Building mortar mixing device

A mixing device and mortar technology, applied in mixing operation control devices, clay preparation devices, cement mixing devices, etc., can solve problems such as difficult discharge, mortar accumulation, affecting device operation, etc., to prevent clogging, save labor costs, and improve The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

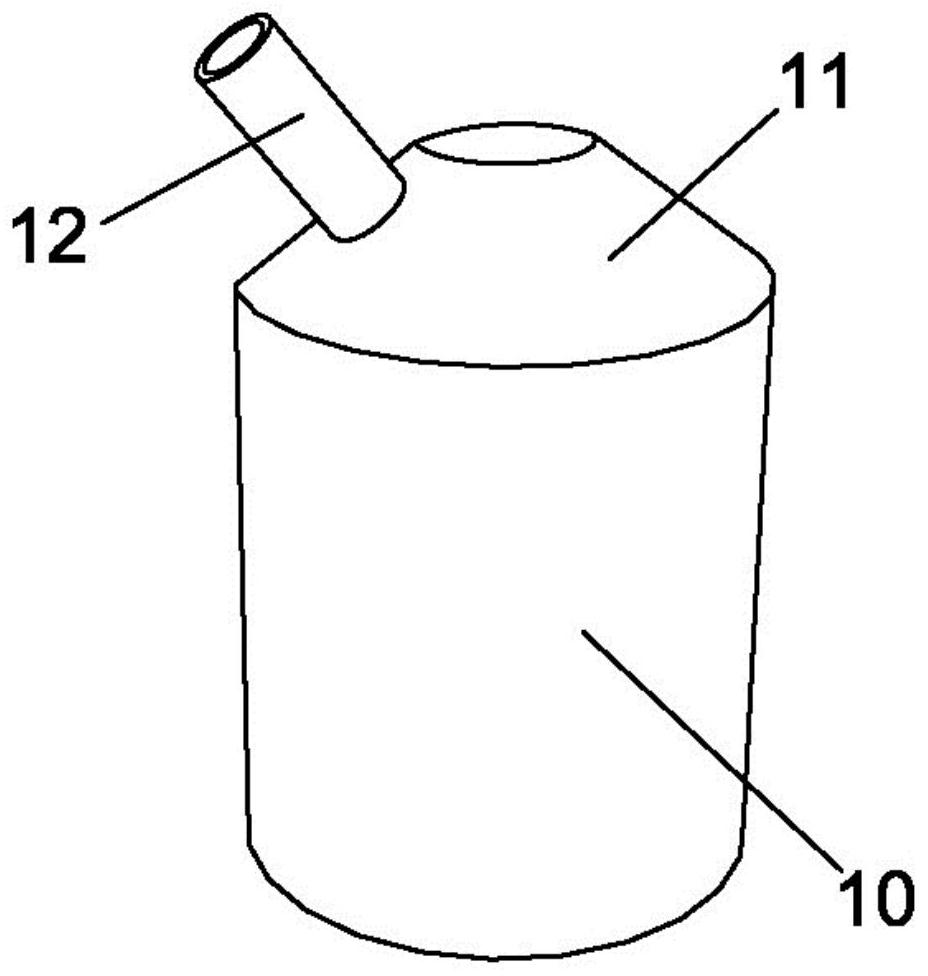

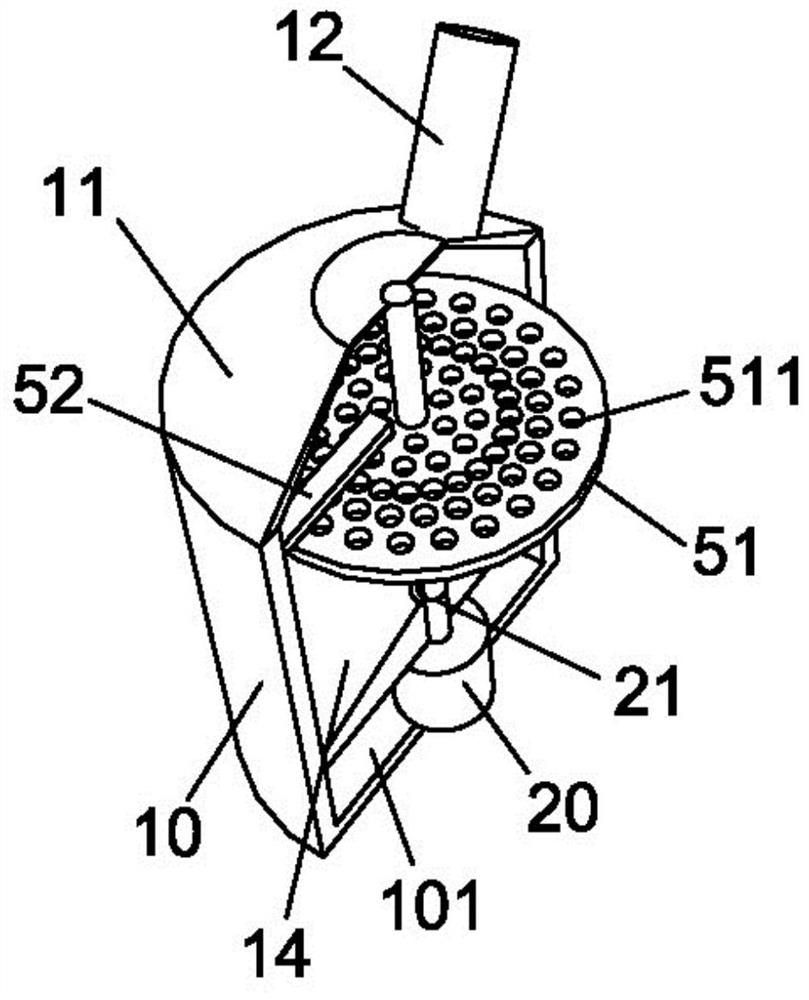

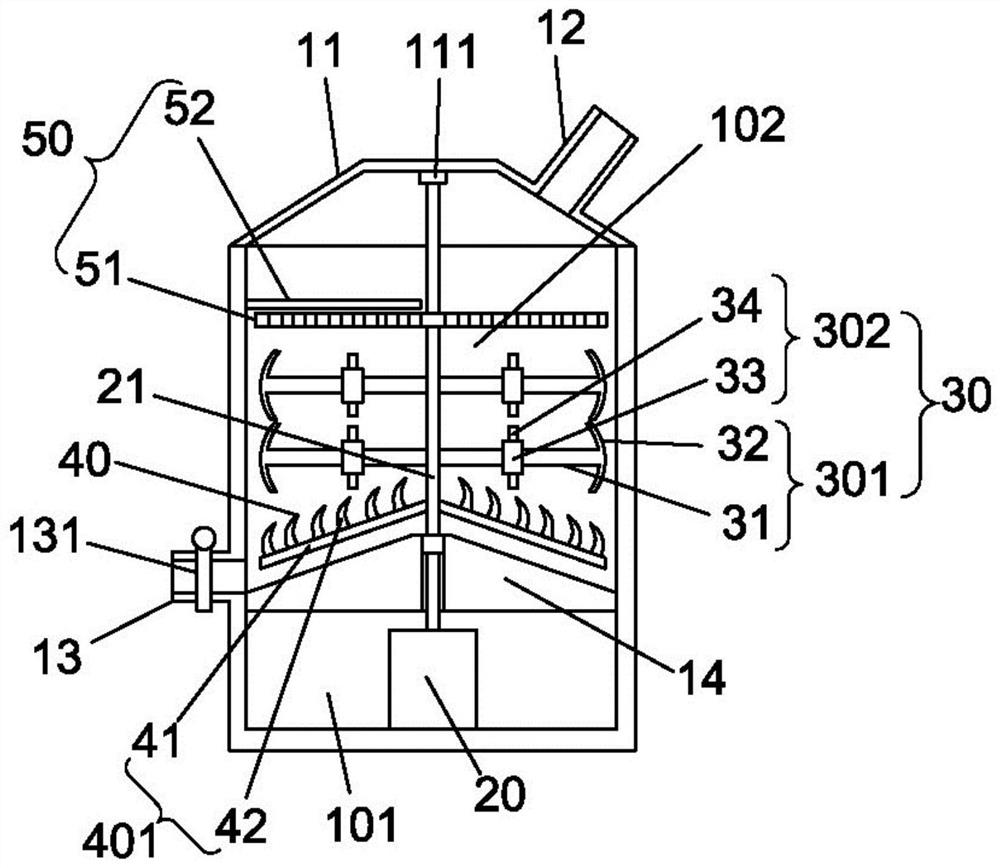

[0030] see Figure 1 to Figure 5 , The present invention provides a building mortar mixing device, which includes a mixing tank 10 and a motor 20 disposed therein, a mixing and stirring assembly 30 , a crushing and stirring assembly 40 and a distribution plate assembly 50 .

[0031] like figure 1 , figure 2 , image 3 As shown, the mixing bucket 10 is shaped as a hollow drum; the inside of the mixing bucket 10 is provided with a partition 14, and the partition 14 separates the inner space of the mixing bucket 10 to form a motor installation space 101 located in the lower part of the space and a motor installation space located in the upper part of the space. The mixing space 102; the upper surface 141 of the dividing plate 14 is shaped as a conical curved surface with a raised center; the top of the mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com