Clamp for testing annular tensile property of tubular product

A test fixture and hoop stretching technology, applied in the direction of analyzing materials, strength characteristics, measuring devices, etc., can solve the problems of low accuracy and high test cost, and achieve the effects of accurate measurement, reduced test cost, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

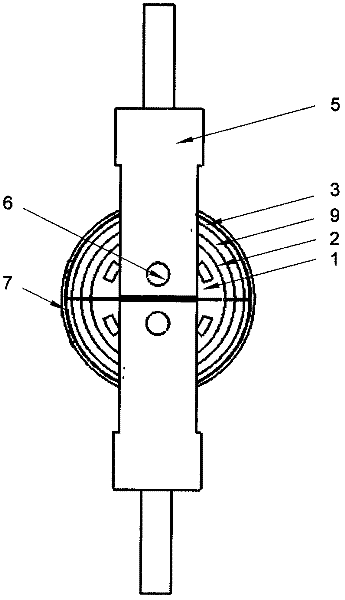

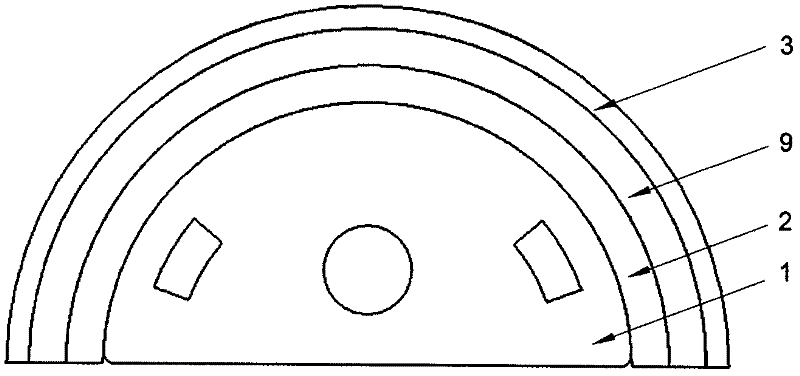

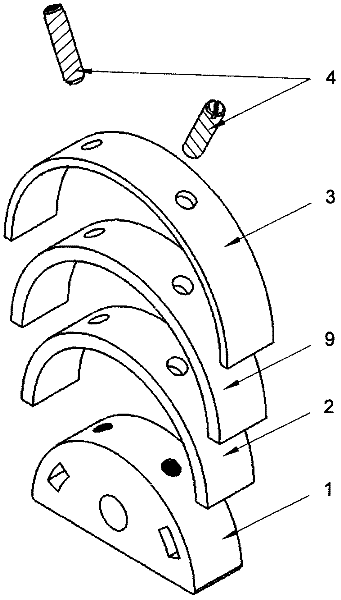

[0024] This embodiment is a jig for testing the hoop tensile properties of pipes, which is suitable for testing the hoop tensile properties of pipes with an inner diameter of 60-100 mm and an inner diameter of 100-150 mm. In this embodiment, the fixture is described by taking the hoop tensile performance test applicable to pipes with an inner diameter of 60-100 mm as an example.

[0025] The pipe tested in this embodiment is a QSTE340 high-strength steel pipe of φ88×3.2 mm (outer diameter×wall thickness), and the axial height of the pipe sample is 12 mm.

[0026] This embodiment is a symmetrical structure, including a first inner insert 1, a second inner insert 10, two inner lining rings 2, two outer lining rings 3, a first clamping block 5, a second clamping block 8, and 2 The middle layer backing ring 9 and the pipe sample 7. The first inner insert 1 and the second inner insert 10 have the same structure, and the first clamping block 5 and the second clamping block 8 have t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com