Waste water bottle crushing and briquetting device for resource regeneration

A technology of resource regeneration and waste water, applied in the direction of grain processing, etc., can solve the problems of long working hours, high production costs, and many manual operations, and achieve the effect of retrieving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

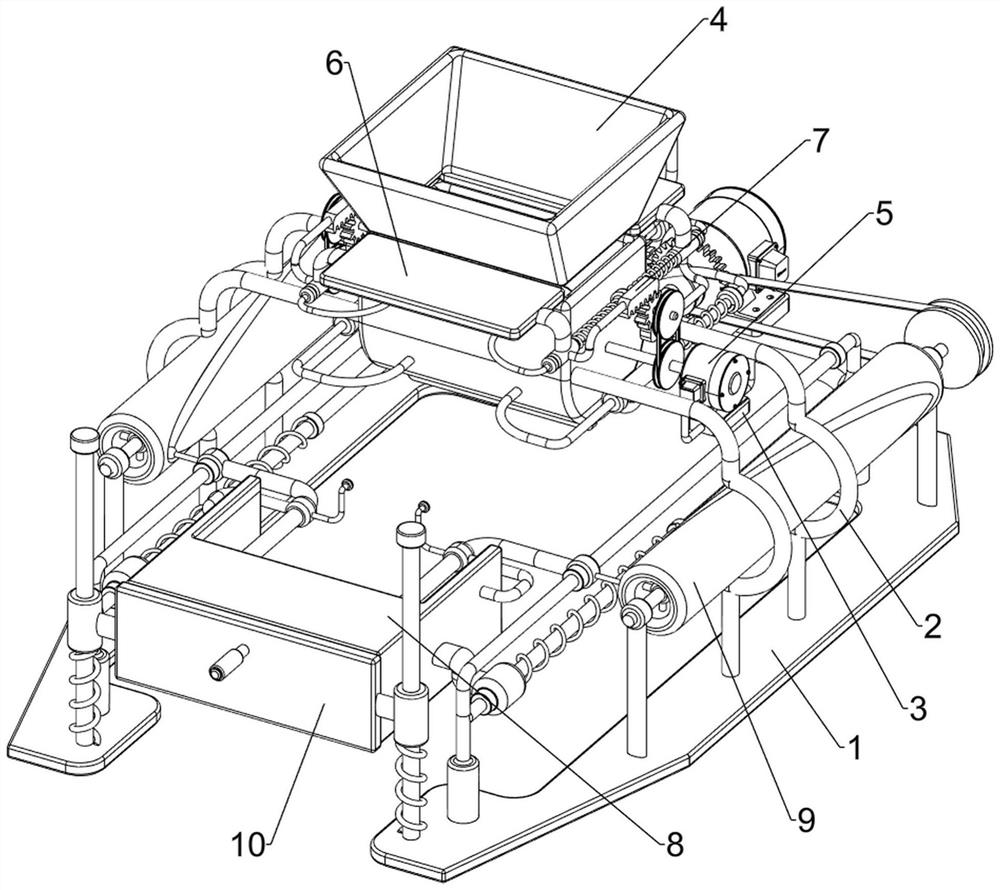

[0069] A waste water bottle crushing and briquetting device for resource regeneration, such as figure 1 As shown, it includes a bottom plate 1, a first support frame 2, a second support frame 3, an accommodating mechanism 4 and a rotation mechanism 5, and four first support frames 2 are evenly arranged in the upper middle of the two bottom plates 1, and the two on the right side A second support frame 3 is connected between the tops of the first support frames 2 , an accommodating mechanism 4 is connected between the four first support frames 2 , and a rotating mechanism 5 is provided on the top of the second support frames 3 .

[0070] When people want to crush waste water bottles, they can use this waste water bottle crushing and briquetting device for resource regeneration. First, the user puts the waste water bottle into the containing mechanism 4, starts the rotating mechanism 5, and the rotating mechanism 5 drives the containing mechanism 4 running, the waste water bottl...

