Deep overcooling treatment method for fine grain copper alloy shaped charge liner

A technology of deep subcooling treatment and liner cover, which is applied in the direction of explosive charge, weapon accessories, offensive equipment, etc. High-level problems, to avoid uneven nucleation rate, good organization uniformity, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with embodiment.

[0030] A kind of preparation method of fine-grained copper alloy drug-type cover, carry out according to the following steps:

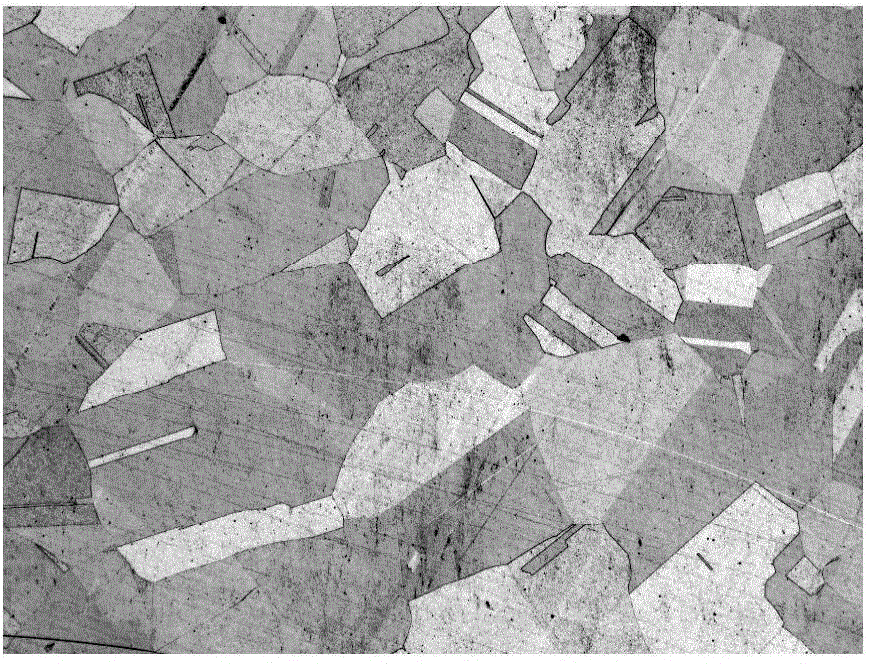

[0031] (1) Preparation of raw materials: The drug-type cover is a single-cone thin-walled structure, the size of the large end is φ146mm, the height is 120mm, the depth of the inner cone is 106mm, the taper is 60°, and the maximum wall thickness is 4.5mm. According to the structural characteristics of the designed formed part, select The rolled T2 copper rod of φ60mm is used as the raw material, and the outer surface is blanked and turned to make a billet with a diameter of φ58mm and a length of 80mm; the content of impurity elements in the T2 copper rod is shown in Table 1, and the microstructure is as follows figure 1 shown.

[0032] Table 1 Content of impurity elements in T2 copper rods

[0033]

[0034] (2) Composite cold extrusion plastic deformati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com