Method for preparing molybdenum-rhenium alloy foil

A molybdenum-rhenium alloy and foil technology, which is applied in the field of preparation of high-molybdenum-rhenium alloy foil, can solve the problems of less research on the preparation process of high-molybdenum-rhenium alloy and no production process has been developed, and achieves simple production and processing technology method, The effect of eliminating work hardening and avoiding contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The features and advantages of the present invention will be described in detail below by means of embodiments, but the present invention is not limited thereto.

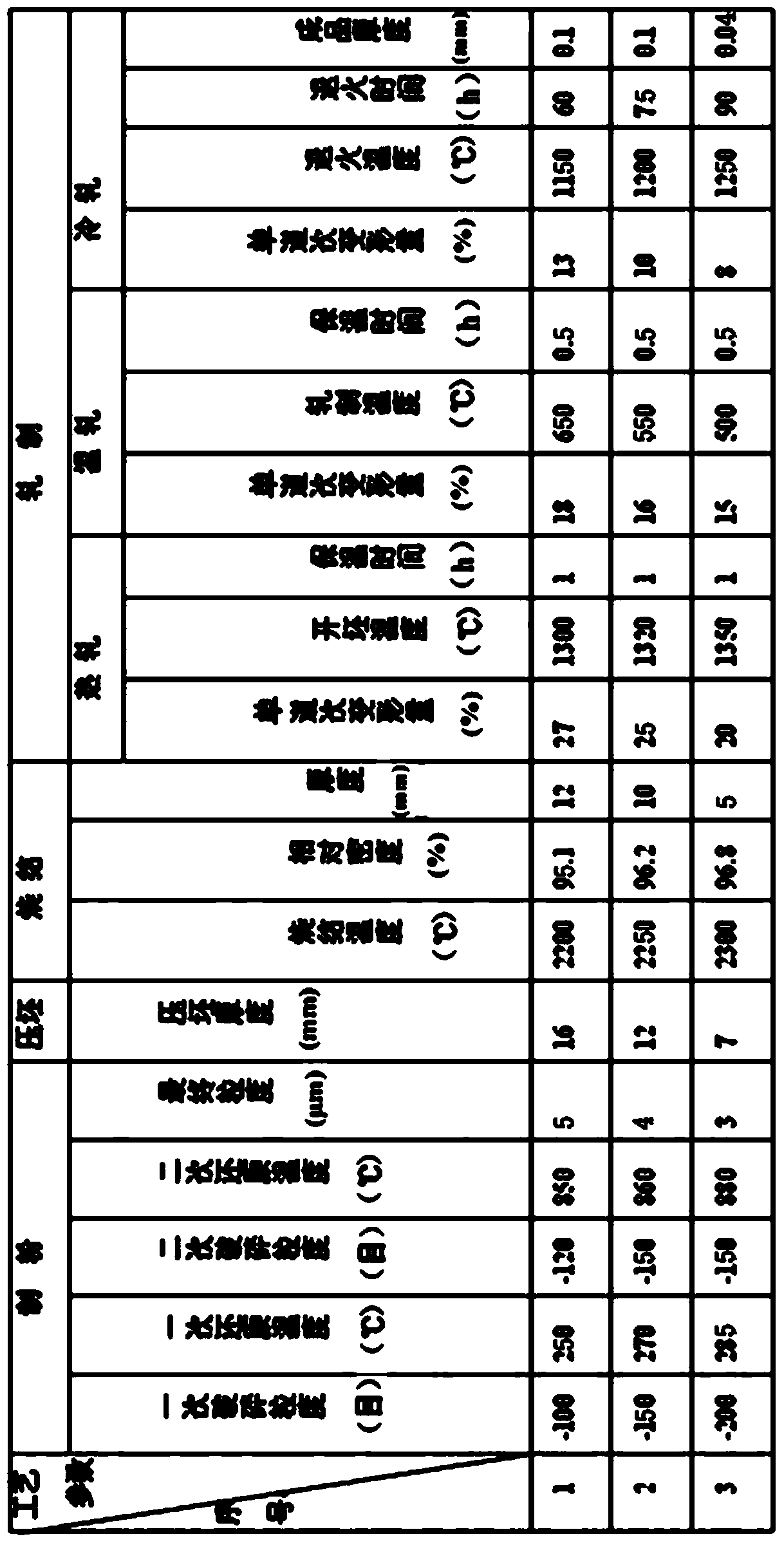

[0021] Three batches of molybdenum-rhenium alloy plates and foils with different rhenium contents have been prepared by the above method. Table 1 shows the specific preparation process steps and process parameters of the three batches of molybdenum-rhenium alloy foils. Table 2 shows the correlation of the obtained three batches of alloy materials. performance data. Among them, the rhenium content in the first batch of molybdenum-rhenium alloy materials is 5wt%, the rhenium content in the second batch of molybdenum-rhenium alloy materials is 35wt%, and the rhenium content in the third batch of molybdenum-rhenium alloy materials is 50wt%.

[0022] In a nutshell, the preparation methods of the above three batches of molybdenum-rhenium alloy plates and foils are as follows:

[0023] 1) According to the distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com