Patents

Literature

95results about How to "Automatic entry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

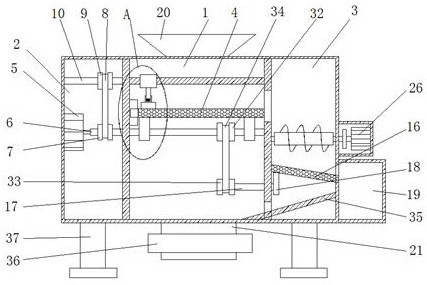

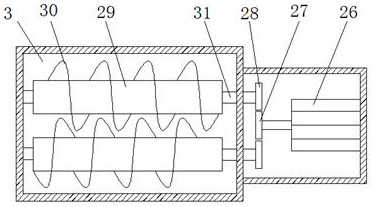

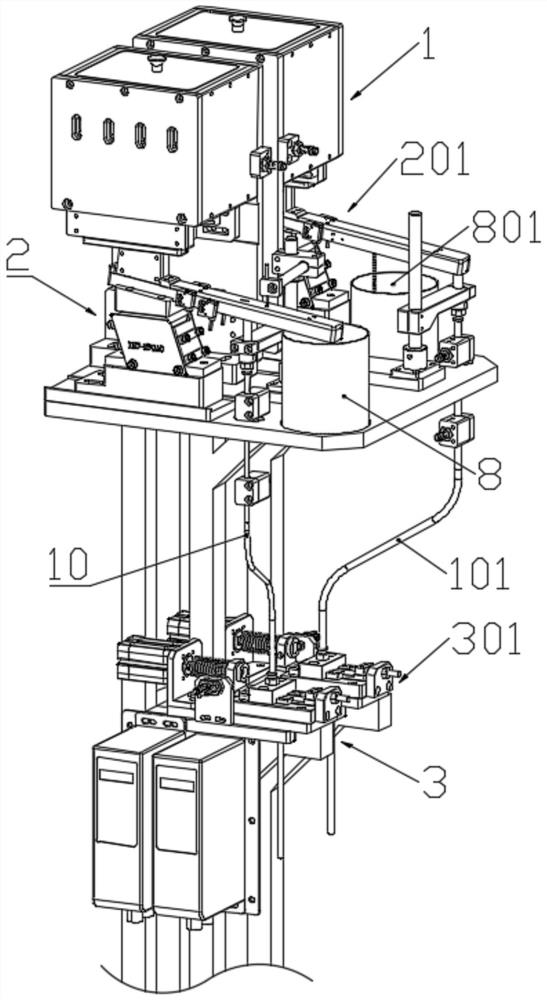

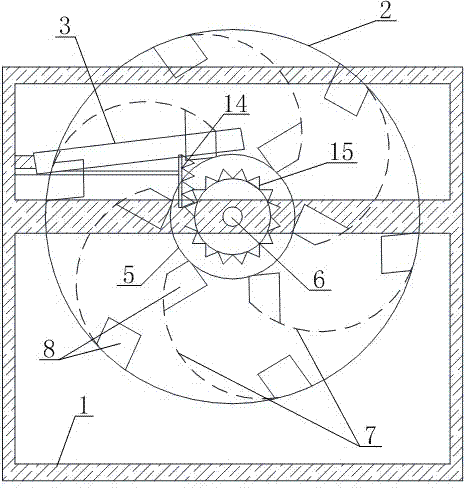

Counting and binding integrated machine and note feeding mechanism thereof

ActiveCN107042903AAutomatic entryFully automated processingPaper article packagingCoin/currency accepting devicesEngineeringMechanical engineering

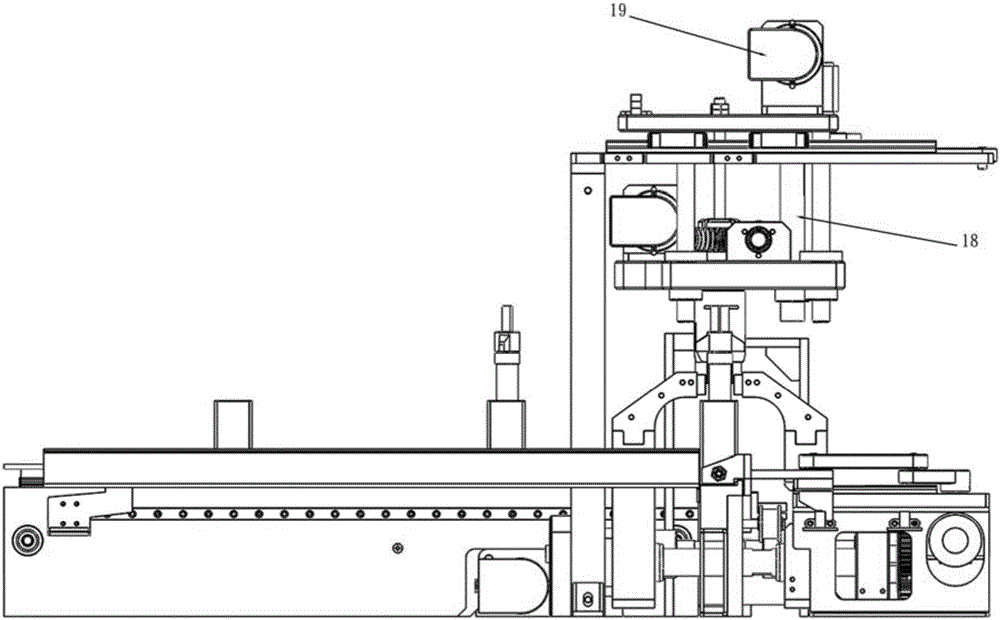

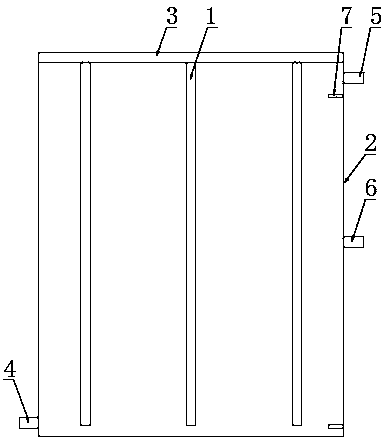

The invention discloses a counting and binding integrated machine and a note feeding mechanism thereof. The note feeding mechanism of the counting and binding integrated machine comprises a note feeding bracket. Two first hoardings are arranged on the top surface of the note feeding bracket. The ends, away from a note counting and detecting body, of the two first hoardings are connected and fixed to the two ends of a second hoarding correspondingly. The first hoardings, the second hoarding and the note supporting bottom surface of the note feeding bracket jointly form a note storage cavity in a surrounding mode. An intermittent note placing plate is arranged at the ends, away from the second hoarding, of the first hoardings. The top of the intermittent note placing plate and the two first hoardings are assembled through a first connecting rotating shaft. Each first hoarding is further provided with an intermittent guide groove. The middle of the intermittent note placing plate is further provided with a power rotating shaft. The power rotating shaft penetrates out of the intermittent guide grooves and is installed in a movable connecting sleeve. The movable connecting sleeve is connected and fixed to one end of a power telescopic rod of a power electromagnet. An electromagnet installation column is arranged at the bottom of the power electromagnet. The bottom of the electromagnet installation column is connected with a reverse supporting base through a connecting ball.

Owner:WEIRONG TECH CO LTD

Environment-friendly refuse treatment equipment

InactiveCN112108491AThorough treatmentEasy to handleTransportation and packagingSolid waste disposalElectric machineryCam

The invention discloses environment-friendly garbage treatment equipment. The equipment comprises a treatment box. An operation box is arranged on one side of the treatment box, a smashing box is arranged on the other side of the treatment box, a first filter screen is arranged inside the treatment box, a first motor is fixedly connected to the inner wall of one side of the operation box, and an output shaft of the first motor is fixedly connected with a rotating rod. One end of the rotating rod is fixedly connected with a first belt pulley, the first belt pulley is connected with a second belt pulley through a first belt, the axis of the second belt pulley is fixedly connected with a rotating shaft, one end of the rotating shaft is fixedly connected with a lead screw, the surface of the lead screw is in threaded connection with a lead screw sliding block, and the bottom end of the lead screw sliding block is fixedly connected with a connecting rod. A pressing mechanism is arranged atthe bottom end of the connecting rod, a scraper blade is fixedly connected to the bottom end of the pressing mechanism, and first cams are symmetrically arranged on the rotating rod. The environment-friendly refuse treatment equipment has the beneficial effects that the scraper blade also moves horizontally while the first filter screen shakes, the solid-liquid separation effect of refuse is achieved, and refuse treatment is more effective.

