Method for forming two conical sestion ring pieces by once cold rolling spreading

A ring and conical technology, applied in the field of conical section ring forming, can solve the problems of time-consuming, waste of materials, discontinuous metal fibers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

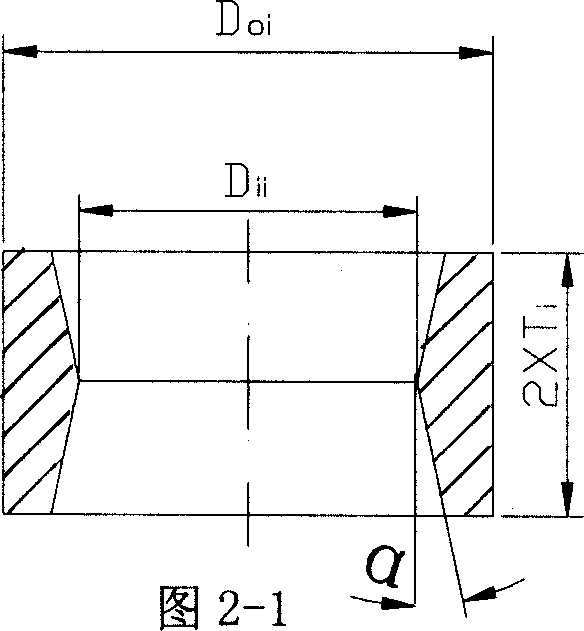

[0039] Example 1: It is integral rolling, that is, two ring blanks are designed together, rolled and expanded as a whole, and then divided into two by turning. A method for forming two tapered cross-section rings by one-time cold rolling, which comprises the steps:

[0040] 1). Cutting: cut the bar into sections, the length of which is L=(1-3)(2T i ), 2T i is the axial dimension of the overall ring blank.

[0041] 2). Blank making: heating the material section to the thermal deformation temperature, upsetting, and then punching, punching and connecting the skin to make the overall ring blank.

[0042] 3). Annealing: annealing the integral ring blank, the annealing temperature is 600°C-800°C, and the time is 1-3 hours.

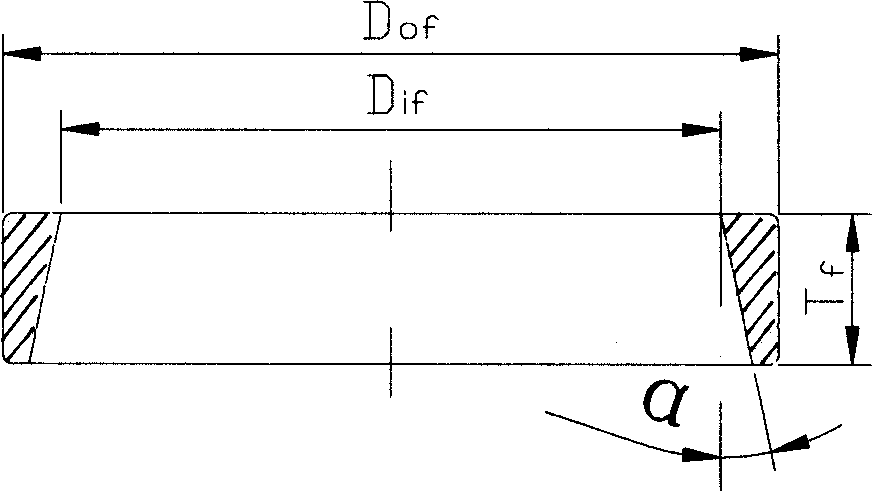

[0043] 4).Blank rough turning: the annealed integral ring blank is turned into an integral ring blank for rolling; see Picture 1-1 , the outer diameter of the tapered section ring product is D of , the inner diameter of the big end is D if , the cone angl...

example 2

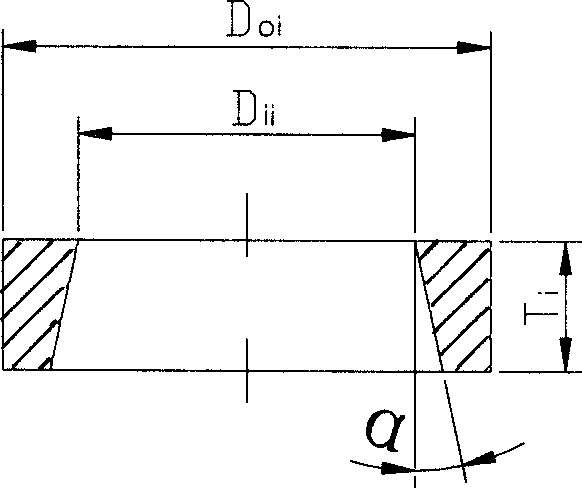

[0057] Example 2: It is a split type rolling, that is, the two ring blanks are independent, and then rolled as a whole. A method for forming two tapered cross-section rings by one-time cold rolling, which comprises the steps:

[0058] 1). Cutting separately: Cut the bar into two sections, the length of each section is L=(1-3)T i ,T i is the axial dimension of the ring blank;

[0059] 2). Blank making: heating the two sections of material to the thermal deformation temperature, then upsetting, then punching, punching and connecting skins to make 2 ring blanks;

[0060] 3). Annealing: annealing of two ring blanks, the annealing temperature is 600°C-800°C, and the time is 1-3 hours;

[0061] 4).Blank rough turning: the two ring blanks after annealing are turned into two ring blanks for rolling; the outer diameter of the tapered cross-section ring product is D of , the inner diameter of the big end is D if , the cone angle is α, and the axial dimension is T f , the equivalen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com