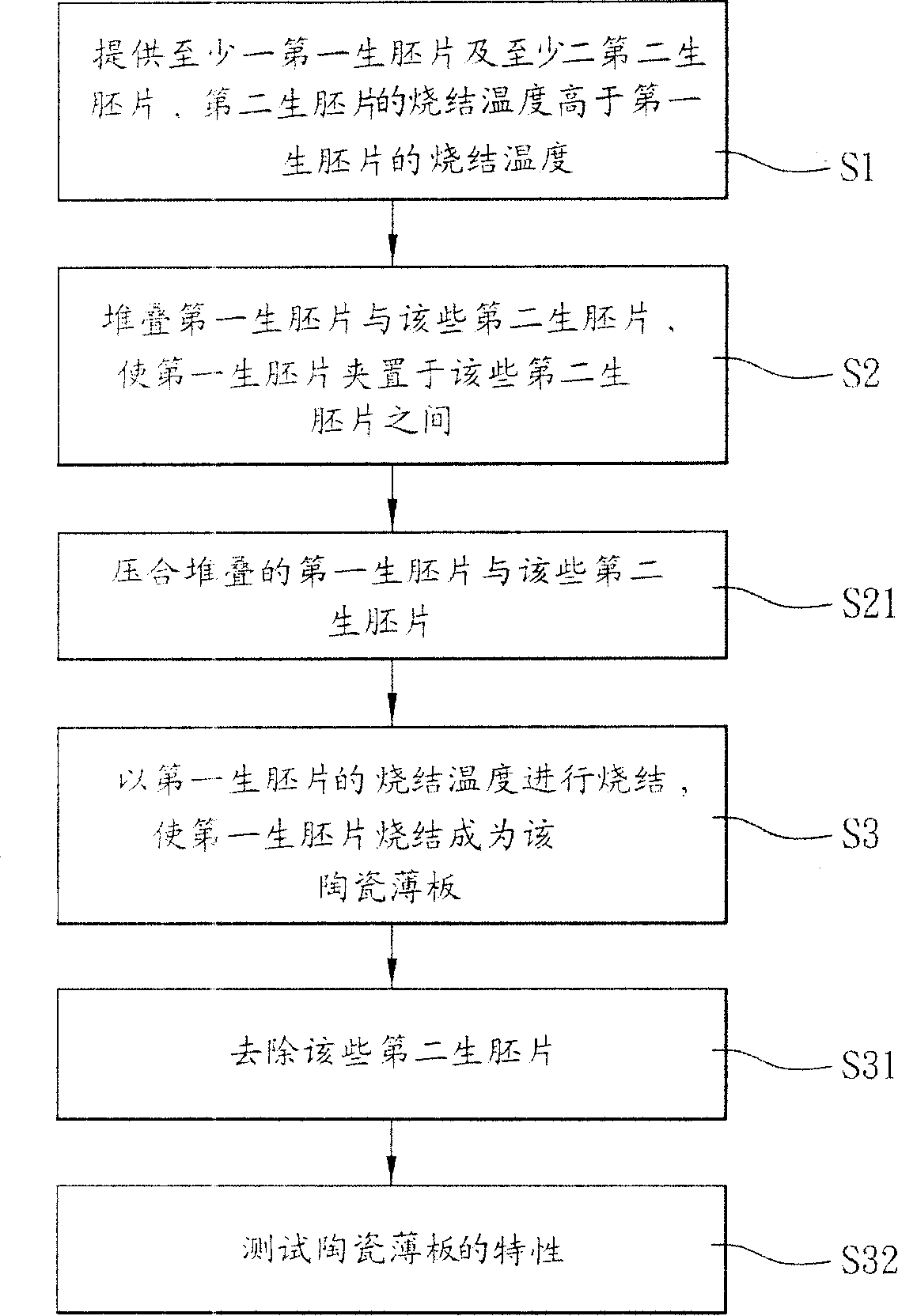

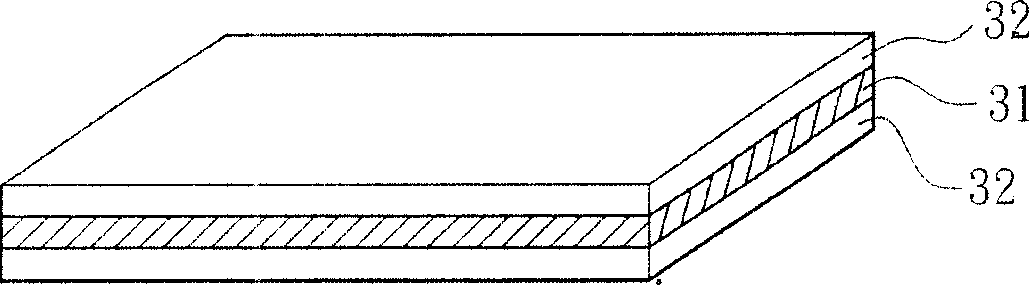

[0025] Please refer to figure 2 and image 3 As shown, a method for manufacturing a thin ceramic plate according to a preferred embodiment of the present invention includes steps S1 to S3. Step S1 provides at least one first green sheet 31 and at least two second green sheets 32, the sintering temperature of the second green sheet 32 is higher than the sintering temperature of the first green sheet 31; step S2 stacks the first green sheet 31 and the second green sheets 32 , so that the first green sheets 31 are sandwiched between the second green sheets 32 ; Step S3 is sintering at a sintering temperature of the first green sheets 31 . Because the sintering temperature is not higher than the sintering temperature of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com