Owner:西安中威环境技术有限公司

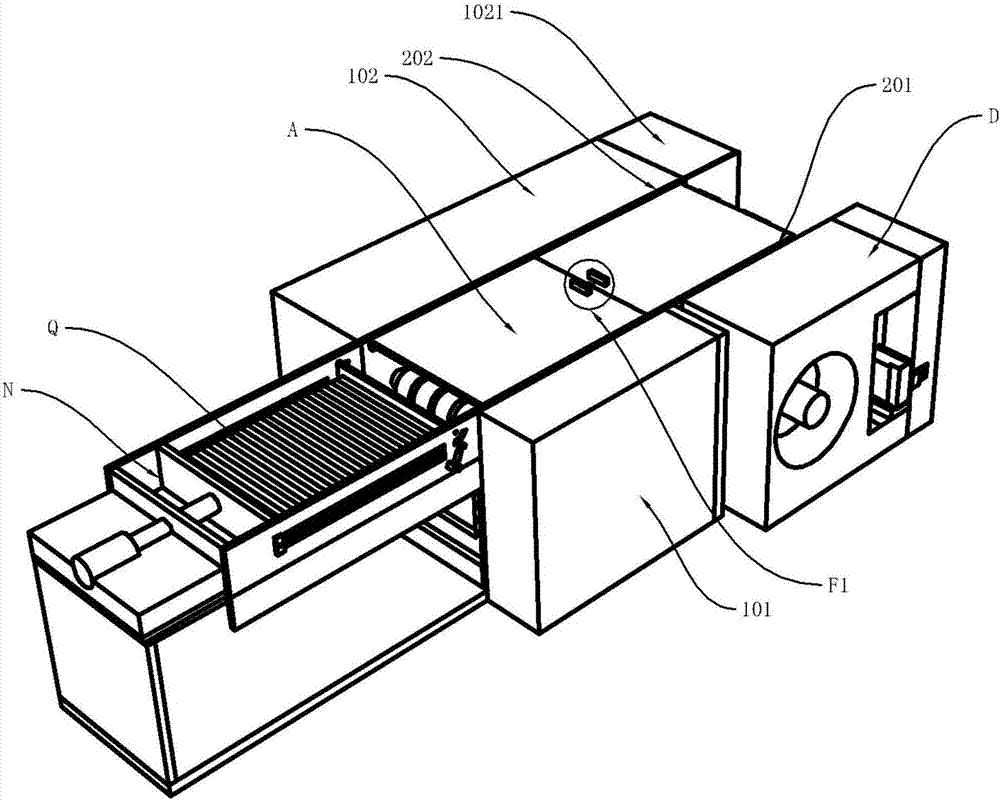

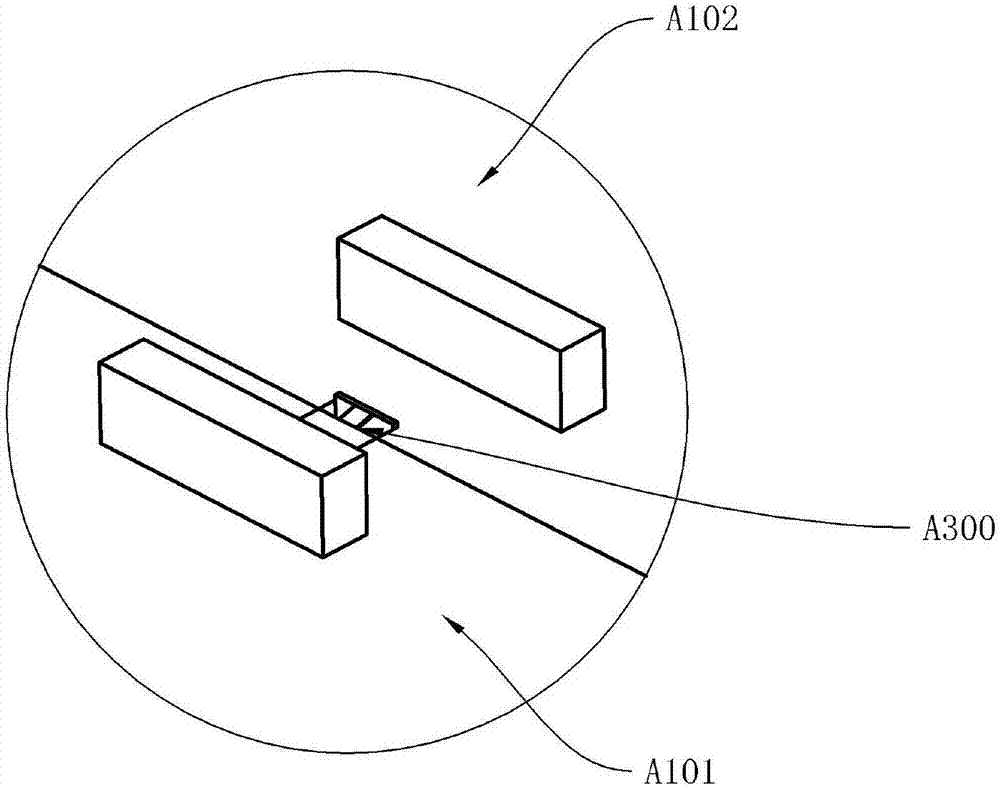

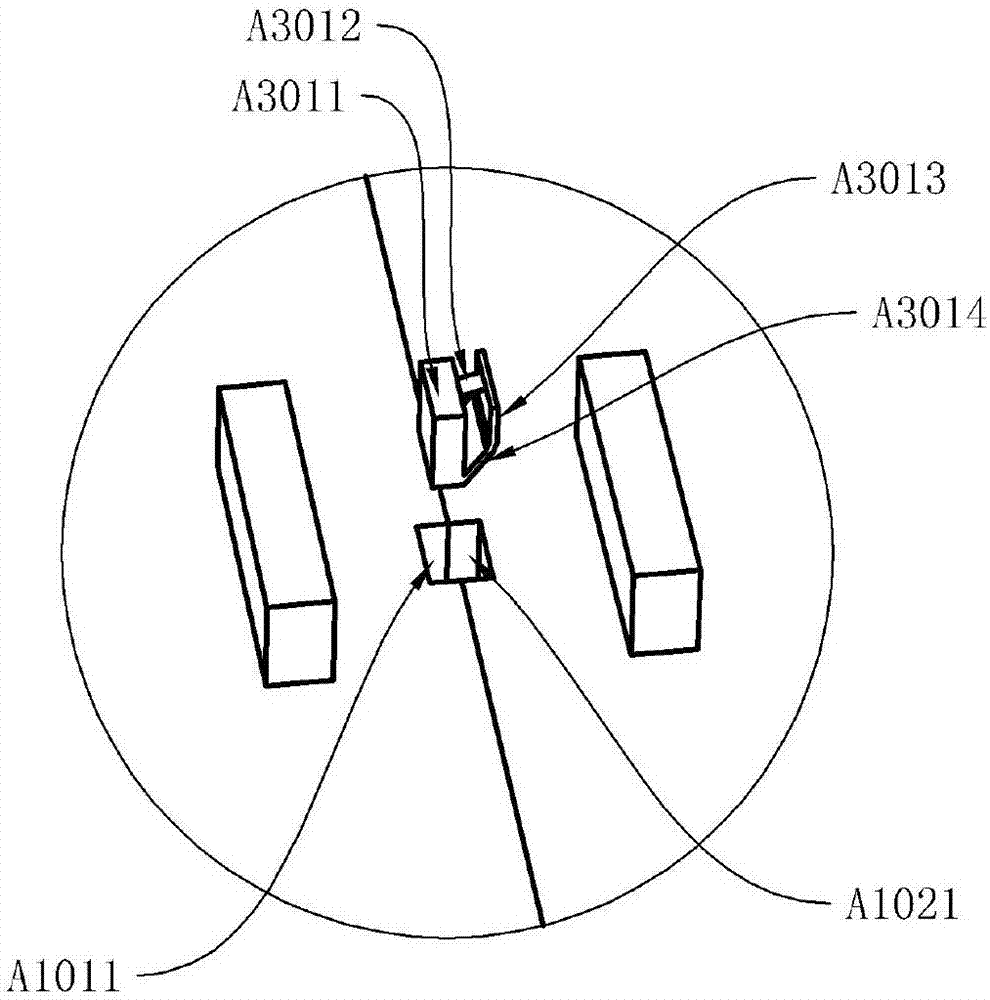

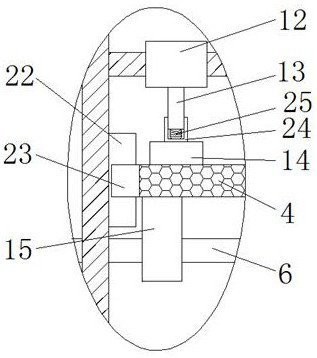

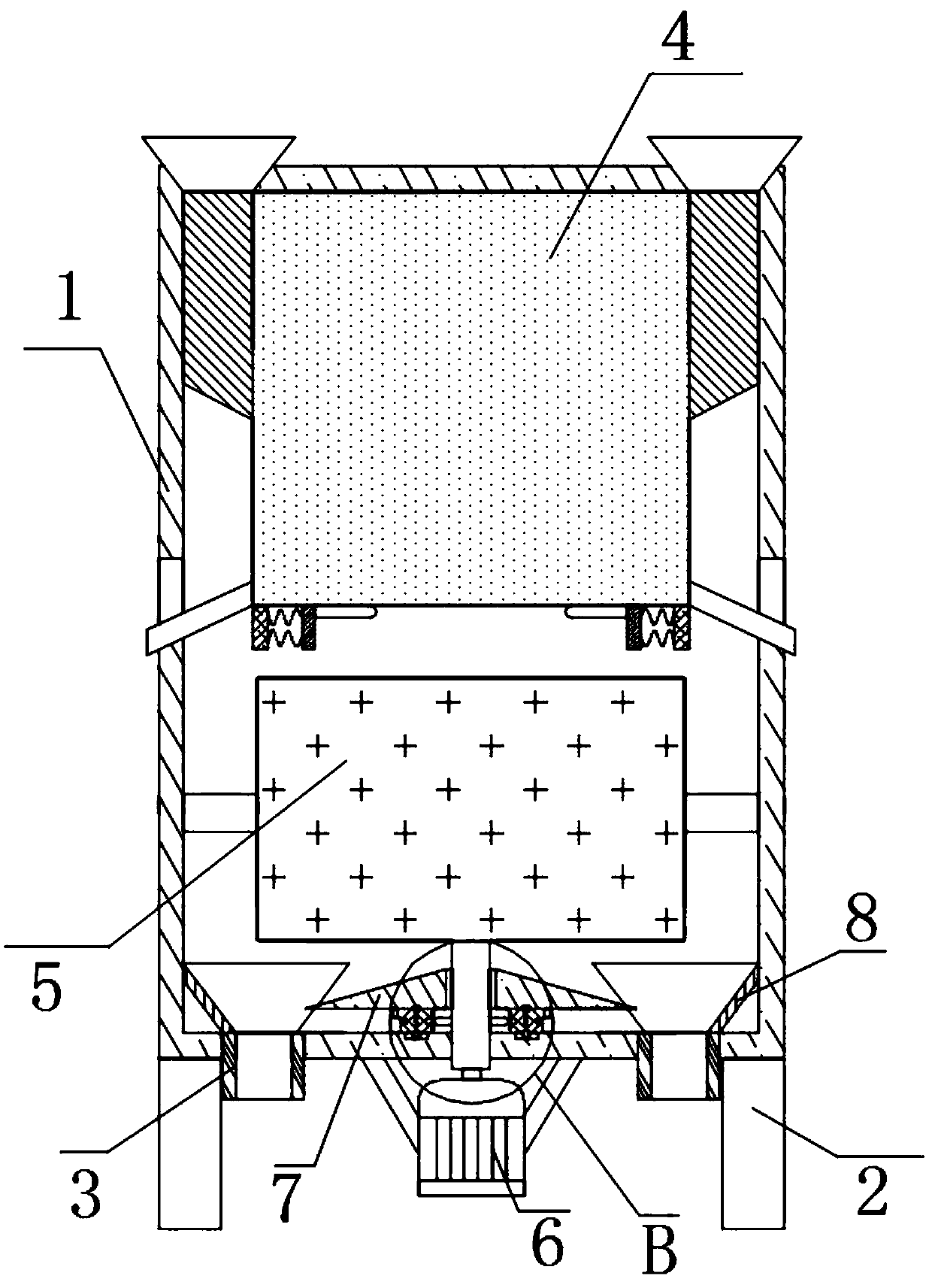

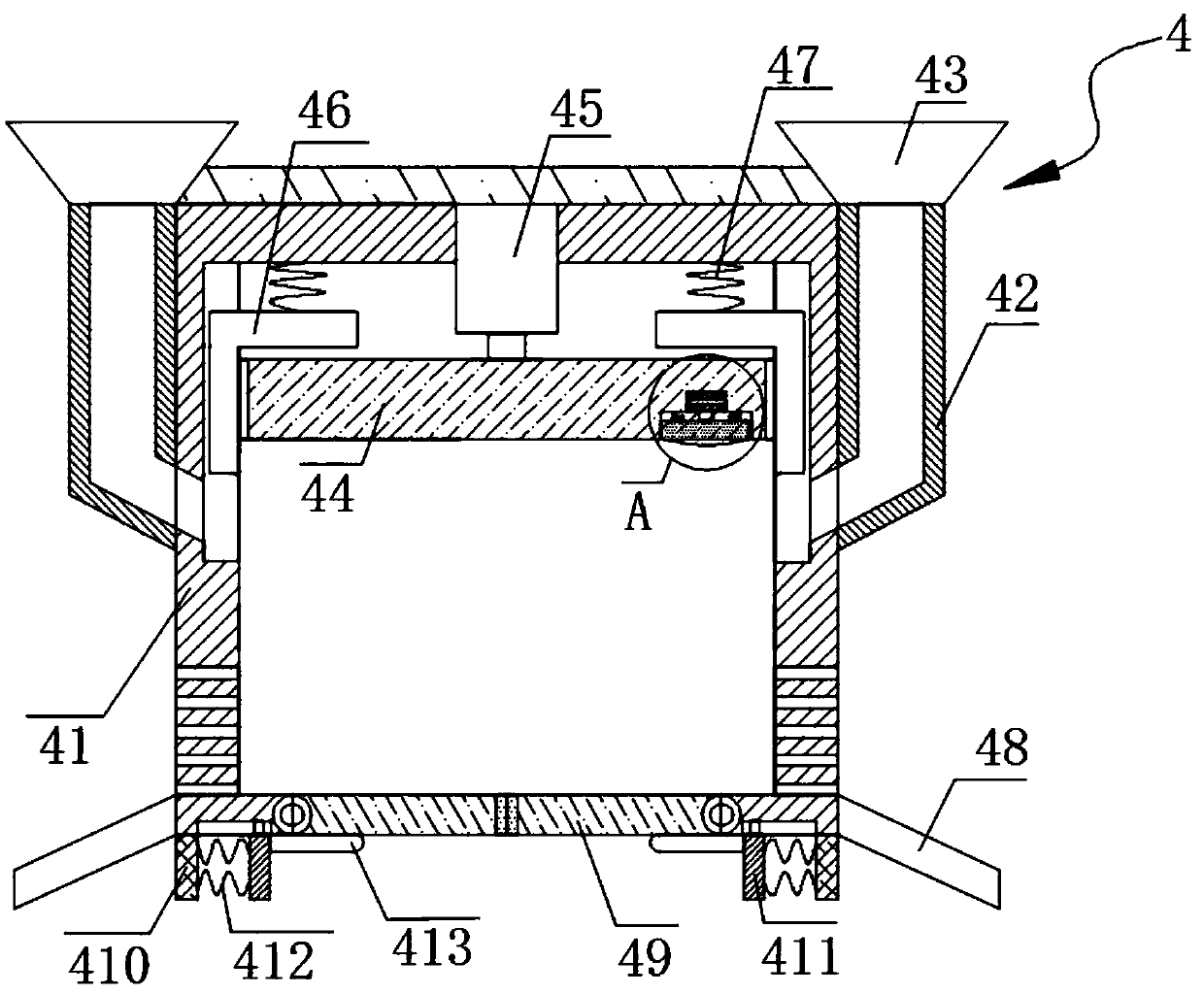

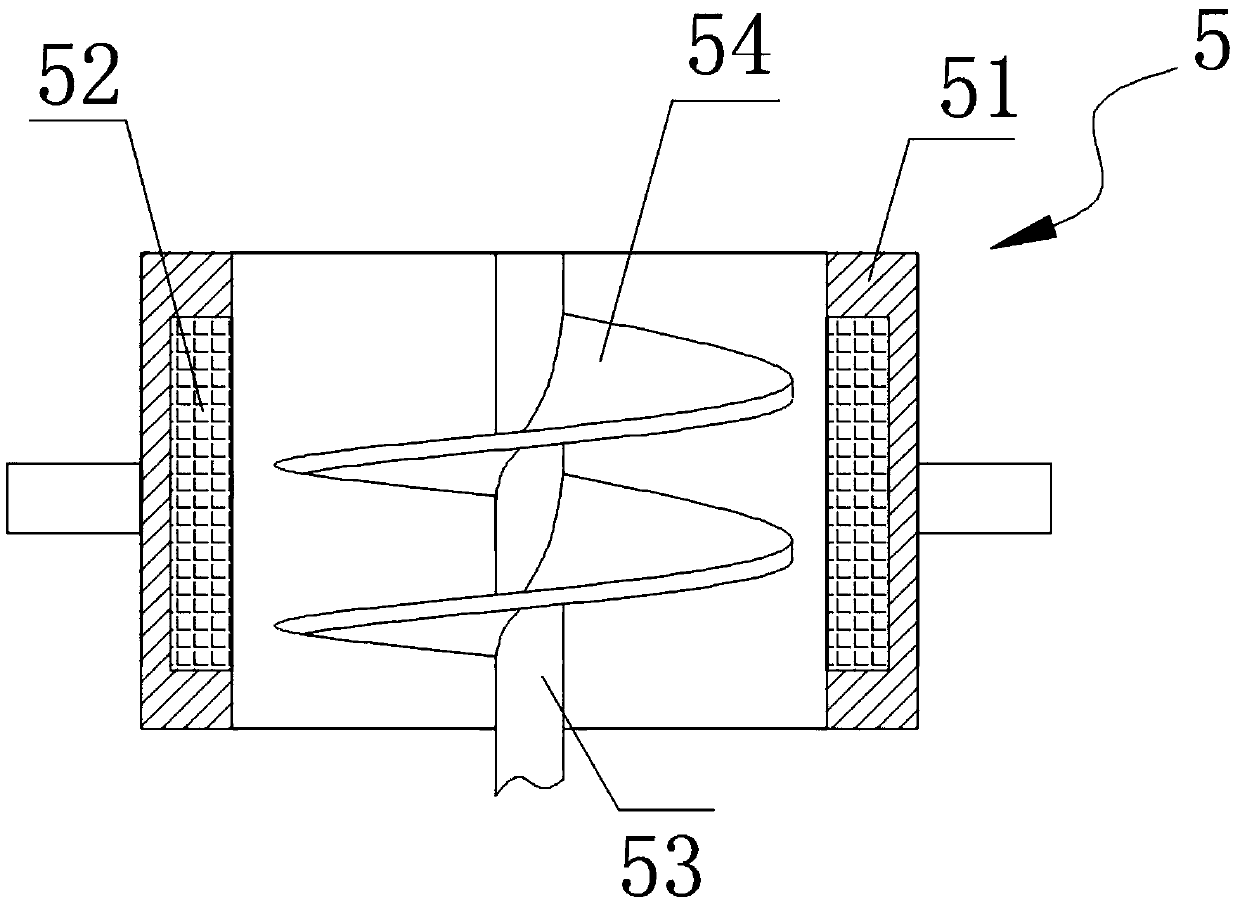

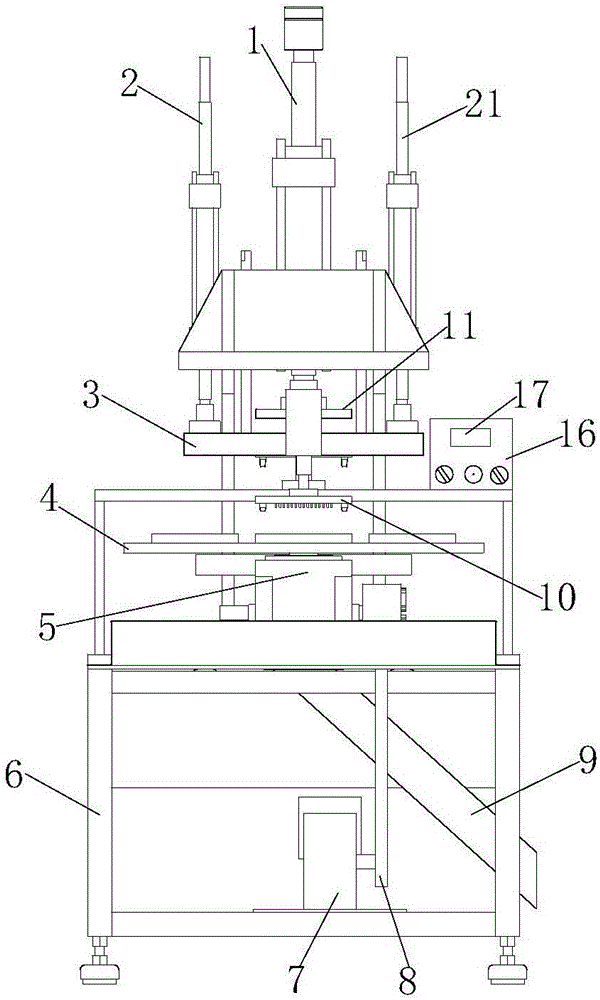

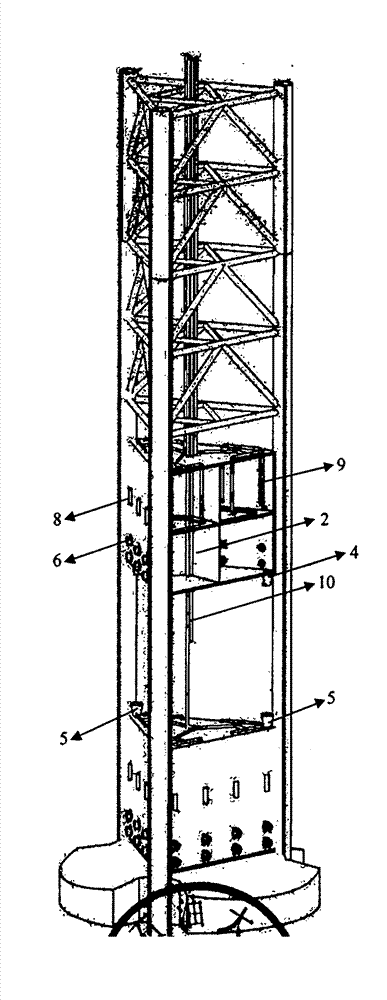

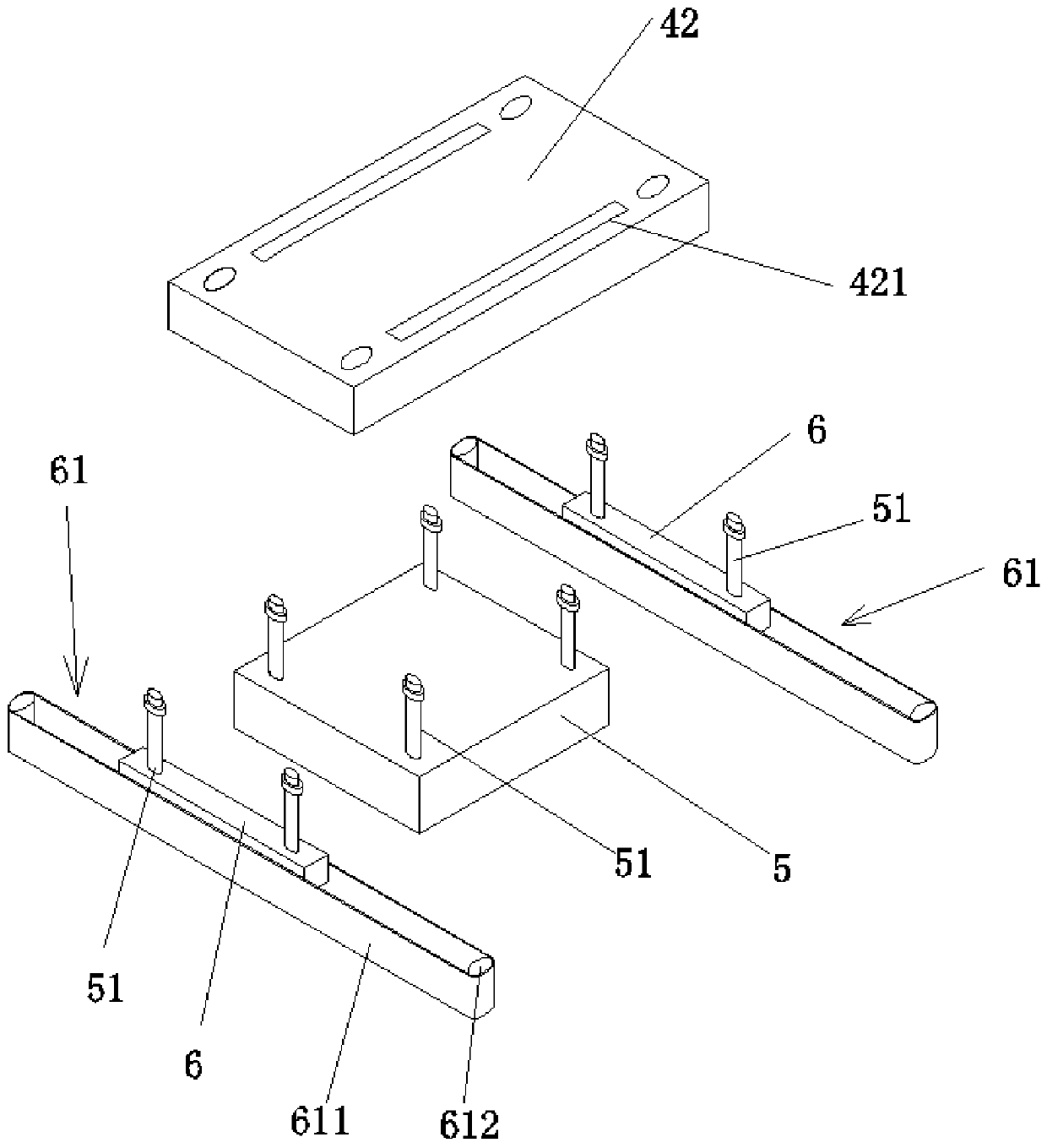

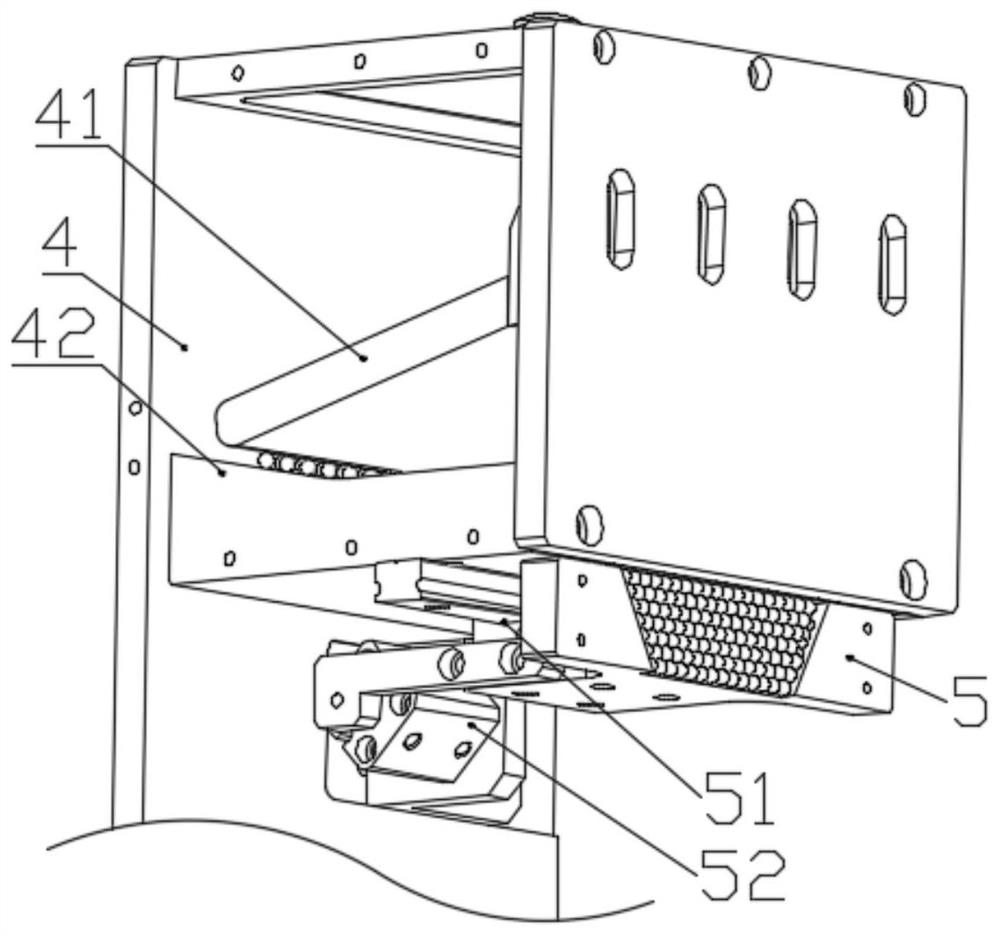

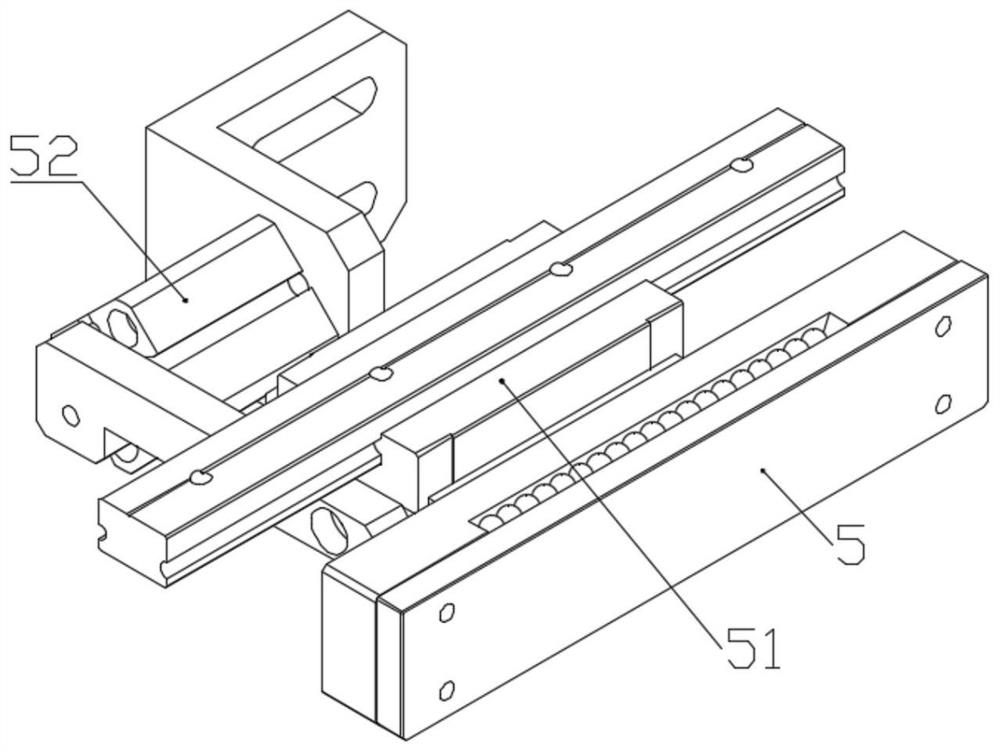

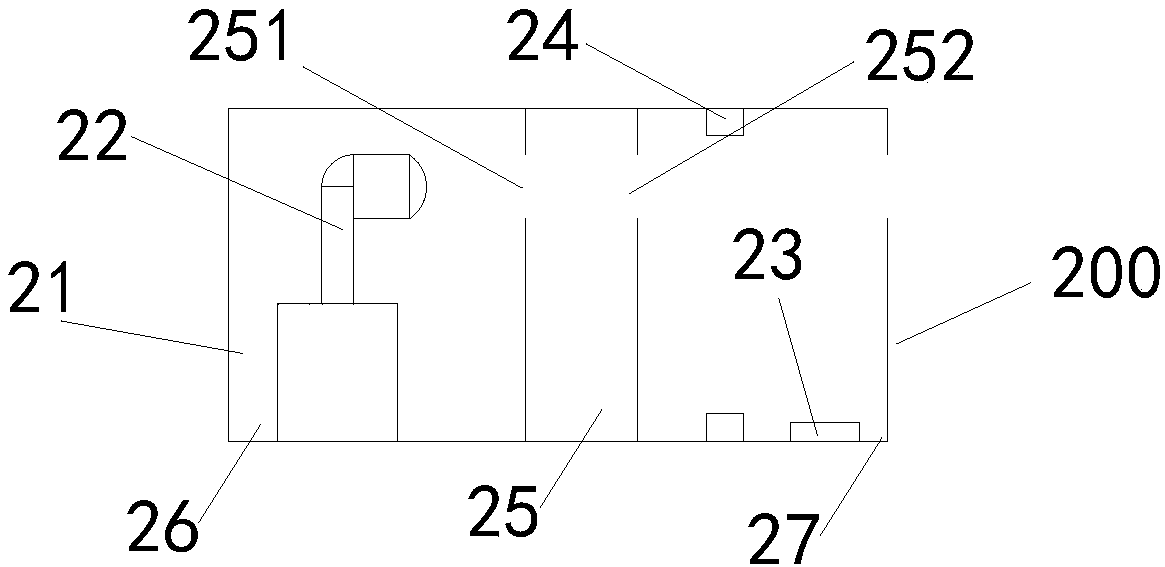

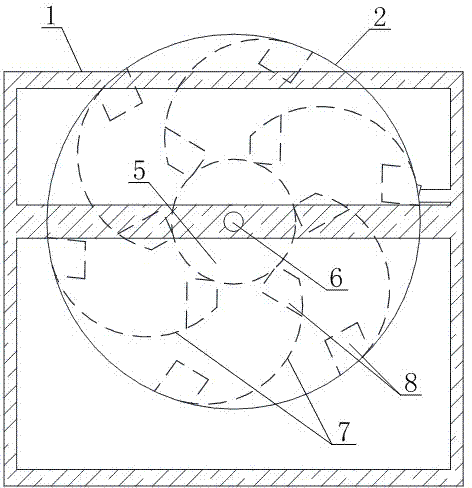

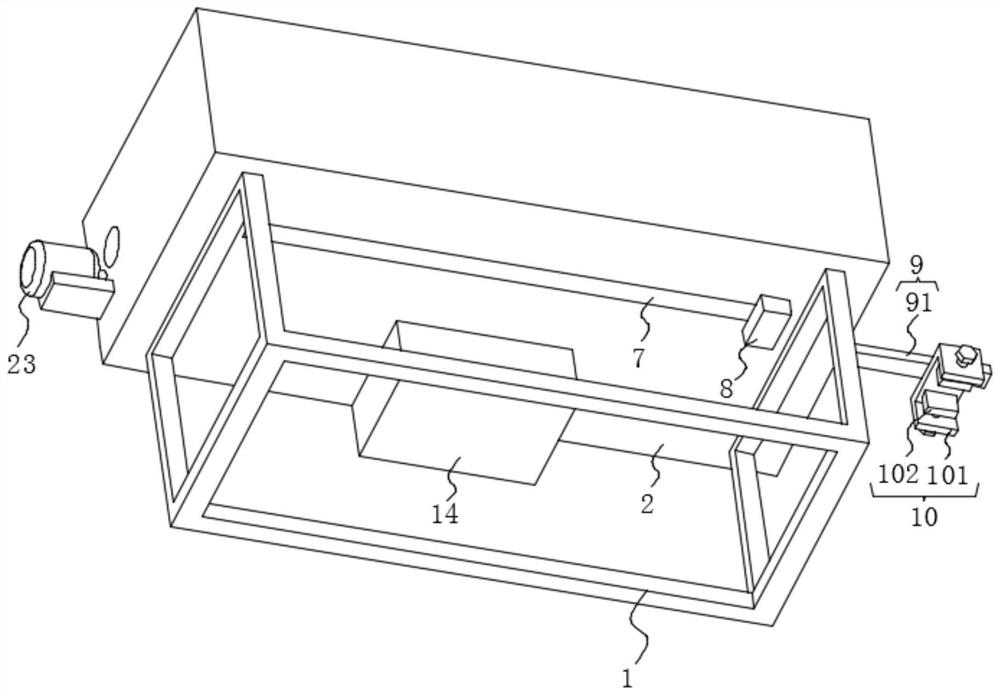

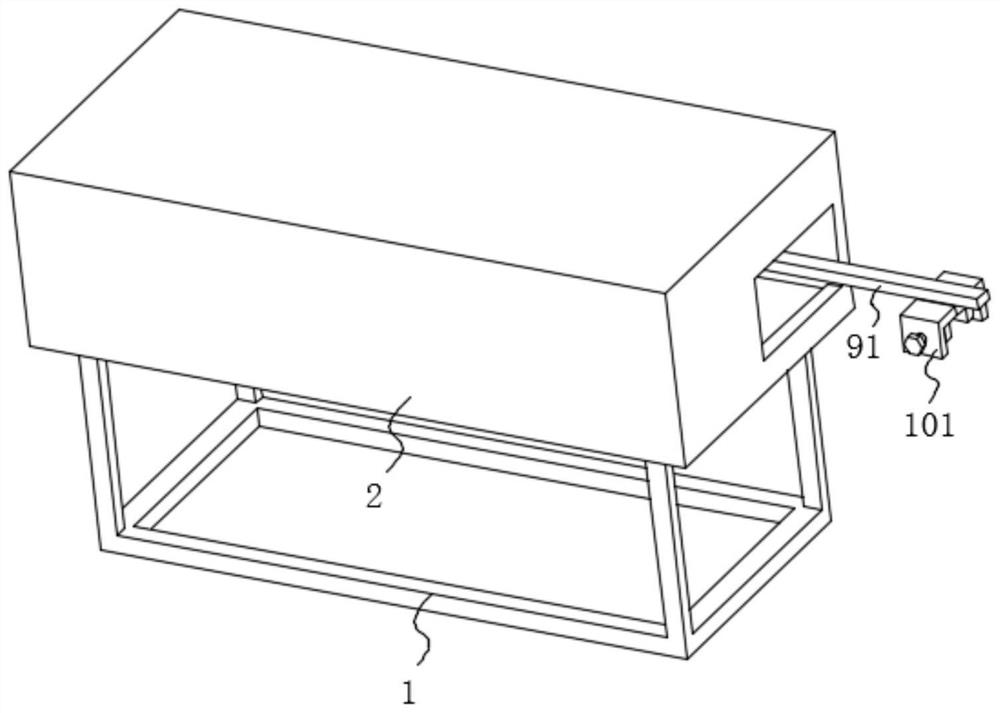

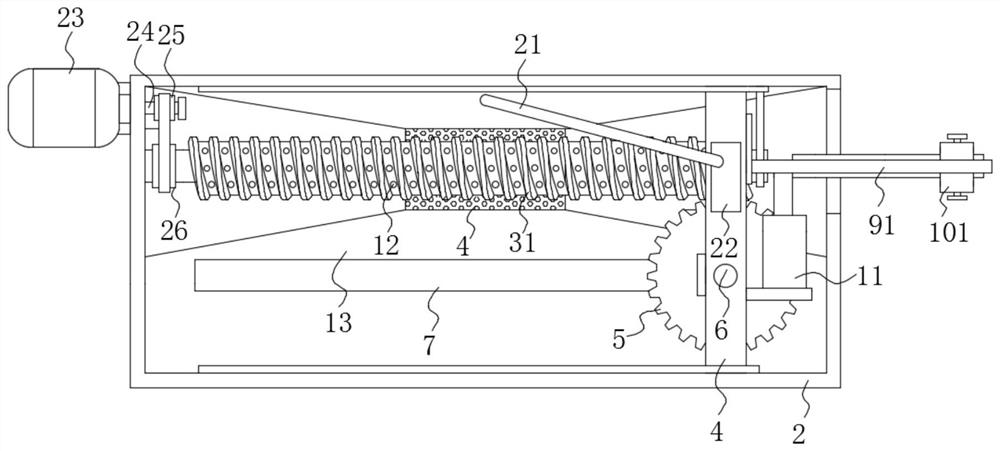

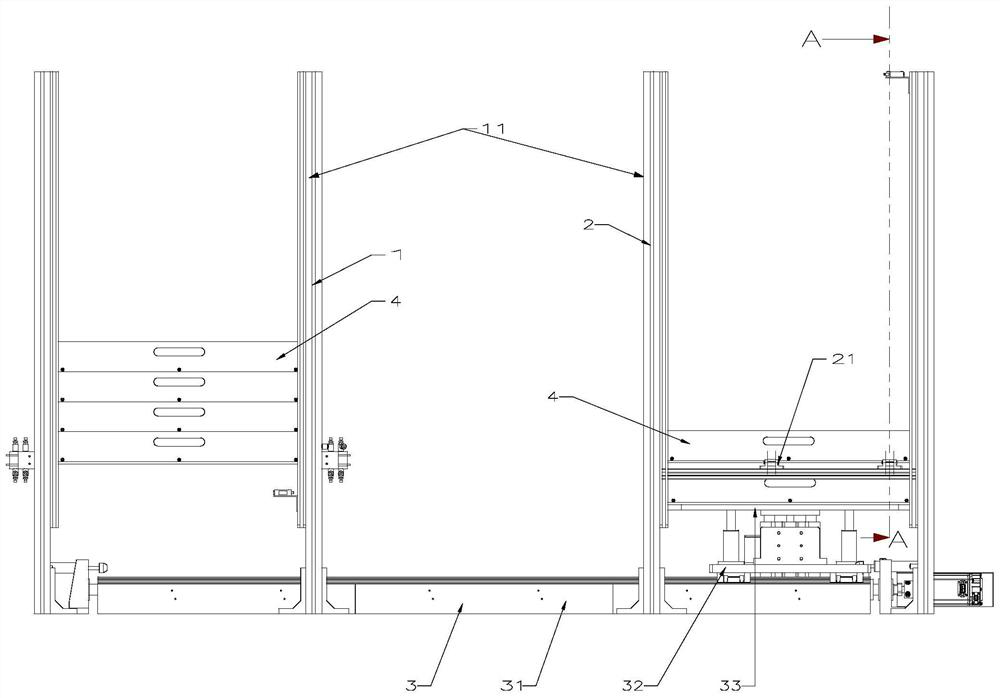

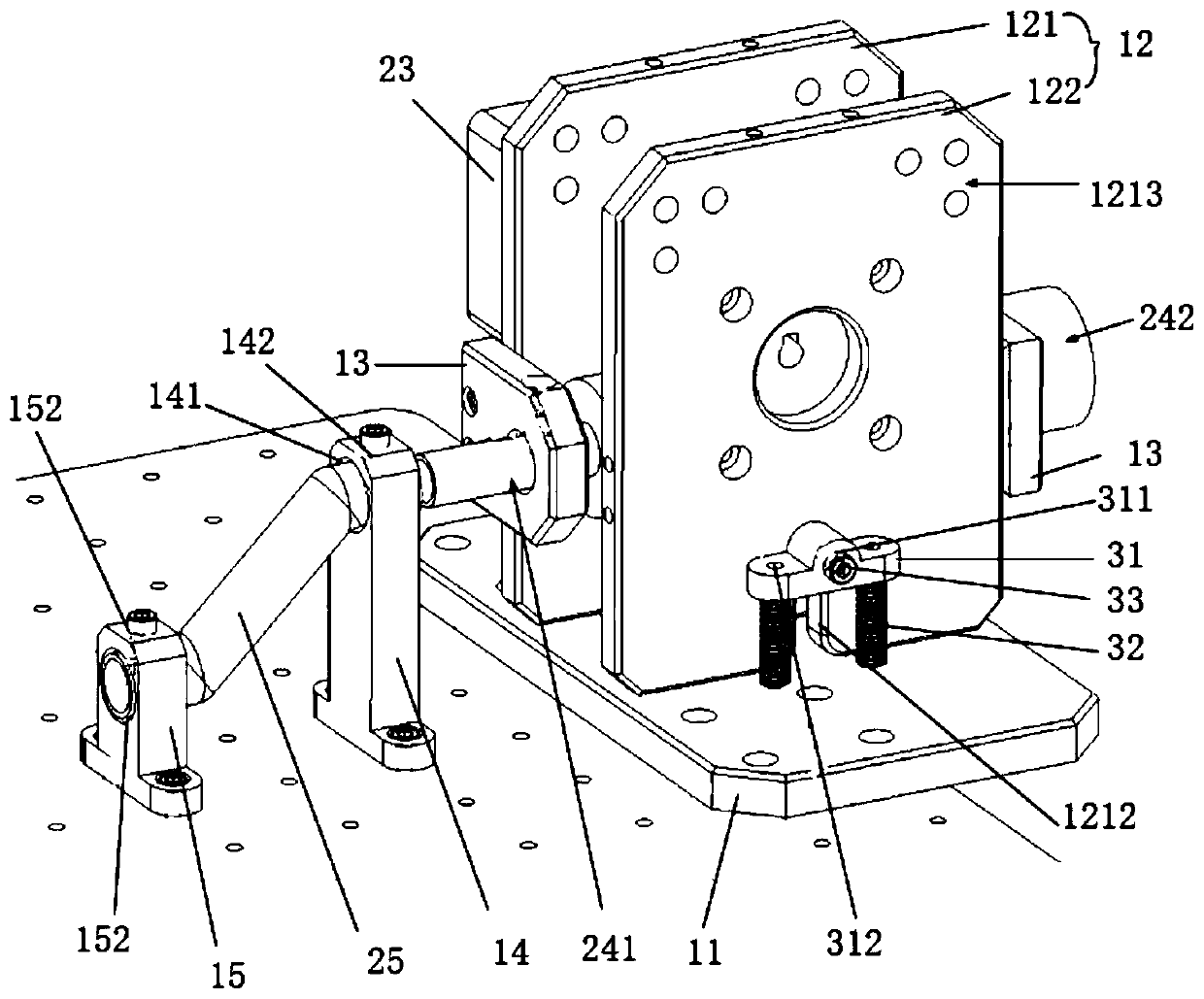

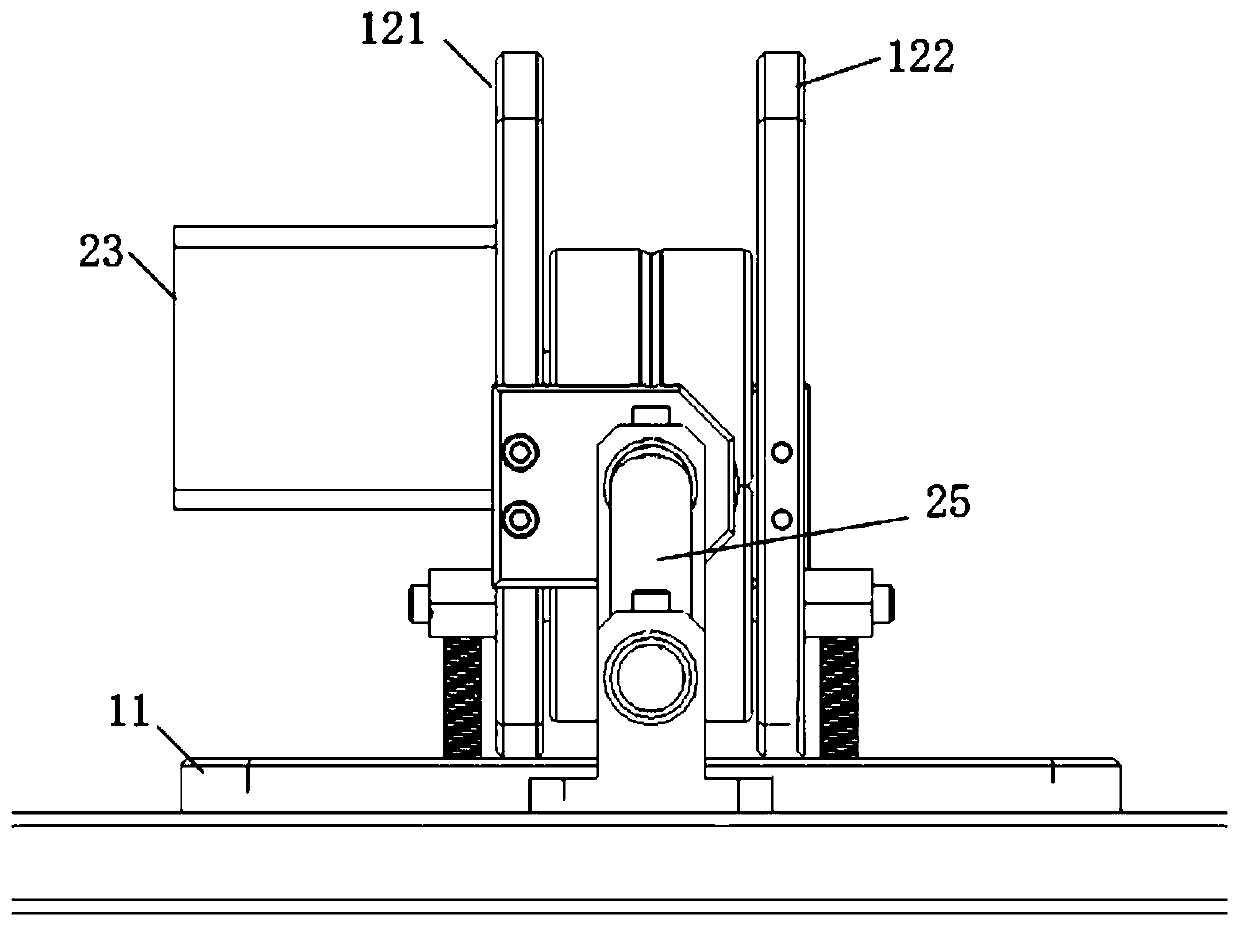

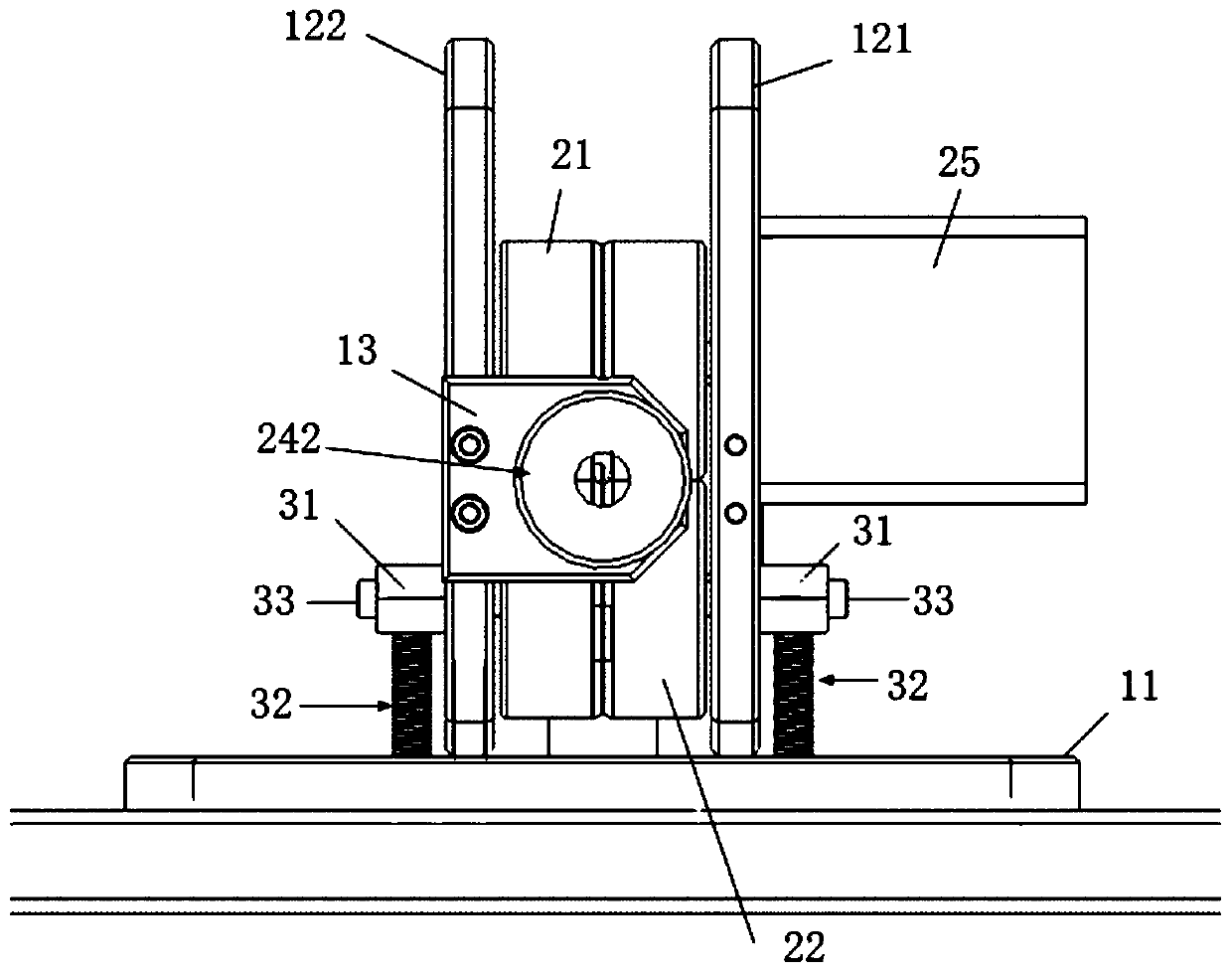

Intelligent counting-binding integrated machine

InactiveCN106780985AAutomatic entryFully automated processingCoin/currency accepting devicesMachine partsEngineering

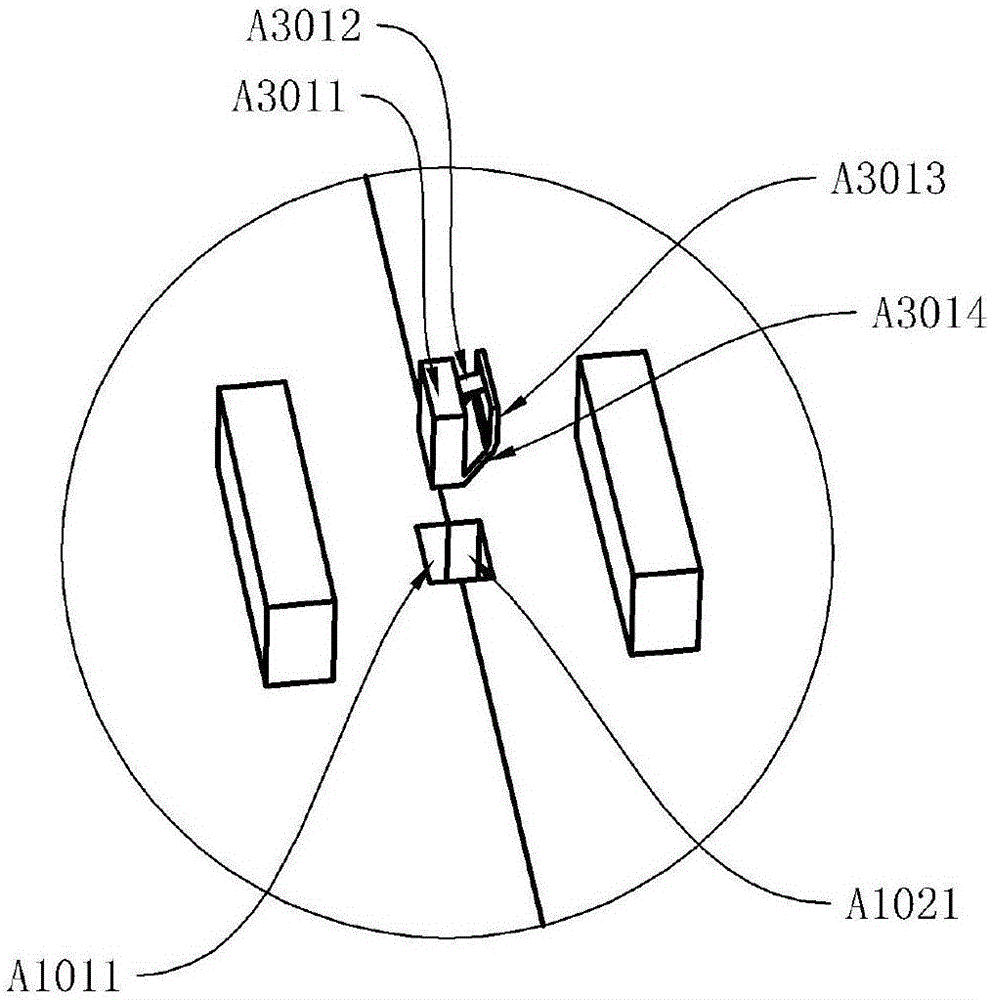

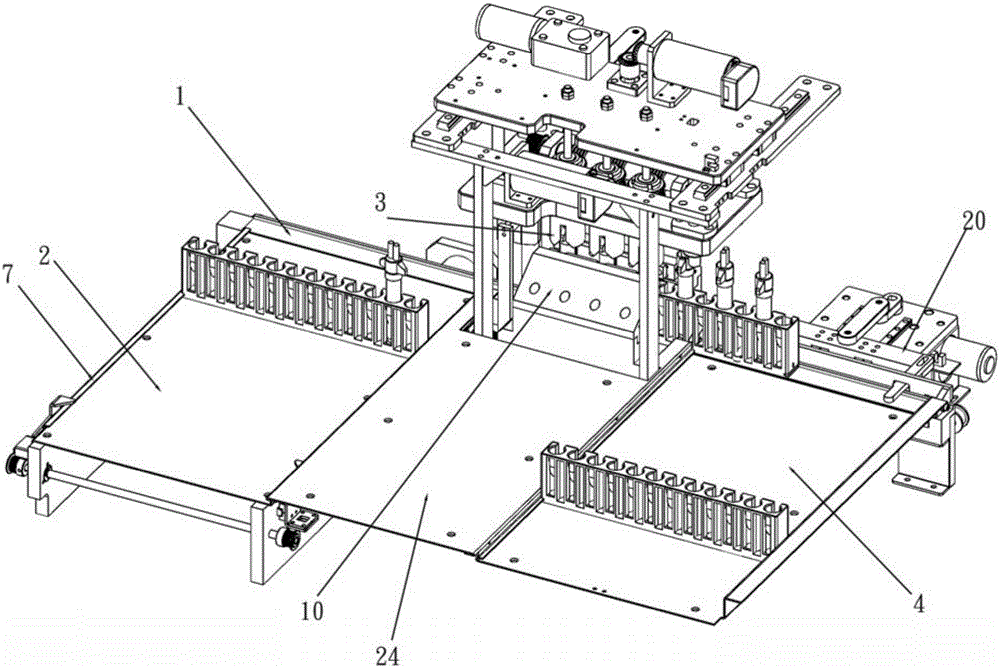

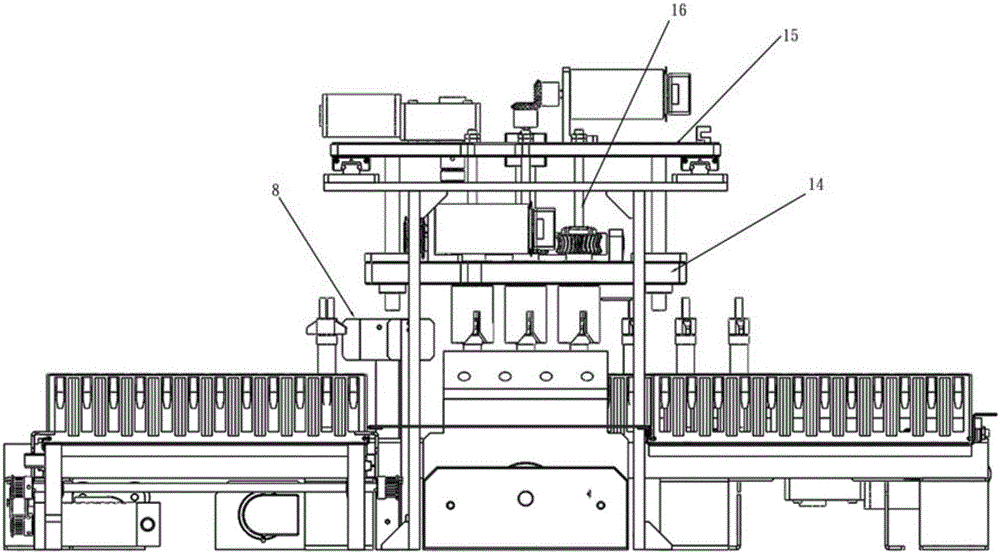

The invention discloses an intelligent counting-binding integrated machine capable of realizing a series of functions of automatic counting, checking, collecting of suspended counterfeit notes, binding and the like. The intelligent counting-binding integrated machine comprises a note feeding mechanism, a note checking body and a note binding mechanism; the note checking body is used for note counting and checking and comprises a top plate assembly, a dust box assembly, a second note receiving plate, a note dividing assembly and a note sending assembly, and the note sending assembly belongs to the note binding mechanism; the note checking body further comprises a frame, a first sleeve and a second sleeve; the frame comprises a first vertical plate and a second vertical plate, the bottom of the first vertical and the bottom of the second vertical plate are connected through a bottom plate, and the top plate assembly is arranged at the top of each of the first vertical plate and the second vertical plate. By the arrangement, notes can be fed into the note checking body intermittently by adopting the note feeding mechanism, note checking and binding efficiency is improved, functions of settling, aligning, pressing and the like of strapped notes are realized by adopting the note sending assembly and a note pressing assembly, and notes to be bound can be fed to a note binding machine part to be bound.

Owner:WEIRONG TECH CO LTD

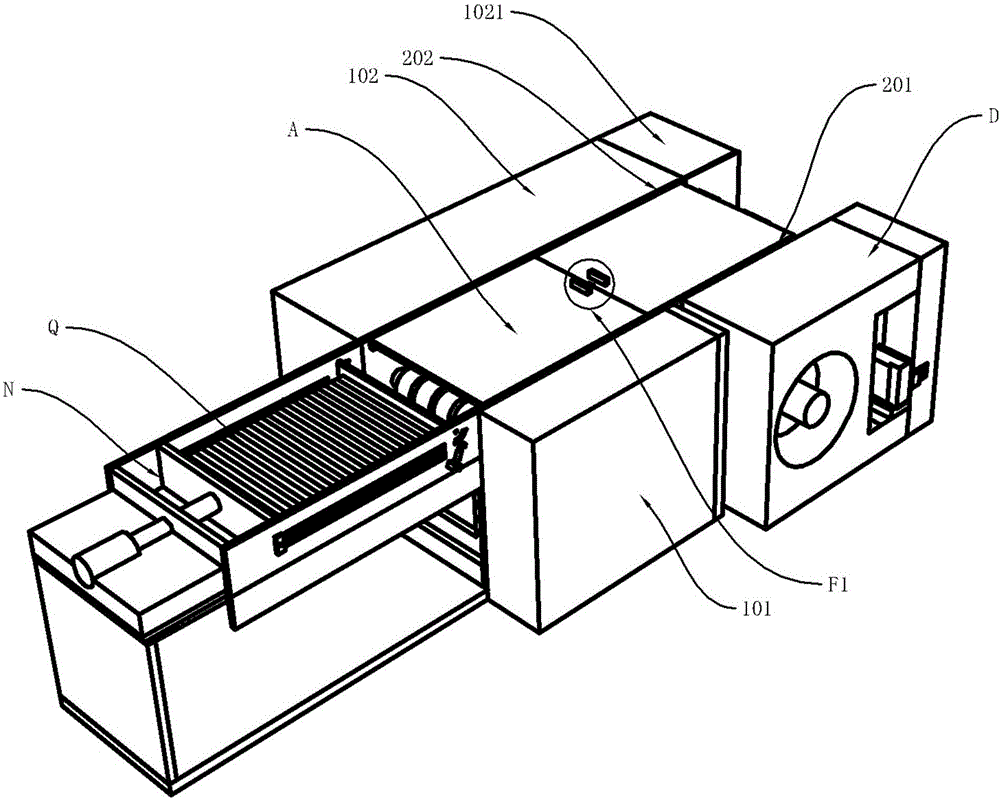

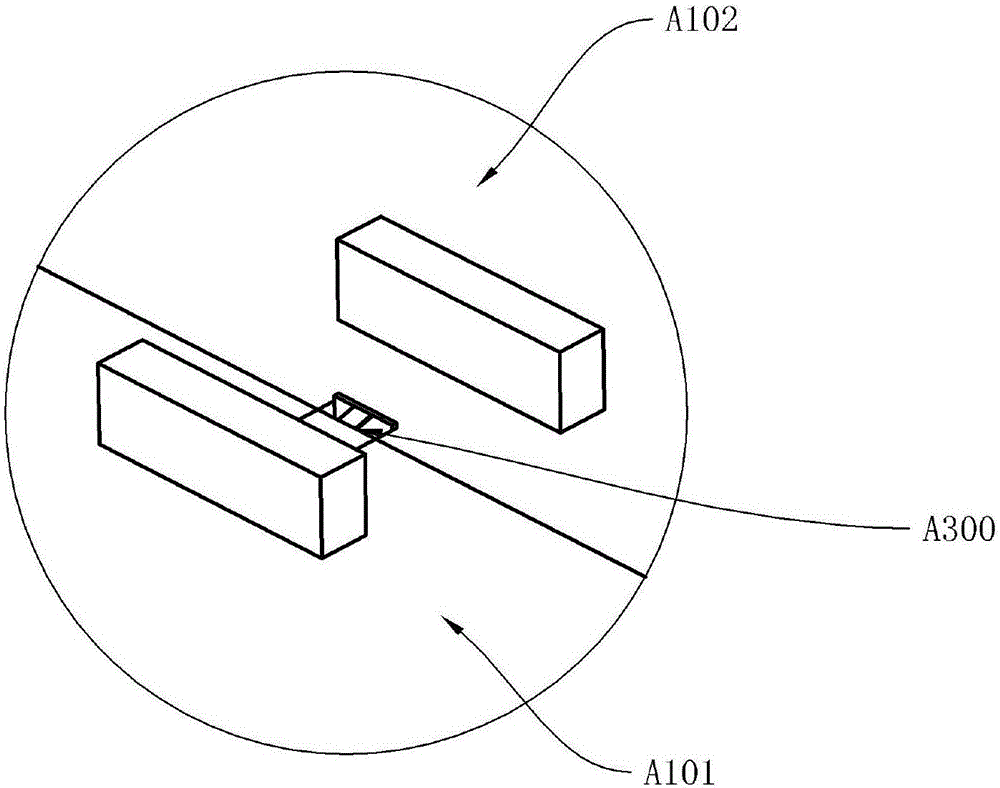

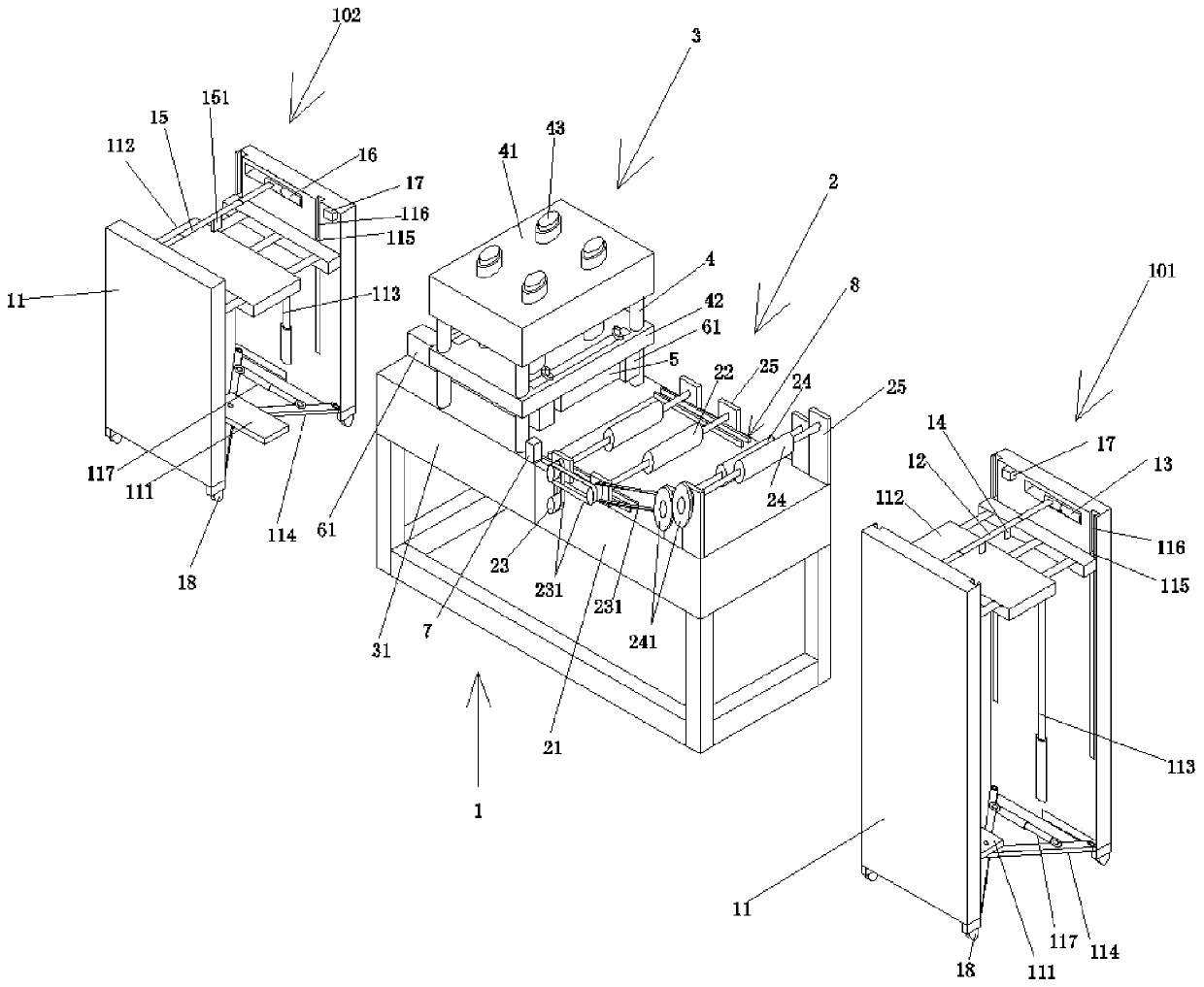

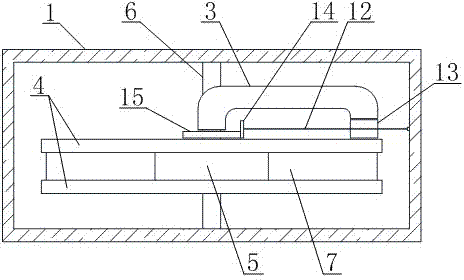

Full-automatic test tube cap tightening instrument

PendingCN106586925AReduce work intensityImprove work efficiencyTight-fitting lid removalThreaded caps removalEngineeringUltimate tensile strength

