Polishing device and method based on engineering machinery

A technology for construction machinery and grinding mechanisms, applied in grinding/polishing safety devices, grinding machines, manufacturing tools, etc., can solve problems such as hidden dangers, wastes that easily hurt operators, and troublesome operations, and achieve the effect of avoiding safety accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

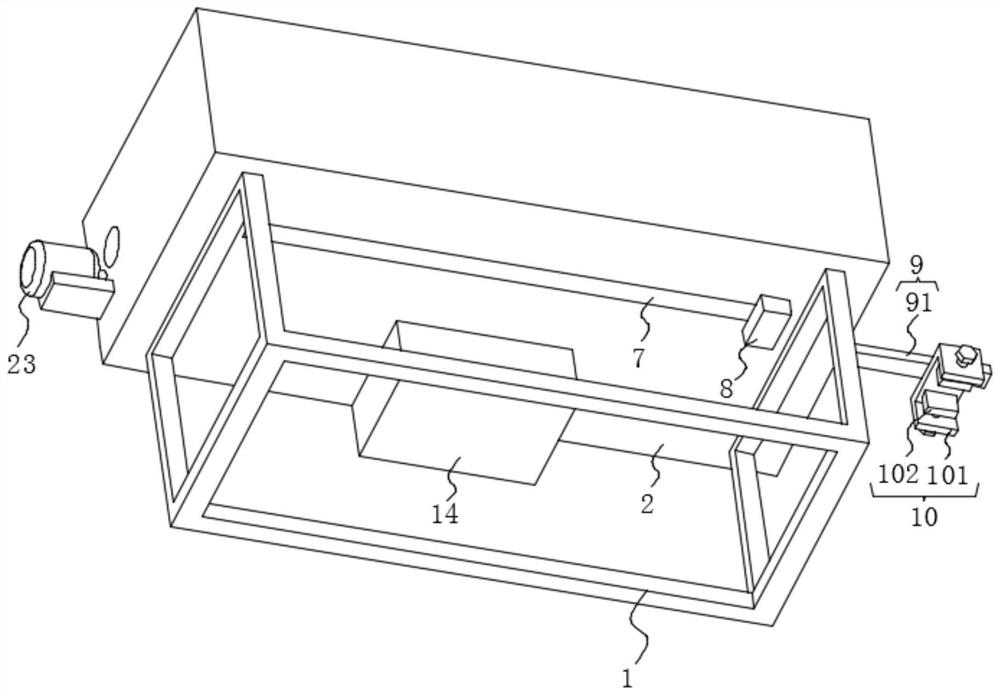

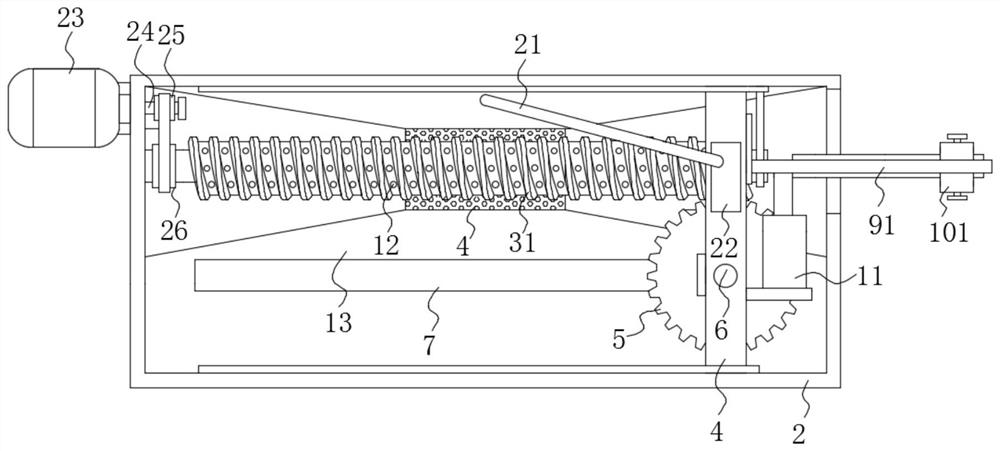

[0041] A grinding device based on construction machinery, comprising:

