Multifunctional gas quantitative leak detector

A technology of gas quantification and leak detector, which is applied in the direction of liquid tightness measurement, instruments, and measuring devices using liquid/vacuum degree, which can solve the problems of low precision, large volume of leak detector, large gas flow rate, etc., and achieve accurate High accuracy and detection efficiency, simple structure design, and easy operation of the instrument

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

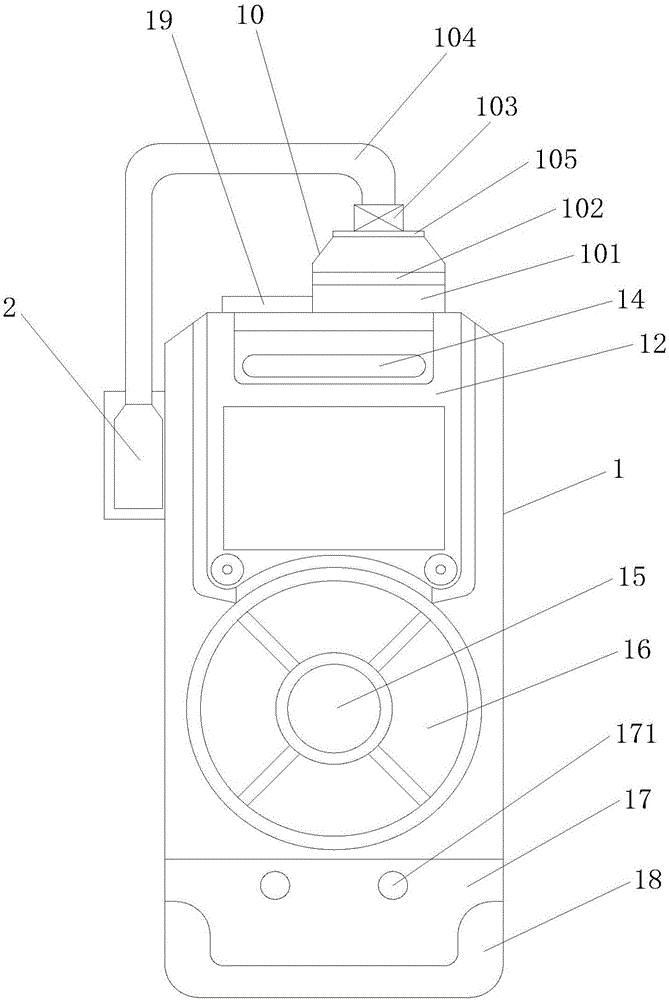

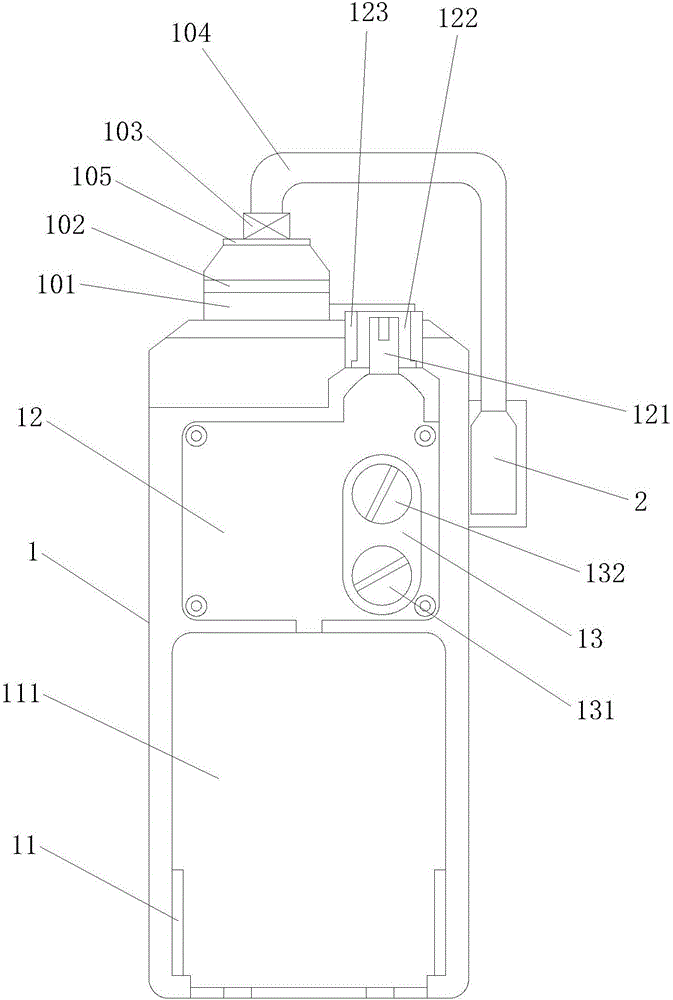

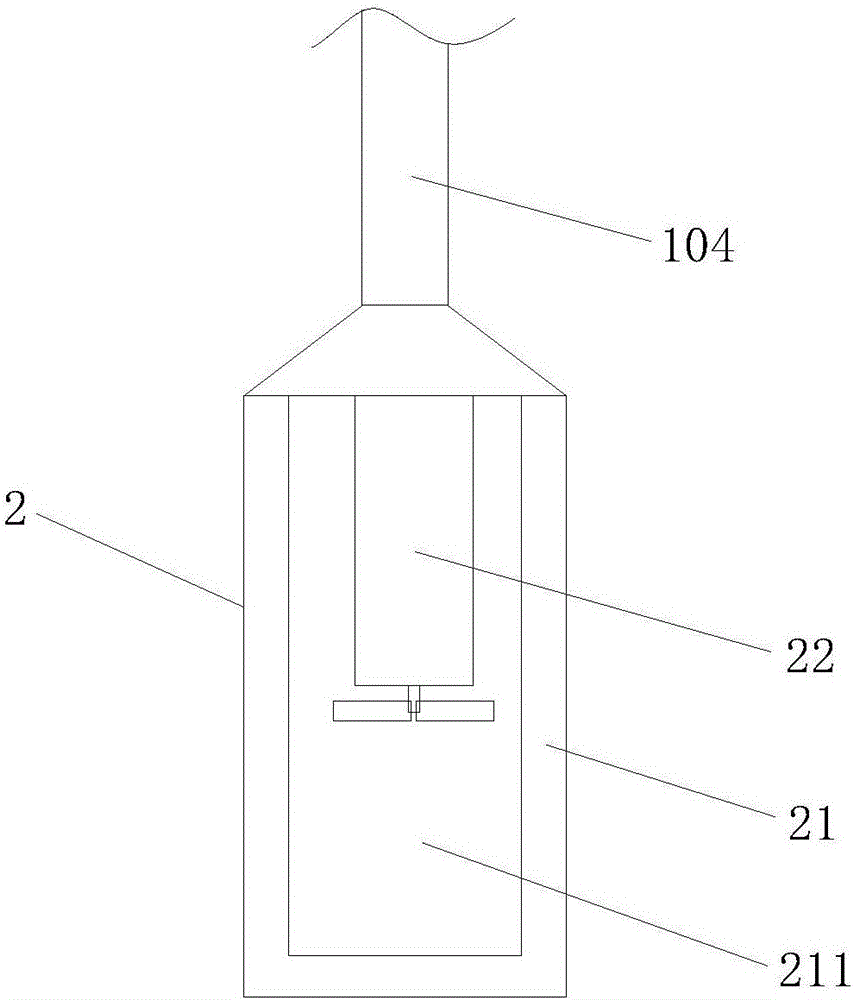

[0021] Such as Figures 1 to 6 As shown, the multifunctional gas quantitative leak detector of the present invention includes a leak detector body 1 , a probe 2 and an electronic control unit 3 .

[0022] The leak detector body 1 is a rectangular parallelepiped, with an inlet filter seat 10 on one side of the top, a power supply chamber 11 inside the lower end and a flow chamber 12 on the upper part of the power supply chamber 11, and a filter chamber 13 inside the flow chamber 12 The lower end root of the inlet filter seat 10 is provided with a sound-absorbing plate 101, and the top of the sound-absorbing plate 101 is provided with a sound-absorbing cotton layer 102; The valve 103 is connected with a gas pipeline 104 , and a pressure sensor 105 is installed between the top of the inlet filter seat 10 and the one-way valve 103 , and the end of the gas pipeline 104 is connected with the probe 2 .

[0023] Wherein, the leak detector body 1 is provided with a detachable power su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com