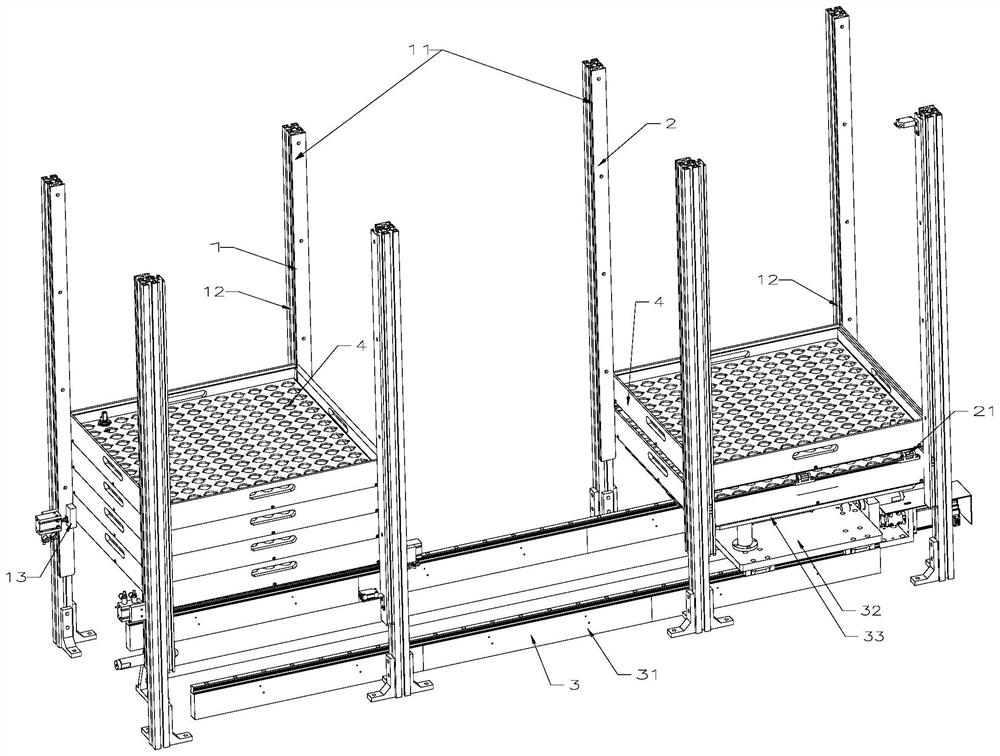

Material conveying mechanism

A conveying mechanism and material technology, applied in conveyors, mechanical conveyors, stacking of objects, etc., can solve the problems that the vibrating plate cannot be used as a discharge module, and the vibrating plate is not suitable, and achieves low noise and improves processing or assembly. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