The invention relates to a full-automatic test tube cap tightening instrument. The full-automatic test tube cap tightening instrument comprises a movable guide rail; the head end of the movable guide rail is connected with a feed frame module; further, the feed frame module is provided with a feed frame table plate positioned on the same one plane with the movable guide rail; a cap tightening module is arranged at the middle end of the movable guide rail; further, the cap tightening module is at least provided with a cap tightening cylinder; a discharge frame module is arranged at the tail end of the movable guide rail; the discharge frame module includes a pushing mechanism; and further, the discharge frame module is provided with a discharge frame table plate positioned on the same one plane with the movable guide rail. The cap tightening module includes test tube clamping blocks arranged on two sides of the movable guide rail; the test tube clamping blocks are connected with clamping inserts; further, accommodating semicircular holes are formed in the inner sides of the clamping inserts; and concave convex grooves are formed in the inner walls of the accommodating semicircular holes. The full-automatic test tube cap tightening instrument can overally realize automatic test tube cap tightening, is high in working efficiency and excellent in cap tightening effect, reduces the working intensity of related staff, and meanwhile, can prevent the sample pollution caused by manual cap tightening.

Owner:YANTAI HAISHENWEI MEDICAL TECH

Calcium carbonate processing device for flame retardant cables

ActiveCN109551804AAutomatic entryImprove work efficiencyDrying solid materials without heatGrain treatmentsWater filterPulp and paper industry

The invention provides a calcium carbonate processing device for flame retardant cables. The calcium carbonate processing device for the flame retardant cables comprises a processing box, a pluralityof supporting feet connected to the lower end of the processing box, two symmetrical discharging openings connected to the lower end of the processing box in a cutthrough mode, a motor connected to the bottom wall of the processing box through a first supporting frame and a rotary shaft connected to a rotating shaft of the motor. According to the calcium carbonate processing device for the flame retardant cables, deficiencies of the prior art are overcome, the design is reasonable, and the structure is compact; a pressure test of a mixed solution of calcium carbonate sediment and water is carried out through a pressing plate, the water in the solution is enabled to outflow through water filtering holes, and thus the dehydration process is achieved; the water in the calcium carbonate sediment is heated and evaporated by annular heating plates, and thus a good drying effect is achieved; and through the structural combination of touch rods and touch plates, a trapezoid circular table is driven to shake, and thus the smashing effect is realized; and the number of operation processes is reduced, and the working efficiency is improved.

