Drying calcining treatment system of drilling well waste mud

A waste mud and calcination treatment technology, which is applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of not fundamentally eliminating environmental pollution, high cost of drilling waste mud, waste mud pollution, etc., and achieves simple structure, manufacturing Low cost, effective in solving pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

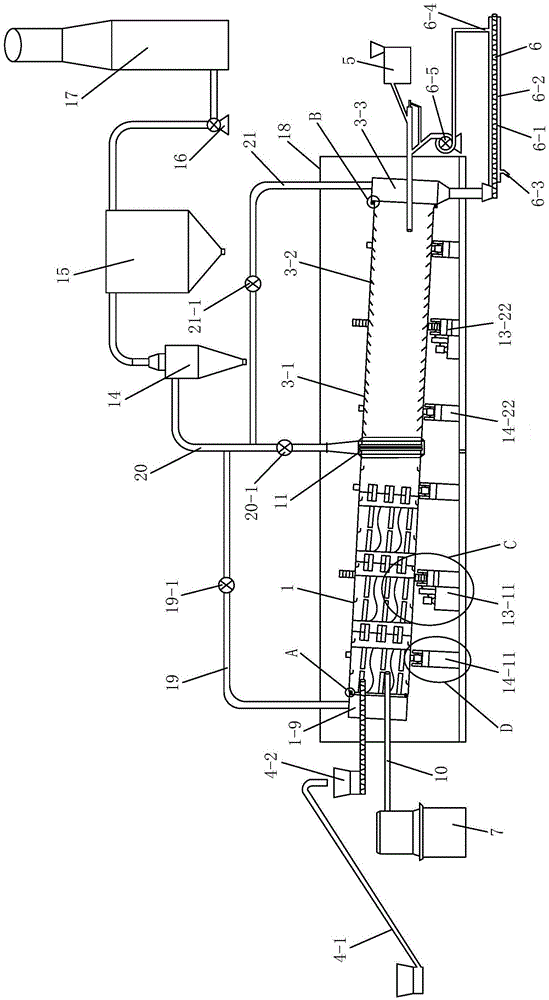

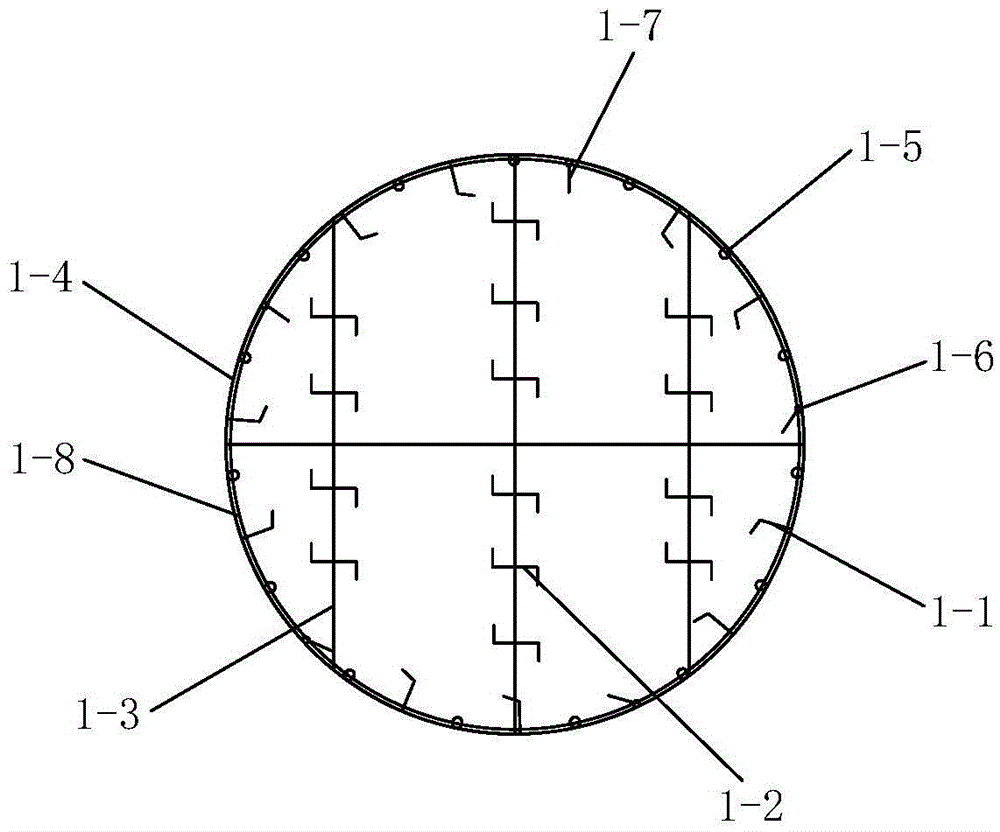

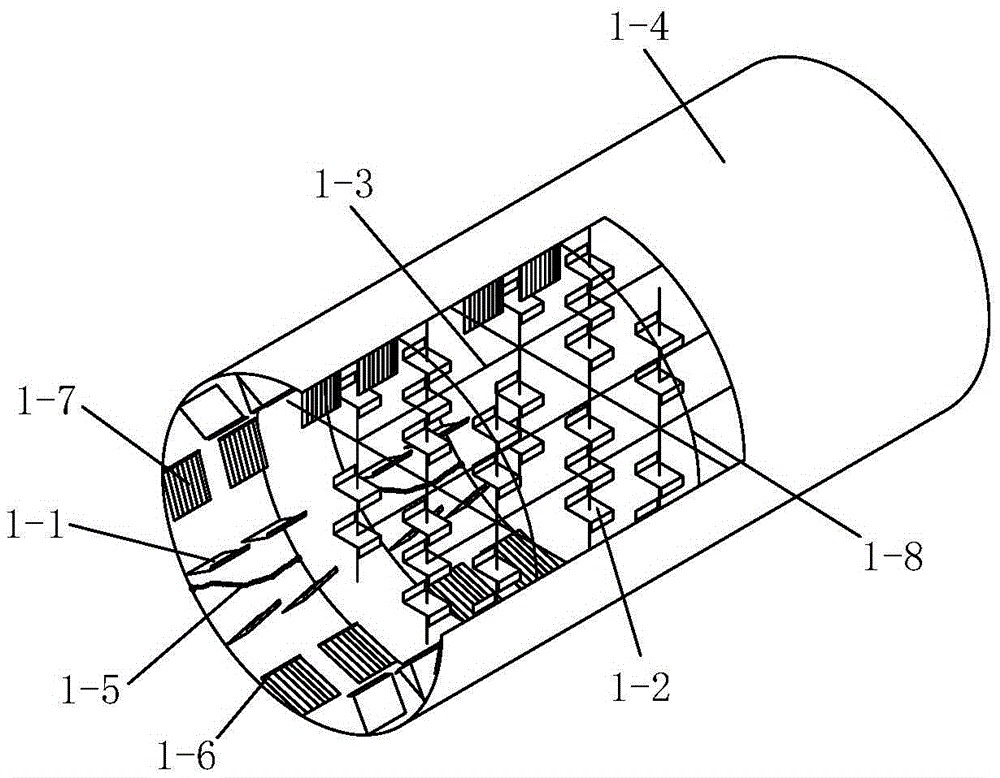

[0059] Such as figure 1 As shown, the present invention includes a rotary drying and calcining device, a rotary driving mechanism for driving the rotary drying and calcining device to rotate, and a rotary supporting mechanism for supporting the rotation of the rotary drying and calcining device. The rotary drying and calcining device passes through the rotary driving mechanism and the rotary supporting mechanism, and the drying end of the rotary drying and calcining device is provided with a raw material feeding system for feeding the rotary drying and calcining device and for the The drying heat supply device 7 that provides heat source for the drying of the rotary drying and calcining device, the calcining end of the rotary drying and calcining device is provided with a pulverized coal combustion device that provides a heat source for the calcination of the rotary drying and calcining device device 5 and a screw conveyor 6 for transporting the calcined ceramic particles out,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com