Embodiment 2

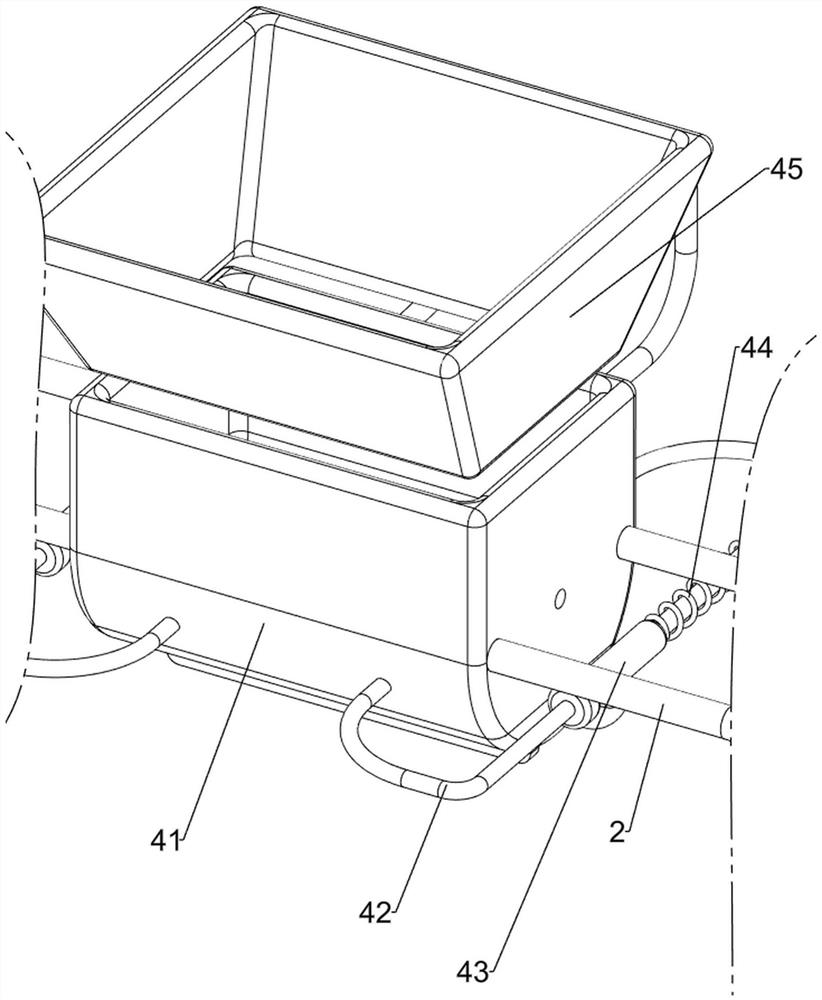

[0072] On the basis of Example 1, such as figure 2 with image 3 As shown, the accommodation mechanism 4 includes a stirring frame 41, a first slide rail 42, a first baffle plate 43, a first spring 44 and a blanking frame 45, and a stirring frame 41 is connected between the four first support frames 2, and the stirring Four first slide rails 42 are arranged on the front and rear sides of the frame 41, and a first baffle plate 43 is slidably connected between the first slide rails 42 on the front and rear sides on the same horizontal line, and the first baffle plate 43 is wound with a first A spring 44, the front end of the first spring 44 is connected with the first baffle plate 43, the rear end of the first spring 44 is connected with the first slide rail 42, and the top of the rear wall of the stirring frame 41 is provided with a blanking frame 45.

[0073] The user puts the waste water bottle into the blanking frame 45, and the waste water bottle enters the stirring frame...