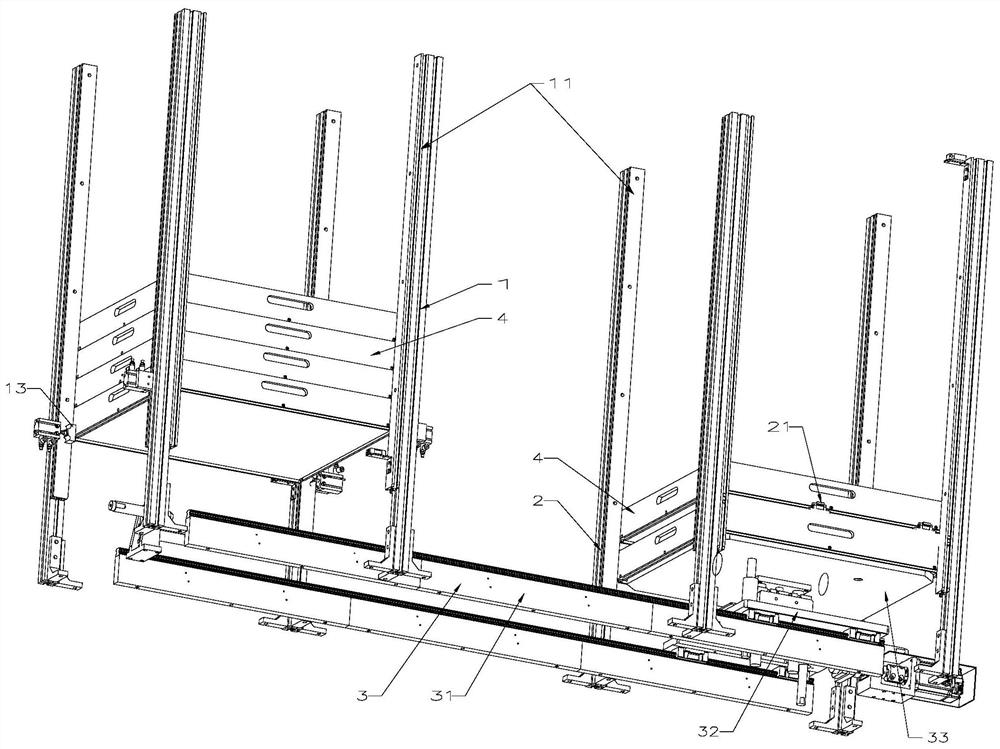

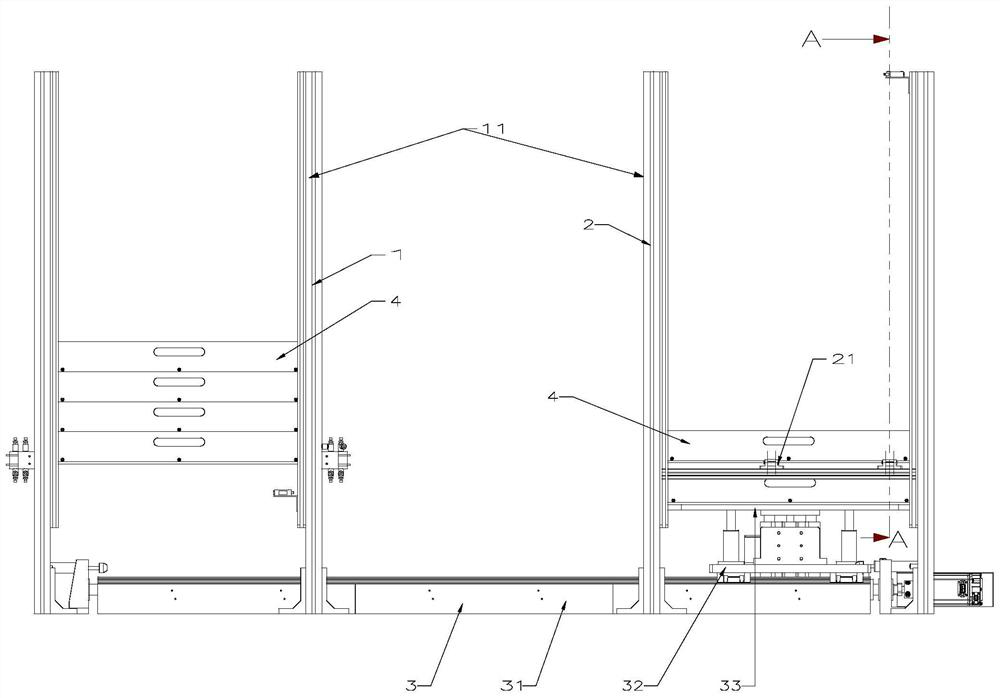

Method used

Image

Examples

Embodiment 2

[0047] On the basis of Embodiment 1, the first shelf and the second shelf are installed on the shelf conveying track, and are driven to move by the driving part, and driven by the moving part, the first shelf and the second shelf can be transported along the shelf The track automatically enters the material conveying mechanism, and can also automatically exit the material conveying mechanism after a loading or unloading is completed, so that the next batch of shelves can enter, reducing the manual delivery or shipping process.

[0048] In this embodiment, the rack conveying track is a closed loop track, the first rack and the second rack are installed on the same rack transporting track, and there are at least two racks on the rack transporting track.

[0049] Through the circular track, when the first shelf loaded with materials takes away the materials, all the pallets are placed on the second shelf, and the second shelf moves out of the material conveying mechanism. At this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com