Carbon nano-tube tire preparation method and carbon nano-tube tire with characteristics of high wear resistance and high roadholding capability

A carbon nanotube and nanotube technology, which is applied in the field of high-performance, high-wear-resistance, high-grip tires and their preparation, can solve the problems of prolonged vehicle braking distance, reduced tire wear resistance, reduced tire service life, etc. Abrasion performance, improved wear resistance, improved grip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

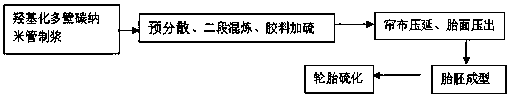

Method used

Image

Examples

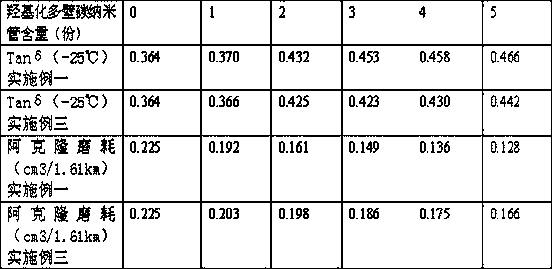

Embodiment 1

[0026] To prepare carbon nanotube slurry, use solid carbon nanotubes, liquid silane and naphthene oil in a weight ratio of 20 parts of carbon nanotubes, 60 parts of liquid silane, and 20 parts of naphthene oil, and use it under the condition of not exceeding 140°C Ball milling for at least 5 hours, (control the temperature to not exceed 140°C during ball milling to prevent self-crosslinking of liquid silane.) to make carbon nanotube slurry, in order to ensure the compatibility of carbon nanotubes and rubber, choose Hydroxylated surface-modified carbon nanotubes are used to make the carbon nanotubes react with the carboxyl groups of the silane coupling agent to form a chemical bond, which improves the reinforcing performance of the carbon nanotubes in the rubber compound. Improve the strength and wear resistance of the tread rubber.

[0027] The formula of crown rubber of the present invention is: 50-80 parts of natural rubber, 20-50 parts of butadiene rubber, 40-60 parts of hi...

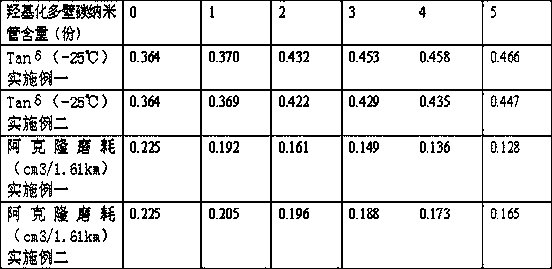

Embodiment 2

[0046] To prepare carbon nanotube slurry, use solid carbon nanotubes, liquid silane and naphthene oil in a weight ratio of 20 parts of carbon nanotubes, 60 parts of liquid silane, and 20 parts of naphthene oil, and use it under the condition of not exceeding 140°C Ball milling for at least 5 hours, (control the temperature during ball milling to not exceed 140°C to prevent self-crosslinking of liquid silane.) Make carbon nanotube slurry.

[0047] The formula of crown rubber of the present invention is: 50-80 parts of natural rubber, 20-50 parts of butadiene rubber, 40-60 parts of high wear-resistant carbon black N375, 10-20 parts of white carbon black, silane coupling agent 2-4 parts, 6-10 parts of oil, 5 parts of zinc oxide, 2.5 parts of stearic acid, 2.5 parts of antioxidant 6PPD, 2 parts of microcrystalline paraffin, 2-5 parts of carbon nanotubes (calculated based on the solid content in the slurry ), Accelerator CZ1-2 parts, sulfur 1-2 parts.

[0048] The formula producti...

Embodiment 3

[0059] To prepare carbon nanotube slurry, use solid carbon nanotubes, liquid silane and naphthene oil in a weight ratio of 20 parts of carbon nanotubes, 60 parts of liquid silane, and 20 parts of naphthene oil, and use it under the condition of not exceeding 140°C Ball milling for at least 5 hours, (control the temperature during ball milling to not exceed 140°C to prevent self-crosslinking of liquid silane.) Make carbon nanotube slurry.

[0060] The formula of crown rubber of the present invention is: 50-80 parts of natural rubber, 20-50 parts of butadiene rubber, 40-60 parts of high wear-resistant carbon black N375, 10-20 parts of white carbon black, silane coupling agent 2-4 parts, 6-10 parts of oil, 5 parts of zinc oxide, 2.5 parts of stearic acid, 2.5 parts of antioxidant 6PPD, 2 parts of microcrystalline paraffin, 2-5 parts of carbon nanotubes (calculated based on the solid content in the slurry ), Accelerator CZ1-2 parts, sulfur 1-2 parts.

[0061] The formula producti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com