Owner:天长市运成电缆辅料有限公司

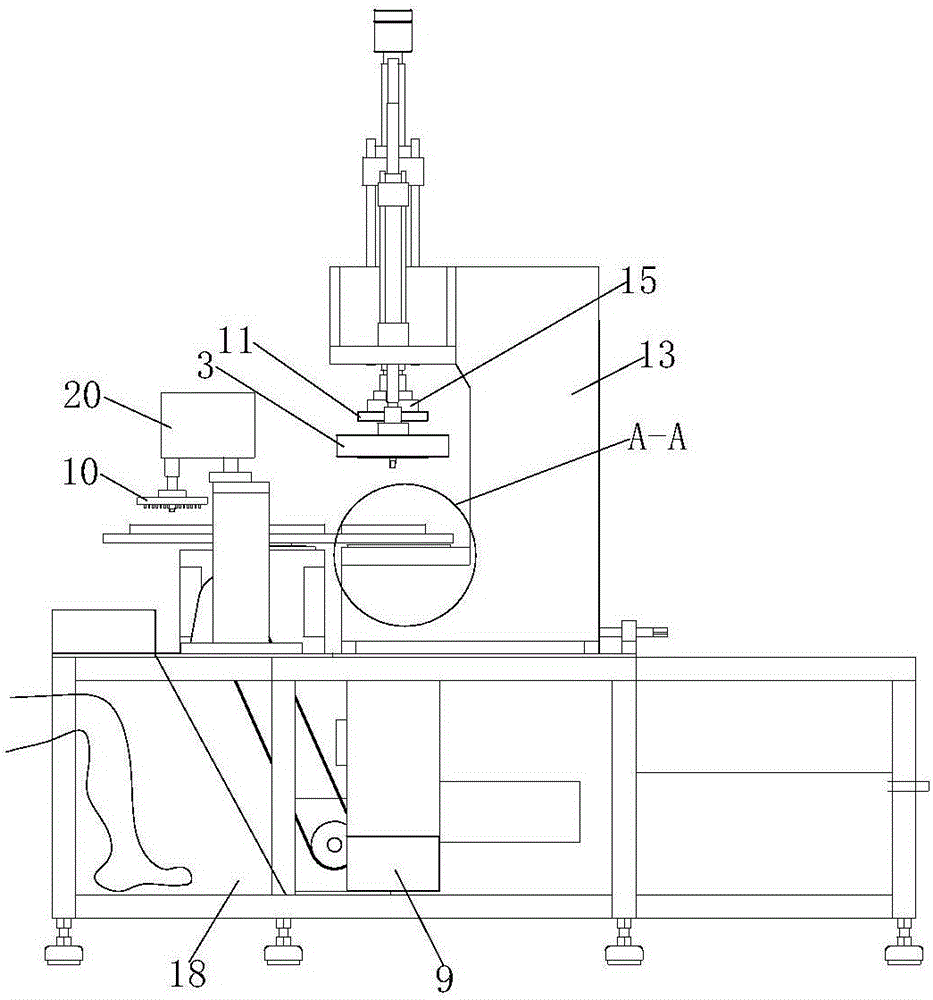

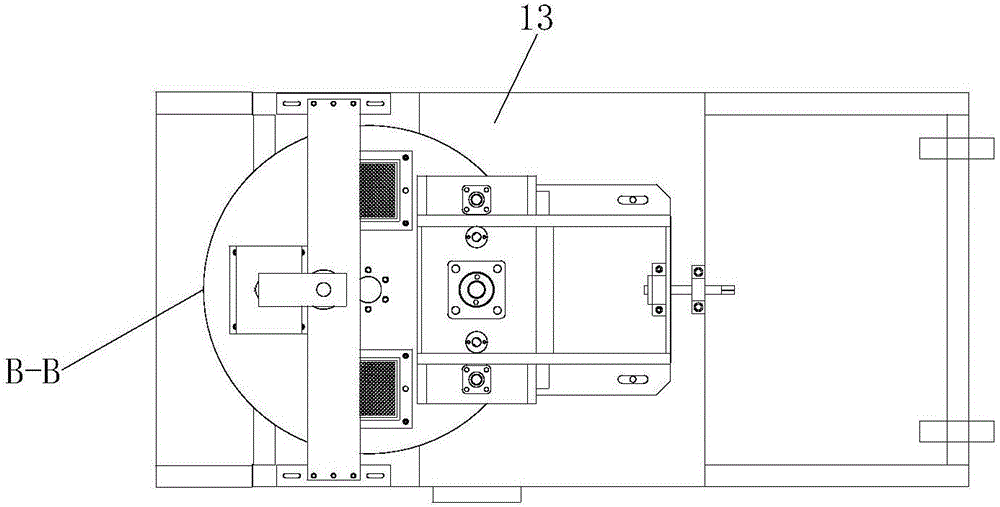

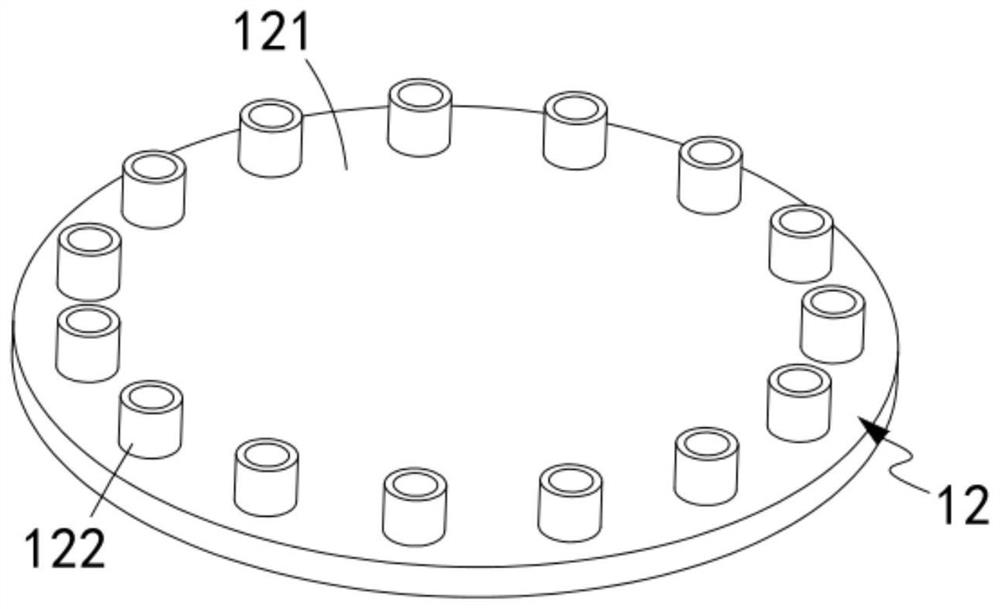

Multi-station rotating disc type force measuring type hydraulic machine

InactiveCN106694671AReduce harmAvoid harmMetal-working feeding devicesShaping safety devicesPunchingEngineering

The invention discloses a multi-station rotating disc type force measuring type hydraulic machine. The multi-station rotating disc type force measuring type hydraulic machine comprises a host body, a large oil cylinder is arranged on the host body, a punching plate is fixedly connected to the bottom of the large oil cylinder, a middle plate is fixedly connected to the bottom of a first small oil cylinder and the bottom of a second small oil cylinder, a worktable rotating disc is arranged below the middle plate, mold products are arranged on the worktable rotating disc, a blanking groove is formed in one side of the worktable rotating disc, and an electric motor is arranged in a rack, and is connected with the worktable rotating disc through a synchronous belt. According to the multi-station rotating disc type force measuring type hydraulic machine, design of the worktable rotating disc can meet multi-station multi-working-procedure requirements, the simultaneous punching working procedure of manual operation and machine punching is flexible and changeable and can adapt to machining of many mold products, precise machining of the mold products can be achieved, the hurt to the person is avoided, and the beneficial effects that cutting and punching are precise, the products automatically enter and are moved out of an operation table, operation is easy, and work efficiency is high are achieved.

Owner:东莞市金拓机械有限公司

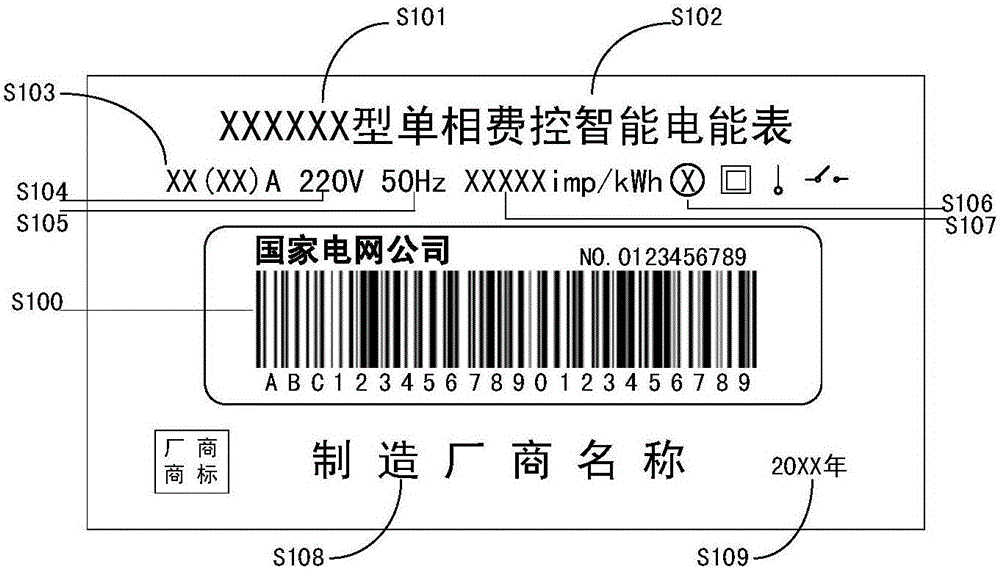

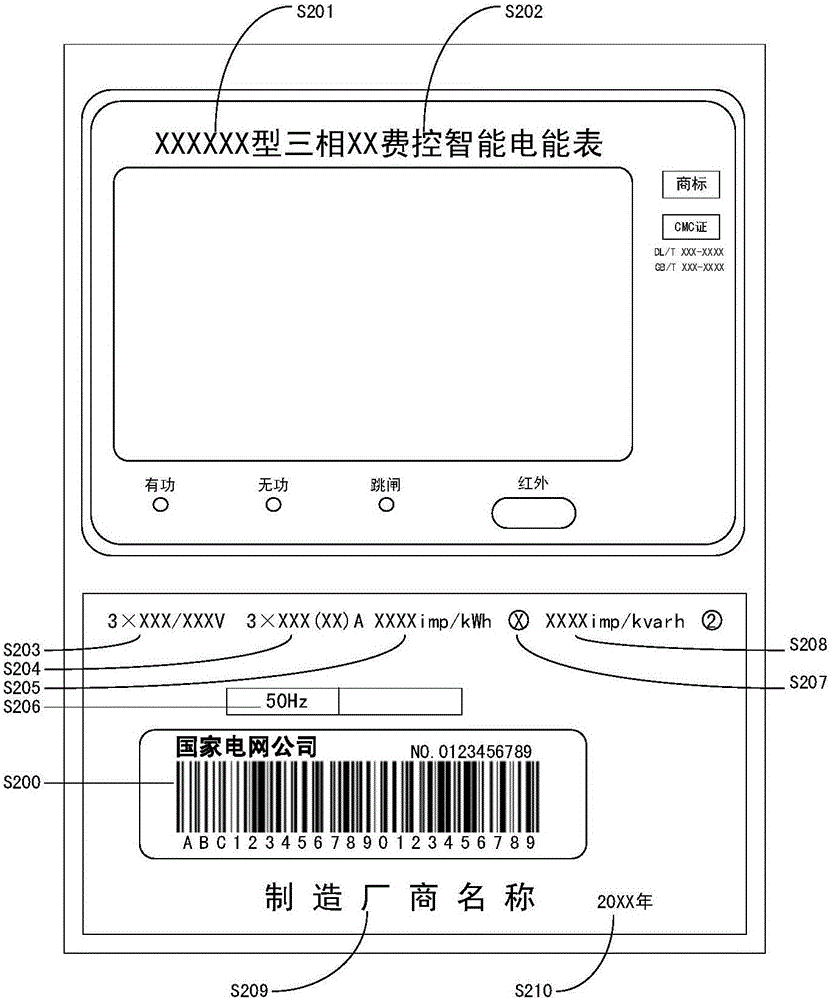

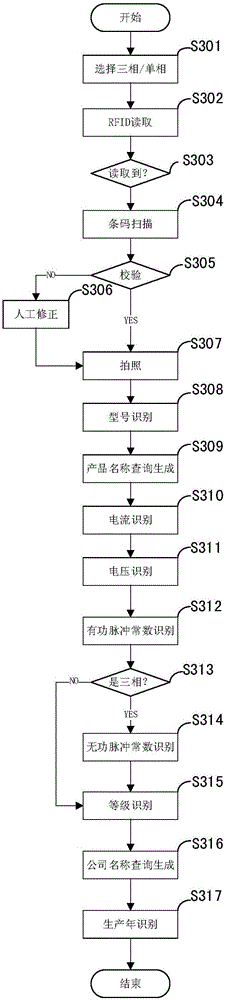

Measuring asset intelligent quick associative type-in method based on image recognition

ActiveCN106203205AHighlight substantive featuresImprove work efficiencyMemory record carrier reading problemsCharacter and pattern recognitionSingle phaseInformation type

The invention provides a measuring asset intelligent quick associative type-in method based on image recognition. The method is characterized by including the following steps that firstly, an operator holds a multifunctional handheld terminal by hand and operates application software to select whether a single-phase table or three-phase table needs to be typed in, and the handheld terminal is aligned to an RFID and a barcode area and is about 5 cm away from an intelligent electric meter; secondly, the operator starts type-in; thirdly, after an asset ID is read to be correct, the multifunctional handheld terminal prompts the operator to take photos; fourthly, after photographing, the multifunctional handheld terminal automatically recognizes the photos, and finally type-in of measuring asset information is finished. Compared with existing manual copying, the method has outstanding substantial characteristics and remarkable progress technically. Specifically, automatic, quick and accurate measuring asset information type-in is achieved on site, on-site work efficiency and accuracy of the typed information are greatly improved, and labor intensity is reduced.

Owner:STATE GRID CORP OF CHINA +1

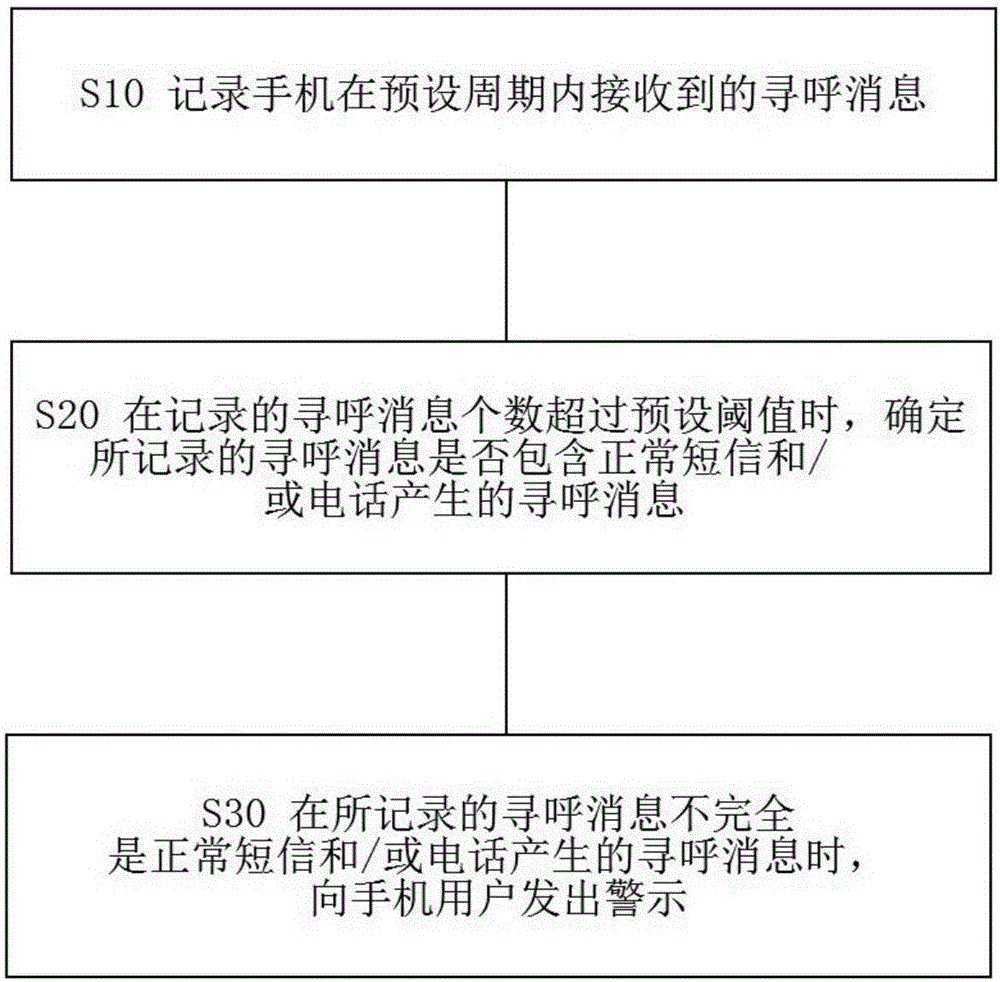

Detecting and monitoring method and system for mobile terminal

InactiveCN106454845AProtect personal privacyProtect informationSecurity arrangementComputer terminalPaging

The invention discloses a detecting and monitoring method and system for a mobile terminal, wherein the method comprises the following steps: recording paging messages received by the mobile terminal within a preset period; when the number of the paging messages recorded in the preset period exceeds a preset threshold, determining whether the recorded paging messages comprise a paging message generated by a normal short message and / or a phone call or not; and when the recorded paging messages are not paging messages generated by normal short messages and / or phone calls completely, giving an alarm to a user of the mobile terminal. According to the detecting and monitoring method and system, the user can automatically find the condition that own mobile phone is being detected, so as to take a measure in time. Therefore, personal privacy and information are protected.

Owner:BEIJING YUANXIN SCI & TECH

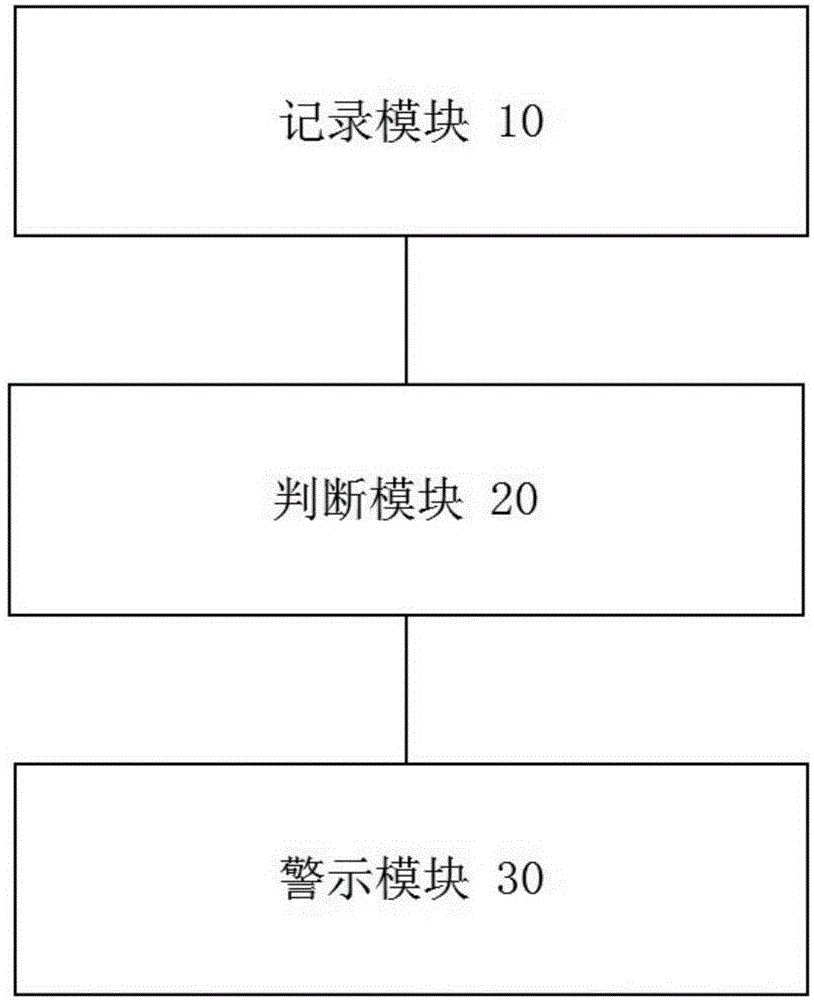

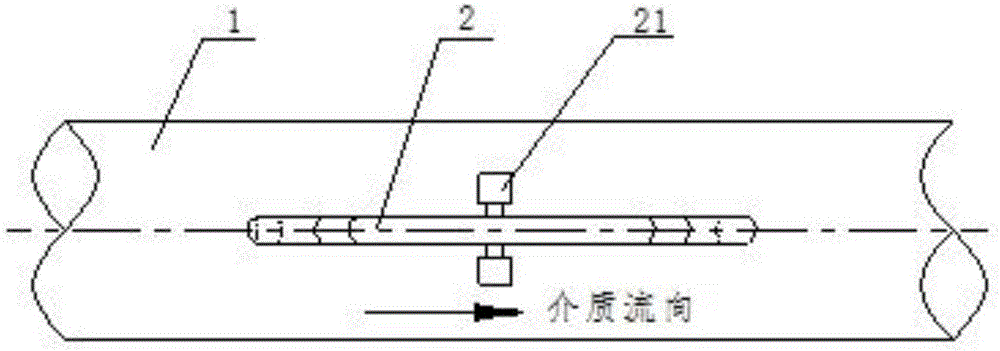

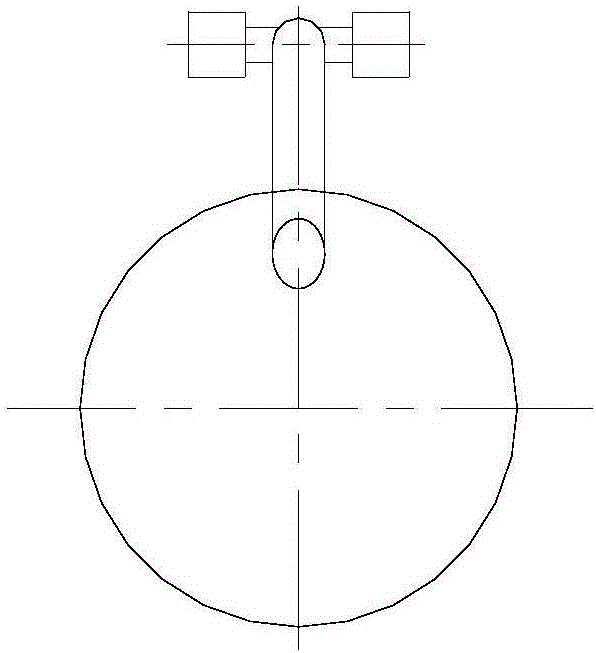

Bypass sampling method for measuring oxygen content of coke oven gas by use of laser gas analyzer

PendingCN106770025AEasy to installEasy to useWithdrawing sample devicesColor/spectral properties measurementsCoke ovenProduct gas

The invention relates to a bypass sampling method for measuring oxygen content of coke oven gas by use of a laser gas analyzer. The method comprises the following steps: 1) a bypass sampling device is arranged at a sampling point of a process medium pipeline; 2) after entering a bypass sampling pipe, the medium in the process medium pipeline automatically flows downstream; and in the flowing process, the medium flow is analyzed and probed by the laser gas analyzer and then flows back into the process medium pipeline through a rear sampling port; and 3) to overhaul the laser gas analyzer, a sampling stop valve I and a sampling stop valve II are shut down in turn. According to the invention, through the bypass sampling pipe parallel to the process medium pipeline and different forms of the rear sampling port, the medium can automatically enter the bypass sampling pipe and flow therein for sure; and by arranging a gas analyzer interface at a proper position on the bypass sampling pipe and connecting with the laser gas analyzer, the installation, use and maintenance of the laser gas analyzer are greatly facilitated.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

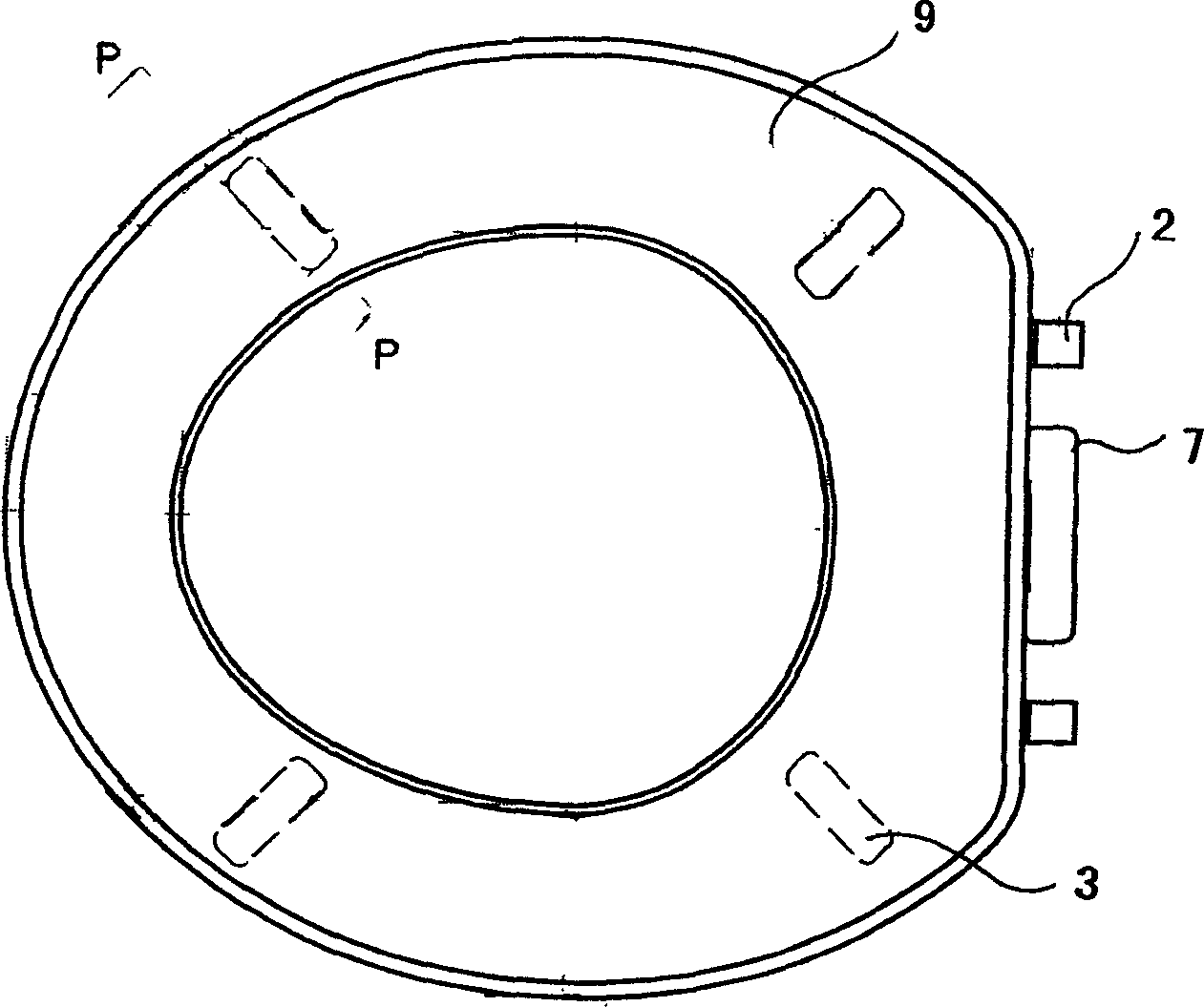

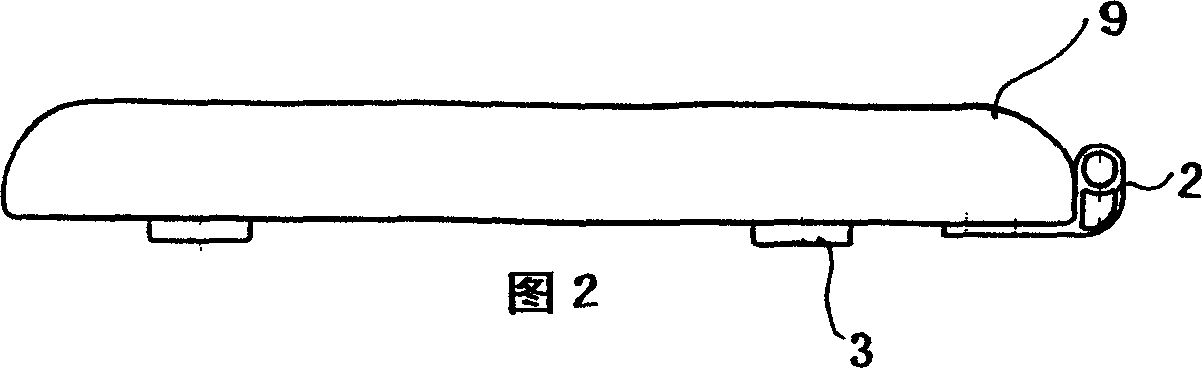

Toilet seat with gas bag structure

A sitting ring with air bag structure for water toilet has a sitting ring body which is composed of symmetrical supporting legs, the air bag structure consisting of concave-convex slots on the internal and external peripheries and multiple sealed U-shaped elastic air cushion sheets, at least one air inlet on at least one leg and communicated with the V-shaped through hole on the sitting ring body, the ball and its protecting bowl with at least two internal holes and positioned in V-shaped through hole and air cavity respectively, an air spraying hole at its back end and with an air spraying tube, and an ingredient box connected with said air spraying tube and laving several air outlet holes.

