Annealing method for high-speed steel cold-drawing wire products

A technology of high-speed tool steel and cold-drawn steel wire, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of slow heat transfer and heating, affecting production progress, low production efficiency, etc., to improve production efficiency and reduce energy consumption. , the effect of improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

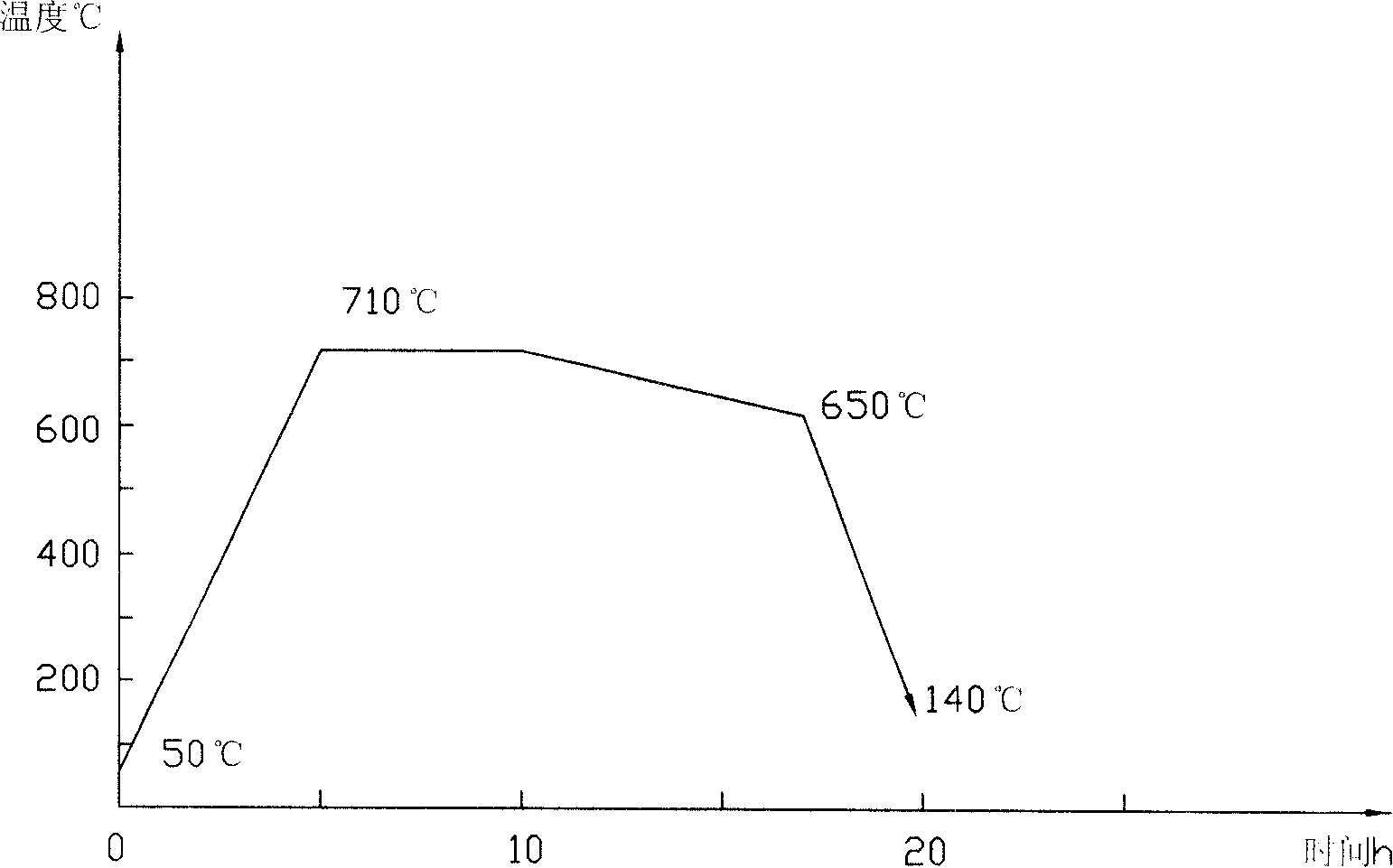

[0037] Put the disk into a strong convection annealing furnace, cover it with a heating mantle, and carry out nitrogen purge; use nitrogen for atmosphere protection during the annealing process; heat it up to 710-730°C for 6-8 hours as the furnace heats up, and then heat it at ≤30°C / After slowly cooling to a temperature below 650°C at a cooling rate of h, remove the heating mantle, and use a cooling mantle to cool to a temperature below 140°C at a cooling rate faster than 100°C / h. During the annealing process, purified nitrogen is used for atmosphere protection. The dew point of nitrogen is ≤-60°C and the oxygen content is ≤5ppm to prevent surface oxidation and decarburization of the finished product. Nitrogen purging process: 30~40m 3 / h purge for 3 to 4 hours; 10 to 20m 3 / h purging for 1 to 2 hours.

[0038]Loading method: In view of the actual charging situation of the current strong convection furnace, when placing the material rack for the furnace steel type, slightly...

Embodiment 2

[0040] Put the disc into the strong convection annealing furnace, cover the heating mantle, and carry out nitrogen purging; use nitrogen for atmosphere protection during the annealing process; heat the furnace to 720-740°C for 5-7 hours, and then heat it to ≤30°C After slowly cooling to a temperature below 650°C at a cooling rate of / h, remove the heating mantle, and use a cooling mantle to cool to a temperature below 140°C at a cooling rate faster than 100°C / h. During the annealing process, purified nitrogen is used for atmosphere protection. The dew point of nitrogen is ≤-60°C and the oxygen content is ≤5ppm to prevent surface oxidation and decarburization of the finished product. Nitrogen purging process: 30~40m 3 / h purge for 4 to 5 hours; 10 to 20m 3 / h purge for 2 to 3 hours.

Embodiment 3

[0042] Put the disc into the strong convection annealing furnace, cover the heating mantle, and carry out nitrogen purge; use nitrogen for atmosphere protection during the annealing process; heat the furnace to 730-750°C for 4-6 hours, and then use ≤30°C / After slowly cooling to a temperature below 650°C at a cooling rate of h, remove the heating mantle, and use a cooling mantle to cool to a temperature below 140°C at a cooling rate faster than 100°C / h. During the annealing process, purified nitrogen is used for atmosphere protection. The dew point of nitrogen is ≤-60°C and the oxygen content is ≤5ppm to prevent surface oxidation and decarburization of the finished product. Nitrogen purging process: 35~50m 3 / h purge for 5-6 hours; 10-20m 3 / h purge for 2 to 3 hours.

[0043] Adopting the annealing method of the present invention greatly simplifies the loading and unloading operation of high-speed tool steel wire finished annealing, and the annealing quality is well guarante...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com