Self-elevating type platform buoyant pile shoe with function of reducing resistance in pile pulling

A self-elevating platform and buoyancy technology, which is applied to sheet pile walls, water conservancy projects, artificial islands, etc., can solve the problems of not pulling out piles, too deep into the mud of platform pile legs, and difficulty in pulling out piles when the platform is evacuated, so as to avoid The effect of sea mud entering and reducing the degree of soil compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] The implementation method of the present invention can be summarized as the following contents:

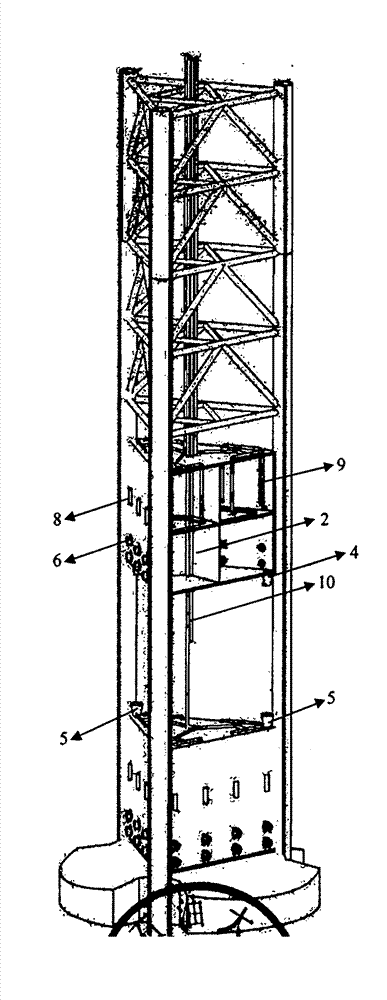

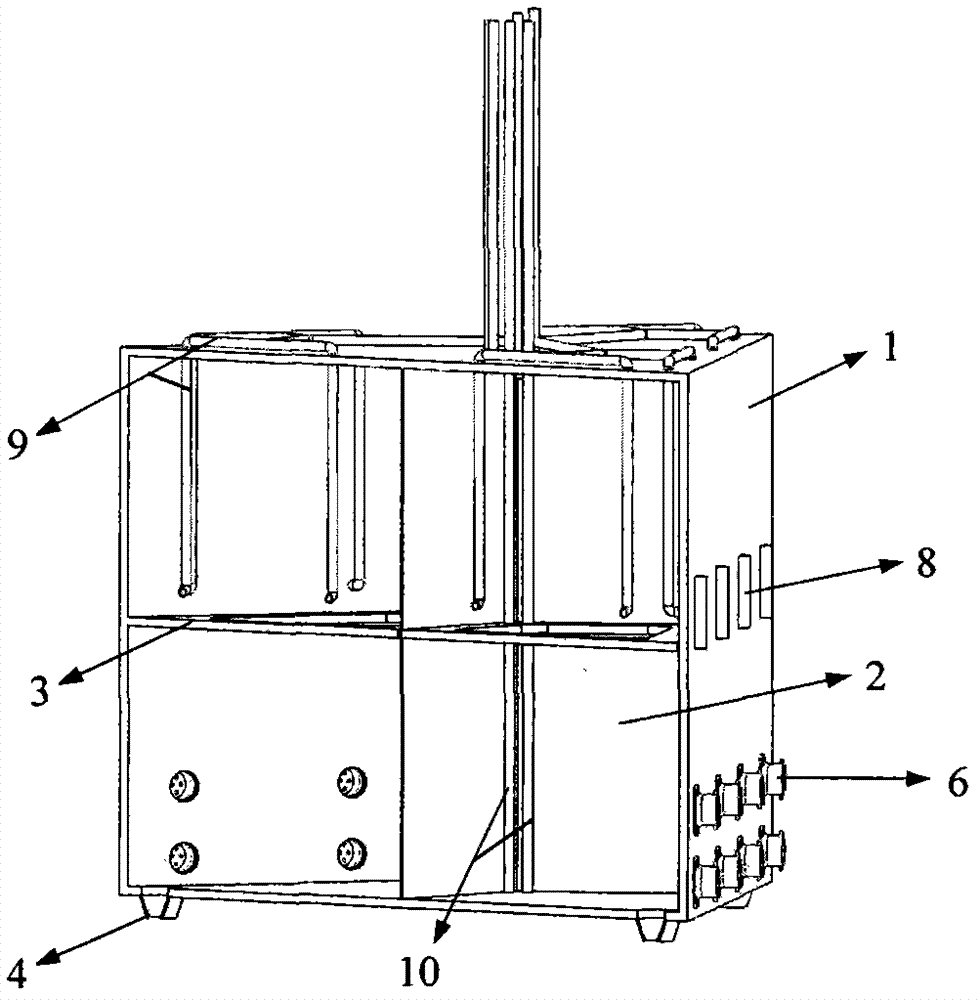

[0016] 1) The buoyancy spud boots are equipped with three sets of buoyancy tanks 1, and each buoyancy tank is equipped with three prismatic ballast tanks 2 and reinforcement rings 3. The pier 4 and the bell mouth 5 are limited and welded. The outside of the pontoon is still the three main columns of the pile legs, and the racks on the columns are connected, so the pontoon does not affect the lifting pile operation of the platform. See figure 1 .

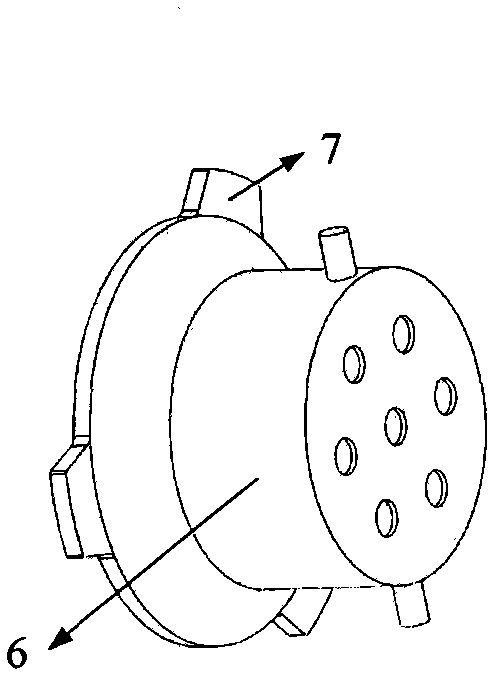

[0017] 2) The lower part of the buoyancy tank is provided with a permeable water-passing device 6, which contains compacted steel wire balls and is installed on the outside of the buoyancy tank through buckles 7, see figure 2 . Steel wire clusters with different degrees of compaction can be selected to adjust the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com