Owner:张铁骑

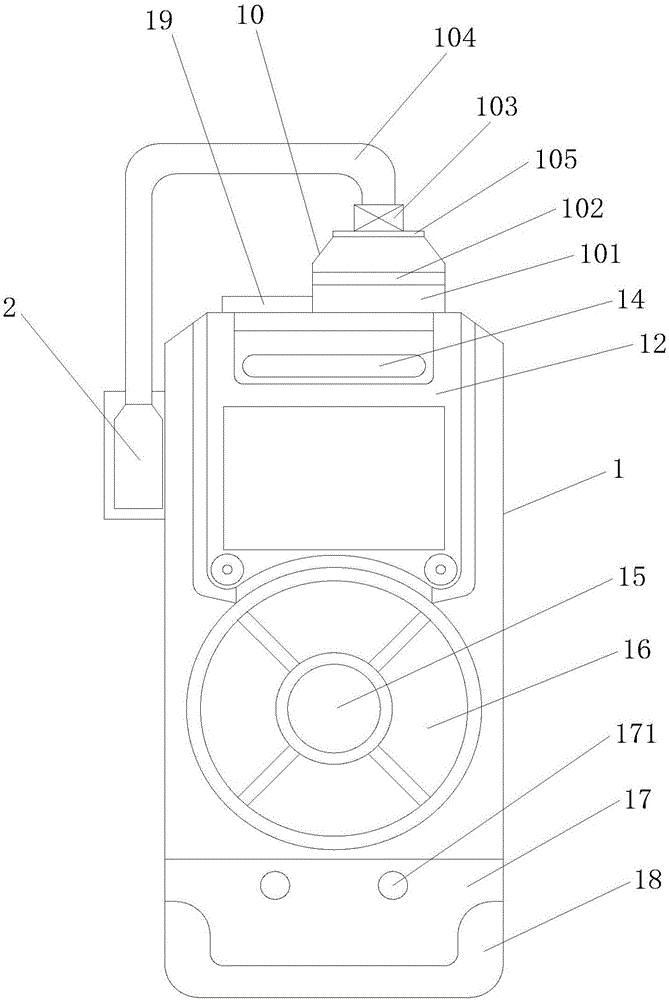

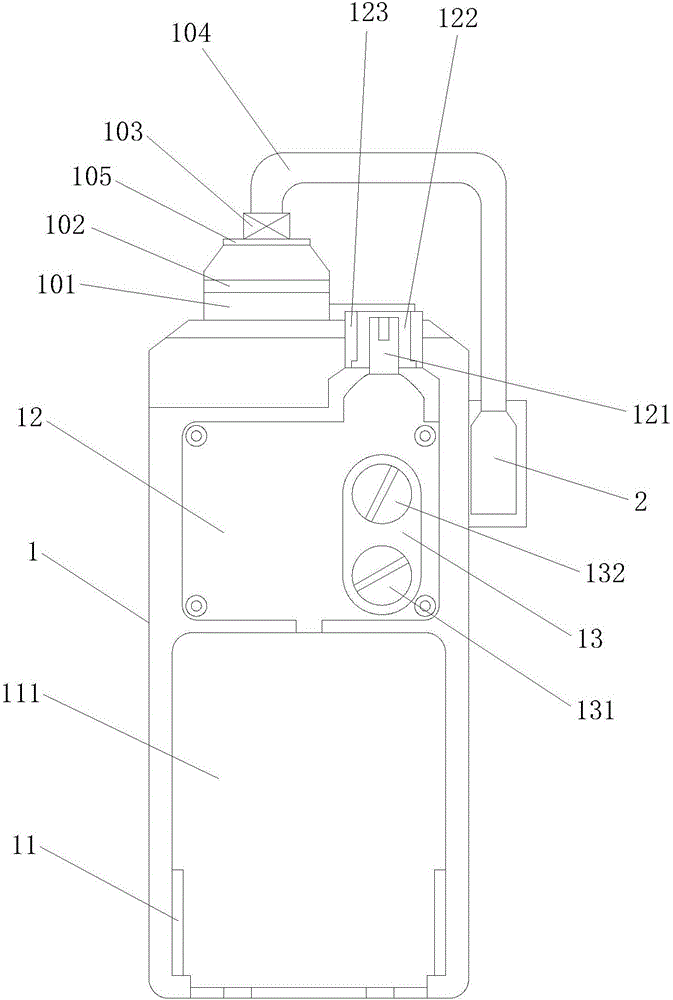

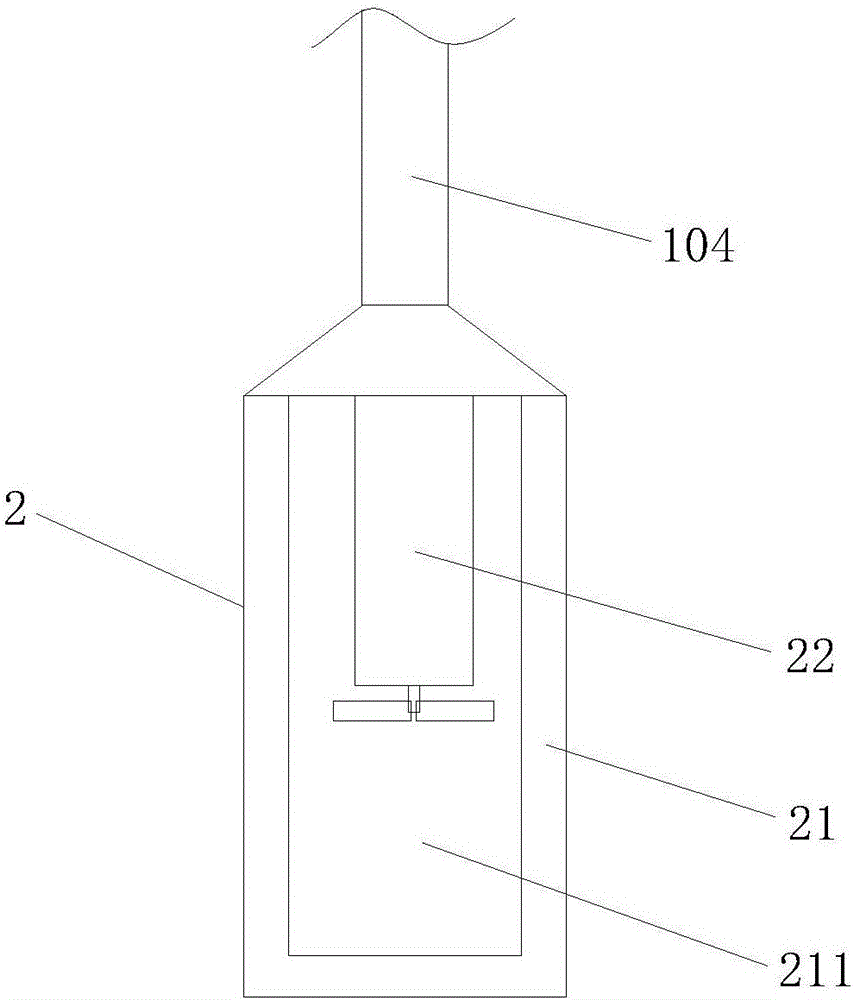

Multifunctional gas quantitative leak detector

ActiveCN106768654ASimple structural designReduce usageAlarmsFluid-tightness measurement using fluid/vacuumGas pipelinePower management

The invention relates to a multifunctional gas quantitative leak detector which comprises a leak detector body, a probe and an electric control unit. An inlet filter seat is arranged on the top of the leak detector body, a power chamber is arranged inside the lower end of the leak detector body, and a flow chamber is positioned on the upper portion of the power chamber; a silencing plate is arranged at the bottom of the inlet filter seat, a check valve is arranged in the center of the top of the inlet filter seat, and a gas pipeline is connected with the inlet filter seat by the check valve; a pressure sensor is further arranged between the top of the inlet filter seat and the check valve; the probe comprises a probe shell and a fan; the probe shell is fixedly connected to the tail end of the gas pipeline; the fan is arranged in a gas chamber of the probe shell; the electric control unit is arranged inside the leak detector body and comprises a controller module, a power switch module, a button module, a gas sensing module, a detection module, a gas alarm module, an indicator lamp module and a power management module. The multifunctional gas quantitative leak detector has the advantages that the multifunctional gas quantitative leak detector is easy and convenient to operate and high in leak detection accuracy and detection efficiency and is small, the flow of to-be-detected gas can be voluntarily adjusted, and the gas can be quantitatively detected.

Owner:WUHAN ORIG TECH CO LTD

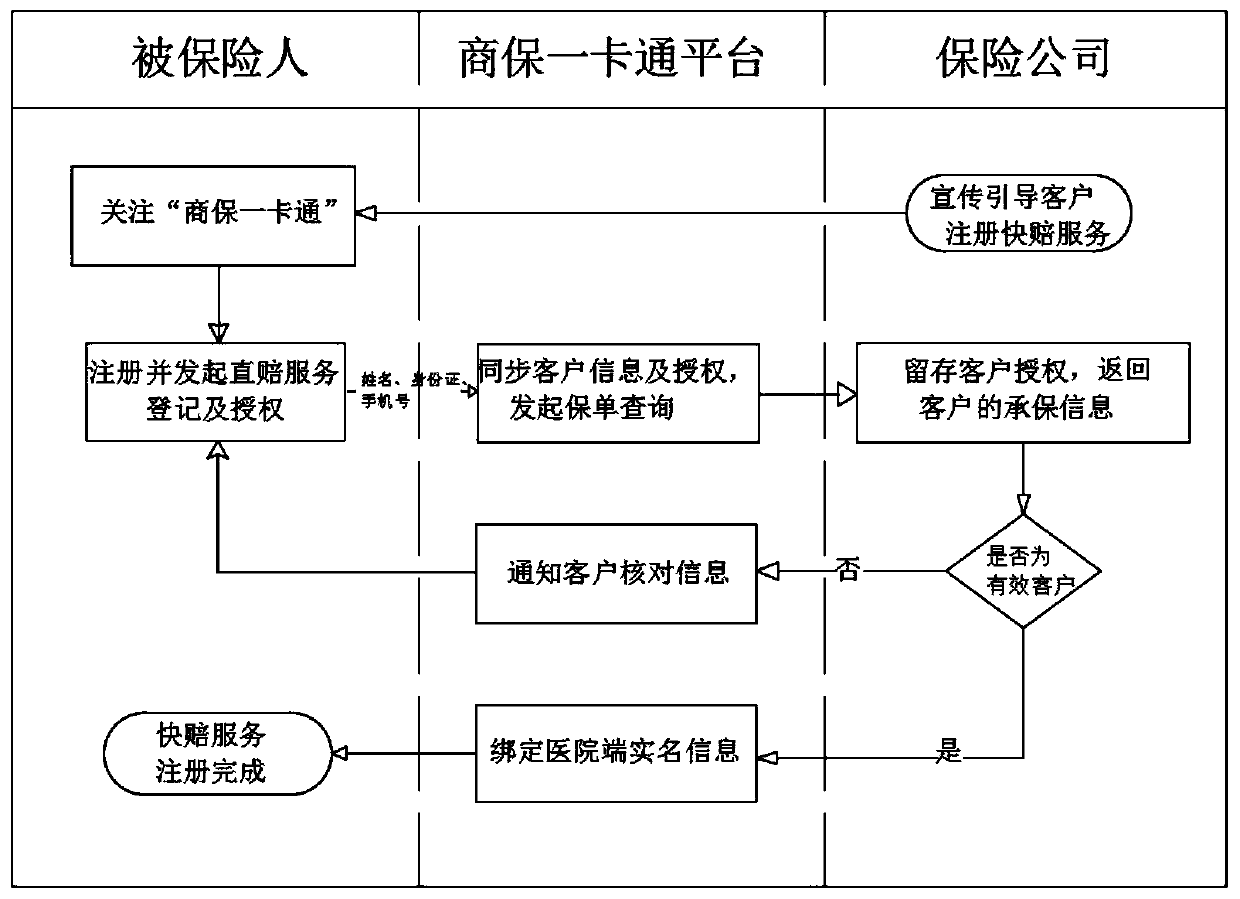

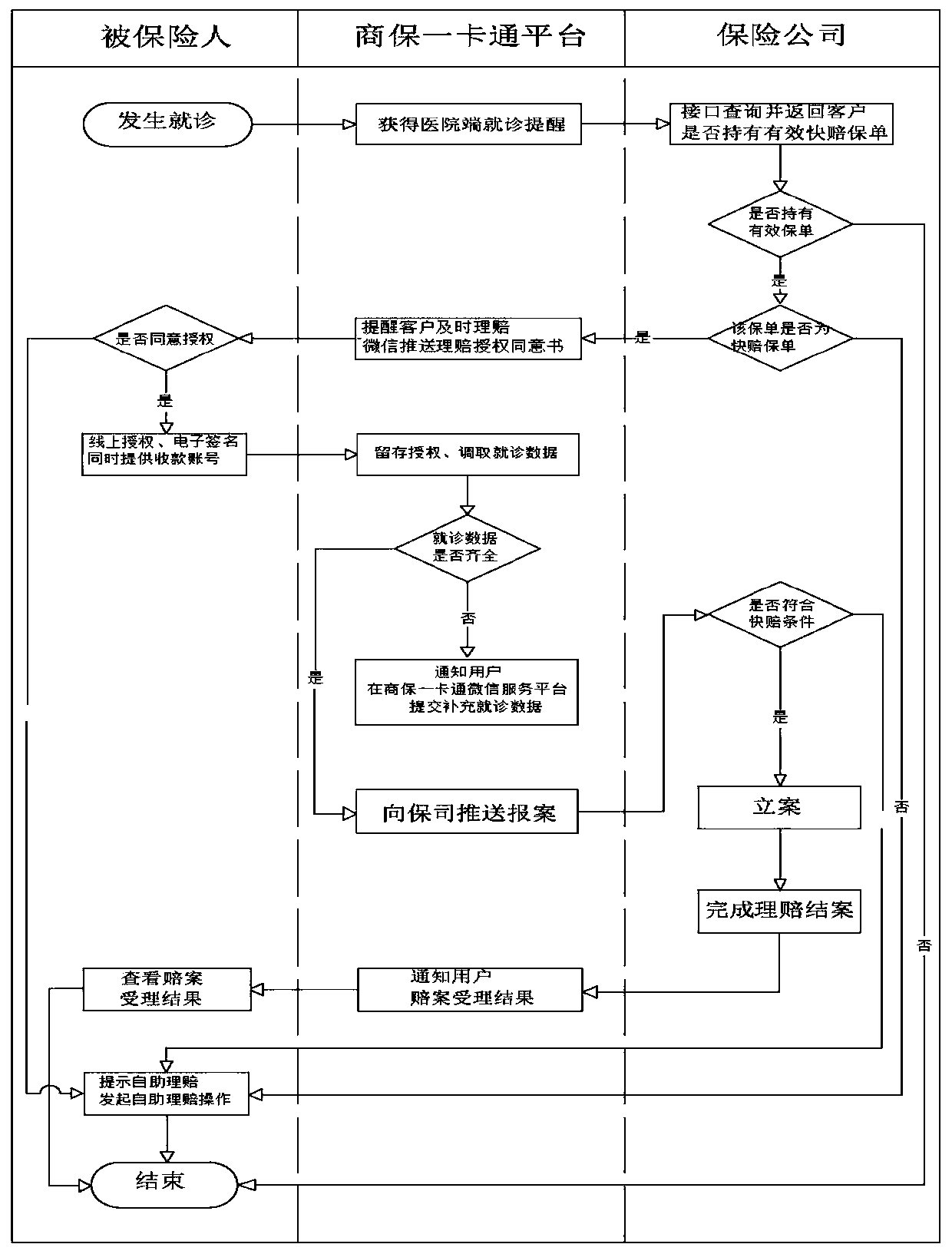

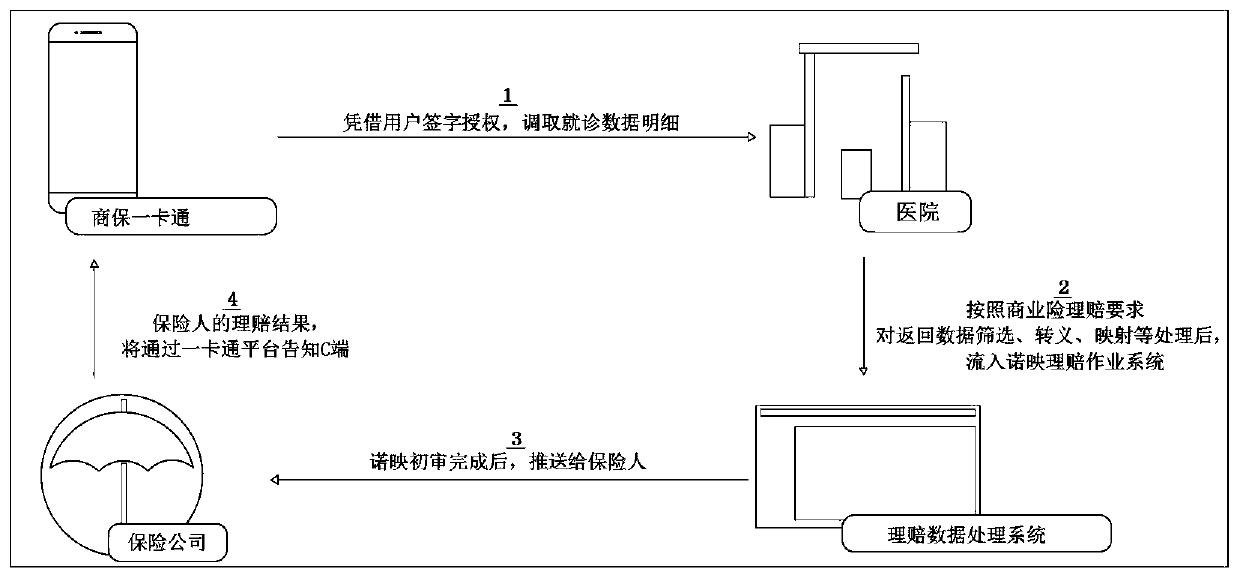

Commercial health insurance online document-free active claim settlement technology

PendingCN111461903AImprove timelinessClaim as soon as possibleFinancePatient-specific dataOnline documentOperations research

The invention discloses a commercial health insurance online document-free active claim settlement technology. The technology comprises the steps that 1) an insured person registers and authorizes toopen an active claim settlement service; 2) the insured person obtains a to-be-claimed reminder after seeing a doctor; 3) the insured person authorizes the commercial insurance one-card online to callthe medical data and initiate an insurance claim settlement application; and 4) the insurance company terminal accepts the compensation case officially, and the insured person checks the latest progress of the compensation case in time. Passive claim settlement is changed into active claim settlement, the insurance case reporting timeliness is greatly improved, the case reporting process is thoroughly simplified, document-free claim settlement and insurance company manual information input are realized, the authenticity and high quality of claim settlement data are ensured at the source end,the claim settlement timeliness is greatly improved, the insurance company is helped to avoid repeated claim settlement, and online closed loop of health insurance is completed.