Embodiment 3

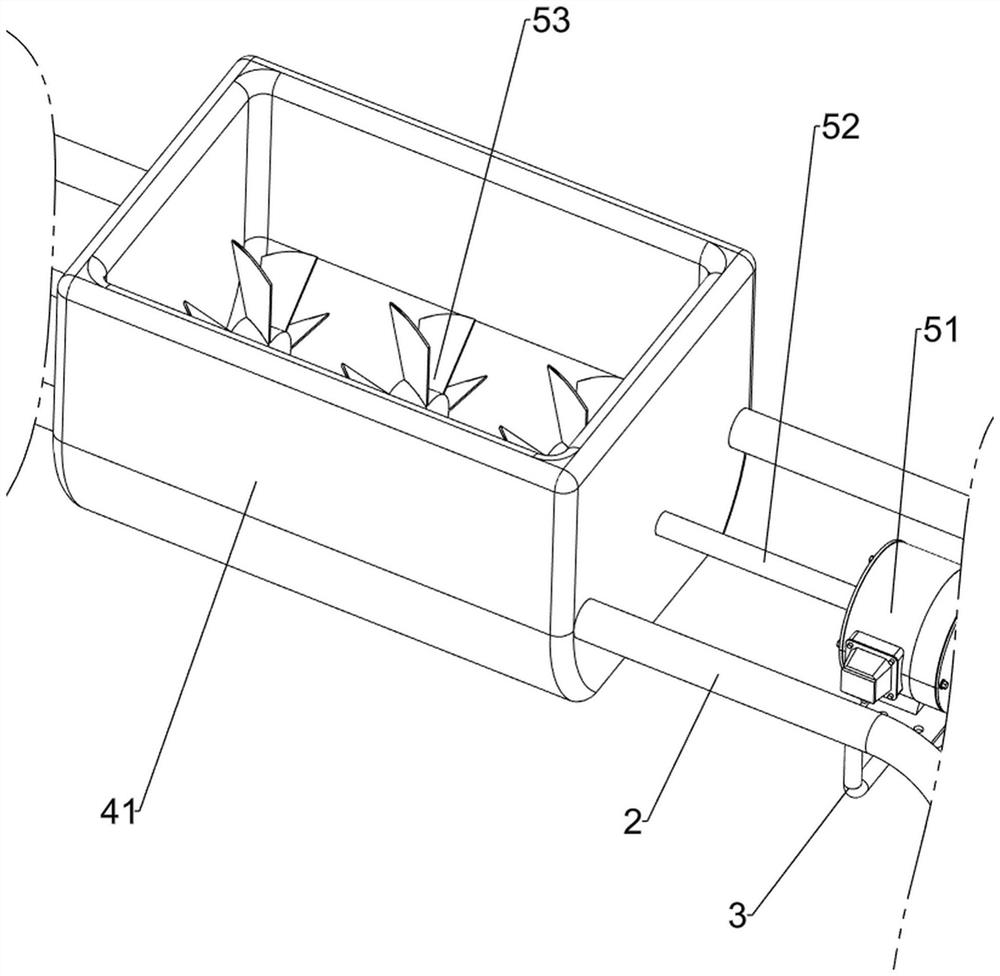

[0077] On the basis of Example 2, such as Figure 4-Figure 8 As shown, a shielding mechanism 6 is also included. The top of the stirring frame 41 is provided with a shielding mechanism 6. The shielding mechanism 6 includes a second slide rail 61, a second baffle plate 62 and a second spring 63. The left and right sides of the stirring frame 41 top are A second slide rail 61 is provided, and a second baffle plate 62 is slidably connected to the front and rear sides between the two second slide rails 61, and two second springs 63 are wound on each second slide rail 61, each The outer ends of each second spring 63 are connected to the second baffle plate 62 , and the inner ends of each second spring 63 are connected to the second slide rail 61 .

[0078] The user pushes the two second baffles 62 towards each other, and the second spring 63 is compressed, thereby covering the feeding port of the stirring frame 41 to realize the blocking effect. When the second baffle 62 is release...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com