Composite optical film structure with multiple coatings

A multi-layer coating, composite technology, applied in optics, optical components, layered products, etc., can solve problems such as decrease in light transmittance, variation in dispersion uniformity of diffused particles, loss of optical properties of composite optical films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

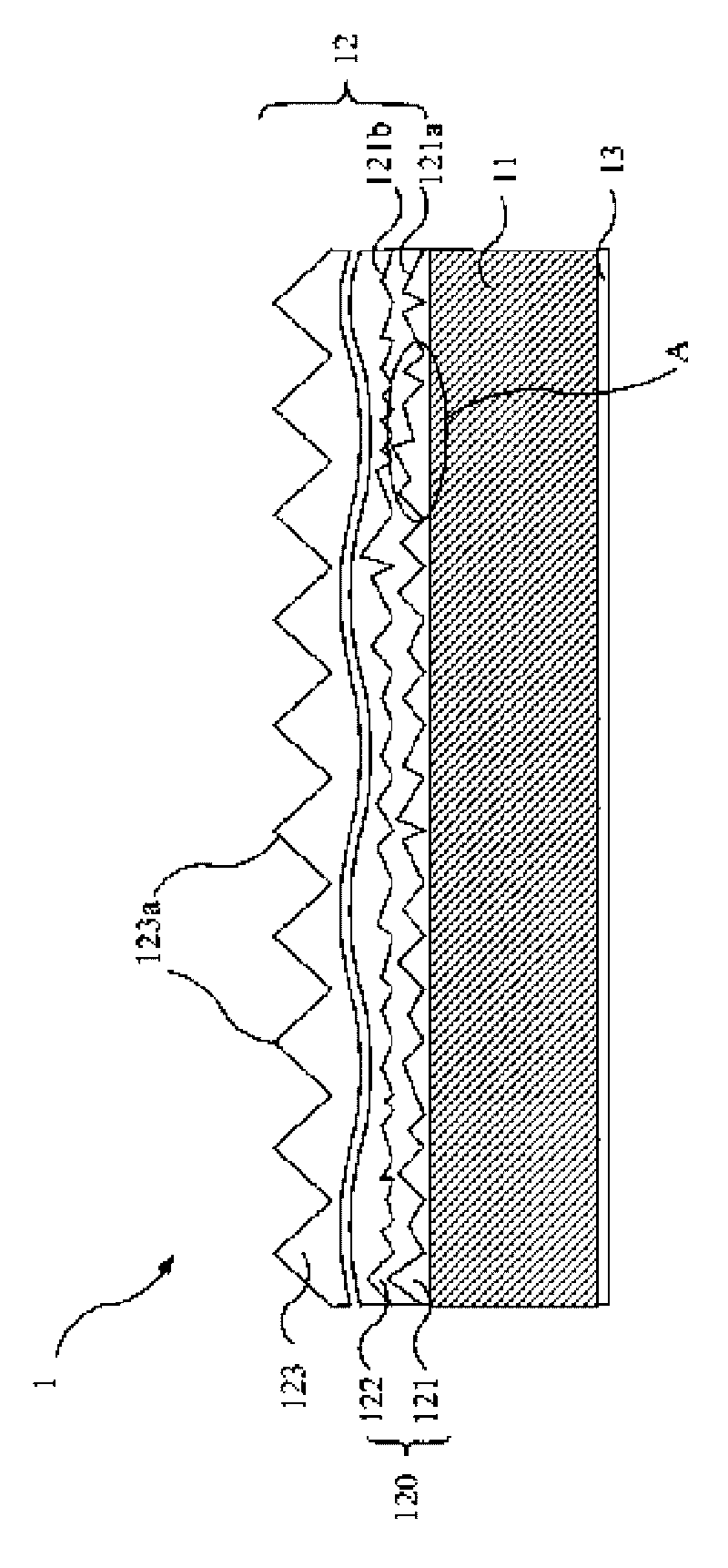

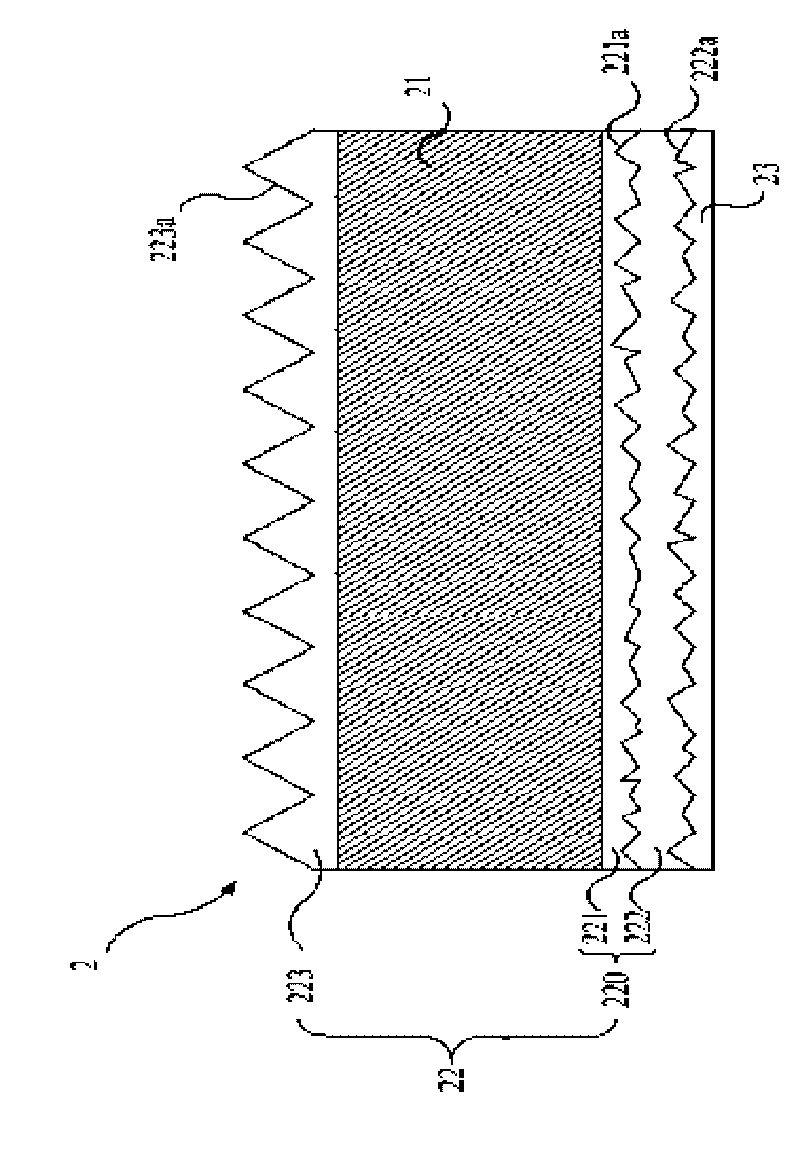

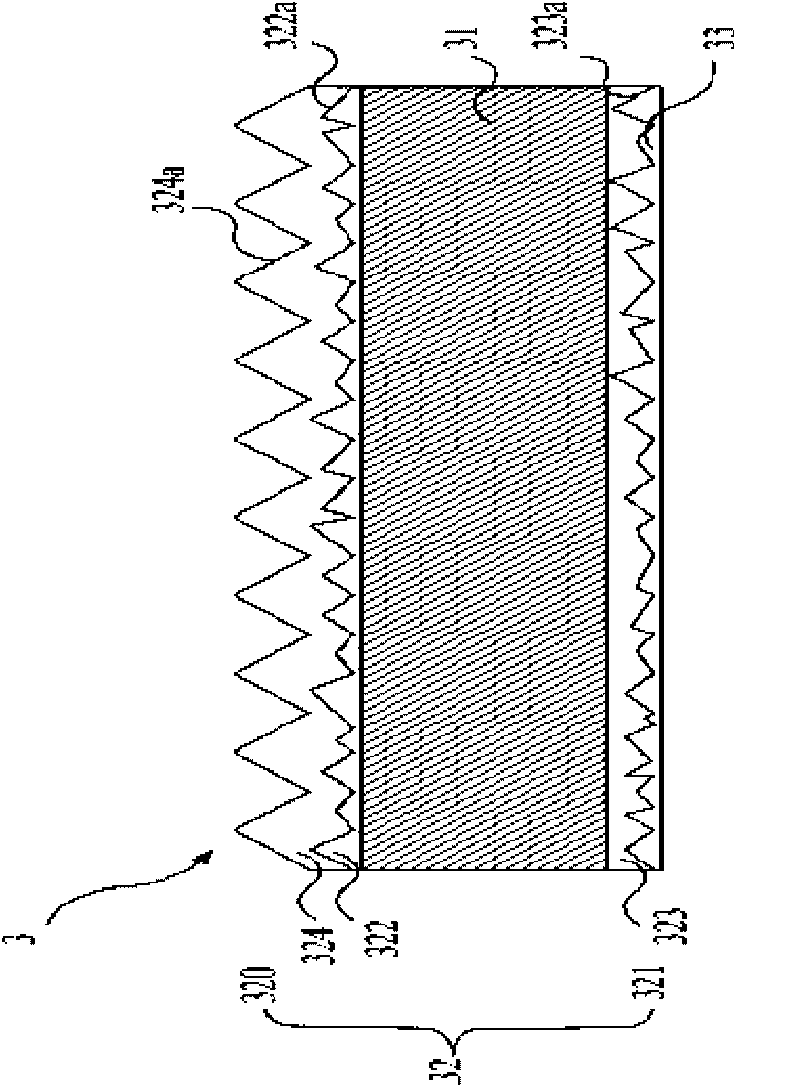

[0042] The invention is a multi-layer coated composite optical film structure, which is characterized in that a diffusion layer with an interface microstructure is used as a light diffusion mechanism. The present invention is a material that utilizes multi-layer coating technology, interfaces control (Interface-Dominating) microstructure (Microstructure) design of the diffusion layer, and is equipped with an effective difference in refractive index between coating layers to obtain a light-diffusing effect, and In terms of structural mechanism, the light-collecting microstructure on the outermost layer is also used to concentrate the scattered light, so as to increase the luminance value of the front viewing angle (On-axis). There are no special restrictions on the microstructure design of the above-mentioned interface control, such as but not limited to random interface microstructure design, and in the following examples, the roughness value (Ra) of the interface microstructur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness value | aaaaa | aaaaa |

| Roughness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com