Owner:诺映(上海)信息科技有限公司

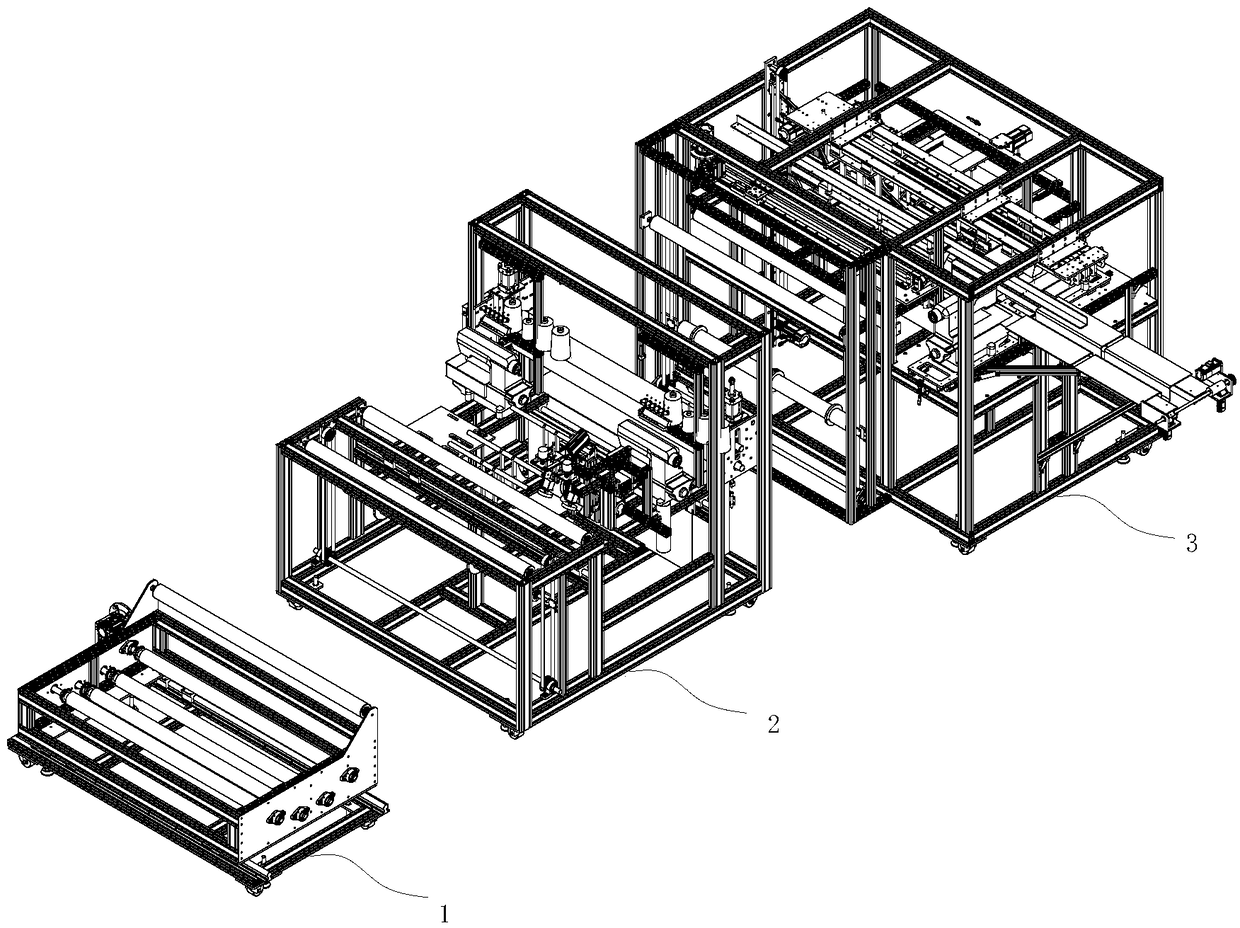

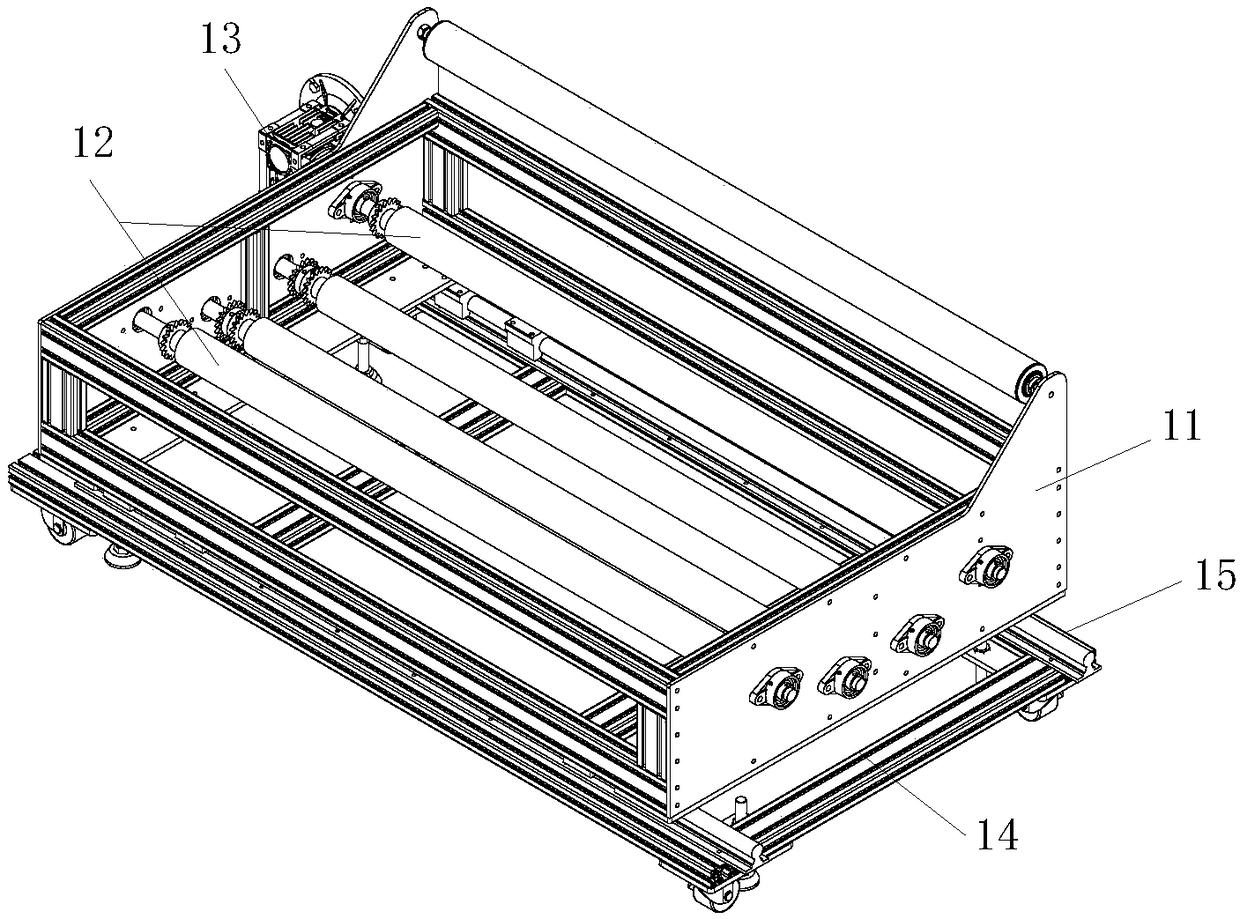

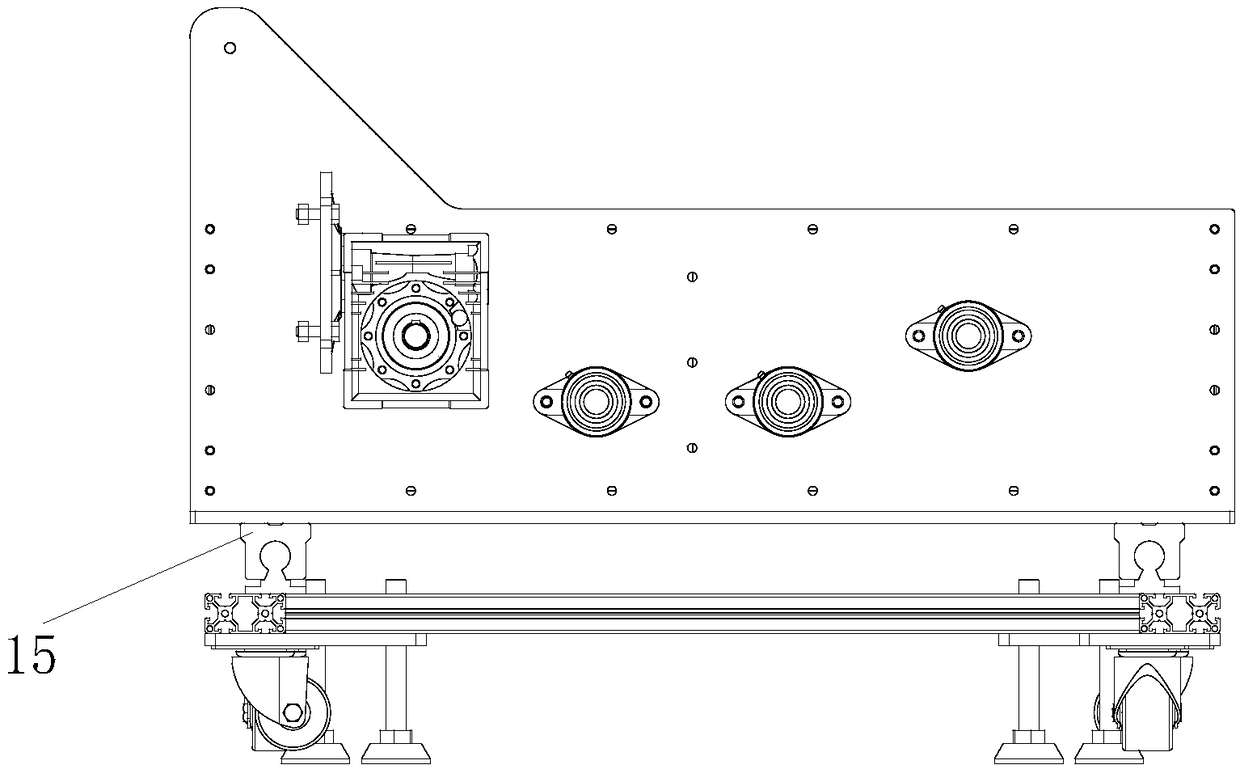

Intelligent sewing work station of square ground mats or bath towels

PendingCN108796833AGuaranteed tidyImprove firmnessWorkpiece carriersWork-feeding meansEngineeringAutomatic testing

The invention discloses an intelligent sewing work station of square ground mats or bath towels, and relates to the field of automatic sewing and processing equipment of soft fabrics. The work stationcomprises a front-section feeding device, a front-section longitudinal sewing device and a rear-section transverse sewing device; the front-section feeding device comprises a feeding roller set whichcan be automatically corrected; the fabrics are sent into the front-section longitudinal sewing device through the feeding roller set; the front-section longitudinal sewing device comprises a first sewing machine head and trimming scissors with a correction function; the first sewing machine head is used for sewing longitudinal edges of the fabrics; the trimming scissors are arranged on one sideof the first sewing machine head; fabrics obtained after longitudinal sewing are sent out to the rear-section transverse sewing device; the rear-section transverse sewing device comprises a cloth cutter mechanism, a second sewing machine head, a feeding mechanism and a material pulling mechanism; the material pulling mechanism is used for pulling the fabrics to the feeding mechanism; the cloth cutter mechanism cuts off the fabrics, and the fabrics fall on the transverse feeding mechanism; the second sewing machine head is arranged at the edge of the feeding mechanism; a discharging mechanism is arranged on the feeding mechanism. The intelligent sewing work station is good in matching effect, high in processing efficiency and outstanding in intelligent degree.

Owner:苏州匠博智能科技有限公司

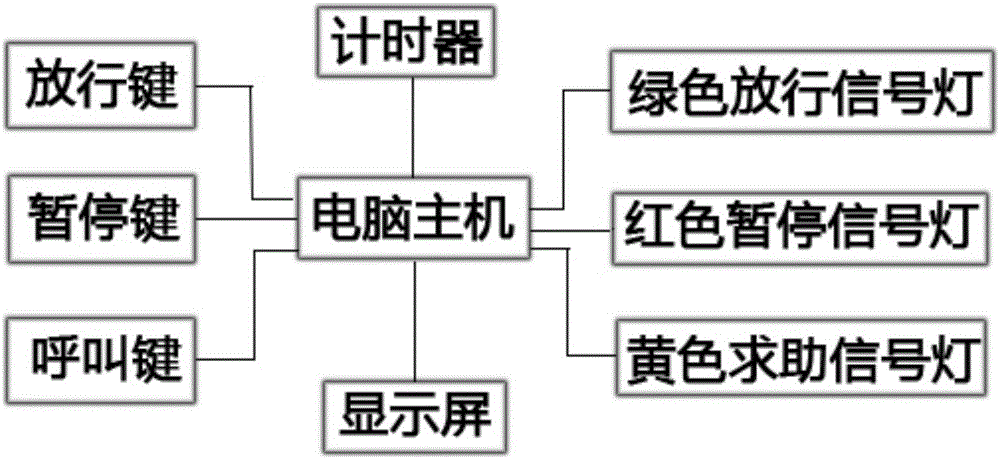

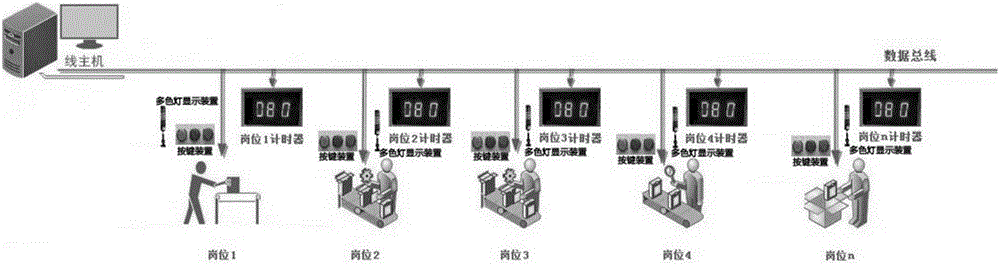

Networked flow production line timing production system

PendingCN106444675AProduction line scheduling optimizationEasy to findTotal factory controlProgramme total factory controlStop timeControl software

The invention discloses a networked flow production line timing production system comprising a computer host with built-in control software, a display screen, a timer, a key device and a multicolor lamp display device. The key device comprises a discharge key, a pause key and a call key. Timing of the working hours of each position is performed through the timer. When a position employee cannot complete the process within the preset time period, the position employee presses the pause key, the computer host controls the timer to stop and controls a red pause signal lamp to be lighted up and the whole line is in the pause state; and after the process is completed, the discharge key is pressed, the computer host controls the red pause signal lamp to be off, the timer starts countdown again and the whole production line operates again. The actual working hours of each position can be recorded by the system, the stopped position and stopping time can be faithfully recorded by the system and statistical analysis is performed so that the bottleneck position can be easily searched, scheduling of the production line can be further optimized for managers, the balance rate of the whole production line can be enhanced and the productivity of the production line can be enhanced.

Owner:ZHONGSHAN LINGCHUANG NETWORK TECH CO LTD

Self-elevating type platform buoyant pile shoe with function of reducing resistance in pile pulling

InactiveCN102776883AReduced amount of alluvial soilReduce compactionArtificial islandsUnderwater structuresWater dischargeBallast tank

The invention relates to a self-elevating type platform buoyant pile shoe with a function of reducing the resistance in pile pulling. The self-elevating type platform buoyant pile shoe is characterized by comprising floating boxes, permeable water passing devices, washing holes, washing pipelines and gas injection pipelines, wherein the upper part of the pile shoe is provided with three floating boxes; each floating box consists of three prismatic ballast tanks; the gas injection pipelines in the tanks can inject air into the three ballast tanks for discharging ballast water; and the lower parts of the outer sides of the floating boxes are provided with the permeable water passing devices which are taken as water discharging channels and can block sea mud from entering. The washing holes are arranged under mud covers at the outer sides of the floating boxes and are used for washing periodically and preventing soil bodies near a pile leg from being solidified. The buoyant pile shoe has the advantages that the space of a pile pit is occupied by means of the floating boxes, the backfill amount of marine-soil silts during the operation of a platform is reduced, and the pile pulling resistance caused by the weight of silted soil is greatly reduced; and simultaneously, certain buoyancy can be provided by discharging of the ballast water in pile pulling, and the pile lifting load of a lifting mechanism is relieved, so that smooth pile pulling is realized.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Automatic embossing machine

PendingCN110395011AAutomatic entryRestricted movement pathMechanical working/deformationPaperboardPulp and paper industry

The invention relates to the technical field of mechanical processing or deformation of paperboards, in particular to an automatic embossing machine. The automatic embossing machine comprises a work table, a placing frame and a collecting frame, the placing frame and the collecting frame are located on the two sides of the work table, the placing frame is used for placing unembossed paper, and thecollecting frame is used for collecting embossed paper; the work table comprises a paper feeding mechanism and an embossing mechanism, and the paper feeding mechanism comprises a first working table,a feeding roller shaft and a first motor and is used for sending paper into the embossing mechanism; the embossing mechanism is configured to emboss the paper and includes a second working table andan embossing device, the embossing device is provided with a transmission mechanism, and the transmission mechanism comprises a connecting frame, a conveyor belt and a transmission device and is usedfor transporting the paper on the second working table to enable the paper to enter or exit from the embossing mechanism; and the collecting frame is used for collecting the embossed paper. The automatic embossing machine can conduct automatic embossing on the paper and automatic removal after embossing is finished, and the embossing efficiency and safety are improved.

Owner:GUANGXI POLYTECHNIC

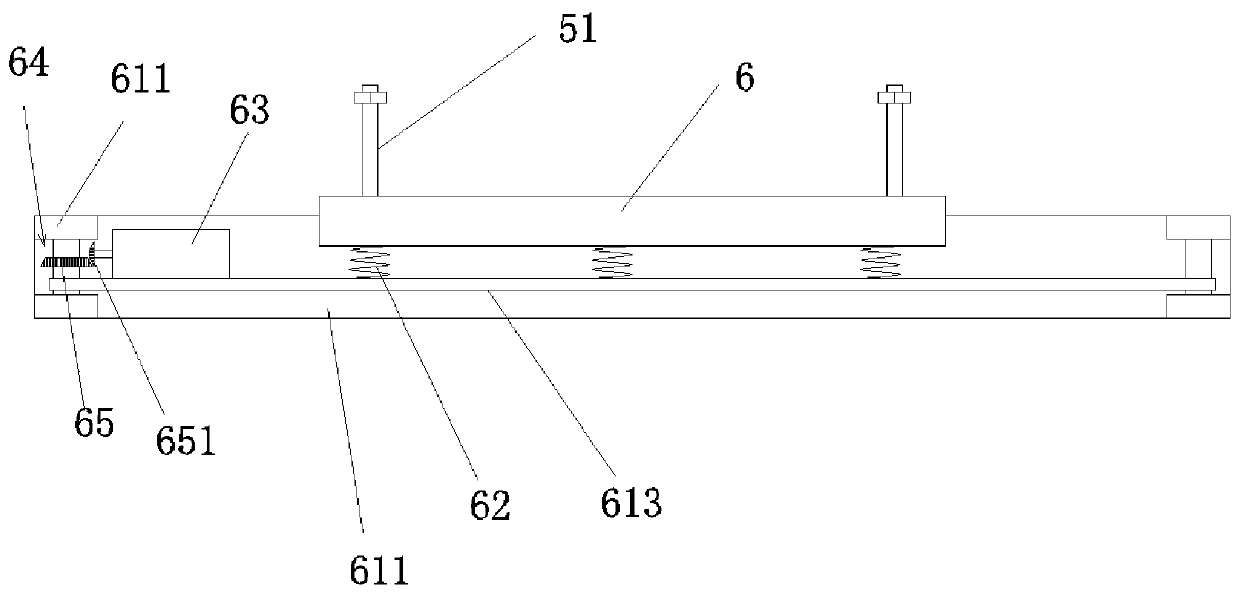

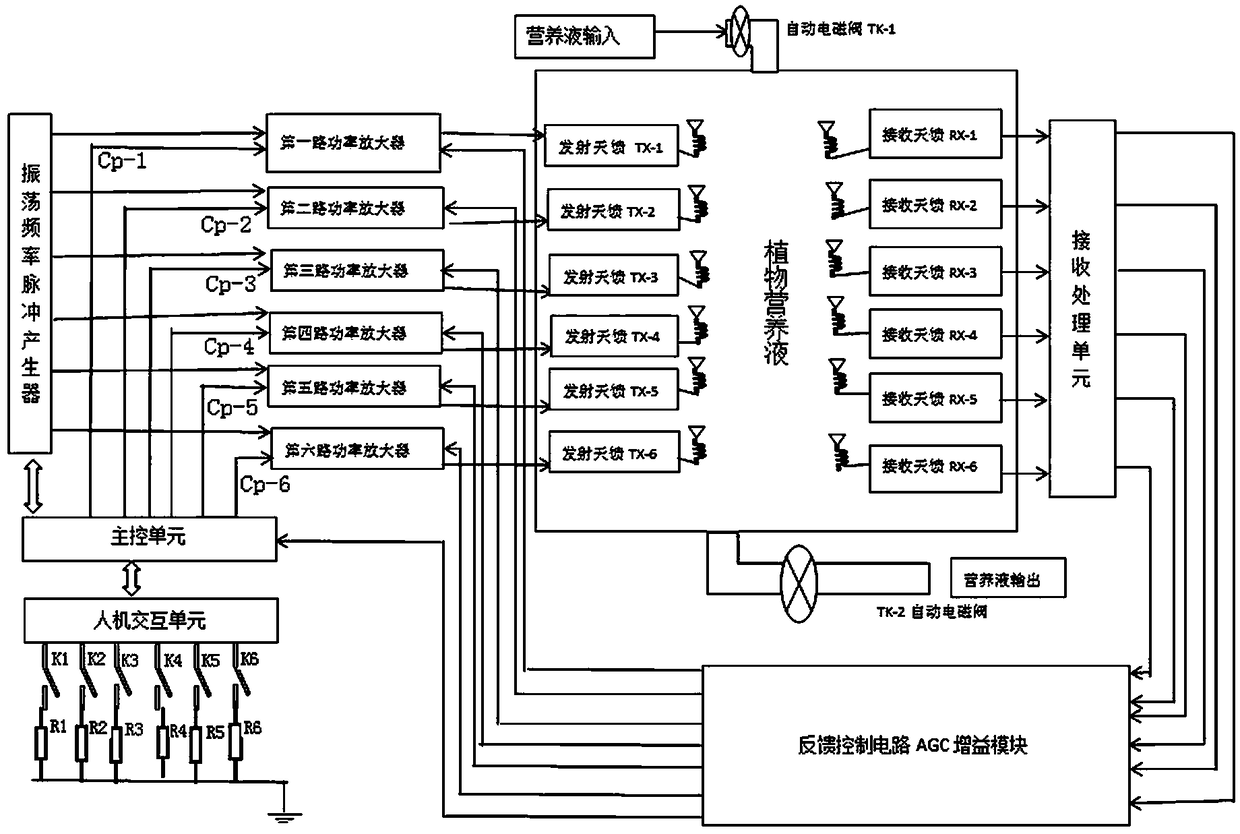

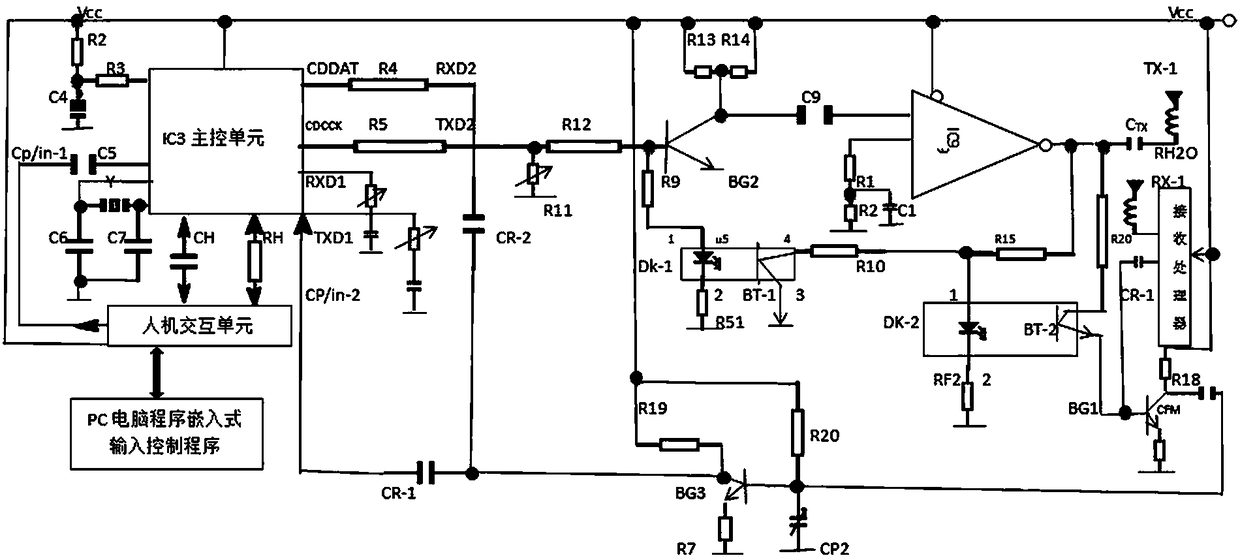

Negative hydrogen ion pulse radar equipment for hydrogen-state agriculture

PendingCN108594218APromote growthImprove nutritional qualityOscillations generatorsRadio wave reradiation/reflectionNutrient solutionAntenna feeder

The invention discloses negative hydrogen ion pulse radar equipment for hydrogen-state agriculture, and the equipment comprises an oscillation frequency pulse generator, a main control unit, a power amplifier, a slot antenna, a human-machine interaction unit, a receiving processing unit and a nutrient liquid container, wherein the slot antenna is fixed in the nutrient liquid container, and the slot antenna includes a transmitting antenna feed TX and a receiving antenna feeder RX. The oscillation frequency pulse generator is connected with the transmitting antenna feeder TX through the power amplifier, and the receiving processing unit is connected with the receiving antenna feeder RX. The main control unit is connected with the human-machine interaction unit, the oscillation frequency pulse generator, the power amplifier and the receiving processing unit, and the main control unit, the oscillation frequency pulse generator, the power amplifier, the slot antenna and the receiving processing unit form a closed cyclic pulsed electromagnetic oscillator circuit through the metal elements in nutrient solution. The equipment can enable the nutrient solution to be polarized into hydride mixed solution with negative hydrogen ions, thereby achieving the purpose of promoting the absorption of plant.

Owner:中亚民生科技发展有限公司

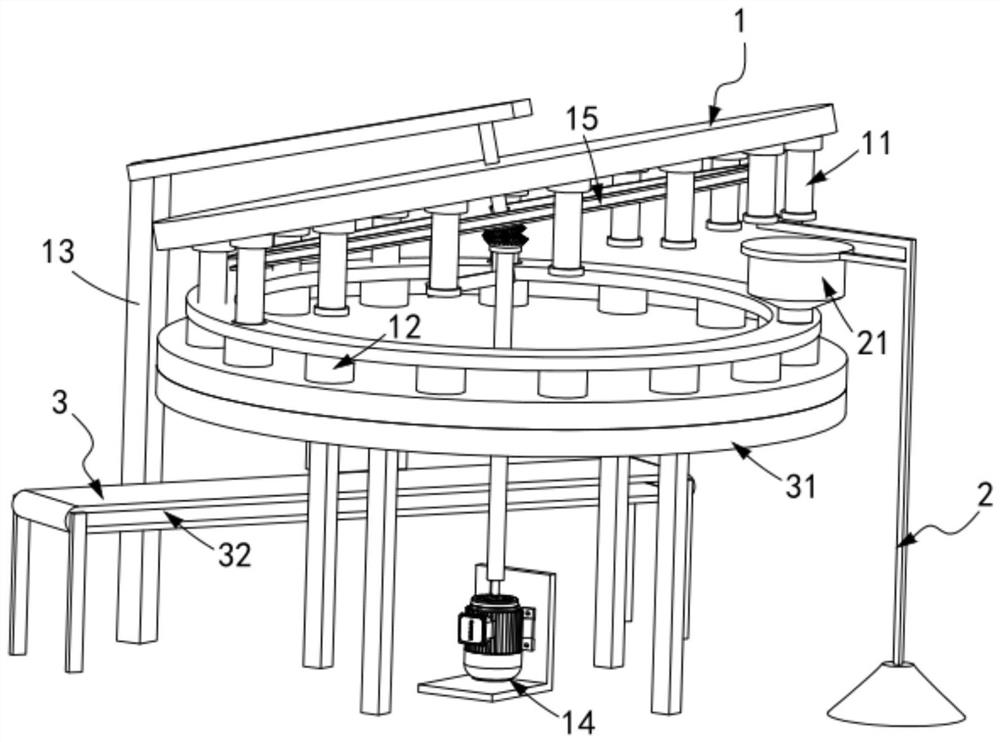

High-survival-rate sheep fertilized egg culture method for Hu sheep embryo in-vitro culture

ActiveCN111876374AReduce the risk of impactImprove fertilization rateCell dissociation methodsBioreactor/fermenter combinationsAnimal scienceFertilised ovum

