Equipment for preparing carbon ceramic through graphite powder

A technology of graphite powder and carbon ceramics, applied in the field of carbon ceramics, can solve the problems of low production efficiency, inability to realize carbon ceramics molding and output continuity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

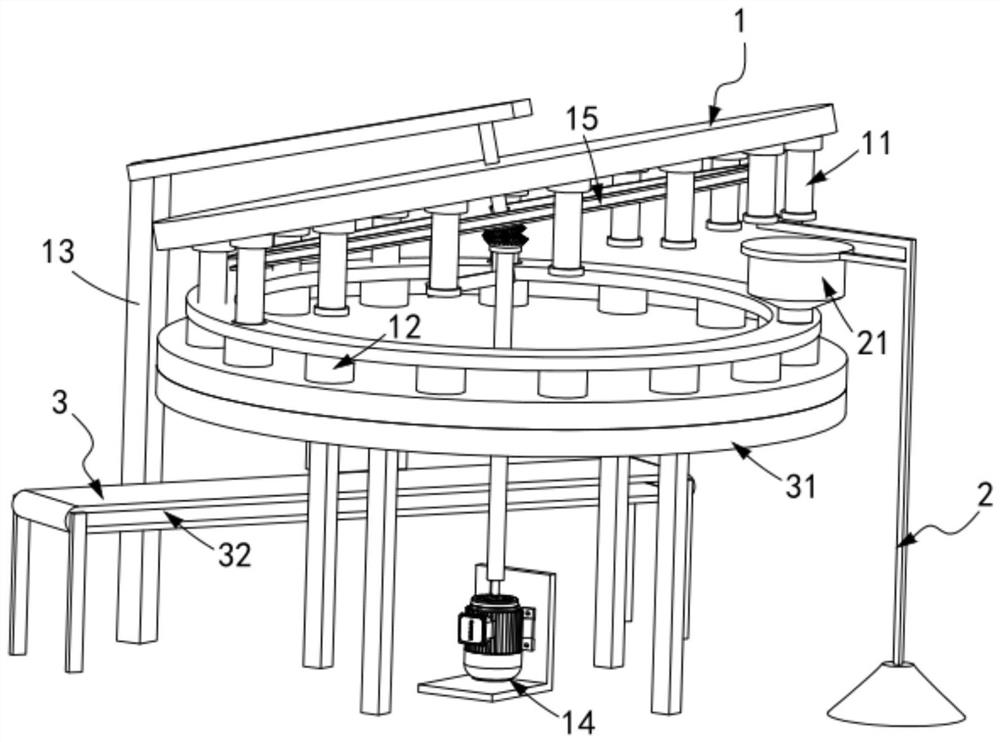

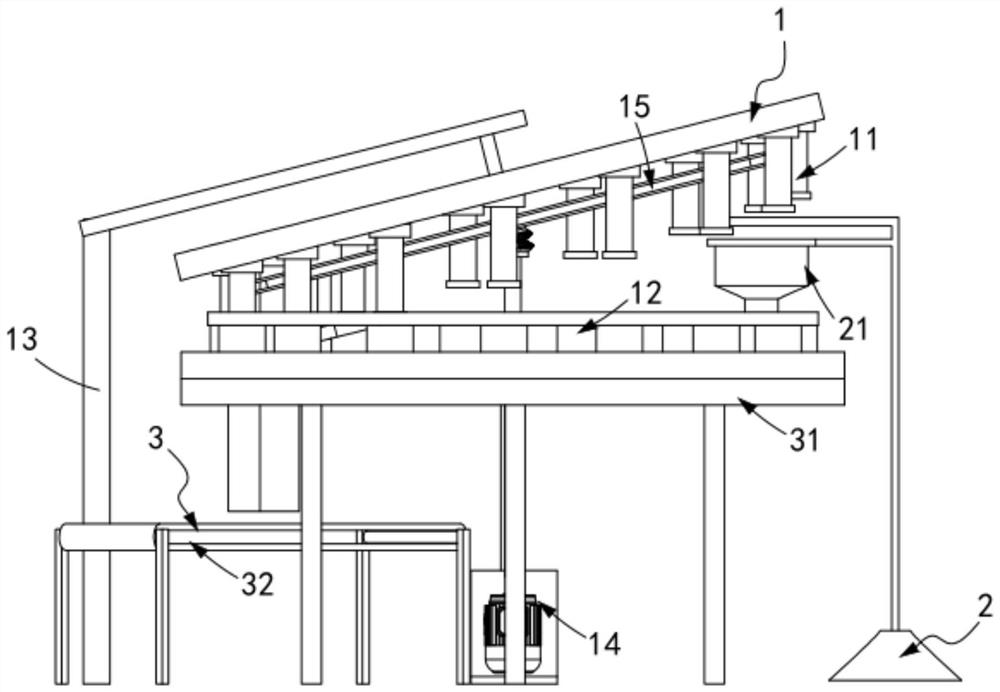

[0050] Such as figure 1 , figure 2 Shown, a kind of equipment that utilizes graphite powder to prepare carbon pottery, comprises:

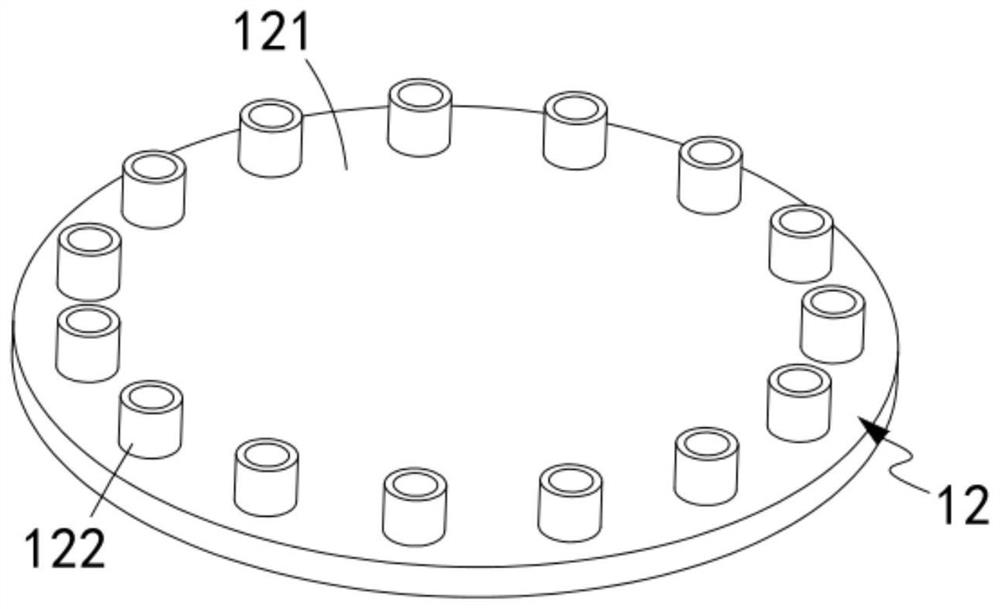

[0051]Forming mechanism 1, described forming mechanism 1 comprises upper mold assembly 11, lower mold assembly 12, is used to drive described upper mold assembly 11 and lower mold assembly 12 to rotate synchronously and is installed on the driving assembly 14 on frame 13 and is installed on The first guide assembly 15 on the frame 13 and used to guide the upper mold assembly 11 to rotate in parallel along the circumferential surface of the upper mold assembly 11, the lower mold assembly 12 is sequentially provided with Loading station Ⅰ, forming station Ⅱ and output station Ⅲ;

[0052] A feeding mechanism 2, the feeding mechanism 2 includes a material storage assembly 21 arranged on the frame 13, the feeding mechanism 2 is located on the feeding station I; and

[0053] The output mechanism 3, the output mechanism 3 includes a discharge assembl...

Embodiment 2

[0075] Such as Figure 13 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0076] further, such as Figure 13 As shown, the transmission assembly 32 is a belt pulley transmission mode;

[0077] The distance between the lower surface of the temporary storage box 312 and the upper surface of the conveying assembly 32 is equal to the thickness of the carbon ceramic 10 .

[0078] It is worth mentioning here that by setting the temporary storage box 312, the height of the carbon ceramics falling output is shortened, thereby reducing the degree of collision wear of the carbon ceramics output and improving product quality; it should be noted that the inner wall of the temporary storage box 312 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com