Secondary curing device for bio-organic fertilizer

A bio-organic fertilizer and secondary ripening technology, which is applied in the direction of bio-organic part treatment, organic fertilizer, fertilization device, etc., can solve the problems that the ripening quality of organic fertilizer cannot be guaranteed, and the organic fertilizer cannot be stirred, so as to improve the processing quality and increase the Aging treatment, effect of reducing residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

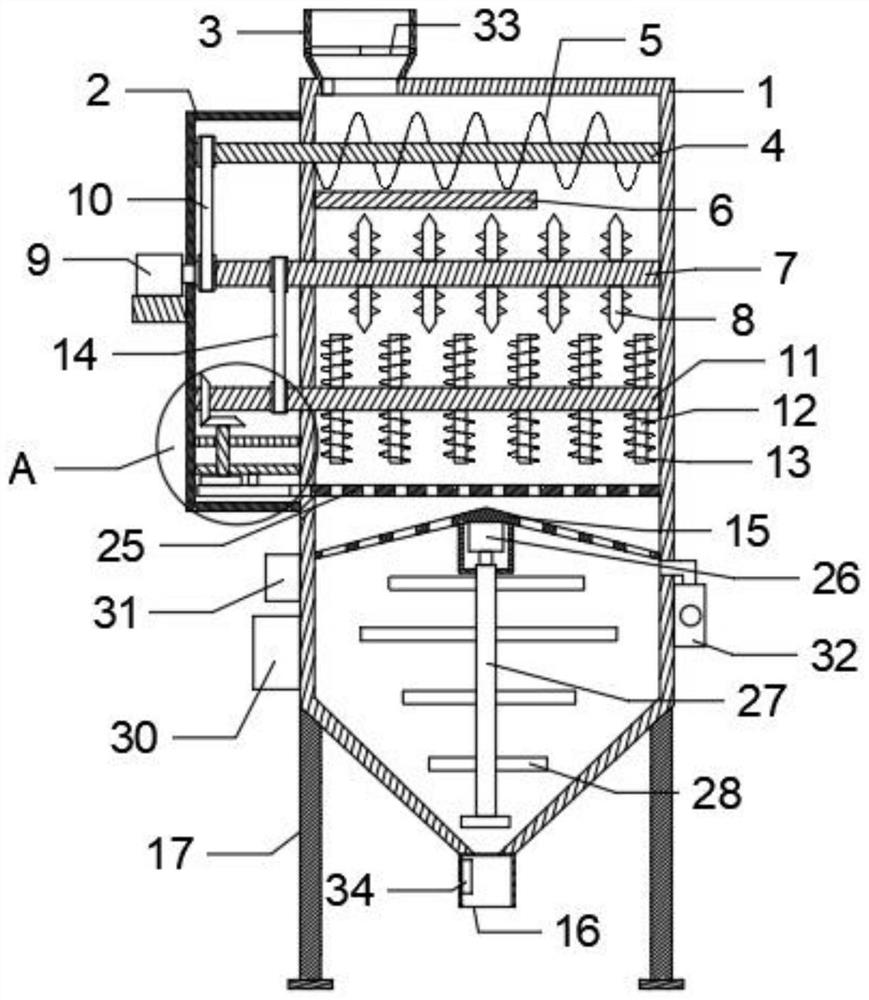

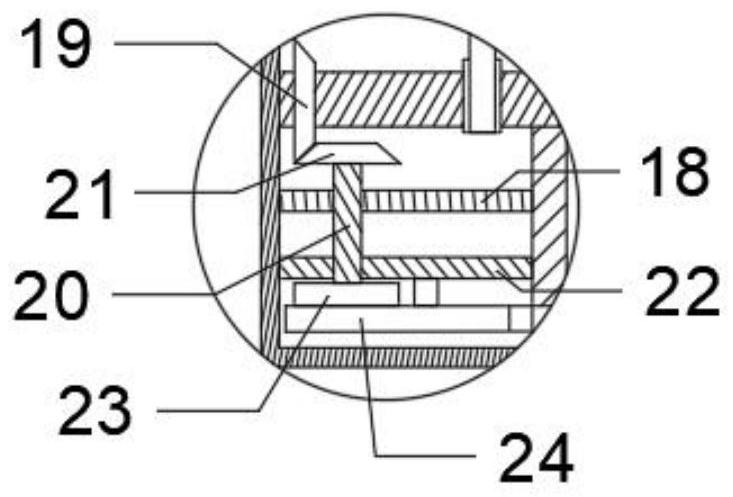

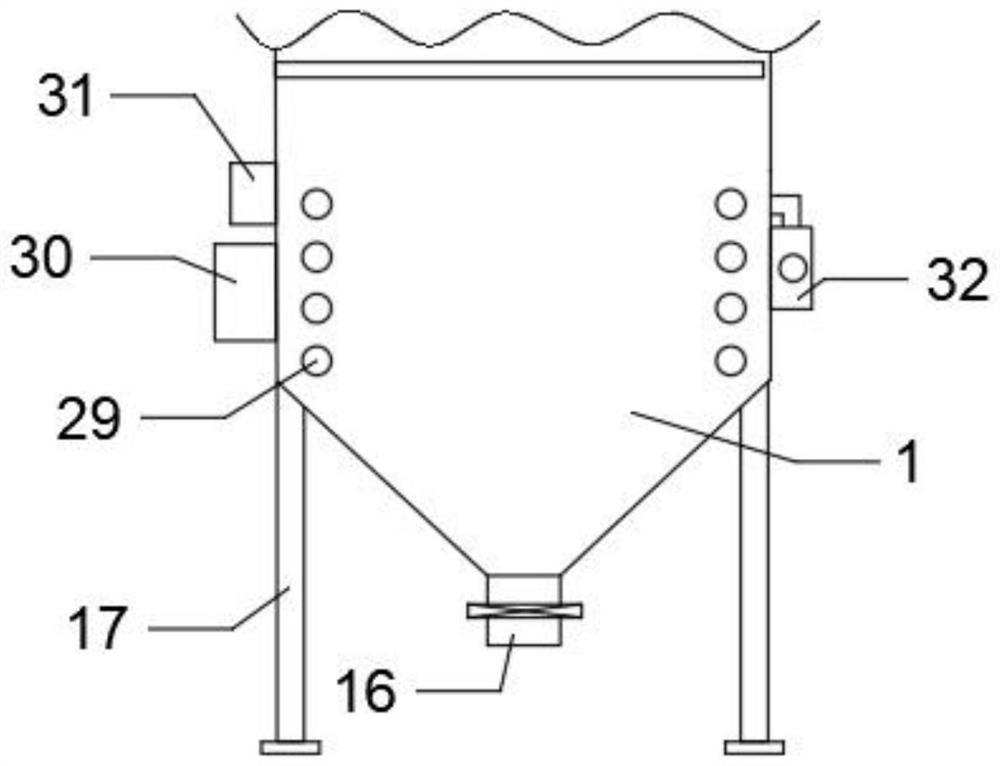

[0030] Such as Figure 1 to Figure 4 As shown, the bio-organic fertilizer secondary curing device includes a curing box 1 and a driving box 2. The driving box 2 is located on the left side of the curing box 1 and is fixedly connected with the curing box 1. The upper end of the curing box 1 is connected with a trapezoidal feed hopper 3 , both ends of the feed hopper 3 are provided with grooves, each groove is rotatably connected with a rotating shaft, the rotating shaft is fixedly connected with a torsion spring, the opposite side of the two torsion springs is fixedly connected to the inner wall of the groove, and the two torsion springs The adjacent side is fixedly connected with a semicircular baffle 33, and the cross-sectional area of the two semicircular baffles 33 is equal to the cross-sectional area of the feed hopper 3, so that the fertilizer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com