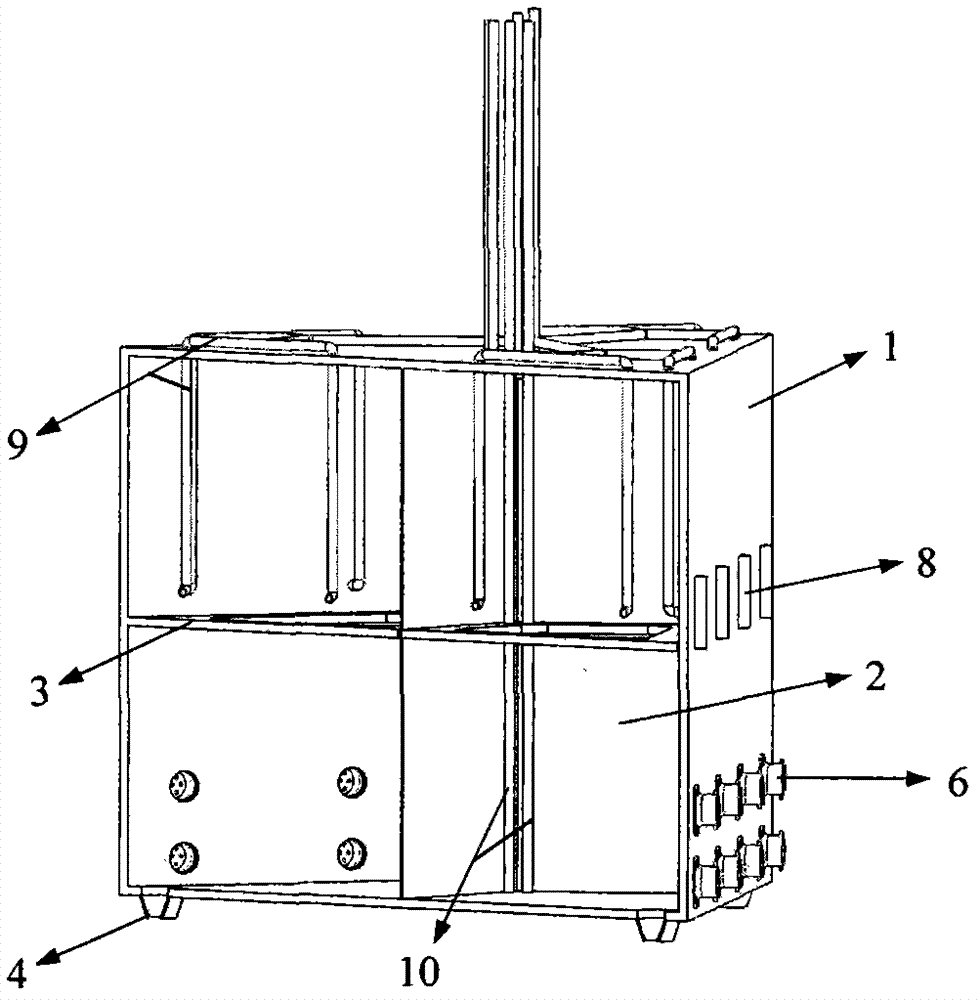

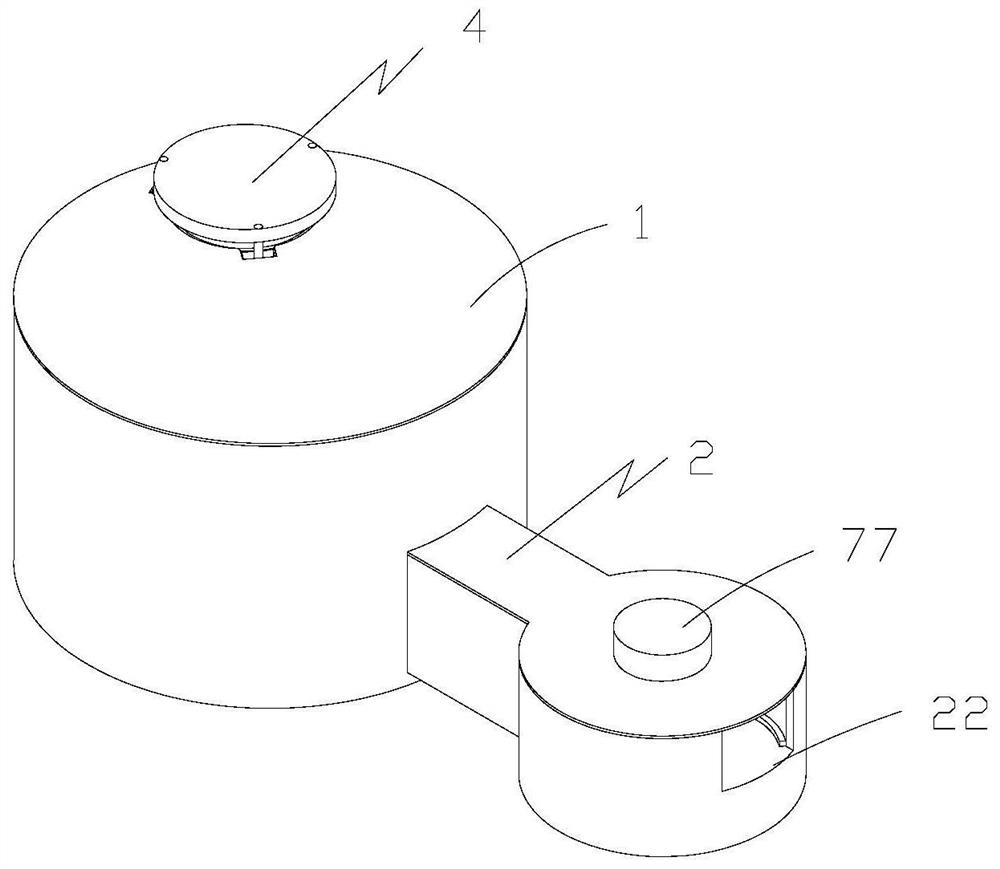

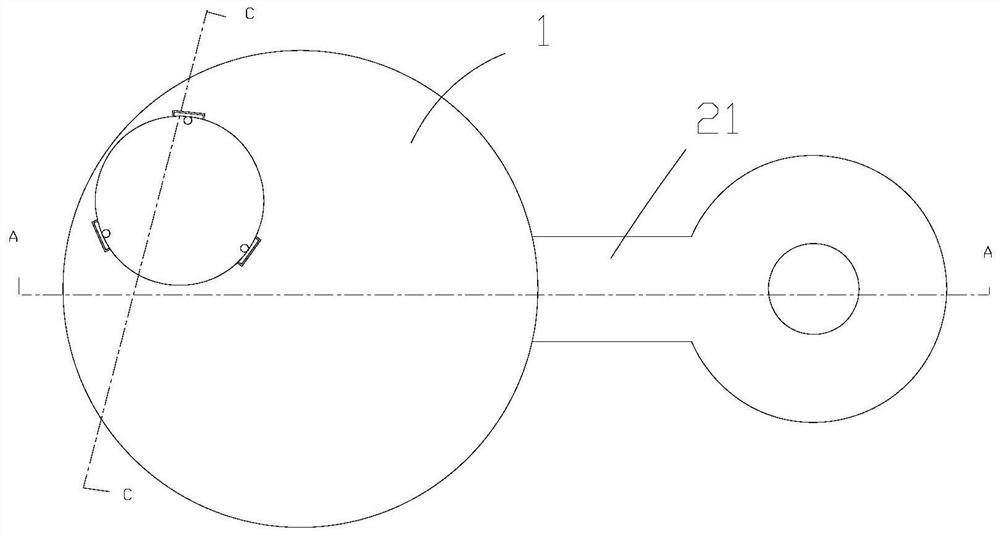

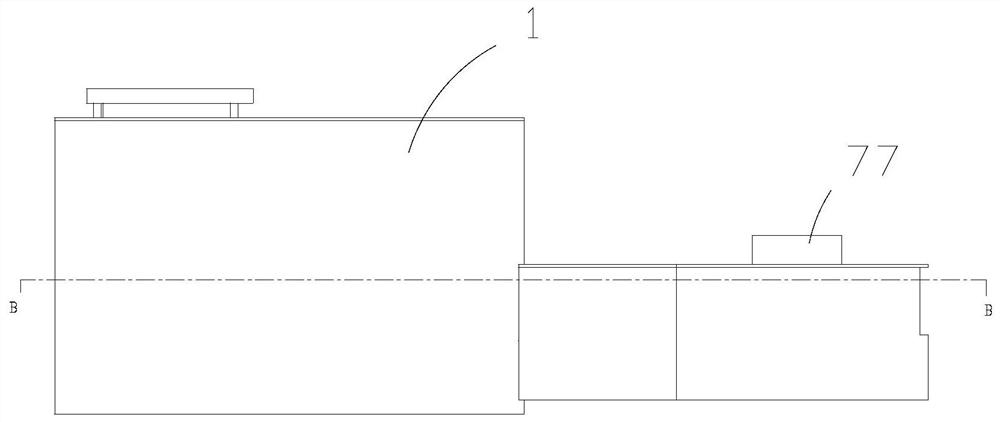

The invention discloses a high-survival-rate sheep oosperm culture method for Hu sheep embryo in-vitro culture. The high-survival-rate sheep oosperm culture method comprises the following steps: (1) oocyte collection: sucking oocytes from ovaries of Hu sheep; (2) sperm collection: extracting sperms from the male Hu sheep; (3) fertilization: carrying out artificial fertilization on eggs and sperms;(4) embryo culture: putting the fertilized eggs into an incubator for culture; and (5) observation: observing the development condition of the embryo, wherein the incubator in the step (4) comprisesa main body, a feeding device, a rotating frame, a culture device and a discharging device, wherein the feeding device comprises a feeding channel, a conveying mechanism, a feeding opening, a rotatingtable and a transition mechanism. According to the method, the embryo survival rate is increased through artificial fertilization, the transition mechanism isolates the embryos from outside air whenthe embryos are placed into the incubator, so that embryo development is prevented from being influenced, and the discharging device realizes the purpose of independent taking a culture dish, so thatthe survival rate of embryos is increased.

Owner:湖州怡辉生态农业有限公司

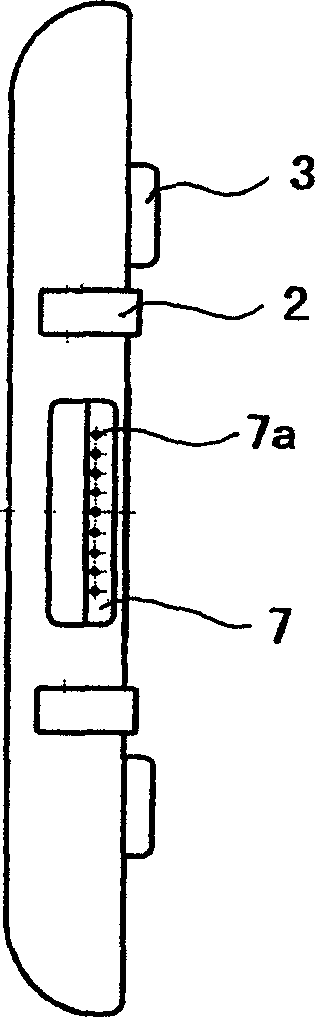

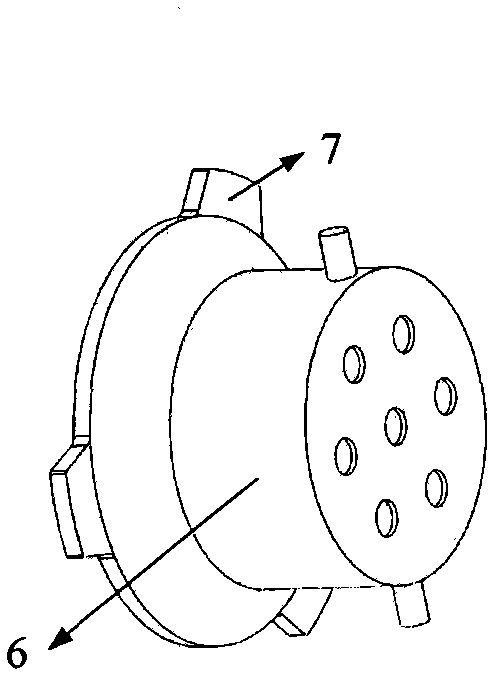

Automatic fiber bundle and crimping machine butting device

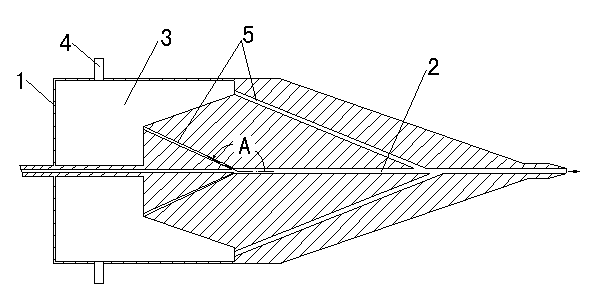

InactiveCN103243423AAutomatic entryNo human intervention requiredTextiles and paperFiber bundleEngineering

The invention discloses an automatic fiber bundle and crimping machine butting device which comprises a main body, wherein a fiber leading hole penetrating through the two ends of the main body is formed in the middle of the main body; an air storage cavity is arranged in the main body; air inlets communicated with the air storage cavity are formed in side walls of the main body; fiber leading air passages are arranged at the front end of the main body; one end of each fiber leading air passage is communicated with the air storage cavity, and the other end thereof is communicated with the fiber leading hole; and included angles between axes of the fiber leading air passages and moving directions of fiber bundles in the fiber leading hole are greater than 90 degrees. According to the device, compressed air is supplied into the air storage cavity through the air inlets, and is sprayed out through the fiber leading air passages via the fiber leading hole, negative pressure is formed in the fiber leading hole, and the fiber bundles are introduced into the fiber leading hole by a suction force of the negative pressure and enter a crimping machine. The compressed air can blow and disperse the fiber bundles, so that the fiber bundles can generate a net structure. The device achieves that the fiber bundles can enter automatically without manual intervention, is efficient and safe, can disperse the fiber bundles to generate the net structure, and ensures the crimping quality.

Owner:JINAN NATURE NEW MATERIALS

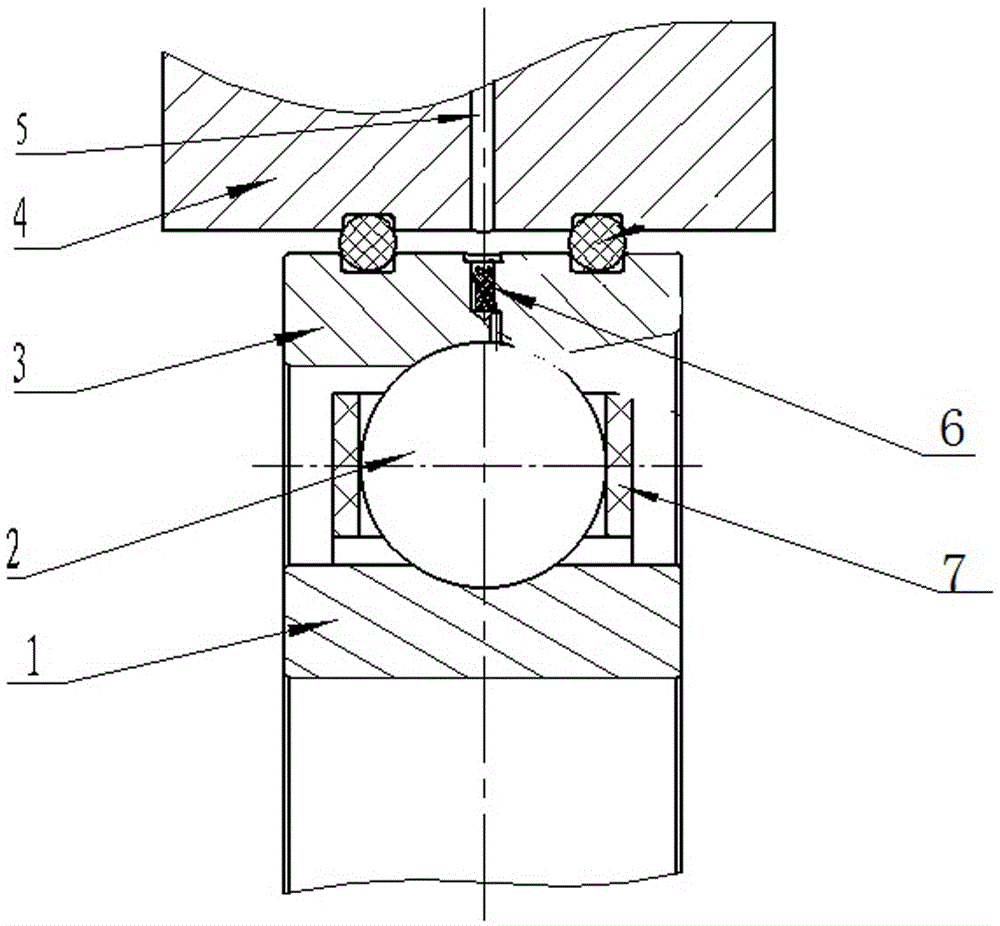

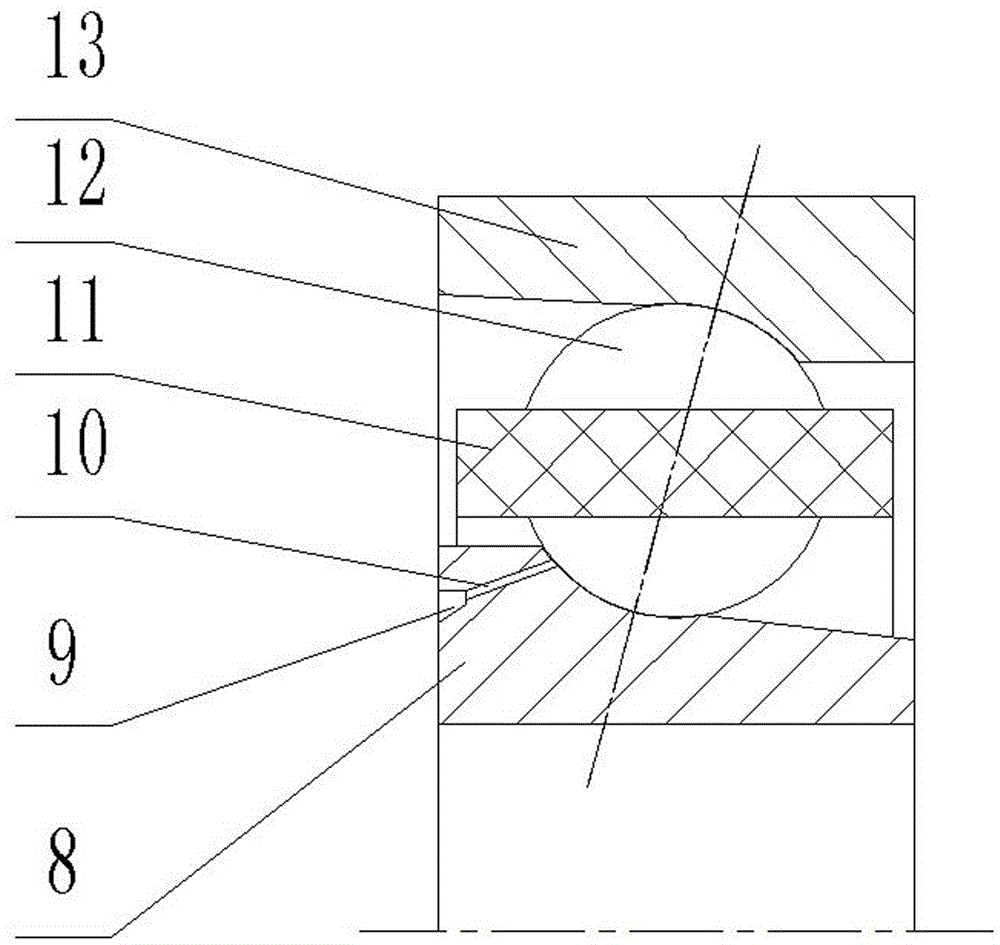

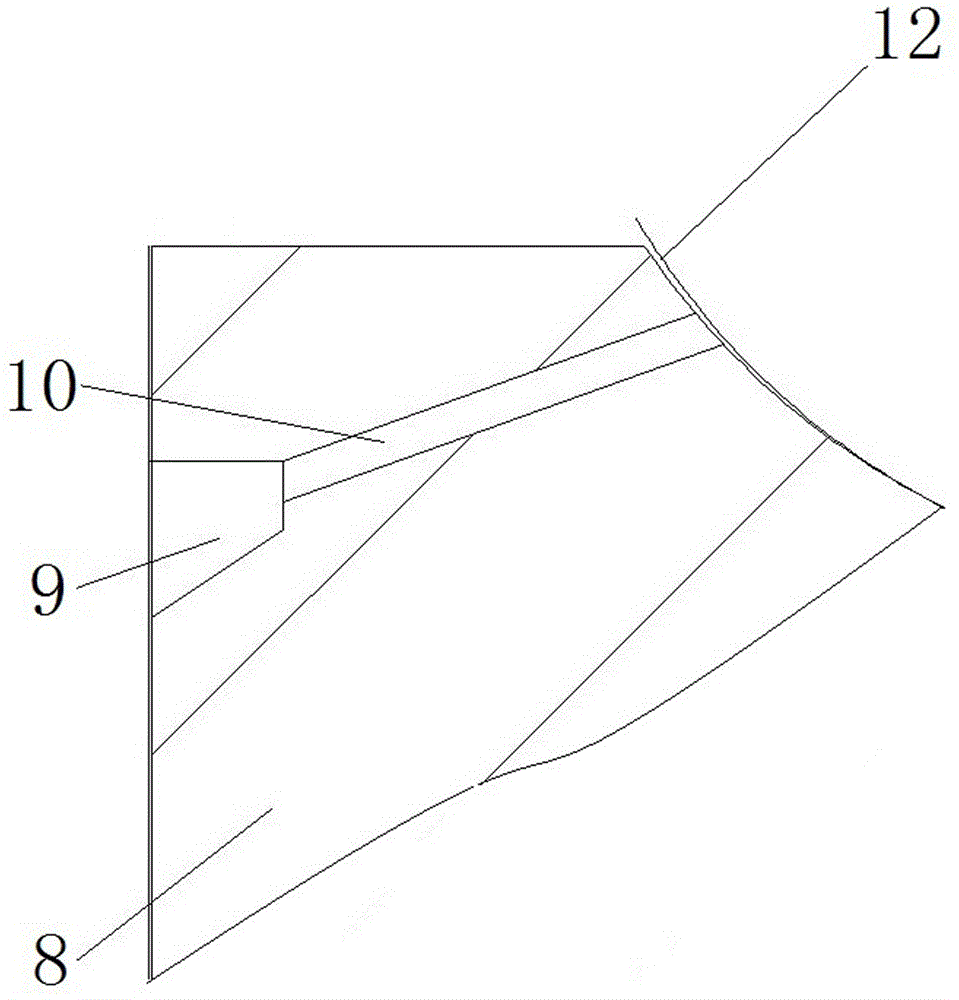

Angular contact ball bearing

The invention provides an angular contact ball bearing in order to reduce noise generated when the angular contact ball bearing operates. The angular contact ball bearing comprises an inner ring, an outer ring and oil injection holes formed in the inner ring or the outer ring; inlets of the oil injection holes are located in the end surface of the inner ring or the outer ring; outlets of the oil injection holes are located in the concave surface, corresponding to a rolling body, of the inner ring or the outer ring; and the outlets of the oil injection holes fall behind the inlets in the rotation direction of the inner ring or the outer ring where the oil injection holes are formed. The outlets of the oil injection holes fall behind the inlets in the rotation direction of the inner ring or the outer ring, lubricating oil in the oil injection holes can be thrown towards a rolling ball of the bearing by a backward throwing force generated when the inner ring or the outer ring rotates, so that the lubricating oil automatically enters the rolling ball of the bearing to realize lubrication; and compared with the existing high-speed jet oil injection way, the angular contact ball bearing has the advantages that the speed of the lubricating oil is reduced, and no relatively high noise can be generated after airflow collision caused when the bearing rotates.

Owner:LUOYANG BEARING RES INST CO LTD

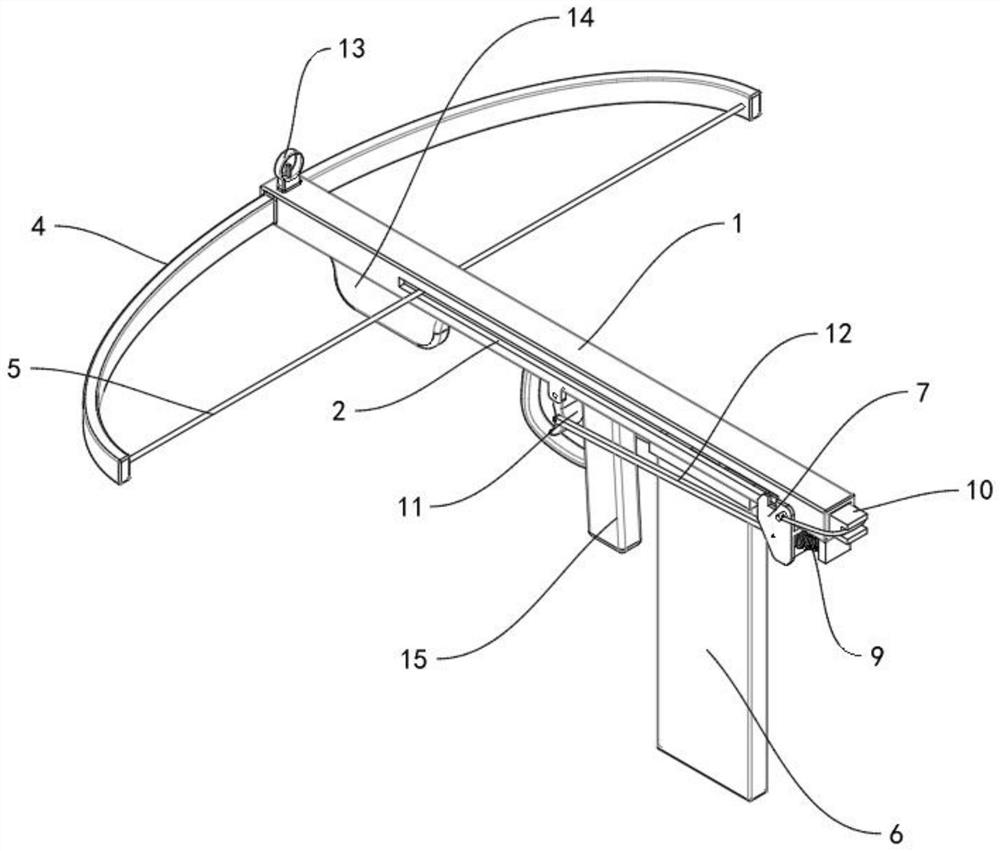

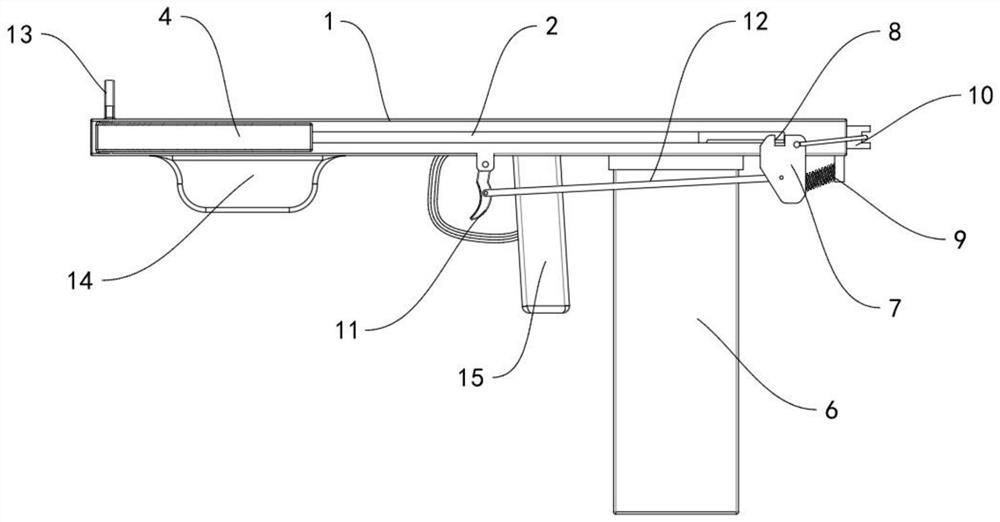

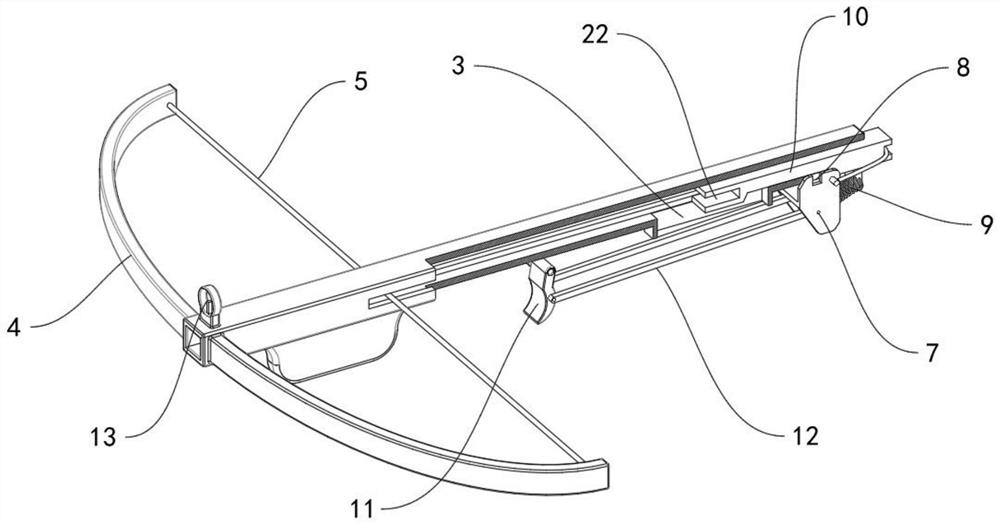

Semi-automatic crossbow achieving arrow supply through arrow magazine

The invention discloses a semi-automatic crossbow achieving arrow supply through an arrow magazine. The semi-automatic crossbow comprises a crossbow barrel, a bow plate, the arrow magazine, a string hook, an arrow stopper and a trigger; the crossbow barrel is provided with a chute and an arrow supply port; the bow plate is provided with a bowstring, and the bowstring is arranged in the chute in a penetrating mode; the arrow magazine is detachably mounted at the arrow supply port so as to automatically supply arrows to the crossbow barrel; the string hook is located on the rear side of the arrow magazine and rotationally connected with the crossbow barrel, a notch used for hooking the bowstring is formed in the string hook, and a first elastic piece is arranged at the rear end of the string hook and the rear end of the crossbow barrel; the arrow stopper is arranged in the crossbow barrel in a sliding mode to shield or open the arrow supply port, the rear end of the arrow stopper extends out of the crossbow barrel backwards all the time to be connected with a second elastic piece, and the second elastic piece is used for driving the arrow stopper to shield the arrow supply port; the trigger is located on the front side of the arrow magazine and rotationally connected with the crossbow barrel; and a connecting rod is rotationally arranged on the trigger and rotationally connected with the string hook. The semi-automatic crossbow is simple in structure and convenient to implement, the process that in a traditional crossbow machine, continuous manual arrow supply is needed is omitted, and the use interestingness is effectively improved.

