Preparation method for cold rolling sheet of duriron

A high-silicon steel and thin plate technology, applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of not being suitable for mass production, etc., and achieve the effects of broad market application prospects, excellent soft magnetic properties, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

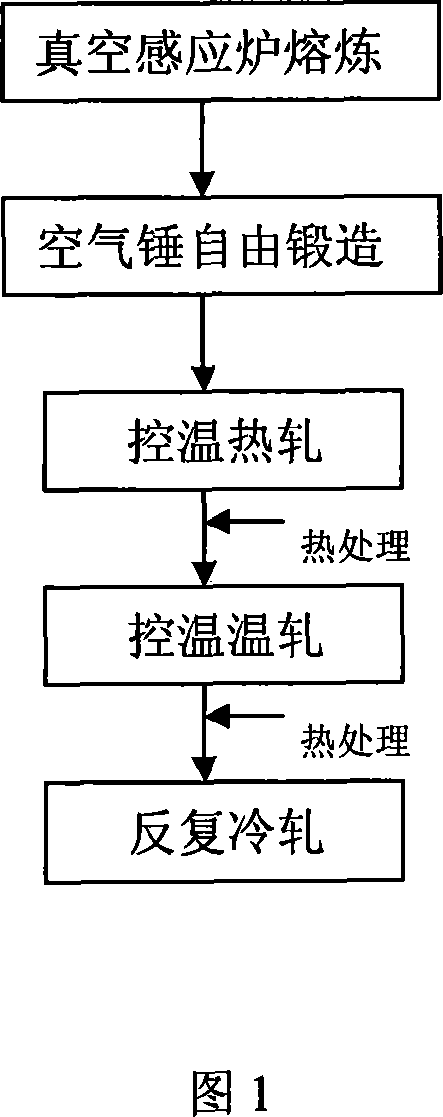

Method used

Image

Examples

Embodiment 1

[0028] For high-silicon steel containing 4.5% silicon and 200ppm boron, the raw material is smelted in an intermediate frequency vacuum induction furnace, and the casting temperature is 1530°C. The ingot is then free forged, the initial forging temperature is 1200°C, and the final forging temperature is 900°C. The ingot is heated up with the furnace to prevent cracks from thermal stress.

[0029] After forging, the thickness of the slab is 20mm, followed by hot rolling, the hot rolling start temperature is 1200°C, and the finish rolling temperature is 700°C. The slab is hot rolled to 1.5mm. The obtained hot-rolled sheet is subjected to heat treatment, the heat treatment temperature is 900° C., the holding time is 1 hour, and the water is cooled.

[0030] After the treated hot-rolled sheet was pickled, it was subjected to steady rolling, the rolling start temperature was 500° C., the final rolling temperature was 150° C., and the reduction was 30% per pass to obtain a 0.3 mm w...

Embodiment 2

[0033] For high-silicon steel containing 5.8% silicon and 600ppm boron, the raw material is smelted in an intermediate frequency vacuum induction furnace, and the casting temperature is 1500°C. The ingot is then free forged, with an initial forging temperature of 1200°C and a final forging temperature of 850°C. The ingot is heated up with the furnace to prevent cracks from thermal stress.

[0034] After forging, a slab with a thickness of 20mm is obtained, and then hot rolled, the hot rolling start temperature is 1200°C, the finish rolling temperature is 650°C, and the slab is hot rolled to 1.5mm. The obtained hot-rolled sheet is subjected to heat treatment, the heat treatment temperature is 900° C., the holding time is 2 hours, and the water is cooled.

[0035]After the treated hot-rolled sheet is pickled, it is warm-rolled. The rolling start temperature was 650°C, the final rolling temperature was 200°C, and the reduction was 25% per pass to obtain a 0.3mm warm rolled sheet...

Embodiment 3

[0038] For high-silicon steel containing 6.5% silicon and 1000ppm boron, the raw material is smelted in an intermediate frequency vacuum induction furnace, and the casting temperature is 1480°C. The ingots are then free forged, with a starting forging temperature of 1100°C and a final forging temperature of 850°C. The forged ingots are heated up with the furnace to prevent cracks from thermal stress.

[0039] After forging, a slab with a thickness of 20mm was obtained, and then hot rolled, the hot rolling start temperature was 1150°C, and the finish rolling temperature was 650°C. The slab is hot rolled to 1mm. The obtained hot-rolled plate is subjected to heat treatment, the heat treatment temperature is 900° C., the holding time is 2 hours, and the brine is cooled.

[0040] After the treated hot-rolled sheet is pickled, it is warm-rolled. The rolling start temperature was 650°C, the final rolling temperature was 250°C, and the reduction was 25% per pass to obtain a 0.3mm wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com