[0042] rack 1;

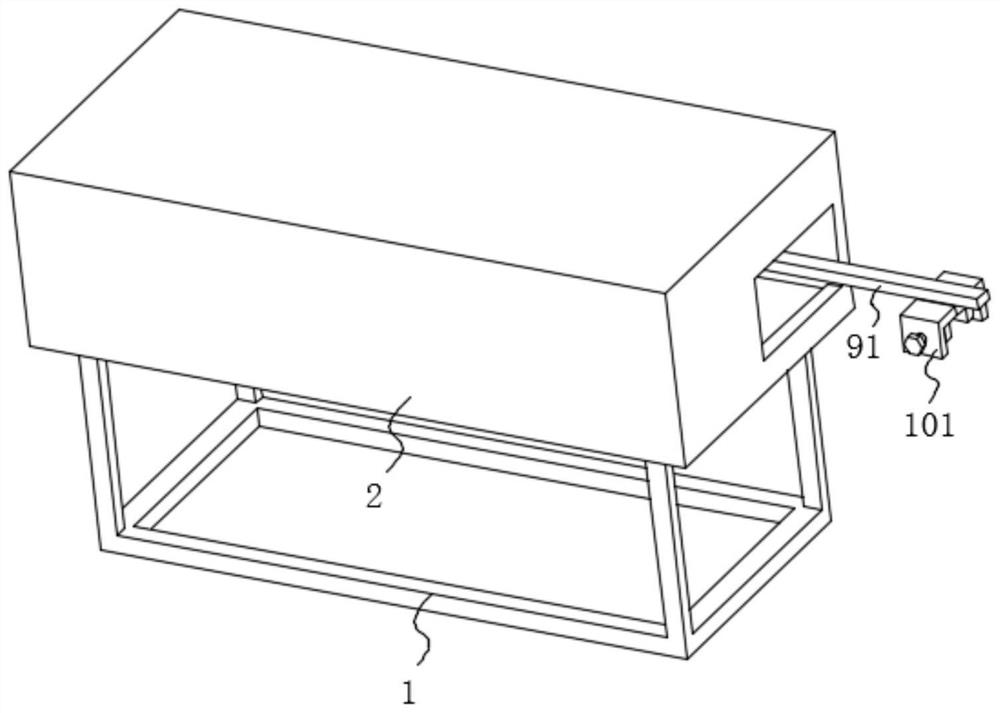

[0043] a box body 2, the box body 2 is fixed on the frame 1;

[0044] Grinding mechanism 3, the grinding mechanism 3 is arranged inside the box body 2, and the grinding mechanism 3 includes a grinding tooth sleeve 31, and the grinding tooth sleeve 31 is rotatably connected to one side of the inside of the box body 2, and used for rough machining the grinding piece, the grinding tooth sleeve 31 is provided with a grinding pad 32 inside, and is used for finishing the grinding piece;

[0045] A displacement plate 4, the displacement plate 4 is slidably connected to both sides of the inside of the box body 2, and a gear 5 is rotatably connected to the displacement plate 4, and a rotating shaft 6 is rotatably connected to the gear 5;

[0046] A through slot 7, the through slot 7 is opened at the bottom of the box body 2, and the interior of the through slot 7 is slidably connected with a slid...

Embodiment 2

[0081] see Image 6 - Figure 8 :

[0082] A fixing plate 27 is fixedly connected to the displacement plate 4 , one side of the fixing plate 27 penetrates the box body 2 and extends to one side of the box body 2 , and the fixing plate 27 extends to the box body The outside of 2 is fixedly connected with a sleeve 28 through a connecting rod, and the inside of the sleeve 28 is provided with a brush cylinder 29 for cleaning the waste debris left by the grinding of the inner wall of the grinding tooth sleeve 31;

[0083] The provided brush cylinder 29 can enter the interior of the grinding tooth sleeve 31, and by contacting the inner wall of the grinding tooth sleeve 31, the remaining waste chips are swept and released from the circular hole 12, And release from the right opening of the grinding tooth sleeve 31 (at this time, the grinding piece has been separated from the grinding tooth sleeve 31, and will not affect the cleaning of the inner wall of the grinding tooth sleeve 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com