Owner:赵威威

Automatic screening and feeding device for large and small steel balls

ActiveCN112079134ARealize automatic feedingNo scratchesWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringSteel ball

The invention discloses an automatic screening and feeding device for large and small steel balls, and belongs to the technical field of material sorting. The automatic screening and feeding device comprises an automatic stock bin, a feeding mechanism and a ball cutting mechanism which are connected in sequence, the automatic stock bin comprises a stock bin body and a cavity plate, and a feed portof the cavity plate is slidably connected to a discharge port of the stock bin body; and the feeding mechanism comprises a material distributing plate, the feeding end of the material distributing plate is connected to a discharging port of the cavity plate, the material distributing plate comprises a small ball trough and a large ball trough arranged at the upper end of the small ball trough, and the small ball trough and the large ball trough are provided with a small ball discharging port and a large ball discharging port correspondingly. Compared with the prior art, automatic feeding, distributing and supplying of the large steel balls and the small steel balls can be achieved, and scratches caused by excessive friction between the steel balls in the feeding, distributing and supplying process are avoided; and the sorted steel balls can automatically enter the corresponding steel ball recovery barrels.

Owner:SUZHOU IND PARK NESTAR AUTOMATION TECH

Ecological breeding method of South Anhui spotted pigs

PendingCN110122419AAutomatic entryEasy to eatFood processingAnimal feeding stuffLean meatSpotted pig

An ecological breeding method of South Anhui spotted pigs comprises the steps as follows: S1, two pigsties are arranged for each South Anhui spotted pig and communicated through an isolation passage,and bells are arranged on the pigsties; S2, when the South Anhui spotted pig is in one pigsty, feed is put in a trough of the other corresponding pigsty and the bell in the pigsty makes sound; the South Anhui spotted pig is driven to enter the other corresponding pigsty to eat, and belling is stopped until the South Anhui spotted pig enters the other corresponding pigsty to eat; S3, after the South Anhui spotted pig eats up all feed in the other corresponding pigsty, feed is put in a trough of one pigsty and the bell in the pigsty makes sound, the South Anhui spotted pig is driven to enter thepigsty to eat, and belling is stopped until the South Anhui spotted pig enters the pigsty to eat; S4, the S2 and the S3 are repeated until the South Anhui spotted pig produces conditioned reflex to eat automatically. With the adoption of the method, the South Anhui spotted pigs can be promoted to eat and the growth speed can be further increased; meanwhile, lean meat production is promoted and the pork quality is improved.

Owner:安徽天野现代农业科技有限公司

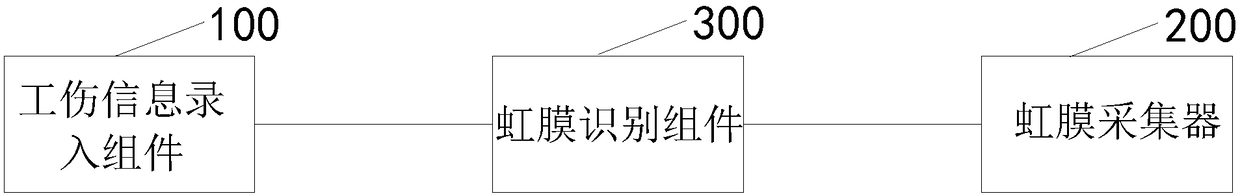

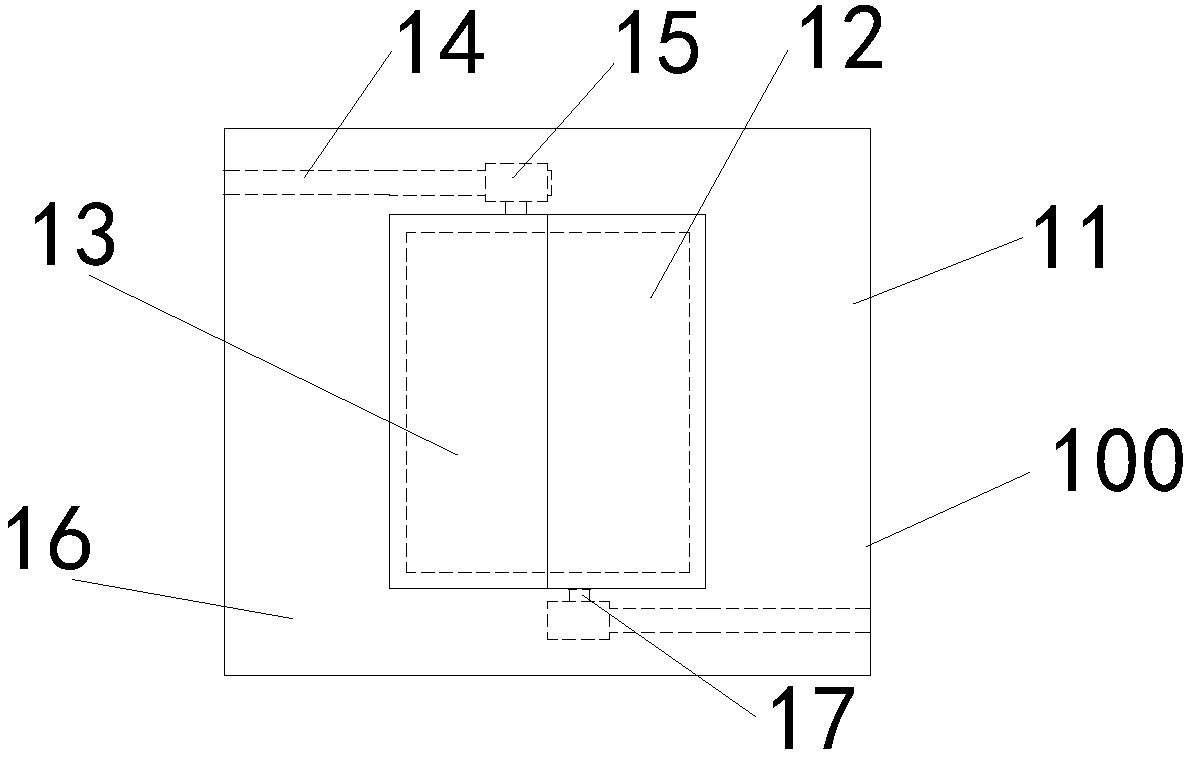

Occupational injury information record method and device

ActiveCN108509865AHigh precisionSimplified throughputAcquiring/recognising eyesOffice automationOccupational injuryInfrared lamp

The present invention provides an occupational injury information record device and method. The occupational injury information record device comprises an occupational injury information record module, an iris collector and an iris identification module. The occupational injury information record module comprises a rectangular box body, a data reader, a shielding door, a linear bearing and a linear motor. The iris collector at least comprises a box body, a camera, a circuit board and an infrared lamp, and the iris identification module is in communication connection with the camera and the infrared lamp. The occupational injury information record device and method improve the identification speed, enhance the identification accuracy and obtain high robustness while saving the storage spaceand reducing the computing amount, after the iris is successful, the shielding door is opened, a received identification tag is put at a data reading channel to automatic record the occupational injury information.

Owner:贵州人和致远数据服务有限责任公司

Power output device

InactiveCN103883489ARealize the function of output powerAuto roll inMachines/enginesMotorsVertical planeGravitational potential

The invention discloses a power output device to solve the problems that an existing power output machine is limited by the geology, the environment, the weather and other factors. The power output device comprises a support, a rotating plate and a roll ball channel, wherein the rotating plate is arranged on the support, the roll ball channel is arranged on the support, seven or more roll balls are arranged inside the roll ball channel, and the two end openings of the roll ball channel are right opposite to the rotating plate. The rotating plate comprises a cylinder, a rotating shaft and two circular plates, sliding tracks are arranged between the two circular plates, and each sliding track is provided with two openings. In addition, the roll ball channel is obliquely arranged, and the opening in the bottom end of the roll ball channel is provided with an overturning piece used for pushing the roll balls into the sliding tracks. The rotating plate can rotate relative to the support in the vertical plane through the roll balls, the roll balls can freely get in and out of the rotating plate, the gravitational potential energy of the roll balls is converted into kinetic energy, and therefore the rotating plate can output power in the rotating process.

Owner:李三营

Polishing device and method based on engineering machinery

ActiveCN114643520AAutomatic entryNo manual operationGrinding carriagesGrinding machinesElectric machineryEngineering

The invention discloses a polishing device and method based on engineering machinery, and relates to the technical field of engineering machinery. The box body is fixed on the machine frame; the grinding mechanism is arranged in the box body, the grinding mechanism comprises a grinding tooth sleeve, and the grinding tooth sleeve is rotationally connected to one side of the interior of the box body and used for conducting rough machining on a grinding part. According to the grinding device, the clamping mechanism is arranged on the grinding tooth sleeve, the grinding piece on the clamping mechanism is pushed to automatically enter the grinding tooth sleeve, the grinding piece is ground during rotation of the grinding tooth sleeve, the grinding tooth sleeve is discharged during rotation through the formed round hole and then falls into the discharging bin to be collected, in the process, automatic feeding and discharging of the grinding piece are achieved, manual operation is not needed, and the working efficiency is improved. Time and labor are saved, and safety accidents are avoided.

Owner:徐州阳森建设科技有限公司

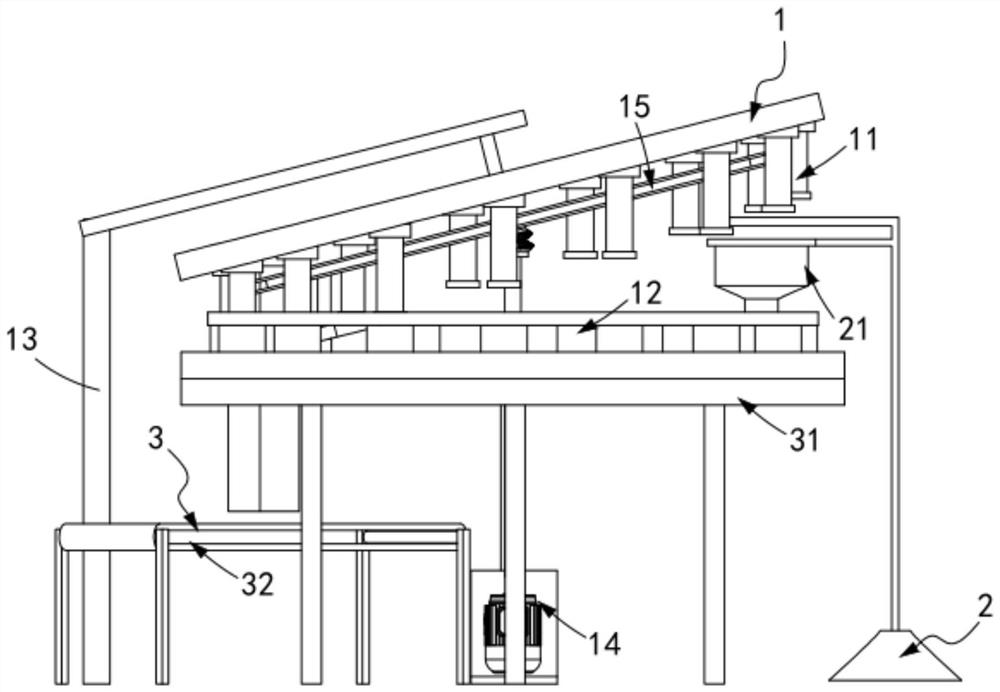

Equipment for preparing carbon ceramic through graphite powder

ActiveCN112356491AImprove production efficiencyHigh degree of automationShaping pressMolding machineGraphite

The invention relates to equipment for preparing carbon ceramic through graphite powder. The equipment comprises a forming mechanism, a feeding mechanism and an output mechanism. The forming mechanismcomprises an upper die assembly, a lower die assembly, a driving assembly and a first guide assembly, and the lower die assembly is sequentially provided with a feeding station, a forming station andan output station in the circumferential rotation direction. The feeding mechanism comprises a storage assembly arranged on a rack, and the feeding mechanism is located on the feeding station. The output mechanism comprises a discharging assembly arranged below the lower die assembly, a conveying assembly arranged below the discharging assembly and a second guide assembly used for driving the upper die assembly to automatically output carbon ceramic in the lower die assembly to the discharging assembly, the first guide assembly is in smooth transition connection with the second guide assembly, and the output mechanism is located at the output station. The equipment solves the technical problems that in the pressing forming work, carbon ceramic forming and output continuity cannot be achieved, and the production efficiency is low.

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

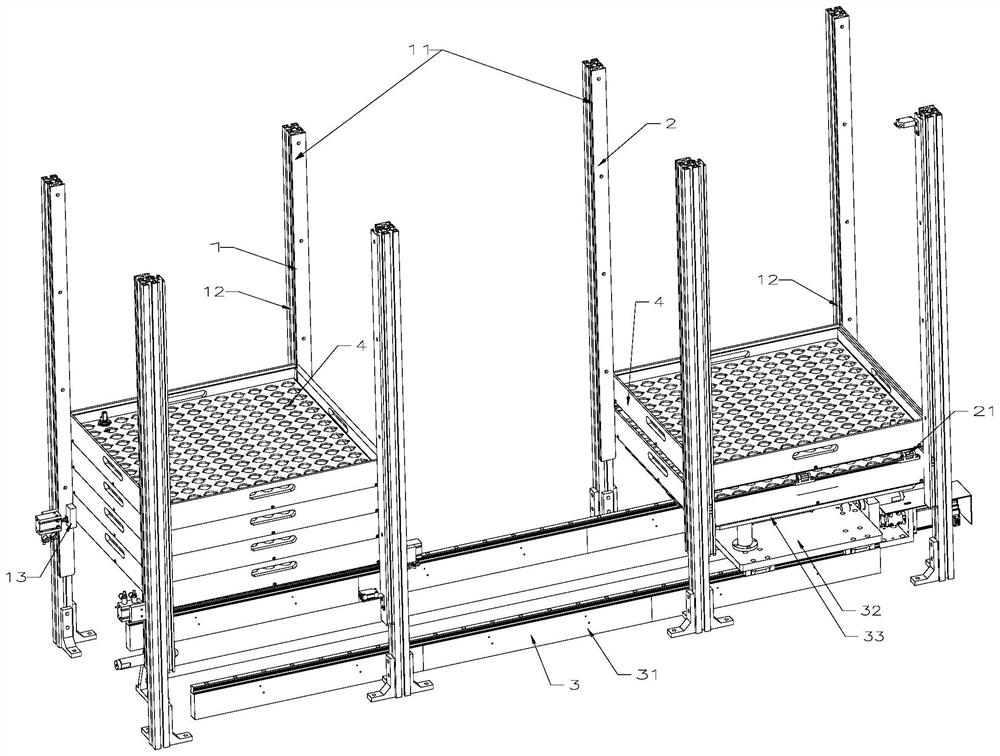

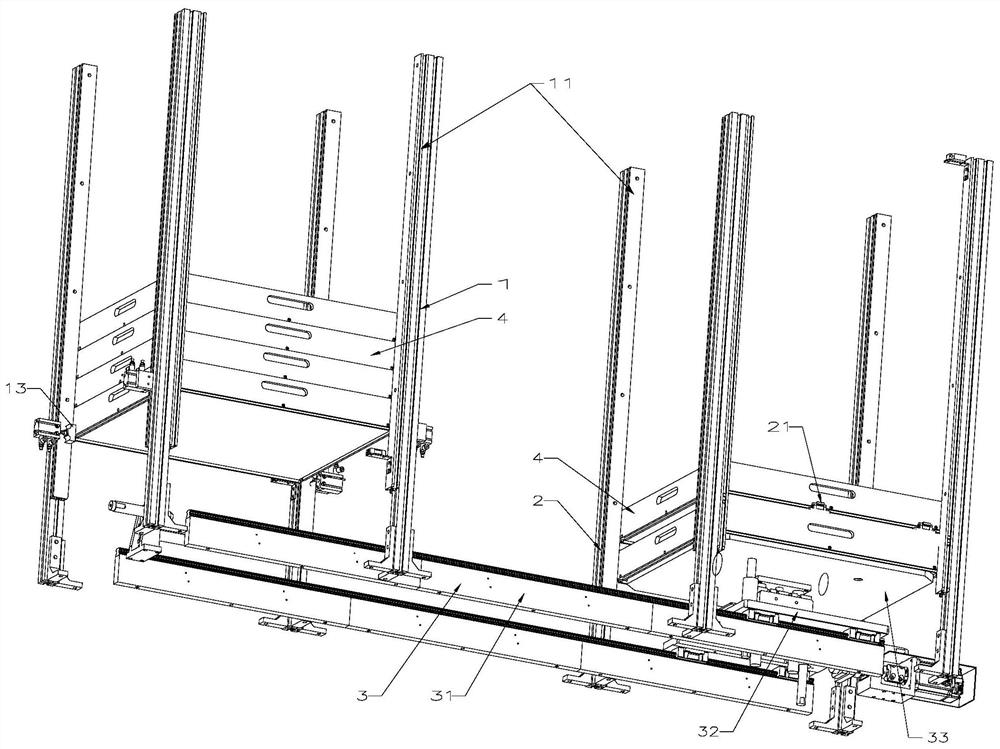

Material conveying mechanism

PendingCN112850185AMeet delivery needsReduce noiseStacking articlesDe-stacking articlesIndustrial engineeringPallet

The invention provides a material conveying mechanism. The material conveying mechanism comprises a first goods shelf, a second goods shelf, a conveying component and pallets. The first goods shelf and the second goods shelf are arranged in a spaced mode and are each defined by at least three vertically-arranged limiting columns, and an up-down moving channel of the pallets is arranged. First limiting pieces are arranged at the bottom of the first goods shelf. Second limiting pieces are arranged at the bottom of the second goods shelf. The conveying component is arranged at the bottoms of the first goods shelf and the second goods shelf. The pallets are taken out from the first goods shelf through the conveying component and conveyed into the second goods shelf through the conveying component. According to the material conveying mechanism provided by the invention, the conveying mode is stable, vibration is avoided, noise is low, even zero noise can be achieved, and enough materials can be conveyed at a time.

Owner:XIAMEN DELMEI SANITARY WARE

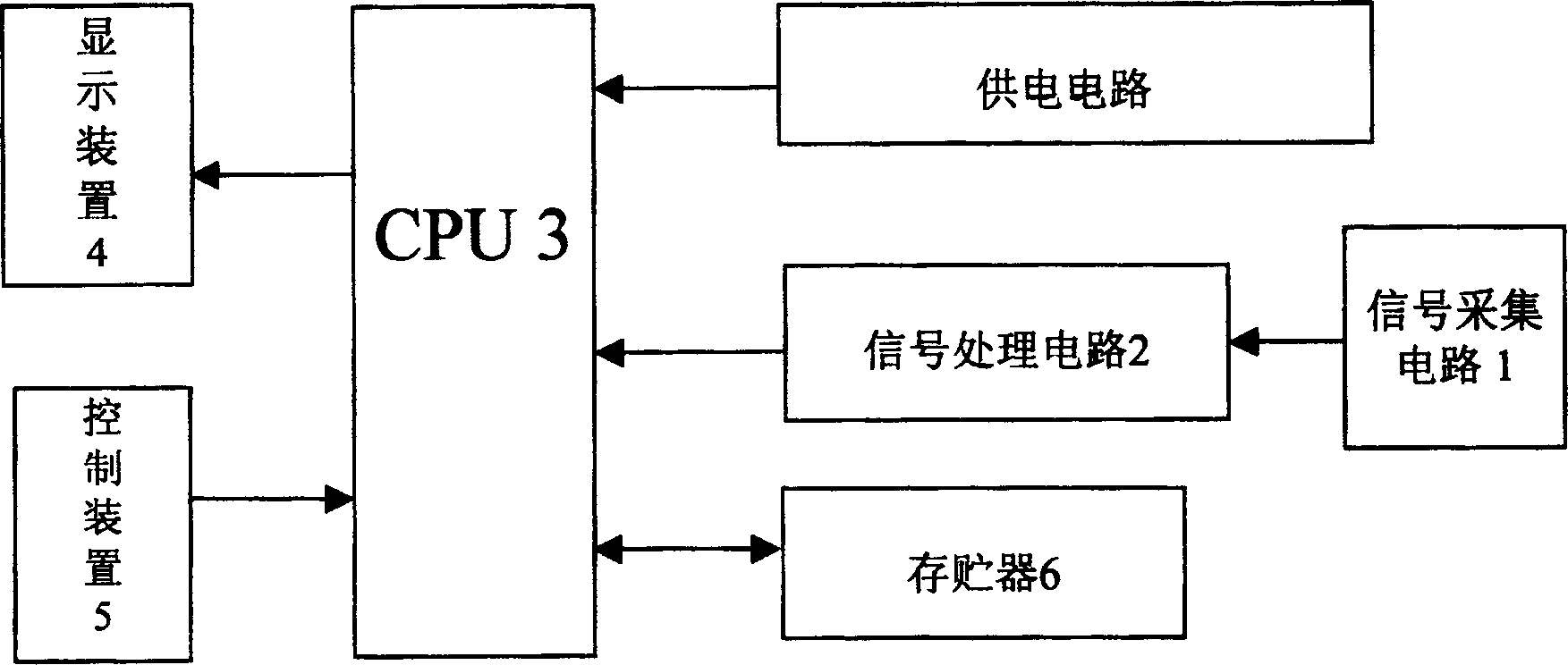

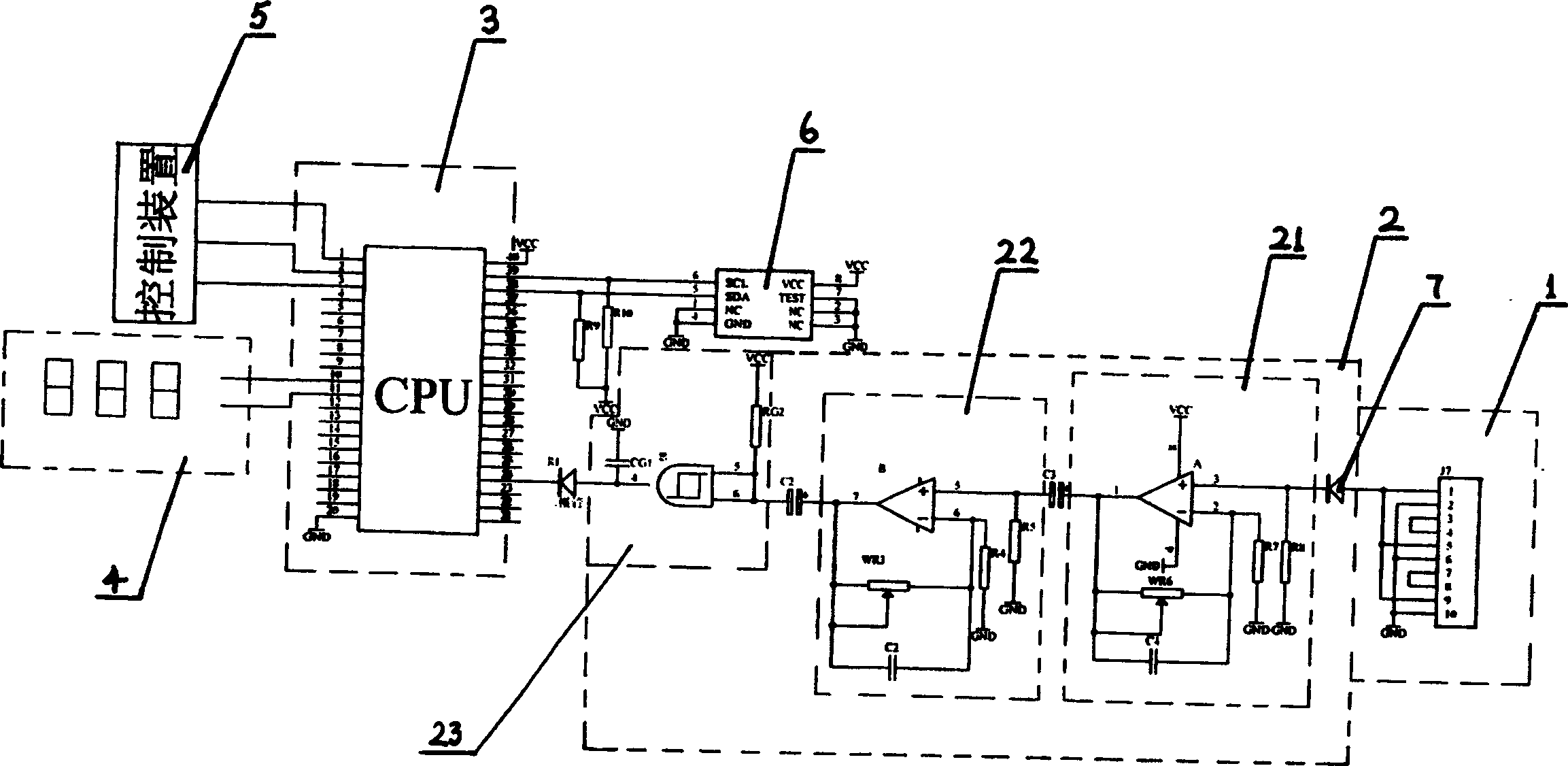

Intelligent score system of wall ball court or tennis exercise court

InactiveCN1270797CAvoid misjudgmentLow costSport apparatusSpecial data processing applicationsElectricitySignal processing circuits

An intelligence score system for the gym of wall ball and tennis ball is composed of signal acquisition circuit with vibration sensors, signal processing circuit, CPU, memory, display device, controller and power supply.

Owner:许惠泉 +2

Wire conveying mechanism facilitating wire replacement

ActiveCN111115353ARealize moving up and downAchieve compactionFilament handlingDrive wheelStructural engineering

The invention relates to a wire conveying mechanism facilitating wire replacement, and belongs to the field of wire manufacturing. The wire conveying mechanism is used for solving the problems that anexisting wire feed mechanism cannot adapt to wires of different specification diameters, and wire replacement operation is complex. The wire conveying mechanism comprises a fixed supporting unit, a wire feed unit and an adjusting unit. The fixed supporting unit comprises a fixed base plate, a supporting plate and fixed blocks, the supporting plate is connected with the fixed base plate, and the fixed blocks are connected with the supporting plate. The wire feed unit comprises a driving wheel, a driven wheel and wire nozzle, and the wire nozzle is connected with the fixed blocks. The adjustingunit comprises adjusting supports and adjusting shafts, and the adjusting shafts penetrate through the adjusting supports to be connected with the driven wheel. According to the wire conveying mechanism, the adjusting support can move up and down by rotating adjusting nuts or through the elasticity of adjusting springs, then the trunking gap of the driving wheel and the driven wheel is adjusted,wires of different specification diameters are pressed and conveyed, and wire replacement operation is simple and convenient.

Owner:BEIJING MECHANICAL EQUIP INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com