Method for producing wide-amplitude double-zero aluminum foil blank by adopting cast-rolled compact

A double-zero aluminum foil, casting and rolling technology is applied in the field of aluminum alloy sheet, strip and foil processing to achieve the effects of low product cost, improved rolling performance, and changes in immaturity and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

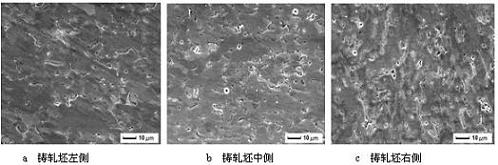

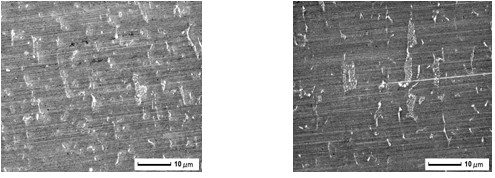

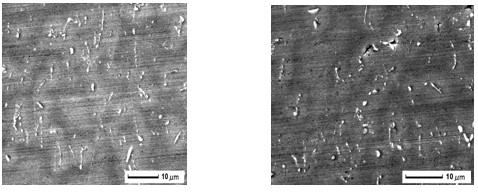

Image

Examples

Embodiment 1

[0033] 99.70% industrial pure aluminum ingot, Fe agent, Si agent and copper agent are used as raw materials to prepare the alloy to meet the burden of a 20t-capacity aluminum alloy melting furnace. The chemical composition is strictly in accordance with the adjusted chemical composition range of the aluminum alloy. The temperature is 740~760 0 C, the temperature of the static furnace is 740±5°C, the hydrogen content in the melt is controlled within 0.12ml / 100gAl, the Al-5Ti-0.2B grain refiner is used, and the addition of the refiner is strictly controlled. After online inspection, actual measurement The chemical composition is:

[0034] Cu Mg Fe Si Zn Ti Al alloy 0.07 0.005 0.80 0.30 0.01 0.02 margin

[0035] choose in Ф Produced on a 980×2000mm inclined casting-rolling machine, the gap between the upper and lower nozzle rolls should be properly controlled when the vertical plate is erected, and the casting-rolling area should be contr...

Embodiment 2

[0040] 99.70% industrial pure aluminum ingot, Fe agent, Si agent and copper agent are used as raw materials to prepare the alloy to meet the burden of a 20t-capacity aluminum alloy melting furnace. The chemical composition is strictly in accordance with the adjusted chemical composition range of the aluminum alloy. The temperature is 740~760 0 C, the temperature of the static furnace is 740±5°C, the hydrogen content in the melt is controlled within 0.12ml / 100gAl, the Al-5Ti-0.2B grain refiner is used, and the addition of the refiner is strictly controlled. After online inspection, actual measurement The chemical composition is:

[0041] Cu Mg Fe Si Zn Ti Al alloy 0.10 0.01 0.9 0.30 0.05 0.03 margin

[0042] choose in Ф Produced on a 980×2000mm inclined casting and rolling machine, the gap between the upper and lower nozzle rolls should be properly controlled when the vertical plate is erected, and the casting and rolling area should ...

Embodiment 3

[0047] 99.70% industrial pure aluminum ingot, Fe agent, Si agent and copper agent are used as raw materials to prepare the alloy to meet the burden of a 20t-capacity aluminum alloy melting furnace. The chemical composition is strictly in accordance with the adjusted chemical composition range of the aluminum alloy. The temperature is 740~760 0 C, the temperature of the static furnace is 740±5°C, the hydrogen content in the melt is controlled within 0.12ml / 100gAl, the Al-5Ti-0.2B grain refiner is used, and the addition of the refiner is strictly controlled. After online inspection, actual measurement The chemical composition is:

[0048] Cu Mg Fe Si Zn Ti Al alloy 0.03 0.02 0.7 0.22 0.08 0.01 margin

[0049] choose in Ф Produced on a 980×2000mm inclined casting and rolling machine, the gap between the upper and lower nozzle rolls should be properly controlled when the vertical plate is erected, and the casting and rolling area should ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com